Advanced Sealants & Waterproofing: Hybrid Formulations for UAE Climate

Standard sealants just don't stand a chance in the UAE. Most are designed for much milder climates and simply can't cope with the relentless assault they face here. This isn't a minor issue; it's a fundamental failure that leads to cracking, shrinking, and a complete loss of adhesion.

Before you know it, the building's protective skin is compromised, letting in water, dust, and all sorts of problems.

The UAE Climate's Assault on Standard Sealants

The environment here is a unique and potent cocktail of challenges that systematically dismantle conventional waterproofing. Basic silicones and polyurethanes, the go-to materials in many other parts of the world, just don't have the chemical backbone to endure this attack. The result? Costly, frequent repairs that feel like a never-ending cycle. Many property owners know this headache all too well, often finding themselves in urgent situations like repairing a leaking flat roof.

This isn't just about the heat. It's a specific combination of aggressive factors that work in concert to weaken a building's defences. Once you understand these stressors, you'll see why advanced hybrid sealants aren't just a "nice-to-have"—they're a necessity.

The Trio of Environmental Stressors

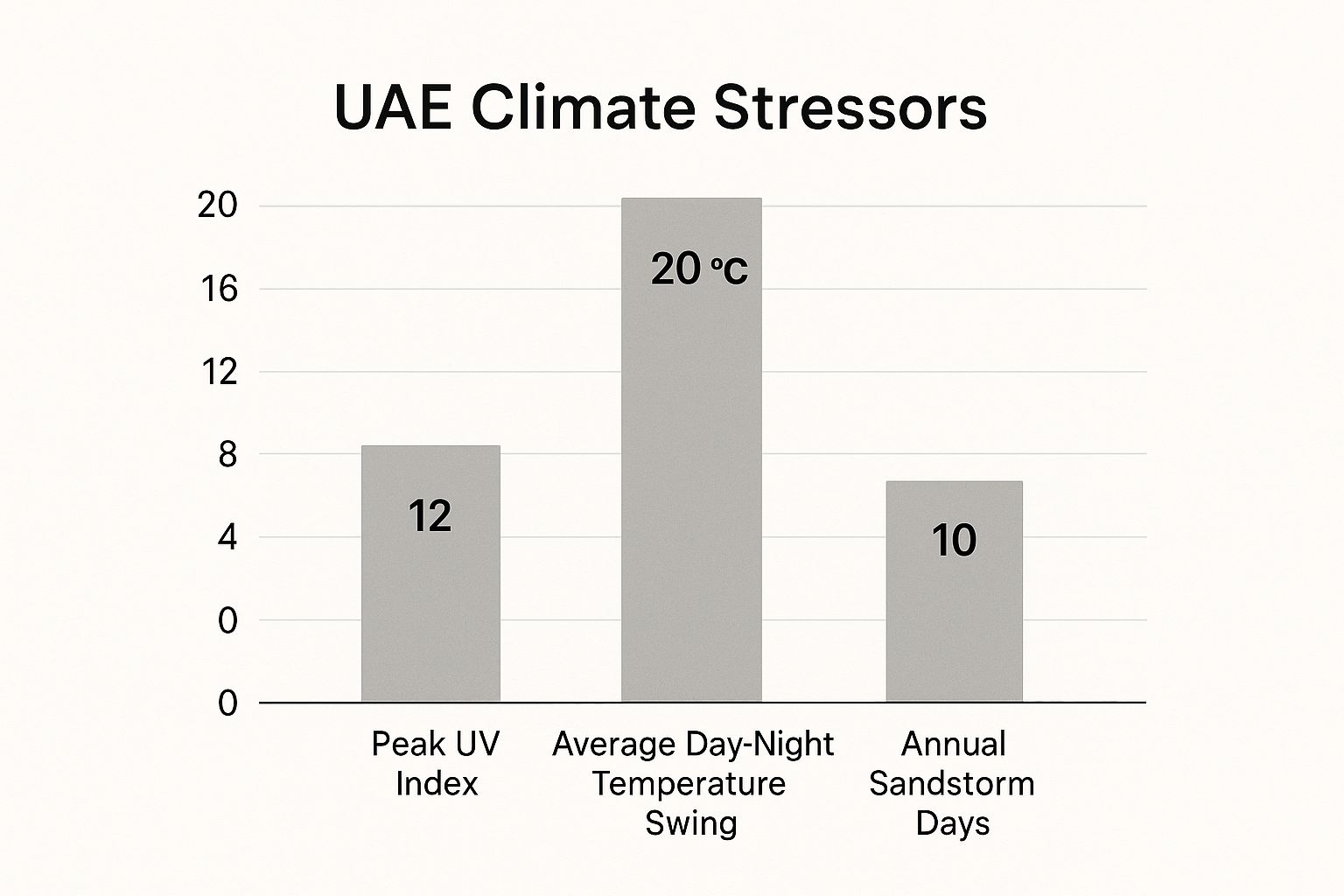

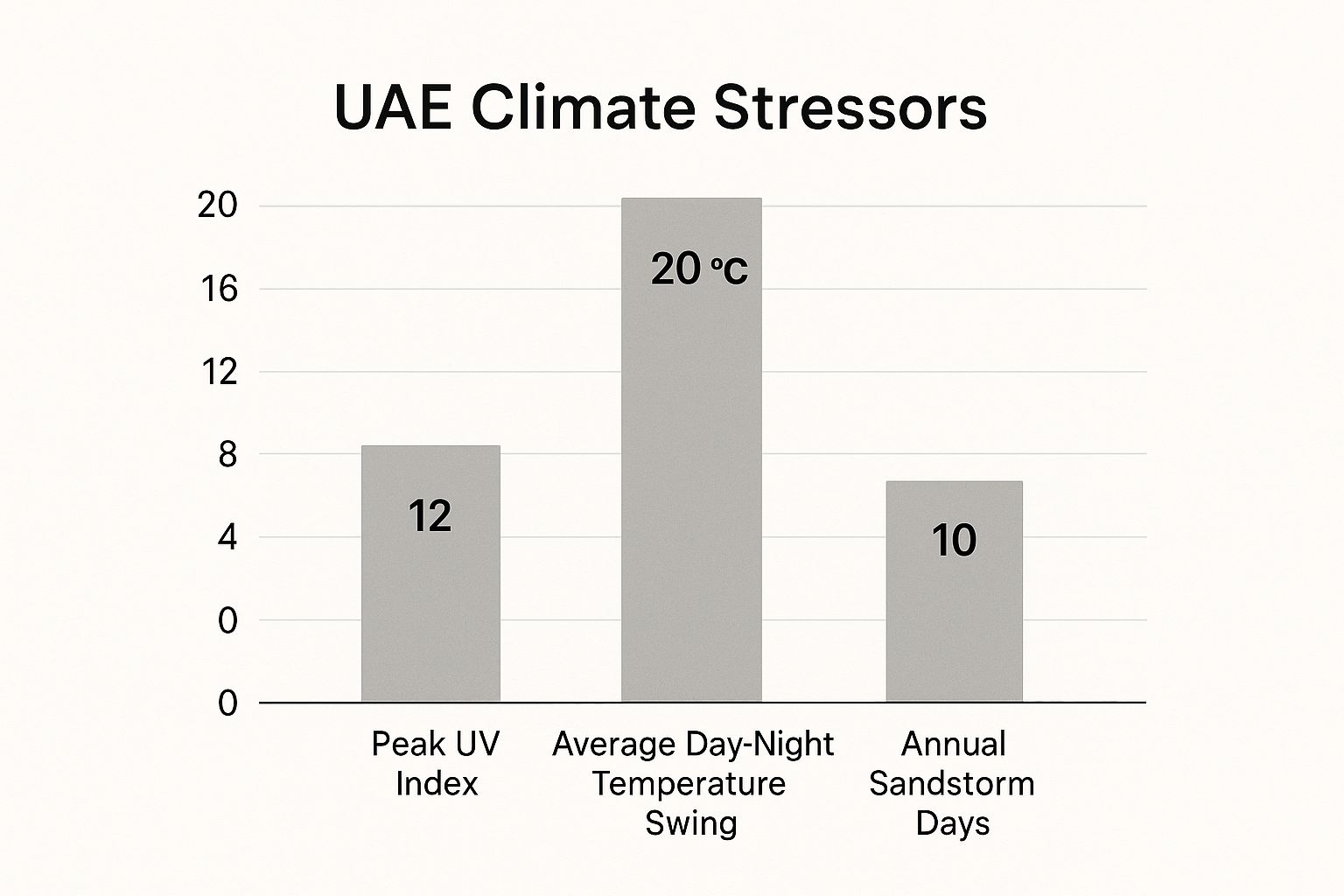

Three main climatic forces are behind the rapid breakdown of traditional sealants in the region.

- Intense UV Radiation: The UAE regularly sees some of the highest UV index levels in the world, often hitting an extreme 11+ in summer. This constant solar bombardment literally shatters the polymer chains in standard sealants, making them brittle, chalky, and inflexible.

