Why Ceiling Access Panels Are Critical to Modern Building Design

Ceiling access panels are often overlooked, but they are essential for maintaining modern buildings across the UAE. These seemingly simple components significantly impact a building's long-term health, efficiency, and cost-effectiveness. Smart architects and facility managers recognize that incorporating ceiling access panels from the beginning saves significant time and resources. This proactive approach transforms routine maintenance from potentially destructive work into simple tasks.

Streamlining Maintenance and Reducing Costs

Strategically placing ceiling access panels is key to streamlining maintenance. Imagine needing access to wiring hidden above a finished ceiling. Without a conveniently located access panel, this simple task could require cutting into the ceiling, leading to costly repairs and disruptions for building occupants.

Consider the routine inspection of HVAC systems, a common practice in the AE region. With easy access, technicians can quickly perform checks and address minor issues before they become major problems. This proactive maintenance, made possible by well-placed ceiling access panels, can reduce maintenance costs by up to 40% over a building's lifetime.

The Hidden Costs of Overlooking Access

Failing to include ceiling access panels during initial construction can lead to significant expenses later. Retrofitting access points often involves disruptive and costly procedures, such as cutting through finished surfaces and patching them afterward. This not only increases the maintenance budget but also inconveniences building occupants.

Furthermore, the lack of proper access can delay timely repairs, resulting in more extensive damage and higher repair costs. For example, a small leak in hidden plumbing could quickly escalate into a major problem if access is delayed due to inadequate access points.

Growing Demand in the MEA Region

The importance of efficient building solutions is reflected in the construction industry's growth across the Middle East and Africa. While specific data on ceiling access panels in the MEA region is limited, the overall construction sector, including related markets, provides valuable insights.

The MEA ceiling tiles market, which often includes ceiling access panels within its systems, was valued at USD 436.5 million in 2024. It's projected to reach USD 830.2 million by 2033, experiencing a CAGR of 7.4% between 2024 and 2032. This growth highlights the increasing demand for accessible building solutions, indirectly boosting the market for ceiling access panels. Learn more about the MEA Ceiling Tiles market here. This trend underscores the growing understanding of how seemingly small components like ceiling access panels can significantly contribute to the overall efficiency and lifespan of buildings in the region. Ultimately, strategically integrating ceiling access panels is not just a best practice; it's a crucial investment in a building's future.

The Ultimate Guide to Ceiling Access Panel Types

Ceiling access panels are essential for modern building design in the UAE. They're not just a functional requirement but a key design element. Choosing the correct panel type is crucial for long-term building performance and efficiency. This involves considering the building's specific needs, including humidity resistance and fire safety. Experienced architects recognize this and carefully select panel types to match their intended function for the best results.

Matching Panel Types to Specific Needs

Different environments require different types of ceiling access panels. For instance, the humid UAE climate necessitates humidity-resistant panels to prevent costly mold and mildew remediation. Fire-rated panels are critical for maintaining fire barriers and ensuring occupant safety.

Security is also a vital factor. In high-security facilities, tamper-resistant panels offer an additional layer of protection. Hospitals, with their strict hygiene standards, often use antimicrobial panels to control bacteria and maintain sterile environments. For spaces requiring noise control, like offices or recording studios, acoustically-rated panels help maintain sound isolation.

Exploring Specialized Ceiling Access Panel Options

Beyond standard push-up or drop-down panels, specialized options address specific building needs:

- Insulated Access Panels: These help regulate temperature and minimize energy loss, a significant advantage in the UAE's climate.

- Security Access Panels: With concealed hinges and locking mechanisms, these protect sensitive areas.

- Airtight Access Panels: These panels prevent air leakage, improving HVAC efficiency and indoor air quality.

- Drywall Access Panels: These blend seamlessly into the ceiling, providing discreet access points.

