Electrical Conduit Installation Guide: Pro Tips That Work

Understanding Conduit Systems Before You Start

Selecting the right electrical conduit system is a critical step for any project in the Middle East and Africa (MEA) region. It's not simply about supplying power; it's about ensuring lasting safety, adhering to local regulations, and preventing expensive revisions later. This involves understanding the differences between rigid conduit and flexible conduit, and how each performs in the region’s specific climate.

Rigid Vs. Flexible Conduit: What's the Difference?

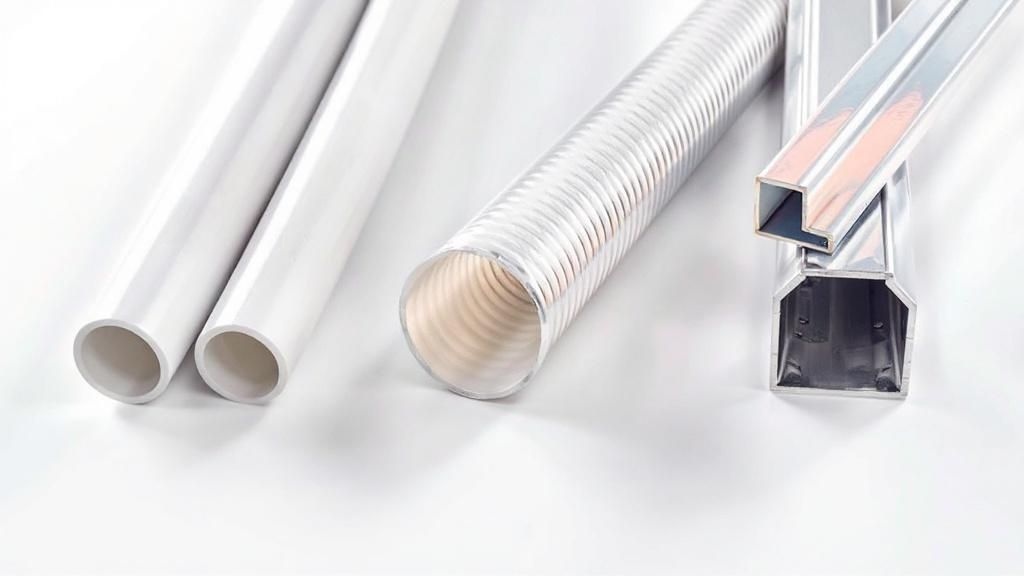

Rigid conduit, usually made of metal or PVC, provides robust protection against physical damage. It's a great choice for exposed installations. However, it can be trickier to install, particularly in confined areas. Working around complex bends, for instance, often requires specialized tools and skilled labor. Flexible conduit, conversely, is easier to handle, especially when retrofitting existing buildings. Its flexibility also makes installation around obstacles much simpler. You might be interested in: How to master electrical fittings and materials.

Choosing the Right Material for Your Project

Choosing the appropriate material depends heavily on environmental conditions and budget. PVC conduit is cost-effective and highly resistant to corrosion, making it a common choice in the UAE. Metal conduits, such as Electrical Metallic Tubing (EMT) and rigid metal conduit, offer exceptional mechanical strength. However, they are more prone to corrosion in the humid coastal environments common throughout the MEA region. In areas with substantial temperature swings, such as the inland regions of Saudi Arabia, thermal expansion and contraction are important factors to consider.

