Understanding Film Faced Plywood That Actually Matters

Film faced plywood is becoming increasingly important in UAE construction projects. This guide clarifies key aspects that regional professionals should understand, based on insights from experienced contractors and project managers. It will equip you to choose the right materials for your next project.

Deciphering the Film: Phenolic vs. Melamine

Understanding the difference between phenolic and melamine films is essential. Phenolic film is incredibly durable and resistant to chemicals and abrasion. This makes it perfect for tough jobs like concrete formwork.

Melamine film, on the other hand, offers a smoother, more decorative finish. This makes it more suitable for interiors and furniture. The right film depends on your project's specific needs.

Manufacturing Processes and Performance

How film faced plywood is made directly affects its performance. High-quality plywood usually uses premium hardwood cores and strong, waterproof adhesives. How the film is applied – whether through hot or cold pressing – also matters.

Hot pressing, for example, creates a stronger bond. This improves the plywood's resistance to delamination.

Quality Indicators: Spotting the Superior Choice

There are several ways to tell high-quality film faced plywood from inferior options. Look for consistent film thickness, a void-free core, and cleanly sealed edges. The type of glue used is also important for moisture resistance and preventing delamination. This is especially crucial in the humid AE climate.

The global market is trending towards quality construction materials. The global film faced plywood market was valued at approximately USD 4.2 billion in 2023. It's projected to reach about USD 6.8 billion by 2032. This growth is driven by industries like construction and furniture that need durable, high-quality materials. Learn more about the global film faced plywood market.

Choosing high-quality film faced plywood saves money in the long run and reduces maintenance needs.

Why AE Construction Professionals Choose Film Faced Plywood

From intense summer heat to constantly shifting humidity, the UAE region presents unique challenges for building materials. Film faced plywood, however, stands up remarkably well to these difficult conditions. Its proven performance in demanding environments makes it a favorite for construction projects throughout the area.

Durability and Resistance: Built to Last

Film faced plywood provides exceptional durability, resisting damage from moisture, abrasion, and impacts. The protective film acts as a shield against the harsh AE climate. This film prevents water from penetrating the plywood, reducing the risk of rot, swelling, and delamination – common problems with traditional plywood in humid climates.

The film also offers resistance to chemicals and UV radiation, further extending the lifespan of the plywood. This resilience translates into considerable long-term cost savings. While the initial cost might be slightly higher compared to standard plywood, the reduced need for replacements and maintenance makes film faced plywood a more economical option over a project's lifecycle. Learn more in our article about building materials quality standards in the UAE.

Streamlined Construction: Saving Time and Labor

The smooth, uniform surface of film faced plywood streamlines construction processes. It minimizes the need for extensive surface preparation before painting or applying other finishes, allowing projects to be completed more quickly and saving valuable time and labor costs.

This smooth finish also contributes to a higher-quality end product. Furthermore, film faced plywood is compatible with a range of modern building techniques. Its strength and stability make it suitable for diverse applications, including concrete formwork, wall sheathing, and flooring.

Sustainability and the Environment

Choosing film faced plywood also aligns with sustainable building practices. Its inherent durability and extended lifespan minimize material waste. Many manufacturers now prioritize sustainable forestry practices when sourcing the wood for their plywood.

The growing emphasis on sustainable construction in the AE region further reinforces the popularity of film faced plywood. This material effectively addresses both performance requirements and environmental responsibility, contributing to the overall quality and sustainability of construction projects across the region.

Real-World Applications Across AE Construction Projects

From towering skyscrapers in Dubai to essential infrastructure projects in Saudi Arabia, film faced plywood has proven its versatility across the AE construction landscape. This section explores how leading contractors are utilizing this resilient material to address regional construction challenges and deliver exceptional results.

Concrete Formwork: Achieving a Smooth Finish

One of the most common applications for film faced plywood in the AE region is concrete formwork. The smooth, resin-coated surface of the plywood ensures a pristine finish on concrete structures, minimizing the need for extensive post-pour finishing.

This not only saves valuable time and labor costs but also results in a superior final product. The plywood's remarkable durability also allows for repeated use, maximizing its cost-effectiveness. For instance, an Abu Dhabi project reported reusing their film faced plywood forms over 70 times, significantly reducing material waste and project expenses.