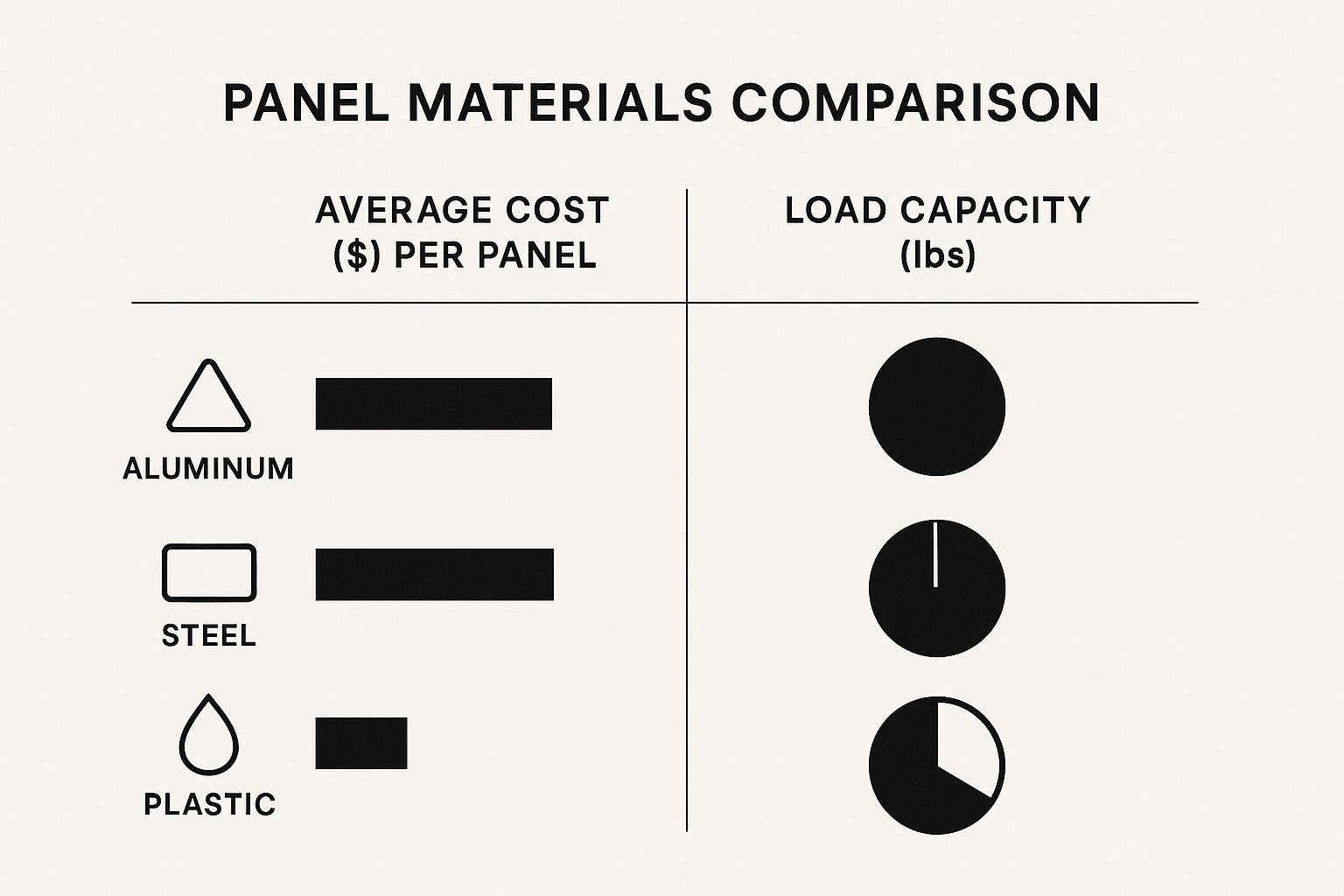

The infographic above compares common ceiling access panel materials – aluminum, steel, and plastic – based on average cost and load capacity. Steel offers the highest load capacity but is more expensive, while plastic is a budget-friendly option with a lower load limit. Aluminum balances cost and load-bearing capabilities. This underscores the importance of selecting a material that meets both budget and performance requirements.