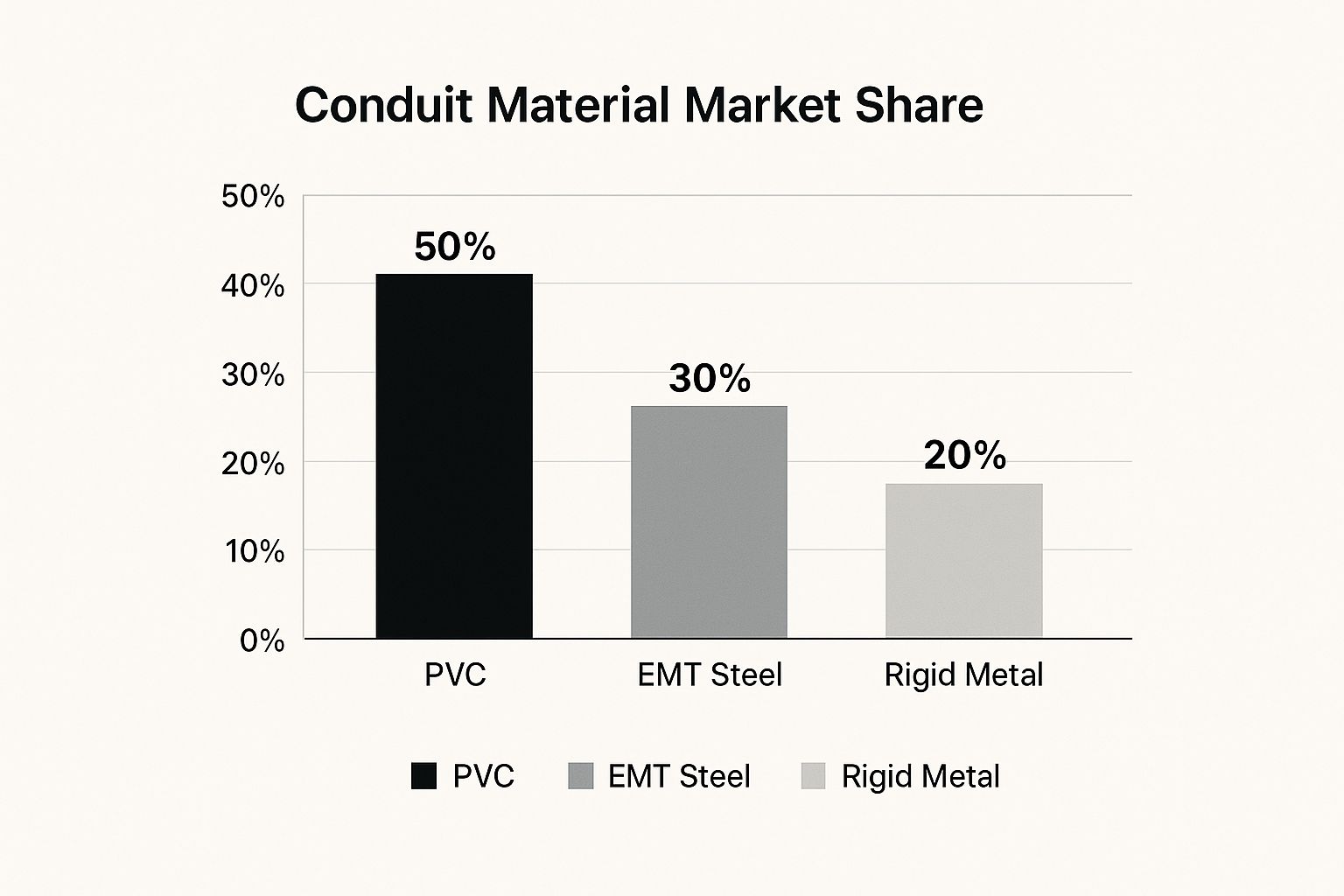

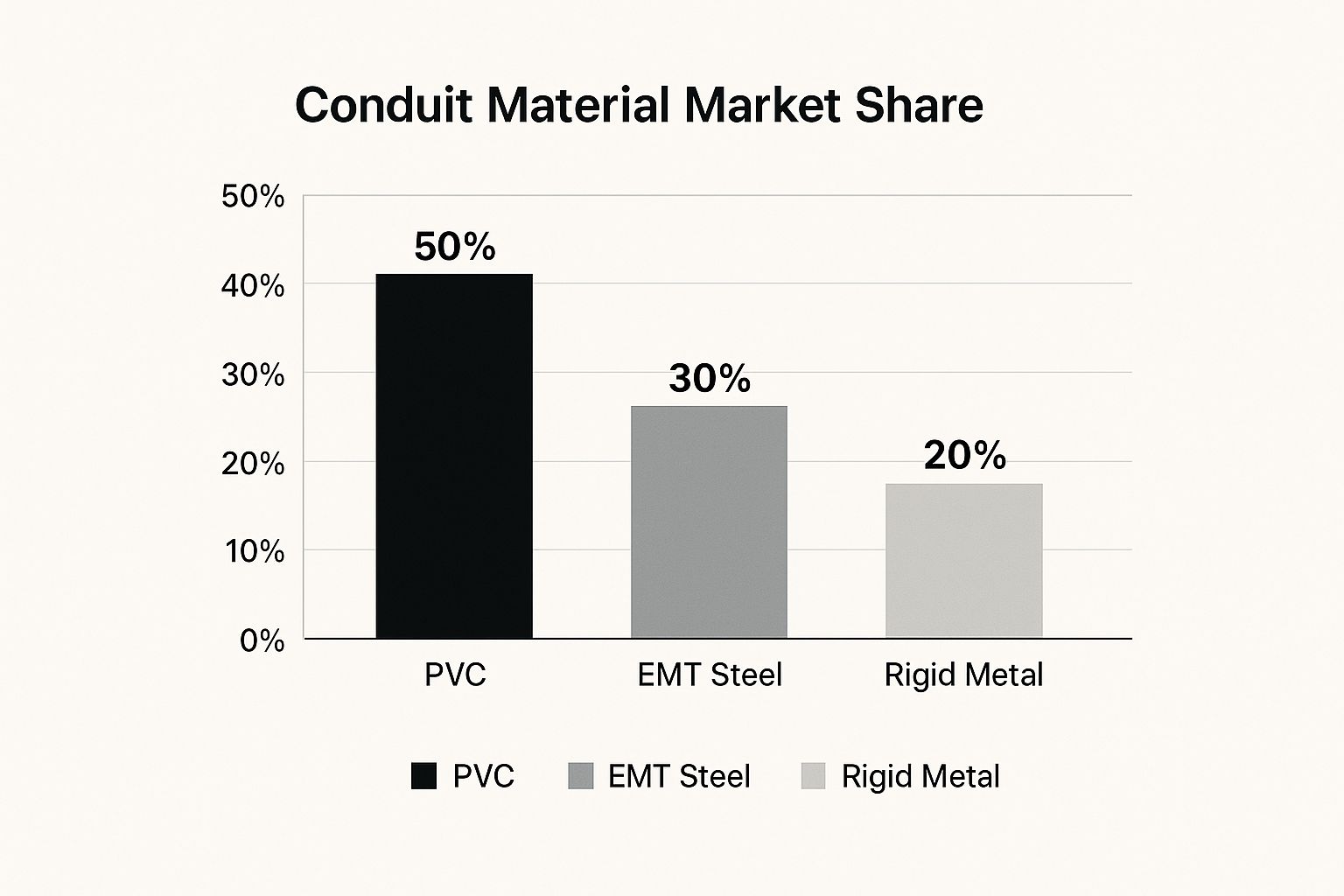

This brings us to an important point: understanding market trends. The MEA cable conduit systems market reached USD 247.3 million in 2024. It's projected to grow at a 7.8% CAGR, reaching USD 383.3 million by 2030. This underscores the growing significance of this sector. Learn more about the cable conduit systems market.

This chart shows the current market share for different conduit materials: PVC at 50%, EMT steel at 30%, and rigid metal at 20%. This clearly highlights PVC's leading position as the preferred material for numerous projects, thanks to its affordability and corrosion resistance.