Exterior Applications: Weathering the Storm

The AE region's harsh climate, characterized by intense sun and fluctuating humidity, demands exterior materials that can withstand these challenging conditions. Film faced plywood's inherent weather resistance makes it a perfect choice for applications like wall sheathing and roofing.

The protective film serves as a barrier against moisture, preventing rot and decay while also providing resistance to UV radiation. This ensures structures built with film faced plywood are better prepared to handle the regional climate and maintain their structural integrity over time.

Specialized Construction Needs: Prefabrication and Beyond

Beyond traditional uses, film faced plywood is increasingly employed in specialized construction methods such as prefabricated and modular construction. Its strength, stability, and ease of fabrication make it well-suited for creating prefabricated wall panels, floor systems, and other building components.

This approach facilitates faster construction times and improved quality control, which are particularly advantageous in large-scale projects across the AE region. Furthermore, some projects are using film faced plywood for temporary structures, site hoardings, and specialized formwork for intricate architectural designs.

Evaluating Project Suitability: Making the Right Choice

Choosing the right material for your project depends on a variety of factors. When considering film faced plywood, assess the specific application, the necessary level of durability and weather resistance, and the overall project budget.

While the initial cost of film faced plywood may be higher than standard plywood, its reusability and long-term performance can offer significant cost savings throughout the project lifecycle. Consulting with experienced suppliers like Yasu Trading Co. LLC in Dubai can provide valuable guidance for informed material selection. They can offer expertise on the optimal type of film faced plywood for your specific needs, taking into account regional climate conditions and project requirements. This ensures you select the most suitable and cost-effective solution for your construction project.

Film Faced Plywood vs Alternatives: The Real Comparison

Making smart choices about construction materials means understanding how they perform and how much they truly cost. This comparison looks at how film faced plywood measures up against other options like traditional plywood, MDF (Medium-Density Fiberboard), and solid wood in typical AE construction projects.

Performance Under Pressure

Film faced plywood shines in tough environments. Its film coating provides excellent moisture resistance, which is essential in the humid AE climate. This protection also makes it more durable, preventing problems like rot and delamination that often affect traditional plywood. For instance, in concrete formwork, the smooth surface of film faced plywood creates a cleaner finish, reducing the work needed after the concrete is poured.

Furthermore, film faced plywood is strong enough to be reused many times. This extends its lifespan compared to alternatives that may deteriorate quickly under similar conditions. This reusability significantly lowers long-term costs.