To help you choose the right ceiling access panel, we've compiled a comparison table outlining key features, applications, and considerations for various panel types:

Ceiling Access Panel Types Comparison: This table compares different types of ceiling access panels based on key features, applications, and considerations to help readers select the appropriate panel for their specific needs.

| Panel Type | Key Features | Best Applications | Maintenance Requirements | Approximate Cost Range |

|---|---|---|---|---|

| Humidity-Resistant | Moisture-resistant materials, sealed edges | High-humidity areas like bathrooms and kitchens | Regular cleaning, inspection of seals | Moderate to High |

| Fire-Rated | Fire-resistant materials, intumescent seals | Areas requiring fire barriers | Periodic inspection of seals | Moderate to High |

| Tamper-Resistant | Concealed hinges, specialized locking mechanisms | High-security areas | Regular inspection of locking mechanisms | High |

| Antimicrobial | Antimicrobial coatings | Hospitals, healthcare facilities | Regular cleaning with approved disinfectants | High |

| Acoustically-Rated | Sound-absorbing materials | Offices, recording studios | Minimal | Moderate to High |

| Insulated | Insulating core | Areas requiring temperature regulation | Minimal | Moderate |

| Security | Concealed hinges, locking mechanisms | Secure areas, storage rooms | Regular inspection of locking mechanisms | Moderate to High |

| Airtight | Gasketed seals | Areas requiring airtight seals | Inspection and replacement of gaskets as needed | Moderate to High |

| Drywall | Flush fit, paintable surface | General access points in drywall ceilings | Minimal | Low to Moderate |

This table summarizes the variety of ceiling access panels available, highlighting the importance of selecting the right panel based on specific needs and budget.

Subtle Design Features for Exceptional Performance

Small details often distinguish an adequate panel from a high-performing one. Features like gasketed seals prevent air and dust leakage, improving indoor air quality. Durable hinges and latches ensure smooth, long-lasting operation. The panel's finish is also important. A quality finish not only enhances appearance but also protects against corrosion and wear, crucial in the demanding UAE environment.

By carefully considering these factors, you can choose a ceiling access panel that not only meets current needs but also provides exceptional performance throughout the building's life. This proactive approach is a smart investment that yields returns through reduced maintenance, improved energy efficiency, and enhanced building longevity. Selecting the right ceiling access panel isn't just about access—it's about optimizing building performance and creating a more sustainable, secure, and efficient environment.

Material Selection: The Foundation of Panel Performance

Selecting the right ceiling access panel involves more than just basic functionality. The material you choose significantly impacts its long-term performance, affecting everything from its durability and longevity to its overall aesthetic appeal. Overlooking this crucial aspect often leads to premature failures and unnecessary replacement costs. Leading contractors across the Middle East and Africa are increasingly recognizing the importance of careful material selection to ensure the lasting success of their projects.

Material Selection for Specific Environments

Different environments have unique demands when it comes to material properties. For instance, in the coastal regions of the UAE, the salty air can quickly corrode standard steel panels. That's why builders are turning to aluminum ceiling access panels for these applications. Aluminum offers exceptional corrosion resistance, ensuring long-lasting performance even in harsh coastal conditions.

Similarly, in sterile settings like hospitals and pharmaceutical facilities, stainless steel ceiling access panels are frequently the preferred choice. Stainless steel's resistance to bacteria and ease of cleaning make it ideal for maintaining stringent hygiene standards. In areas with significant temperature fluctuations, specialized composite materials can provide superior performance and dimensional stability.

Key Considerations for Material Selection

Several critical factors should be considered when selecting a ceiling access panel material:

-

Thermal Expansion: Materials expand and contract with temperature changes. This is especially important in regions like the UAE, where temperature swings can be substantial. Choosing a material with the right thermal expansion properties prevents warping and ensures a consistently proper fit.

-

Galvanic Compatibility: When different metals come into contact, galvanic corrosion can occur, weakening the panel and the surrounding structure. Choosing galvanically compatible materials is crucial to avoid this problem.

-

Regional Environmental Challenges: The MEA region presents specific environmental challenges, such as dust, humidity, and extreme heat. These factors should be considered when choosing a material to ensure the panel can withstand these conditions.

Market trends also play a role in material selection. While specific data on ceiling access panels in the MEA may be limited, the market is influenced by broader construction trends. The MEA ceiling tiles market is trending toward sustainable and energy-efficient products, a trend likely influencing ceiling access panel demand. The growing emphasis on sustainability, including the use of recycled materials and low-VOC coatings, is driven by environmental regulations and consumer preferences. Explore this topic further. This focus on sustainability will likely increase the demand for ceiling access panels that meet these evolving standards.

