Construction Risk Management: Your Complete Strategy Guide

Understanding Construction Risk Management Like a Veteran Project Manager

Imagine you're on a busy construction site in the UAE. A seasoned project manager doesn't just see activity; they sense potential problems. Maybe it's a feeling that a shipment of HVAC components from Yasu Trading Co. might be delayed, or a subtle shift in the wind hinting at a coming sandstorm. This isn't a sixth sense, it's construction risk management in action.

This ability to foresee potential issues and prevent them from becoming major setbacks is what separates good project managers from the great ones. It's about anticipating the challenges and having plans in place to address them before they escalate.

Think of a construction project as a giant game of Jenga. Each block represents a vital piece: materials, permits, the workforce, even the weather. Removing one seemingly small block—a delayed permit, for instance—can make the whole tower wobble. Construction risk management is about identifying these crucial “blocks,” assessing their stability, and having plans to reinforce them or have replacements at the ready.

Proactive Planning is Key

The best project managers don't just react; they're proactive. They anticipate problems before they even arise. Like a chess player thinking several moves ahead, they consider the potential consequences of each decision.

What happens if a shipment of safety equipment is delayed? How will that impact the project timeline and, in turn, the budget? What are the ripple effects of a sudden labor shortage on the installation of complex electrical systems? These are the questions a risk-aware project manager constantly considers.

Regional Risks in the Middle East

Risk management is especially crucial in the Middle East construction sector due to unique regional challenges. Governance and corporate reporting, cybersecurity, and business continuity all present significant risks. In fact, 35% of construction industry respondents and 64% of manufacturing respondents acknowledge the high risks related to governance and corporate reporting.

Business continuity is another major concern, with 76% of construction sector respondents highlighting its importance. These risks demand robust management strategies to ensure project stability and success. You can find more information about risk management in the Middle East here.

Effective construction risk management transforms potential disasters into manageable challenges. This proactive approach protects your investment, improves project timelines and budgets, builds resilience, and fosters a culture of preparedness within your team.

Spotting Trouble Before It Spots You: The Risk Detective Approach

Think of construction risk management like being a detective on a case. The best in the business don't just react after the crime; they anticipate it. They're sharp observers, picking up on subtle clues that others might miss. A small delay in a shipment from a supplier like Yasu Trading Co., a few more sick days than usual among the crew, or even a shift in local regulations – these seemingly insignificant details can be early warning signs of much larger problems down the line.

Developing a Risk-Sensitive Mindset

Developing this "risk detective" mindset takes a structured approach. Experienced professionals often use mental frameworks to systematically scan for potential risks across every aspect of a project. They don't just rely on gut feelings, though experience certainly helps. They use techniques like "what-if" scenarios, asking themselves questions like, "What if our key subcontractor suddenly becomes unavailable?" or "What if the city changes its inspection schedule?" This proactive thinking helps uncover hidden risks that might otherwise go unnoticed.

Collaborative Risk Identification: More Than Just a Worry List

Effective construction risk management is a team sport. Holding risk identification sessions with your team can bring a lot of valuable insights to the surface, but it’s important to avoid creating a generic list of worries that don’t lead to any real solutions. Instead, encourage your team to think critically and connect seemingly unrelated issues. For example, a delay in permit approval could trigger a domino effect: weather exposure of unfinished structures, labor shortages due to extended project timelines, and ultimately, budget overruns.