- Extreme Thermal Cycling: Buildings here go through a dramatic daily cycle of expansion and contraction. It's not uncommon to see a temperature swing of over 20°C from the peak of the day to the cool of the night. This puts immense fatigue on sealant joints, causing cracks and eventually pulling the sealant away from the substrate.

- Abrasive Sand and Salinity: The frequent sandstorms are like a slow, gritty sandblasting session that erodes the surface of any exposed material. If the project is near the coast, you also have airborne salt attacking the sealant, accelerating chemical decay and weakening its bond.

This infographic paints a clear picture of what building materials are up against.

This data isn't just academic; it shows the continuous, severe strain that demands a much higher standard of performance from any exterior product.

When a sealant fails, it's not just a cosmetic problem. It's a direct threat to the building's health and the people inside. Water intrusion can quickly lead to mould and damage foundational structures, turning a small leak into a massive structural headache. You can explore our comprehensive guide on essential water proofing material to learn more about preventative measures.

This unforgiving environment is precisely why the demand for better solutions is skyrocketing. To put it in perspective, let's look at how these materials stack up head-to-head.

Conventional vs Hybrid Sealant Performance in the UAE

This table breaks down the real-world performance differences when these sealants face the specific challenges of the UAE.

| Performance Factor | Conventional Sealants (Silicone/Polyurethane) | Hybrid Sealants (MS Polymer/STP) |

|---|---|---|

| UV Resistance | Degrades quickly, becomes brittle and chalky. | Excellent stability, retains colour and flexibility. |

| Thermal Movement | Loses elasticity, cracks under repeated expansion/contraction. | Maintains high elasticity, moves with the building without failure. |

| Adhesion Over Time | Bond weakens, especially on non-porous surfaces in high heat. | Forms a tenacious chemical bond that withstands climate extremes. |

| Durability | Prone to shrinking and cracking within a few years. | Long-term performance, resisting abrasion from sand and dust. |

The takeaway is clear: while conventional products might be a temporary fix, hybrid sealants offer the long-term, reliable protection that modern construction in the UAE demands.

This urgent need for durable solutions is driving major market growth. The UAE's adhesives and sealants market was valued at around USD 380.5 million and is expected to climb to USD 595.44 million by 2033. This isn't just market fluctuation; it's a direct response from the industry for products engineered to survive here. You can find more details on the UAE adhesives and sealants market growth on imarcgroup.com.

Understanding Hybrid Sealant Chemistry

The incredible performance of today’s advanced sealants isn't some kind of magic. It’s the result of some seriously clever molecular engineering. These materials, known as hybrid formulations, are purpose-built to overcome the classic weak points of older products by combining their strengths into one powerful polymer.

A great way to think about it is like creating a high-performance alloy. Pure iron is incredibly strong, but it rusts. Aluminium resists corrosion beautifully but lacks iron's toughness. Blend them together with other elements, and you get stainless steel—a material that's both tough and rust-resistant. Hybrid sealants work on the exact same principle.

They fuse the legendary UV and temperature resistance of silicone with the strength, flexibility, and paint-friendly nature of polyurethane. This "best of both worlds" approach creates a sealant that's uniquely equipped to handle the extreme demands of the UAE climate. The two most common technologies leading the way are Silylated Modified Polymers (SMP) and Silylated Terminated Polyethers (STP).

The Core of Hybrid Technology

If you could zoom in to the molecular level, you'd see that these hybrids have a long, flexible "backbone" made of polyurethane or polyether. This is where they get their core strength and elasticity. Capping the ends of this backbone are silyl groups—the reactive part borrowed directly from silicone chemistry.

This unique structure is the secret to their success. As soon as the sealant is applied and exposed to moisture in the air, a chemical reaction kicks off.

This isn't just a simple drying process. The moisture triggers a chemical transformation, creating a durable, cross-linked network. A brand new, resilient material is formed right there in the joint, creating a tenacious bond that is both incredibly strong and remarkably flexible.

It's this dual nature that lets hybrid formulations perform where traditional sealants fail, easily accommodating building movement while shrugging off environmental attacks.

Why This Chemistry Matters in the UAE

The practical payoff of this hybrid structure is a perfect match for the challenges here in the UAE. The formulation delivers a finely balanced set of properties that directly combat the region's most aggressive environmental stressors.

Here’s how that chemistry translates into real-world advantages on a job site:

- Superior Adhesion: The polyurethane component ensures the sealant grabs onto a huge range of construction materials—from concrete and aluminium to glass and wood—often without needing a primer.

- Exceptional Flexibility: Thanks to the polyether backbone, the sealant can stretch and compress without breaking a sweat, handling the daily thermal expansion and contraction of building joints without cracking or losing its seal.