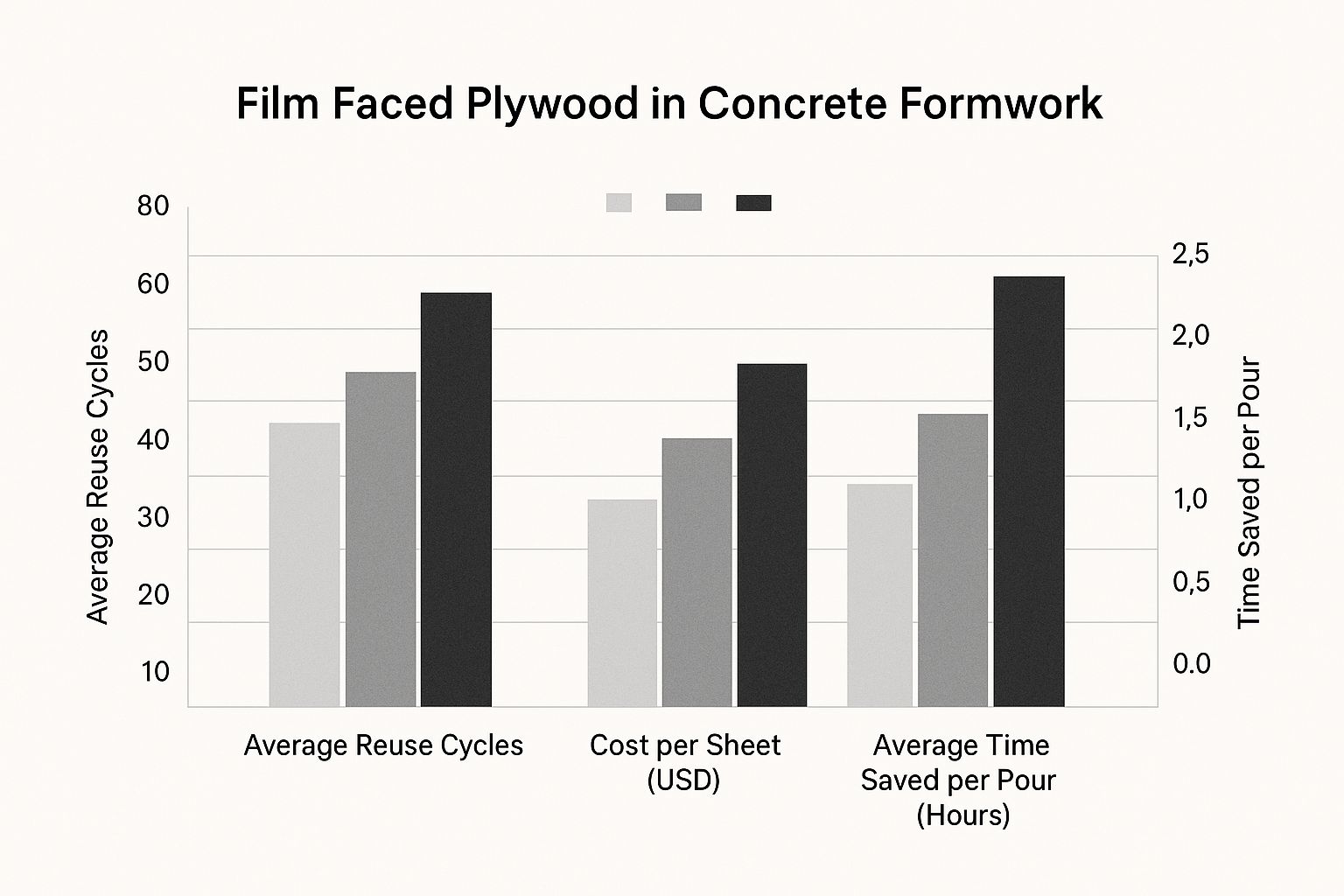

This infographic highlights key metrics of film faced plywood used in concrete formwork, showing average reuse cycles, cost per sheet, and time saved per pour. The data shows that film faced plywood, while possibly having a higher initial cost per sheet, can achieve up to 70 reuse cycles. This can save upwards of two hours per pour compared to other materials, ultimately reducing overall project expenses.

Cost Considerations: Beyond the Initial Price

The initial price of film faced plywood might be higher than options like MDF or standard plywood. However, it’s important to consider the total cost of ownership. MDF, for example, is easily damaged by moisture, leading to replacements and higher costs over time. Solid wood, while durable, is often much more expensive and requires more finishing work.

Film faced plywood’s durability and reusability help lower long-term costs. This makes it a more budget-friendly choice for many applications. This long-term value makes film faced plywood an attractive option despite the potentially higher upfront cost.

To better understand the cost and performance differences, let's look at a detailed comparison:

Film Faced Plywood vs Alternative Materials Comparison: A detailed comparison of film faced plywood against other common construction materials used in the AE region, covering cost, durability, and performance factors.

|

Material Type |

Moisture Resistance |

Durability Rating |

Cost per sqm (AED) |

Best Applications |

|---|---|---|---|---|

|

Film Faced Plywood |

Excellent |

High |

Varies based on thickness and grade |

Concrete formwork, exterior sheathing, high-moisture environments |

|

Traditional Plywood |

Moderate |

Medium |

Lower than film faced plywood |

Interior applications, protected environments |

|

MDF |

Poor |

Low |

Lowest initial cost |

Interior applications with controlled humidity |

|

Solid Wood |

Varies depending on species |

High |

Highest initial cost |

Structural framing, high-end finishes, aesthetic applications |

As the table shows, while film faced plywood may have a higher initial cost, its superior moisture resistance and durability make it a cost-effective choice in the long run, especially for demanding applications. Other materials like MDF or traditional plywood might offer lower initial costs but may require more frequent replacement in challenging environments.

Choosing the Right Material: A Balanced Perspective

Film faced plywood excels in demanding applications like concrete formwork, exterior sheathing, and projects requiring high moisture resistance. This makes it a good option for structures exposed to the harsh AE weather. However, other materials might be better suited for certain uses. MDF, for example, might be appropriate for interior work with controlled humidity. Solid wood is still a good option when aesthetics are important. In the end, the best choice depends on the specific needs and budget of the project. Carefully considering these factors leads to informed decisions and, ultimately, more successful construction projects.