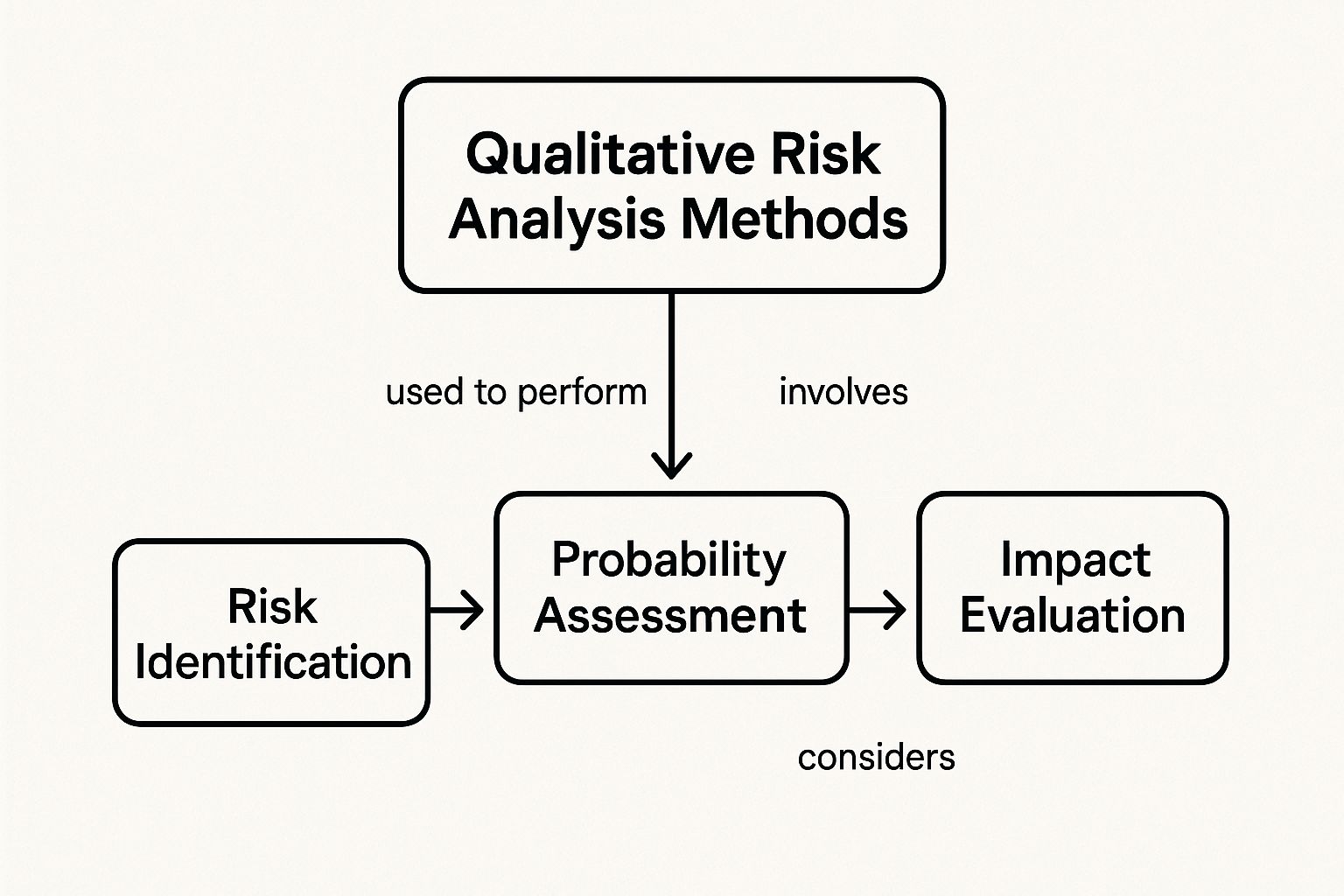

This infographic shows the core components of Qualitative Risk Analysis Methods: Risk Identification, Probability Assessment, and Impact Evaluation. The flow highlights how each element builds on the one before it, emphasizing the interconnectedness of risk analysis. Effective risk management depends on understanding not only what could go wrong, but also how likely it is and how big the impact would be.