Balancing Aesthetics, Performance, and Budget

Ultimately, choosing a ceiling access panel material requires balancing aesthetics, performance, and budget. While aluminum performs exceptionally well in coastal environments, it can be more expensive than steel. Plastic panels are often the most budget-friendly but may not offer the same durability as metal options. The long-term cost of ownership should be a key consideration. A more expensive, durable panel might ultimately be more cost-effective than a cheaper panel requiring frequent replacement. By carefully considering these factors, you can select a ceiling access panel material that offers the optimal balance of performance, durability, and value for your project.

Sizing Ceiling Access Panels for Perfect Functionality

Selecting the right size for your ceiling access panel is a critical step in any project. A panel that's too small or too large can lead to unnecessary expenses and compromise both the appearance and functionality of your ceiling. Whether you're working on a new construction project or renovating an existing space in the UAE, understanding your project's specific needs is essential. Through discussions with maintenance professionals in the region, we've highlighted key factors to consider when determining the ideal dimensions for your ceiling access panels.

Calculating the True Working Area

While standard sizes are readily available, they might not always be the perfect fit. A standard 2' x 2' panel may seem adequate at first glance, but if you need access to large ductwork or intricate wiring, it could prove insufficient. This is where accurately calculating the true working area becomes vital.

Think about the size of the equipment or systems that require access. Also, factor in the space needed for technicians to maneuver and utilize their tools effectively. For example, if a bulky component needs to be removed, the access panel must be large enough to allow for its extraction without causing any damage.

Strategic Placement for Optimal Access

The location of your ceiling access panel is just as important as its size. An improperly placed panel can obstruct access and create difficulties for maintenance personnel. Experienced designers use a strategic approach to panel placement, carefully considering several crucial factors.

-

Clearance for tools and equipment: The area surrounding the panel should provide ample space for technicians to comfortably operate their tools without any hindrance.

-

Equipment removal: Ensure the panel allows enough space for the safe and efficient removal of components that need maintenance or replacement.

-

Technician maneuverability: The panel should allow technicians enough room to comfortably access and work within the ceiling cavity.

Standard Dimensions and Recommended Applications

To help guide your selection process, the table below provides common ceiling access panel dimensions and their recommended applications. This information serves as a valuable starting point for planning your project.

Before we delve into the table, let's clarify its purpose. It's designed to give you a quick overview of standard sizes and their typical uses, making it easier to choose the right panel for your needs.

| Size Category | Standard Dimensions (inches) | Recommended Applications | Accessibility Considerations |

|---|---|---|---|

| Small | 12 x 12 | Electrical junctions, small plumbing fixtures | Limited access for larger components |

| Medium | 24 x 24 | HVAC access, larger plumbing fixtures | Suitable for most general maintenance tasks |

| Large | 24 x 48 | Ductwork, complex wiring, equipment removal | Provides ample space for larger components and technician movement |

| Custom | Varies | Specialized applications requiring non-standard sizes | Tailor-made for specific project needs |

While this table provides a helpful overview of common sizes, remember that your specific requirements should always guide your final decision. Adjustments may be necessary based on the unique needs of your project.

Planning for Future Expansion

Finally, anticipating future system expansions or upgrades is a crucial aspect of sizing your ceiling access panels. Opting for a slightly larger panel than currently required can save you significant time and money down the road. This proactive approach eliminates the need to cut new access points later, preserving the ceiling's aesthetics and structural integrity. Utilizing practical templates for specifying panels helps maintain consistency and guarantees adequate access for future requirements without compromising the overall design. By carefully considering these factors, you can choose a ceiling access panel that not only meets your present needs but also accommodates future growth. This forward-thinking approach is essential for ensuring the long-term functionality and efficiency of your building in the UAE.

Installation Mastery: Beyond the Basics

Proper installation of a ceiling access panel is crucial for long-term performance and smooth operation. While the basic steps might appear simple, experienced ceiling contractors across the UAE utilize specific techniques to ensure a truly professional result. This section explores these often-overlooked details, empowering you to achieve a flawless finish every time. It's more than just fitting the panel; it's about ensuring seamless functionality and maintaining the ceiling's integrity.

Framing Techniques for Structural Integrity

One common mistake that leads to sagging frames and sticking doors is inadequate framing. Standard installations sometimes neglect the importance of a robust support structure, particularly in the UAE where heavier ceiling materials are often used.