To help compare different conduit types for MEA applications, we've compiled the following table:

Conduit Types Comparison for MEA Applications: Detailed comparison of different conduit types including durability, cost, installation complexity, and climate suitability.

| Conduit Type | Durability Rating | Installation Difficulty | Climate Resistance | Cost Range |

|---|---|---|---|---|

| PVC | High | Easy | Excellent (Corrosion, Moderate Temperature) | Low |

| EMT Steel | High (Mechanical) | Moderate | Moderate (Corrosion) | Medium |

| Rigid Metal | High (Mechanical) | Difficult | Low (Corrosion) | High |

This table provides a quick overview of the strengths and weaknesses of each conduit type, highlighting PVC's balance of durability, ease of installation, and cost-effectiveness. While metal conduits offer high mechanical strength, their susceptibility to corrosion and higher cost can be drawbacks in the MEA region.

Local Regulations and Building Codes

Finally, understanding local building codes is essential. Regulations differ between countries and even within specific regions of the MEA. Non-compliance with these standards can cause project delays, penalties, and even safety risks. Therefore, consulting local authorities and experienced professionals is crucial before starting any electrical conduit installation work.

Getting The Right Tools Without Overspending

Choosing the right tools for electrical conduit installation is essential for efficient, high-quality work. The correct tools can make all the difference between a smooth process and frustrating setbacks, especially in challenging environments like those found in the MEA region. Let's take a look at the essentials.

Essential Tools for Conduit Installation

Putting together a complete toolkit doesn't require breaking the bank. You can focus on the most important tools and find affordable alternatives that still perform well. Here's what you'll need:

Conduit Cutters: Invest in a good cutter specifically designed for the type of conduit you'll be working with. A clean cut is crucial for a proper fit and helps prevent problems down the line.

Conduit Benders: Bending conduit properly, without kinks, requires the right bender. Choose benders that are the correct size and material for your conduit. A hickey bender is extremely useful for making precise bends in tight spaces.

Fish Tapes and Rods: These tools are vital for pulling wires through conduit, especially for longer runs. Durable, high-quality fish tapes and rods will save you time and protect your cables from damage.

Measuring Tools: Accurate measurements are the foundation of a successful installation. A reliable tape measure and a spirit level are absolutely essential.

Drilling Tools: You'll need a suitable drill with the correct drill bits for securing conduit and making pathways. Hammer drills are especially helpful when working with concrete or masonry.

Sourcing Tools and Materials in the MEA Market

Finding good tools and materials at reasonable prices is possible with careful sourcing. Local suppliers in the MEA region often have competitive prices on fittings and connectors that comply with local electrical codes. Developing relationships with reliable suppliers can also guarantee access to quality products and prompt deliveries. Check out our guide on How to select the right building hardware for your Dubai projects.

Tool Maintenance for Harsh Climates

Proper tool maintenance is vital for extending their lifespan, especially in the tough climates common across the MEA region. Regular cleaning and appropriate storage can prevent corrosion and keep your tools in good working order. Simply wiping down your tools after each use and storing them in a dry, protected area can make a big difference in minimizing the effects of humidity and dust.

Building Your Toolkit Gradually

A sensible approach is to begin with a core set of essential tools and gradually expand your collection as needed. Focus on the tools you use most regularly based on the type of installations you typically do. As you gain more experience, you can invest in specialized equipment. This method allows you to build a custom toolkit without unnecessary upfront costs. For tools you only need occasionally, such as large conduit benders or hydraulic crimpers, consider renting them instead of buying them outright. This is a more cost-effective way to ensure you have the right tools for every job without overspending.

Remember, keeping your tools organized improves efficiency and protects your investment. A well-organized toolbox or tool chest keeps your equipment easily accessible and prevents damage during transport.

Step-By-Step Installation That Actually Works

Let's put our electrical conduit knowledge into action with a proven process used by experienced installers. This electrical conduit installation guide takes you through each step, from site assessment to final testing, offering practical tips and quality checks that mark a professional installation.

Site Assessment and Planning

A thorough site assessment is the first step. Identify potential obstacles such as existing utilities or structural elements. Accurate measurements are key to determining the necessary conduit length, the number of fittings, and the optimal routing path. This careful planning minimizes waste and avoids costly rework.