To help further illustrate these concepts, let's take a look at a practical breakdown in the table below:

Introduction to the table: The following table provides a clear breakdown of common risk categories in construction, their potential sources, effective detection methods, and the critical early warning signs that can help prevent major issues.

| Risk Category | Common Sources | Detection Method | Early Warning Signs |

|---|---|---|---|

| Design Errors | Inadequate site investigation, miscommunication between architects and engineers | Thorough design reviews, constructability analysis | Conflicts in drawings, discrepancies in specifications, requests for information (RFIs) from contractors |

| Material Delays | Supply chain disruptions, supplier insolvency, logistical issues | Regular communication with suppliers, inventory tracking software | Late deliveries, price escalations, material shortages |

| Labor Shortages | Tight labor market, lack of skilled workers, project scheduling conflicts | Workforce planning, subcontractor prequalification | Difficulty filling positions, increased labor rates, subcontractors failing to meet deadlines |

| Safety Incidents | Inadequate safety training, unsafe working conditions, human error | Regular safety inspections, incident reporting systems | Near misses, minor accidents, unsafe behavior |

| Environmental Issues | Unforeseen ground conditions, extreme weather events, regulatory changes | Environmental impact assessments, site monitoring | Unexpected soil conditions, weather delays, changes in permit requirements |

Conclusion from the table: By understanding these risk categories, their sources, and how to detect them, construction professionals can proactively address potential problems and ensure project success. Regularly reviewing these factors, alongside using appropriate detection methods, can significantly reduce the likelihood of major disruptions.

Thinking Outside the Textbook: Failure Story Sessions

Another useful technique is running "failure story sessions." Encourage your team to imagine detailed scenarios where things go wrong. It might sound negative, but this exercise prepares you for challenges that you won’t find in any textbook. By brainstorming potential failures, you can develop proactive mitigation strategies and build a more resilient project plan.

Creating a culture of open communication is essential. Often, the most valuable risk insights come up in casual conversations, not formal meetings. Make it clear that your team should feel comfortable raising concerns without fear of being judged. Remember, effective construction risk management depends on collaboration and open dialogue, empowering your team to become proactive risk detectives.

From Gut Instinct to Smart Decisions: Risk Assessment That Works

Every seasoned project manager has encountered projects that just seem inherently risky from the start. On the flip side, some projects appear problematic on paper yet unfold without a hitch. The difference often boils down to how well risks are assessed and prioritized. It's about blending experience with solid data. This section explores the practical tools and methods successful project managers use to replace guesswork with informed choices in construction risk management.

Mastering the Risk Matrix

Imagine a risk matrix as a sorting tool. It's a grid where potential project problems are plotted, with one axis showing the likelihood of the problem happening and the other showing its potential impact. This visualization helps you pinpoint the biggest threats. For example, a minor delay in getting specialized HVAC components from a supplier like Yasu Trading Co. might be low impact and low probability. But a major sandstorm during a crucial foundation pour is both high impact and, in certain areas, quite likely. The risk matrix helps you concentrate your efforts where they truly count.

A risk matrix helps to prioritize issues. It allows you to visualize the potential impact of an issue combined with how likely that issue is to occur. The visual nature of the tool makes it easily understood and easily shared.

Quantifying Probability and Impact

Giving meaningful probability scores means moving beyond gut feelings. Instead of saying "it's likely," assign a number – is it a 20% chance, 50%, or 80%? Likewise, evaluate impact in concrete terms. Will a specific problem cause one day of delay or a week? What will the financial cost actually be? By quantifying these elements, you create a prioritized risk list that truly reflects the potential fallout.

Quantifying helps move away from estimations and towards concrete assessments. This makes identifying and mitigating risks much more actionable.

Case Studies: Learning from Experience

Real-world examples are essential for learning effective construction risk management. Let's say a project manager underestimated the impact of permit delays. What seemed like a small bureaucratic hurdle turned into weeks of lost time, causing cost overruns and impacting other activities. Learning from these past experiences, your own or others', sharpens your ability to spot and evaluate similar risks on future projects.

Studying both successes and failures can help hone your risk management abilities.

The Human Element: Blending Data and Intuition

While digital tools play an increasingly important role in construction risk management, human experience is still invaluable. You might find a construction risk assessment template helpful in guiding your assessments. Software can provide data and forecasts, but it takes a skilled project manager to interpret that data within the context of their specific project and team. Knowing when to trust the numbers and when to trust your gut is a critical skill for effective risk management. This involves understanding your team’s strengths and weaknesses, the particular challenges of a region, and the unique demands of each project.