To avoid structural problems, build a solid frame around the access panel opening with timber or metal studs. This frame provides crucial support for the panel and ensures it can handle the weight of the ceiling material.

Securely attaching the frame to the surrounding ceiling joists provides added stability. This creates a strong foundation for the ceiling access panel, preventing issues such as sagging or warping over time.

Fastener Selection and Placement

The correct fasteners are essential for securely attaching the ceiling access panel. Different ceiling systems require specific fastener types. Using the wrong type, like drywall screws in a concrete ceiling, won't provide a secure hold.

Consult a supplier like Yasu Trading Co. to determine the best fasteners for your application. They can offer expert advice on selecting the appropriate hardware for various projects across the UAE. Choosing the right fasteners ensures the panel stays secure and flush with the ceiling, eliminating unwanted movement or gaps.

Finishing Methods for Seamless Integration

Achieving a nearly invisible ceiling access panel requires careful finishing. Professionals use specific techniques to seamlessly blend the panel with the surrounding ceiling.

For drywall ceilings, apply a thin layer of joint compound around the panel edges, feathering it outward for a smooth transition. Then, prime and paint the panel to match the ceiling color.

For tiled ceilings, ensure the cut tiles around the panel fit cleanly and align precisely, minimizing visible gaps. These finishing touches create a professional, polished look, making the access panel practically disappear when closed.

Common Installation Pitfalls to Avoid

Understanding common installation errors can help prevent future problems. Here are some key pitfalls to watch out for:

-

Insufficient Support Structures: A weak frame can lead to sagging and operational problems. Reinforce the framing around the panel for adequate support.

-

Improper Sealing Techniques: Gaps around the panel can compromise fire ratings and cause air leakage. Use appropriate sealants to create an airtight and fire-safe seal.

-

Alignment Errors: Misaligned panels can be difficult to operate and may not seal correctly. Double-check measurements and alignment during installation for a perfect fit.

Step-by-Step Guidance for New Construction and Retrofits

Whether installing in new construction or retrofitting, follow these steps:

New Construction:

- Frame the opening during the ceiling framing stage.

- Install the panel after the ceiling material is installed.

- Finish the panel to match the surrounding ceiling.

Retrofit:

- Carefully cut the opening in the existing ceiling.

- Frame the opening as needed.

- Install and finish the panel to blend with the existing ceiling.

By following these steps and incorporating these professional techniques, you can ensure a flawless ceiling access panel installation. This provides long-lasting functionality and enhances the overall aesthetics of your project, reflecting the high standards of the UAE construction industry.

Maintaining Ceiling Access Panels for Optimal Lifespan

Proper installation is only the beginning when it comes to ensuring your ceiling access panels stand the test of time. Regular maintenance of these often-forgotten components is essential for preserving their functionality and maximizing their lifespan. This is particularly true in the UAE's demanding climate, where dust, humidity, and temperature swings can significantly impact building materials.

Implementing a Regular Inspection Schedule

Preventative maintenance starts with a consistent inspection schedule. Much like routine car maintenance, regular checks can catch potential issues early. This proactive approach is much more economical than addressing major repairs later. This is especially important for ceiling access panels, often exposed to challenging environmental conditions in the UAE.

Aim to inspect your ceiling access panels at least twice a year. Increase the frequency in high-traffic areas or harsh environments. Focus on key stress points like hinges, latches, and gaskets. These components are particularly prone to wear and tear. Addressing problems early in these areas can prevent bigger issues and costly repairs later on.

Lubrication and Cleaning: Essential for Smooth Operation

Smooth operation is key for easy access when you need it. This means using appropriate lubricants on moving parts like hinges and latches. Choose a lubricant designed for the panel's material and the surrounding environment. In the UAE's humid climate, consider a lubricant with anti-corrosion properties. This can significantly extend the life of your access panels.

Cleaning is just as crucial. Dust buildup can hinder operation and damage the panel over time. Regularly clean the panel and the surrounding frame with appropriate cleaning solutions. Avoid abrasive cleaners, which can scratch or damage the panel's surface. This maintains both the appearance and function of the panel, ensuring it blends seamlessly into the ceiling.