Measuring and Routing the Conduit

After assessing the site, accurately measure and mark the conduit path with a reliable tape measure. Ideally, the conduit path should be as straight as possible. This minimizes voltage drop and simplifies wire pulling. However, navigate around obstacles strategically. For instance, bend the conduit around an existing beam if necessary.

Bending the Conduit

Bending conduit correctly is crucial. Use the correct bender for your conduit type to achieve clean bends without kinks or damage. A hickey bender is particularly useful for precise bends in tight spaces. Practice on scrap conduit pieces to perfect your technique and save time and materials on the actual project.

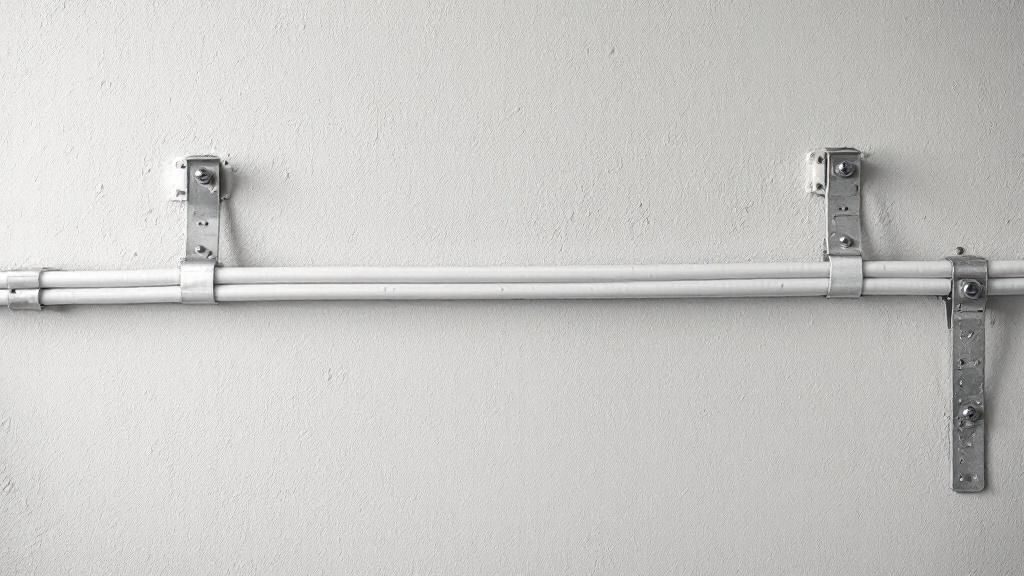

Securing and Supporting the Conduit

Once bent, the conduit needs proper securing. Use appropriate straps, clamps, or other fasteners to attach the conduit firmly to the structure. Adequate support prevents sagging, especially for long runs, and protects the conduit from accidental damage. Refer to your local electrical codes for proper spacing between supports, as this varies depending on conduit size and material.

Pulling the Cables

With the conduit secure, it's time to pull the cables. Use a fish tape or rod to guide the cables through the conduit. Lubricating the cables with a pulling lubricant can ease the process and prevent damage, especially for longer runs or complex routes. This reduces friction and minimizes stress on the cables.

Terminations and Connections

Proper termination ensures safe and reliable connections. Make sure cables are stripped correctly and terminations are secure and weatherproof. When using metal conduit, proper grounding and bonding are critical for safety. Use suitable connectors and fittings to maintain a tight seal and the conduit's integrity.

Testing and Inspection

After installation, thorough testing is essential. Use a multimeter to check for continuity and ensure secure connections. An insulation resistance test confirms the wiring's integrity. These tests help identify potential issues before they become costly problems. Finally, ensure compliance with all local electrical codes and regulations before the final inspection. This safeguards you and ensures your work meets safety standards.