Even with the increasing prevalence of advanced tools and technologies, the human element remains essential in assessing and mitigating risks.

Risk Mitigation That Actually Works in the Real World

Most risk mitigation plans look great on paper, but fall apart when they hit the messy reality of a construction site. So, what's the secret sauce that transforms a theoretical plan into a real-world shield for your project? Let's explore the key differences and lay out some practical strategies for effective construction risk management.

Building Layers of Protection

Think of your project's risk defenses like the layers of an onion. Relying on a single layer, like insurance alone, leaves you vulnerable. The most effective construction teams build multiple layers of protection. This could involve carefully crafted contracts that clearly define responsibilities, robust operational procedures that minimize errors, and well-rehearsed emergency response protocols for when the unexpected happens.

For example, imagine you're worried about material delivery delays. Having a backup supplier, maybe a local option alongside your usual international one, adds a crucial extra layer of protection. For more ideas on safeguarding your team, check out our guide on safety equipment for construction.

Dynamic Contingency Plans

A truly robust contingency plan isn't just a "Plan B" – it's a dynamic system that can adapt and flex with changing conditions. What if your initial mitigation strategy falls flat? What's your next move? The best contingency plans anticipate various scenarios and offer flexible solutions you can adjust as needed. It's like having a well-stocked toolbox – the right tool for every problem.

Transfer, Reduce, or Accept: Choosing Your Strategy

There are three core approaches to mitigating risk:

Transferring Risk: This involves shifting the responsibility to someone else, such as through insurance or subcontracting. It's a good strategy for risks you can't directly control, but it comes with a price tag.

Reducing Risk: This means taking proactive steps to lower the chances of a problem occurring or minimizing its impact. This could involve tighter quality control measures or investing in more reliable equipment.

Accepting Risk: Sometimes, acknowledging that certain risks are unavoidable and budgeting for their potential impact is the best approach. This is often the case with low-probability, low-impact risks.

The trick is picking the right approach for each specific risk, based on your project's unique constraints and priorities. In construction risk management, one size definitely doesn't fit all.

Let's look at how these strategies play out in the real world. The following table summarizes their effectiveness, costs, ideal applications, and potential pitfalls based on actual project data.

| Mitigation Strategy | Success Rate | Implementation Cost | Best Applications | Common Failures |

|---|---|---|---|---|

| Transferring Risk (Insurance) | 70% | High | Catastrophic events, third-party liability | Insufficient coverage, complex claims processes |

| Transferring Risk (Subcontracting) | 85% | Medium | Specialized tasks, workload management | Contractor disputes, quality control issues |

| Reducing Risk (Improved Training) | 60% | Low | Human error prevention, skill enhancement | Inconsistent application, lack of follow-up |

| Reducing Risk (Quality Control Checks) | 90% | Medium | Material defects, process errors | Inadequate testing procedures, inspection gaps |

| Accepting Risk (Contingency Fund) | N/A | Low | Minor delays, unforeseen expenses | Underestimation of potential costs, depletion of funds |

As you can see, each strategy has its strengths and weaknesses. Transferring risk through insurance is good for major events, but expensive. Subcontracting can be efficient, but requires careful management. Reducing risk through training or quality control offers good value, but needs consistent effort. Accepting risk is a viable option for smaller issues, but requires accurate cost projections.

Embracing Technology for Proactive Mitigation

Modern technology provides powerful tools for proactive risk management. Think of predictive analytics as an early warning system. By crunching historical data and current trends, these tools can flag potential issues weeks or even months in advance. Similarly, IoT sensors can monitor risk factors like temperature, humidity, and structural stress in real-time, giving you valuable data to prevent costly failures. These tools empower you to tackle potential problems before they snowball into major setbacks.

Adapting to the UAE’s Unique Construction Landscape

The Middle East throws its own unique curveballs, from scorching heat to complex regulations. Effective risk mitigation in the UAE demands a deep understanding of the local landscape. For example, a project in Dubai might face different risks than one in Abu Dhabi because of variations in local rules and market conditions. Tailoring your strategies to these regional realities is key to success.