Gasket Replacement: Preventing Leaks Before They Start

Gaskets are vital for a tight seal, preventing dust, air leaks, and water damage – especially important in the UAE's climate. But gaskets can degrade over time due to environmental factors or regular use. Regularly inspect and replace gaskets as needed.

Gasket replacement is a simple and inexpensive task. However, it can prevent major problems like water damage or compromised fire ratings. This proactive step can save building owners significant money in the long run, avoiding extensive repairs.

Addressing Regional Challenges in the MEA Region

The MEA region poses unique challenges for maintaining ceiling access panels. The combination of dust, humidity, and temperature fluctuations requires specific maintenance strategies.

-

Dust Infiltration Prevention: Regular cleaning and a tight seal around the panel are essential for minimizing dust. Specialized dust-control gaskets offer added protection in dusty environments.

-

Humidity Management: In humid areas, choose panels made from humidity-resistant materials like aluminum or stainless steel. Regular inspection and cleaning help prevent corrosion and ensure long-term performance.

-

Temperature Fluctuations: Extreme temperature changes cause materials to expand and contract, potentially leading to warping or cracking. Choose materials with suitable thermal expansion properties and ensure proper installation to minimize these effects.

By addressing these regional challenges and following the maintenance practices outlined above, building owners in the UAE can ensure their ceiling access panels remain functional and look great for years. For expert advice and all your ceiling access panel needs, consider consulting trusted suppliers like Yasu Trading Co. in Dubai. They can help you choose the right panels and offer valuable maintenance support.

The Future of Ceiling Access Panel Innovation

The often-overlooked ceiling access panel is getting a modern makeover. It's evolving beyond simple entry points to incorporate features that provide real benefits for both builders and building owners in the UAE. These improvements offer practical solutions to everyday challenges in construction and maintenance. Let's explore how these panels are adapting to the demands of modern buildings.

Integrated Sensor Systems for Predictive Maintenance

A key advancement is the use of sensor technology within access panels. These sensors can monitor environmental factors like temperature, humidity, and even structural stress. This allows for predictive maintenance, catching potential issues like leaks or overheating before they become major problems. Imagine a humidity sensor in a bathroom panel alerting facility managers to a leak before it causes serious water damage – that's the power of this technology.

Imagine a humidity sensor in a bathroom panel alerting facility managers to a leak before it causes serious water damage – that's the power of this technology.

Specialized Coatings for Enhanced Durability

The MEA region's climate can be tough on building materials. New specialized coatings are being developed to combat these challenges. These coatings boost resistance to corrosion, UV degradation, and fire, resulting in longer lifespans for ceiling access panels and lower maintenance costs. This translates to significant long-term savings, especially in harsh environments.

Modular Designs for Flexibility and Efficiency

Modular ceiling access panel designs offer increased flexibility and efficiency during installation. These designs allow for easy customization, adapting to various ceiling types and configurations. They also simplify future modifications or upgrades. Need to expand an access panel to accommodate new equipment? A modular design makes it easy.

Integration with Smart Building Technology

Ceiling access panels are no longer stand-alone components. They are becoming integrated into the smart building ecosystem. This allows for remote monitoring, automated documentation, and better security. Facility managers can remotely track access points, ensuring maintenance compliance and boosting security. Automated documentation simplifies record-keeping and streamlines maintenance.

Separating Hype from Reality: MEA Implementation

While these innovations offer great potential, it's essential to assess their true value for specific applications in the MEA region. Not every innovation is a perfect fit for every project. Consider factors like dust, humidity, and temperature fluctuations. A smart access panel with remote monitoring might be ideal for a large commercial building but unnecessary for a small residential project.

Practical Recommendations for the UAE

For construction projects in the UAE, prioritize durability and resistance to environmental factors. Choose panels made from corrosion-resistant materials like aluminum or stainless steel with specialized protective coatings. Consider integrating smart building technology features like remote monitoring and automated documentation, especially for larger projects. These considerations will ensure your chosen ceiling access panels offer optimal performance and value in the UAE's unique climate.

For all your ceiling access panel needs in the UAE, contact Yasu Trading Co.. We offer a wide selection of high-quality ceiling access panels for various applications, along with expert advice and support. Reach out to us today to discuss your project requirements and discover how we can help.