Troubleshooting Tips

Sometimes, unexpected issues arise, such as damaged conduit, alignment problems, or fitting compatibility issues. A coupling can often repair a damaged conduit section, avoiding a complete replacement. For alignment problems, carefully loosen the fasteners and readjust the conduit. If fittings don't align, double-check measurements and ensure you are using the correct fittings for your conduit type. Keeping spare fittings on hand can save valuable time.

Advanced Techniques For Challenging Projects

Building upon the foundational knowledge of conduit installation, this section explores the complexities of challenging scenarios often encountered in Middle East and Africa (MEA) industrial and commercial projects. These are the installations that truly test an electrician's expertise.

Navigating Multi-Level Installations and Underground Challenges

Multi-level installations present unique conduit routing challenges. Imagine designing a complex highway system, considering different elevations, access points, and potential intersections with other services. This requires detailed blueprints and careful coordination with other trades.

Underground installations also demand a thorough understanding of soil conditions. Rocky terrain might require specialized drilling techniques, while sandy soil necessitates extra precautions to prevent conduit shifting and sand infiltration.

Handling High-Temperature Environments and Retrofit Projects

High-temperature environments, common in the MEA region, require specific considerations. Standard conduit materials may not withstand extreme heat, making heat-resistant options crucial. Choosing the correct material is as important as selecting the right engine coolant for a desert climate—the wrong choice can lead to system failure.

Retrofitting conduit in occupied buildings adds another layer of complexity. Minimizing disruption to ongoing operations and ensuring safety requires meticulous planning, flexible work schedules, and clear communication with building occupants. The work area must be treated as an active environment.

Furthermore, effective coordination with other trades, such as HVAC and plumbing, is essential to avoid delays and conflicts.

When discussing electrical conduit installation in the MEA region, the prewired flexible conduit market is a significant segment. As of 2024, this market is valued at USD 142.50 million and is projected to grow at a CAGR of 7.7%. More detailed statistics can be found here. This growth reflects the increasing demand for efficient and flexible solutions in the region's construction sector.

Advanced Bending and Working Around Existing Infrastructure

Advanced bending techniques are crucial for navigating tight spaces and complex geometries. Picture fitting a pipe through a maze—precise bends are essential. This might involve specialized bending tools like a hickey bender or using segmented bends for gradual curves.

Working around existing infrastructure, such as pipes and ducts, requires careful mapping and strategic planning. It's like solving a 3D puzzle, ensuring each piece fits perfectly without disturbing the existing structure.

Emergency Repairs and Hazardous Environments

Emergency repairs require quick thinking and effective solutions. Rapidly diagnosing the issue, obtaining replacement parts, and implementing the repair without compromising safety are paramount. This is similar to a surgeon performing an emergency operation—speed and precision are critical.

Hazardous environment installations necessitate specialized safety procedures and equipment. Understanding the specific hazards, such as flammable gases or corrosive chemicals, and taking appropriate precautions is vital for protecting both personnel and the installation. This might involve using intrinsically safe equipment or implementing strict grounding and bonding procedures. Maintaining code compliance when modifying standard procedures for challenging installations is crucial. Documenting these modifications ensures adherence to safety standards and provides a clear record for future maintenance and inspections.

Safety And Code Compliance That Matters

Electrical conduit installation requires a strong focus on safety. Overlooking safety measures can have serious repercussions, impacting both workers and the project's success. This section covers the essential safety protocols to protect personnel and ensure installations meet stringent inspection criteria.

MEA Regional Codes and Standards

Understanding regional regulations within the MEA area is crucial. These codes and standards differ between countries, with key variations among UAE, Saudi Arabian, and other local specifications. For instance, grounding and bonding methods effective in the UAE's coastal climate may not be suitable for drier inland areas. Ignoring these local differences can lead to project failure.

Proper grounding and bonding are also vital for electrical safety and preventing equipment damage. This creates a low-resistance path to the earth, diverting fault currents and preventing shocks. Given the MEA region's challenging conditions, including high humidity and saline environments, using corrosion-resistant materials and proper installation techniques is especially important.