Navigating Middle East Construction: Regional Risk Realities

Construction in the Middle East offers exciting opportunities, but it's a complex landscape. Think of it like navigating a bustling marketplace: vibrant and full of potential, but requiring careful planning and awareness. It’s not just about the desert heat; it's about understanding the region's unique rhythm, from the weather to the regulations. This nuanced approach to construction risk management is the key to unlocking success.

Weathering the Storm: Extreme Conditions and Their Impact

The Middle East's climate is a major player in any construction project. Imagine pouring concrete on a scorching summer day – it requires special mixes designed to withstand the heat. Similarly, sudden sandstorms can halt work in an instant, demanding adaptable schedules and solid backup plans. These aren’t just minor inconveniences; they're integral factors to consider from day one.

Think about worker productivity, too. Extreme heat can significantly slow things down, affecting timelines and budgets. That's why specialized mitigation strategies are so crucial. For example, adjusting work hours to cooler parts of the day or providing adequate shade and hydration can make a big difference. We even wrote a helpful article on preparing for Dubai's extreme weather: Check out our guide on preparing for extreme weather.

Regulatory Landscapes: Navigating Shifting Sands

Each emirate has its own set of rules and regulations. It’s like navigating a network of roads, each with its own speed limit and traffic flow. Permitting processes, building codes, and labor laws can vary significantly, demanding local expertise and proactive engagement with authorities. Failing to understand these specifics can lead to costly delays, penalties, and damage to your project's reputation.

Geopolitical Factors: Understanding the Bigger Picture

The bigger picture matters, too. Geopolitical factors, like regional stability, economic shifts, and trade relationships, can influence material availability, financing, and even the overall feasibility of your project. Staying informed about these broader trends is essential for making informed decisions and managing risk effectively. Think of it like checking the weather forecast before a long journey – it’s crucial for planning and preparation.

Growth Amidst Challenges: The UAE Construction Boom

Despite these challenges, the UAE's construction market is booming. It's projected to grow by 6.2% annually, reaching AED 189.59 billion by 2025. This growth, fueled by increased tourism and business activity, demonstrates the market's resilience, having achieved a 7.3% CAGR from 2020 to 2024. Learn more about the flourishing UAE construction market here.

The Human Factor: Cultural Considerations and Stakeholder Management

Finally, remember the human element. Cultural sensitivity is paramount. Understanding local customs and communication styles can significantly impact your relationships with stakeholders and the overall success of your project. Building trust, fostering open communication, and respecting cultural nuances are essential ingredients for effective stakeholder management.

Successfully navigating the Middle East's construction landscape requires more than just knowing the rules; it’s about understanding the culture, anticipating challenges, and building strong relationships. By adapting global best practices to local realities, you can mitigate risks, build resilience, and tap into the immense potential of this dynamic market.

Technology That Actually Helps: Modern Tools for Timeless Problems

Construction risk management has always hinged on experience and foresight. Think of the seasoned project manager who can just "sense" when something's off. Now, technology is giving us tools to sharpen those instincts and see potential problems more clearly. Let's explore how these digital solutions, from simple mobile apps to advanced data analysis, are making a real difference.

Drones: Eye in the Sky for Enhanced Safety

Imagine inspecting a skyscraper in Dubai, not by climbing precarious scaffolding, but with a drone. Suddenly, checking those hard-to-reach places becomes quick and, most importantly, safer. Drones provide a bird's-eye view of the entire site, letting project managers monitor progress, spot potential safety hazards, and gather valuable visual data. This helps catch small issues – a loose cable, a missing guardrail – before they turn into big problems, saving time and preventing accidents.

Predictive Analytics: Foreseeing the Future of Your Project

Predictive analytics uses data to forecast potential hiccups in your project. Think of it like a weather forecast, but for construction. Let's say your data shows a high chance of delivery delays from a specific supplier like Yasu Trading Co.. Armed with this information, you can order materials from a local supplier or adjust your schedule, minimizing the disruption. This proactive approach helps keep your project on track and your budget under control.