Market Opportunities and Growth Trends in the AE Region

The construction sector in the AE region is experiencing rapid growth. This surge is driving increased demand for high-quality building materials, particularly film faced plywood. This section delves into the market dynamics behind this demand, focusing on key markets like the UAE and Saudi Arabia, along with emerging Gulf economies.

Key Market Drivers

Several factors contribute to the growing need for film faced plywood. Large-scale infrastructure projects, especially in the UAE and Saudi Arabia, require durable materials. Film faced plywood is well-suited for applications like formwork and sheathing.

The booming residential and commercial construction sectors also contribute to this demand, making film faced plywood a versatile choice for various building needs. For more insights into construction trends in the region, check out this article: exploring trending construction materials in Dubai.

The Middle East and Africa are seeing a rise in plywood demand, including film faced plywood, due to rapid urbanization and infrastructure development. This growth is especially noticeable in Saudi Arabia, the United Arab Emirates, and South Africa.

In 2023, the UAE imported over 400,000 cubic meters of plywood. This figure is projected to increase by 5-8% annually until 2030. More detailed statistics can be found here.

Supply Chain and Pricing

Supply chain dynamics significantly influence the availability and cost of film faced plywood. Global supply chain disruptions can impact both raw materials and finished products, affecting market prices. Regional factors, such as import regulations and logistics, also contribute to the product's final cost.

Sustainability and Building Codes

Sustainability is increasingly important in the AE construction industry. Film faced plywood, especially from sustainably managed forests, is a durable and environmentally responsible choice. Evolving building codes in the region, which emphasize energy efficiency and sustainable practices, further encourage the use of this material.

Opportunities for Contractors and Suppliers

These market trends create opportunities for both contractors and suppliers. Contractors can use film faced plywood to enhance construction efficiency, minimize waste, and achieve better finishes. Suppliers can meet the growing demand by offering quality products and reliable services. Yasu Trading Co. LLC, based in Dubai, serves the UAE construction sector by supplying premium building materials, including film faced plywood.

Future Outlook

The future of film faced plywood in the AE region appears promising. Continued investments in infrastructure and construction will likely fuel further demand. The growing emphasis on sustainability and the adoption of modern building techniques will probably solidify film faced plywood's role as a preferred building material.

Smart Selection Guide for Film Faced Plywood Success

Choosing the right film faced plywood is crucial for successful construction projects in the AE region. This guide offers practical advice drawn from real contractor experiences, focusing on key evaluation criteria. By understanding these factors, you can select materials that ensure project success and avoid costly mistakes.

Assessing Film Quality and Core Construction

The quality of both the film and the core significantly impacts the overall performance of film faced plywood. When evaluating film quality, prioritize consistent thickness and a smooth, unblemished surface. The film should adhere securely to the core, showing no signs of peeling or bubbling.

Also, inspect the core construction for voids and gaps, which compromise the plywood's structural integrity. A dense, uniform core is key for maximizing strength and stability.

For instance, high-quality film faced plywood typically uses hardwood cores renowned for durability and resistance to warping. The adhesive used to bond the layers is also critical. Waterproof adhesives are a necessity in the AE region's humid climate.

Verifying Compliance with Regional Standards

Film faced plywood used in the AE region must comply with local standards and regulations. Look for certifications and markings indicating compliance with standards for fire safety, moisture resistance, and structural performance. These certifications guarantee the material meets project specifications. You might find this helpful: Expert tips for selecting the best building materials in Dubai.

Evaluating Suppliers and Grade Classifications

Choosing a reliable supplier is just as important as selecting the right product. Seek suppliers with a proven history of delivering high-quality film faced plywood and excellent customer service. Inquire about their quality control procedures and request references. Understanding grade classifications is also key. Different grades serve specific applications. Grade A plywood typically has a smooth, flawless surface ideal for concrete formwork, while Grade B may have minor imperfections, making it suitable for less visible uses.