- Unmatched Durability: The silicone-like ends provide fantastic resistance to UV radiation and extreme temperatures, stopping the sealant from turning brittle or breaking down under the relentless sun.

This move toward high-performance blends is happening everywhere, even in highly specialised fields. Take the UAE's surgical adhesives market, valued at USD 14.8 million. Its fastest growth is in combination formulas that offer better mechanical properties and resilience for critical medical uses. You can see more data on the growth of advanced blended adhesives on grandviewresearch.com. This trend mirrors what we're seeing in construction, where hybrid sealants provide the essential toughness needed to survive in the UAE.

Key Performance Benefits in Real-World UAE Projects

The advanced chemistry is fascinating, but where these hybrid sealants really prove their worth is on the ground, on the bustling construction sites of Dubai and Abu Dhabi. This is where theory becomes reality, and where their unique properties solve the very real challenges posed by the UAE's demanding climate. We're not talking about small upgrades here; these are game-changing performance boosts that protect a building's longevity and appearance.

Every advantage these materials offer comes from that clever molecular blend of silicone and polyurethane. This combination creates a performance ceiling that older, single-chemistry sealants just can't reach, especially under the relentless stress of our region. From the glass curtain walls of soaring towers to vast rooftop waterproofing projects, hybrid sealants are making their mark.

Unyielding UV and Thermal Resistance

In a place where the sun can chew through and spit out lesser materials in just a few seasons, hybrid formulations stand firm. Their silicone heritage gives them an incredible defence against UV radiation, stopping the chalking, fading, and cracking that you see on buildings sealed with conventional products. A building's facade keeps its sharp, clean look and, more importantly, its protective seal for many years longer. This means fewer costly and disruptive repairs down the line.

Think about the expansion joints on a large concrete plaza or bridge. With daily temperature swings often jumping by more than 20°C, those joints are constantly expanding and contracting. The incredible flexibility of hybrid sealants—a gift from their polyurethane side—allows them to absorb this constant movement without tearing or losing their bond. They stretch and compress, day in and day out, maintaining a perfect seal where a more rigid material would have failed long ago.

For architects and developers, this translates into peace of mind. The sealant becomes a reliable, long-term component of the building envelope, not a recurring maintenance headache. It’s the difference between a building that gracefully weathers the climate and one that constantly fights it.

Superior Adhesion and Non-Staining Properties

One of the most practical benefits of advanced sealants & waterproofing: hybrid formulations for UAE climate is their sheer versatility when it comes to sticking to things. They create an incredibly strong bond to a whole range of common building materials.

- Glass and Aluminium: This is absolutely vital for the sleek curtain walls that define our modern skyscrapers. Hybrid sealants bond directly and securely, often without needing a separate primer, which saves a huge amount of time and labour on site.

- Precast Concrete: They grab hold of porous concrete panels and don't let go, creating a tough weather seal that stands up to wind-driven rain and sandstorms.

- Natural Stone: Many silicones have a nasty habit of "bleeding" plasticisers, which leaves a permanent stain on expensive facade materials like marble and granite. Hybrids are different. They are non-staining, so they preserve the intended beauty of the building's design.

This ability to stick to almost anything simplifies the whole process of specifying materials and drastically cuts down the risk of application mistakes. A single, high-performance product can be used with confidence, whether you're sealing a window frame on a villa in Sharjah or waterproofing a mall rooftop in Ras Al Khaimah. It’s this reliability that will keep the UAE's landmark projects looking and performing their best for decades.

How to Select the Right Hybrid Sealant

Choosing the right hybrid sealant isn't just a finishing touch; it's a fundamental decision that can make or break a building’s integrity. In a place like the UAE, where materials are constantly under attack from the climate, a generic, off-the-shelf solution is asking for trouble.

The wrong choice leads to cracked seals, water ingress, and costly repairs down the line. To avoid this, you need to match the sealant’s chemistry to the specific challenges of your project, ensuring it can handle everything from punishing sunlight to salty coastal air.

Evaluating Key Project Variables

Before you can pick a product, you have to play detective. What specific stresses will this sealant face day in and day out? Every project has its own unique demands, and getting these details right is the first step to a successful application.

Substrate Compatibility: What are you actually sealing? Hybrids are famous for their fantastic adhesion to common materials like concrete, glass, and aluminium. However, if you're working with specialised coatings or unusual plastics, you may need a specific formulation or a primer to ensure a proper bond.

Expected Joint Movement: Think about how much the joint will shift. A massive curtain wall facade baking in the desert sun will expand and contract significantly. For these high-movement areas, a sealant with a high movement capability, like +/- 25%, is absolutely essential.