Fire Safety and PPE Requirements

Fire safety is another key area of concern. Inspectors carefully evaluate firestopping methods used where conduits penetrate walls and floors. These measures prevent fire from spreading, containing it within specific areas and minimizing potential damage. Using fire-resistant conduit materials and correct sealing techniques is crucial for compliance.

Using appropriate Personal Protective Equipment (PPE) is mandatory for all electrical work. Essential PPE includes safety glasses, gloves, and insulated footwear. Selecting PPE specific to the task, such as arc flash protection in high-voltage situations, is crucial for risk mitigation.

Risk Assessment and Coordination

Effective risk assessment forms the basis of a safe work environment. Identifying potential hazards like overhead power lines or underground utilities before they become problems allows for proactive solutions. This could involve rerouting conduits or implementing specific safety protocols for working near hazards.

Coordination with other trades is also essential. Clear communication with teams working on plumbing or HVAC systems, for example, prevents accidental damage to electrical installations and avoids conflicts. Collaboration streamlines the project and reduces accident risks.

The overall context of electrical conduit installation in the MEA region is also affected by the broader electrical conduits market. Global data projects the electrical conduits market to grow from USD 9,126.47 million in 2023 to USD 16,638.04 million by 2032. However, specific regional data shows MEA markets are smaller yet experiencing rapid growth. Learn more here.

Documentation and Ongoing Monitoring

Detailed documentation is vital. Recording information such as installation methods, materials used, and test results provides legal protection and valuable data for future maintenance. This documentation should include diagrams, specifications, and any deviations from the original plan.

Finally, ongoing monitoring of the electrical conduit system is important for long-term safety and performance. This might include regular visual inspections, thermal imaging, and performance tests. These proactive measures help identify potential issues early, preventing costly repairs and ensuring continued safe operation.

Solving Problems Before They Cost You Money

Even experienced electricians run into issues during conduit installations. It's how these problems are handled that sets a professional apart. This part of our electrical conduit installation guide covers common problems and offers practical solutions for real-world scenarios. Also, check out this helpful guide: Ensuring Timely Delivery of Construction Materials.

Handling Conduit Damage and Alignment Issues

Sometimes, conduit gets damaged during installation. A dropped tool or accidental impact can create a dent or crack. A coupling can often repair the damage, avoiding a full replacement. However, if the damage is severe, replacement is the safest course of action.

Alignment problems can also occur, causing the conduit to stray from its intended path. This can happen if the supports aren't placed correctly or the conduit is bent the wrong way. Carefully loosening the fasteners and readjusting the conduit often solves this.

Addressing Fitting Compatibility and Cable Pulling Difficulties

Using incompatible fittings can also delay a project. This frequently happens when different conduit types or sizes are involved. Always double-check your measurements and make sure all fittings match the conduit you’re using. Keeping a good supply of assorted fittings on hand is always a smart move.

Pulling cables through conduit can be tough, especially with long runs or multiple bends. A good quality fish tape or rod and cable lubricant will usually solve the problem. For particularly tight situations, a vacuum-based cable pulling system might be necessary.

Resolving Grounding Problems and Connection Issues

Grounding problems are serious and pose electrical hazards. One common mistake is improper bonding of the conduit to the electrical system. This creates a shock risk if a fault occurs. Make sure all grounding connections are tight and comply with local electrical codes.

Loose connections can also affect the reliability of an electrical system and create a fire hazard. Always double-check every connection to ensure it's secure and correctly insulated. This is especially important in tough environments where temperature changes and humidity can impact connections.