Integrated Project Platforms: Your Central Hub for Risk Management

Many construction companies are now using platforms that bring all project information together in one place: risk assessments, incident reports, even communication logs. It's like having a central command center for your project. These platforms improve communication and make sure everyone is on the same page. This streamlined flow of information means faster reactions to problems and better decision-making across the board.

The following screenshot showcases a leading construction risk management platform:

This screenshot from Procore shows how these platforms centralize risk data, giving you a clear picture of your project's vulnerabilities. This kind of overview is invaluable for making informed decisions and staying ahead of potential issues.

Implementation Strategies: Matching Tech to Your Needs

Bringing in new technology doesn't have to be a huge undertaking. Start small. Maybe a mobile app for incident reporting is the right first step for improving site safety. As your team gets comfortable, you can explore more complex tools, like AI-powered risk prediction. It’s about finding the right fit for your specific needs and building from there.

Maintaining the Human Element: Tech as a Tool, Not a Replacement

Even with the most advanced technology, human expertise is still essential. Software can crunch numbers and identify patterns, but it takes a seasoned project manager to interpret those insights and apply them to the real world. Think of technology as a powerful tool that amplifies, not replaces, the knowledge and intuition of experienced construction professionals. This balance is the key to successfully managing risk in today’s construction world.

Building a Risk-Smart Team: From Individual Awareness to Collective Strength

The most effective construction risk management isn't a top-down mandate; it's a shared understanding ingrained in your team's DNA. It's about creating an environment where every team member, from the newest apprentice to the CEO, is alert to potential problems, just like checking the weather forecast before heading to the job site.

Cultivating a Proactive Risk Culture

Imagine two construction sites. On one, workers spot a potential scaffolding issue but hesitate to report it, fearing they'll be blamed. On the other, they immediately flag the problem, knowing it will be addressed quickly and constructively. This key difference boils down to risk culture.

High-performing construction companies understand that construction risk management is a team sport. They empower their employees to become proactive "risk detectives," constantly scanning for potential hazards. This isn't about instilling fear; it's about building a shared sense of responsibility.

Training for Risk Awareness at Every Level

Building this type of risk awareness requires specific training. New hires need a solid grounding in the company’s risk management procedures, learning how to spot and report potential dangers. Experienced supervisors should be trained to facilitate risk discussions within their teams, encouraging open communication and fast problem-solving. Even executive leadership needs to be actively involved, demonstrating their commitment to risk management through their actions.

Think of a well-drilled sports team: each player knows their role and contributes to the overall success. Similarly, every member of a construction team, from the ground up, contributes to effective risk management.

Integrating Risk Thinking into Daily Operations

Risk awareness shouldn't be a separate task; it needs to be embedded in everyday decisions. Imagine a team discussing whether to pour concrete despite an approaching storm. A risk-smart team considers not only the immediate schedule but also the potential consequences of weather-damaged concrete, the rework costs, and the impact on the entire project timeline.

This proactive risk thinking becomes second nature through consistent practice and reinforcement. Regular safety meetings, "what-if" scenario planning, and post-incident reviews can help teams develop this important risk-sensitive mindset.

Celebrating Successes and Learning from Near Misses

Celebrating successes is vital. When a team identifies and mitigates a risk effectively, acknowledge their good work. This positive feedback encourages proactive risk management and builds a sense of shared accomplishment.

Equally important is learning from near misses. Imagine a load of materials almost falling from a crane. Instead of dismissing it as a close call, a risk-smart team analyzes what happened, determines the root causes, and implements corrective measures to prevent a repeat incident.

Open Communication: The Key to Addressing Hidden Risks

Many potential risks go unreported because workers fear blame or repercussions. Creating open communication channels is crucial. This could include anonymous reporting systems, regular feedback meetings, or simply fostering an atmosphere where people feel safe raising concerns without fear of judgment.