The following table provides a helpful overview of quality parameters:

Film Faced Plywood Quality Standards and Specifications

Essential quality parameters and specifications to consider when selecting film faced plywood for AE region construction projects.

|

Quality Parameter |

Grade A Standard |

Grade B Standard |

Testing Method |

Regional Requirements |

|---|---|---|---|---|

|

Surface Smoothness |

No visible defects |

Minor imperfections allowed |

Visual Inspection |

Varies by project |

|

Film Thickness |

Consistent across the panel |

Minor variations allowed |

Thickness Gauge |

Specific standards apply |

|

Core Density |

High and uniform |

Medium to High |

Density Measurement |

Varies by application |

|

Moisture Resistance |

Compliant with regional standards |

Compliant with regional standards |

Moisture Content Test |

Specific standards based on humidity levels |

|

Adhesion Strength |

High bond strength between film and core |

Medium to High bond strength |

Adhesion Test |

Specific standards apply |

This table summarizes the key quality standards for different grades of film faced plywood, outlining testing methods and regional requirements. Ensuring your chosen plywood adheres to these standards is critical for project success.

Quality Control and Storage Best Practices

Implementing robust quality control throughout the supply chain prevents costly errors and ensures consistency. Regularly inspect incoming shipments for defects or deviations from specifications.

Proper storage is crucial, especially in the AE region's climate. Store film faced plywood in a cool, dry, and protected area, shielded from direct sunlight and excessive humidity. This prevents warping, delamination, and moisture-related issues.

Identifying Substandard Materials

Be wary of signs indicating substandard film faced plywood. Uneven film thickness, bubbling or peeling film, and a soft or spongy core all point to inferior quality. Suspiciously low prices can also signal compromised materials or manufacturing processes. Prioritizing quality over price ensures long-term project success.

Investing in high-quality film faced plywood and implementing effective quality control measures will yield superior results, reduce maintenance costs, and contribute to a successful construction project.

Installation Mastery and Long-Term Performance

Film faced plywood offers incredible durability and versatility for construction projects in the AE region. However, achieving its full potential depends on proper installation tailored to the local climate. This guide, drawing on insights from experienced contractors, outlines the key steps for optimal, long-lasting results with film faced plywood.

Handling and Cutting Techniques

Proper handling is crucial from the very beginning. Always store film faced plywood in a cool, dry, and shaded location to prevent warping or damage from the sun. When transporting sheets, secure them to prevent shifting and potential damage.

Cutting film faced plywood requires precision. Use carbide-tipped blades for clean cuts to minimize splintering and chipping, especially with the tougher phenolic film. A jigsaw with a fine-tooth blade is recommended for complex shapes. Always wear appropriate safety gear, including eye protection and gloves.

Fastening Methods for a Secure Installation

Choosing the right fasteners and techniques is essential for a secure installation. For structural applications, use corrosion-resistant screws designed for exterior use. This is particularly important in the humid coastal areas of the AE region.

For formwork applications, ensure fasteners are compatible with the concrete and form release agents. The spacing of the fasteners depends on the structural requirements and the thickness of the plywood. Over-fastening can weaken the plywood, while under-fastening compromises its structural integrity.

Preparation and Prevention of Common Failures

Before installation, make sure the supporting structure is clean, level, and free of debris. This provides a stable base for the plywood and prevents issues like uneven surfaces or premature wear. In humid conditions, pre-drilling fastener holes can prevent splitting, especially with thinner plywood sheets.

Common installation failures, such as delamination and buckling, can be avoided by following manufacturer recommendations for fastener spacing. Also, ensure proper acclimation of the plywood to the ambient humidity before installation.

Tool Requirements and Maintenance Strategies

While specialized tools aren't always necessary, the right equipment ensures a professional finish and efficient workflow. A circular saw with a carbide-tipped blade is essential for clean, straight cuts. A jigsaw provides more flexibility for curved or intricate cuts.

Maintaining film faced plywood is relatively simple. Regular cleaning with a mild detergent and water removes dirt and grime. For formwork applications, thoroughly clean and inspect the sheets after each use, addressing any damage promptly. These practices extend the plywood's lifespan and maximize your investment.

Seasonal Considerations and Troubleshooting

Seasonal changes in the AE region, particularly temperature and humidity fluctuations, require special attention. During hotter months, schedule installations for cooler parts of the day to minimize thermal expansion and contraction. In humid periods, proper ventilation during and after installation helps manage moisture buildup.

If you encounter any installation challenges, consult with experienced contractors or suppliers for advice. For example, bubbling beneath the film often indicates trapped moisture or inadequate surface preparation. Addressing the root cause ensures a lasting solution.

Investing in high-quality film faced plywood and using meticulous installation techniques is crucial for maximizing its long-term performance. Ready to explore the benefits of film faced plywood for your next project? Contact Yasu Trading Co. LLC today for a comprehensive range of high-quality products and expert guidance tailored to your needs.