Troubleshooting and Prevention

The following table provides a quick guide to common installation problems, their causes, solutions, and prevention tips:

Common Installation Problems and Solutions: Quick reference guide showing typical conduit installation problems, their causes, and step-by-step solutions

| Problem | Common Causes | Solution Steps | Prevention Tips |

|---|---|---|---|

| Damaged Conduit | Impact, bending | Repair with coupling or replace section | Protect conduit during handling |

| Alignment Issues | Incorrect measurements, loose supports | Loosen fasteners, realign, tighten | Double-check measurements, secure supports |

| Fitting Compatibility | Incorrect fittings used | Replace with correct fittings | Verify fittings before starting |

| Cable Pulling Difficulties | Tight bends, insufficient lubrication | Use fish tape/rod, lubricant | Plan for smooth bends, use lubricant |

| Grounding Problems | Loose connections, improper bonding | Tighten connections, ensure bonding | Verify grounding procedures |

| Loose Connections | Improper tightening, corrosion | Tighten connections, clean contacts | Use proper connectors, protect from environment |

By proactively addressing potential issues and implementing preventative measures, you can smooth out the installation process and avoid costly rework. A successful installation isn't just about finishing the job; it's about building a safe and reliable electrical system that lasts.

Long-Term Performance That Lasts

Your reputation as an electrician depends on installations that can withstand the challenging MEA environment. This means understanding how to maintain your electrical conduit systems and monitor their performance over time. This section of our electrical conduit installation guide covers the maintenance strategies and monitoring techniques that will keep your conduit systems operating smoothly, preventing costly failures and ensuring client satisfaction.

Identifying Early Warning Signs

Early detection is the key to preventing major issues. Learn to spot the signs of corrosion, mechanical damage, and thermal stress before they turn into expensive repairs or system failures. For instance, rust on metal conduit or cracks in PVC conduit are clear indicators of potential problems. Overly hot conduit could signal an overloaded circuit and a serious fire hazard.

Maintenance Strategies That Work

Effective maintenance begins with regular cleaning. Sand infiltration, a common issue in the MEA region, can accelerate wear and tear. It's like sandblasting the inside of your conduit, which isn't good. Develop cleaning procedures specific to your environment, such as using compressed air to remove dust and debris. Remember to always de-energize the system before performing any maintenance.

Protective measures also play a role in extending system life. This might include using sealant to prevent moisture from getting in or applying corrosion-resistant coatings to metal conduit. Taking these proactive steps now will save you money and hassle in the future.

Inspection and Monitoring

Regular inspections are essential for maintaining a healthy electrical system. Create a schedule based on the environment and the type of conduit used. Installations in harsh environments will likely require more frequent inspections. During these inspections, look for signs of damage, loose connections, and other potential problems.

Monitoring key performance indicators helps you track the health of your system. This could include measuring voltage drop, checking Ground Fault Circuit Interrupter (GFCI) functionality, or using thermal imaging to detect hot spots. This proactive approach allows you to address issues before they escalate.

Environmental Factors and Preventive Measures

The MEA region presents unique environmental challenges. High temperatures, humidity fluctuations, and sandstorms can all impact conduit systems. Understanding how these factors affect different materials is critical. For example, PVC can become brittle in extreme heat, while metal conduit is prone to corrosion in humid coastal areas.

Choose preventive measures suited to your specific location. In areas with a lot of sand, consider using sealed conduit fittings. In hot climates, make sure there is enough ventilation to prevent heat buildup. These strategies can significantly extend the lifespan of your installation.

Documentation, Future Planning, and Client Education

Proper documentation is crucial for maintaining warranties and managing future maintenance. Record all installation details, including materials used, testing results, and maintenance schedules. This documentation serves as a valuable resource for future reference and protects you in case of any disputes.

When planning future expansions, consider how they will integrate with the existing system. This could involve using modular components or strategically placing junction boxes to allow for future additions without major rework. Careful planning prevents future headaches.

Client education is essential for preventing maintenance problems. Explain to your clients the importance of regular inspections and proper system usage. Advise them not to overload circuits or tamper with the system. Educated clients contribute to the longevity of the installation.

By implementing these strategies, you’ll establish a reputation for quality work and ensure your installations deliver long-term performance. Contact Yasu Trading Co. LLC today for all your electrical conduit and building hardware needs. Get a quote now! We provide premium products and expert guidance to help your projects succeed from start to finish.