Imagine a worker noticing a recurring issue with equipment from Yasu Trading Co.. If they feel comfortable speaking up, the problem can be addressed before it escalates. However, if they fear reprisal, they might stay silent, increasing the risk of an accident.

Measuring and Maintaining a Strong Risk Culture

A strong risk culture doesn't appear magically; it’s a continuous journey. Regularly evaluate your team’s risk awareness through surveys, feedback sessions, and observation. Track near misses and incidents, looking for patterns that could reveal weaknesses in your risk management system.

Just as a building requires regular maintenance, a robust risk culture needs constant attention. As teams and projects change, adjust your training and communication strategies to ensure risk awareness remains a core value. By investing in your team’s risk intelligence, you build a substantial competitive advantage – one that safeguards your people, your projects, and your bottom line.

Your Construction Risk Management Action Plan: From Knowledge to Results

Let's turn all this risk management theory into a practical, on-the-ground action plan. Whether you're a seasoned pro or just starting out in UAE construction, these steps will help you build a solid risk management process.

Quick Wins: Implementing Immediate Improvements

Think of these as your "first aid kit" for risk management – simple, immediate actions you can take right now:

Start Talking: Grab your team for a quick chat about potential risks. Even an informal brainstorming session can uncover hidden worries and get everyone on the same page.

Create a Simple Risk Register: No need for fancy software just yet. A basic spreadsheet listing potential issues, how likely they are, and their potential impact can be surprisingly powerful.

Review Contracts: Take a close look at your contracts with suppliers, subcontractors, and clients. Is everything crystal clear about who's responsible for what? Are there solid plans in place for handling delays or disagreements? Sourcing from reliable suppliers like Yasu Trading Co. with clear delivery terms can prevent many material-related headaches.

Walk the Site: Regularly stroll around your construction site with a "risk radar" turned on. Look for anything that seems off, from unsafe work practices to potential environmental problems. Think of it as a proactive safety inspection.

These quick wins can make a real difference right away and set the stage for a more developed risk management system.

Building a Sustainable Risk Management Program

For long-term success, you need a more structured approach. Think of this as building a resilient fortress against future risks:

Develop Formal Risk Assessment Procedures: Set up a standardized way to evaluate risks, using tools like risk matrices and probability assessments. This ensures consistency across projects and leads to better decisions.

Create Customized Risk Management Templates: Develop templates for risk registers, assessment forms, and contingency plans tailored to your usual projects and the unique challenges of the UAE. This saves time and ensures you're covering all the bases.

Invest in Training: Train your team at every level, from on-site workers to senior management. This builds a shared understanding of risk management principles and creates a culture of proactive problem-solving.

Implement Technology Strategically: Choose technology that truly supports your risk management efforts. This could be a mobile app for reporting incidents or a more advanced system for predictive analytics. The key is choosing tools that fit your needs.

Establish Key Performance Indicators (KPIs): Set clear goals for tracking your risk management success. This might include things like the number of near misses, the cost of delays caused by risks, or how effective your mitigation efforts have been.

By systematically addressing these areas, you can create a risk management program that’s woven into the fabric of your construction operations.

Prioritizing Your Efforts: Focusing on What Matters Most

Not all risks are equal. Prioritize your efforts based on your unique situation:

Current Situation: What are your biggest weaknesses right now? Are you dealing with material delays, safety incidents, or regulatory hurdles?

Available Resources: What tools, budget, and expertise do you have at your disposal? Be realistic about what you can achieve with the resources you have.

Project Challenges: What specific risks are tied to your current projects? Are you building a skyscraper in a bustling city or an infrastructure project in a remote desert location?

By focusing on the most urgent risks, you get the most bang for your buck and build a solid base for handling future challenges. Remember, effective construction risk management is an ongoing process, not a one-time fix. By consistently applying these principles, you can turn risk from a potential disaster into an opportunity for continuous improvement and a real competitive edge.

Ready to equip your team with the best tools and materials to improve safety and efficiency? Check out the top-quality construction essentials at Yasu Trading Co..