Environmental Exposure: Where is the project located? A coastal tower in Abu Dhabi faces a constant battle with salt spray and humidity, while an inland project might be more concerned with extreme UV rays and abrasive sand. For coastal applications, superior UV stability and salt resistance are non-negotiable.

For a deeper look at material selection in harsh environments, this guide on choosing the right marine sealant offers some great parallels for coastal construction challenges.

Matching Formulation to Application

Once you’ve got a clear picture of the project's demands, you can start matching them to specific sealant properties. It’s a bit like a doctor prescribing the right medicine—the goal is precision.

For instance, sealing the glass panels on a Dubai Marina skyscraper requires a sealant with rock-solid UV resistance and non-staining properties to keep the facade looking pristine. On the other hand, for a basement waterproofing job, you’d prioritise immense adhesive strength and the ability to withstand constant water pressure over UV performance.

It's also worth noting the growing importance of sustainability. Many projects now require low-VOC products to meet green building standards, a topic we cover in our guide to sustainable adhesives and low-VOC solutions for green construction.

Hybrid Sealant Selection Guide for UAE Projects

Navigating the options can be tricky, so this table simplifies the process. It connects common UAE applications with their biggest environmental challenges and the key sealant properties needed to overcome them.

| Application Area | Primary UAE Challenge | Recommended Hybrid Property | Example Product Type |

|---|---|---|---|

| High-Rise Façade Joints | Extreme UV exposure & thermal movement | High movement capability (+/- 25%), UV stable | MS Polymer Façade Sealant |

| Coastal Window & Door Perimeters | Salt spray, humidity, wind-driven rain | Excellent adhesion, salt-spray resistance | Silyl-Terminated Polyether (STPE) |

| Interior Wet Areas (Bathrooms) | High humidity, potential mould growth | Fungicide-enhanced, non-staining | Sanitary-Grade Hybrid Sealant |

| Basement Waterproofing | Hydrostatic pressure, constant dampness | High bond strength, low water absorption | High-Modulus MS Polymer |

| Roofing & Gutter Sealing | Intense heat, ponding water, UV | Excellent weatherability, waterproof | UV-Resistant Roof Sealant |

This table is a great starting point, but always double-check the product’s technical data to ensure it’s the right fit.

Key Takeaway: The "best" hybrid sealant is simply the one that’s properly engineered for its specific job. Always, always check the technical data sheet (TDS) to confirm that a product's performance specs line up with your project’s needs. This simple step can save you from a world of headaches and rework.

Mastering Application for Lasting Performance

A top-tier hybrid sealant is only as good as the person applying it. You can have the most advanced chemistry in the world, but if the on-site work is sloppy, it’s going to fail. That makes the application itself the single most critical step for locking in long-term durability, especially here in the UAE.

Success starts long before you ever pick up a sealant gun. It begins with the surface. Dust, oil, moisture, or any loose particles will kill the bond before it even has a chance to form. Think of it as a barrier preventing the sealant from doing its job. It’s no surprise that poor prep is one of the biggest reasons for premature sealant failure—a small oversight that creates a massive weak point.

Perfecting the Application Process

With a clean surface ready to go, the focus shifts to the actual technique. Proper joint design is absolutely essential. The joint needs to be wide enough to handle the building's movement from thermal expansion, but not so deep that you waste material and hinder its flexibility. A backer rod is your best friend here; it controls the sealant depth and ensures it only sticks to two sides of the joint, which is what allows it to stretch without tearing.

Once the sealant is in the joint, the final, crucial touch is tooling. This isn't just for looks. This simple step physically presses the sealant into the sides of the joint, forcing full contact and creating a neat, concave surface that helps water run right off.

Application isn't just a task; it's a craft. Precision dictates performance. Rushing the job or cutting corners on prep will always compromise the seal, no matter how good the product in the tube is.

Avoiding Common Climate-Specific Mistakes

The intense conditions in the UAE mean you have to be extra careful. A classic mistake is applying sealants under the direct, blazing sun. When a building surface gets superheated—easily topping 60°C—it can "flash cure" the sealant, causing it to bubble up and form a weak, flimsy bond.

Here are a few key mistakes to sidestep:

- Ignoring Humidity: Trying to apply sealants when the air is thick with extreme humidity can mess with the moisture-curing reaction, impacting its final strength.

- Contaminated Surfaces: Fine dust from a nearby sandstorm or construction site can settle into a joint just moments before you seal it, completely ruining adhesion.

- Incorrect Timing: Your best bet is always to work during the cooler parts of the day. Think early morning or late afternoon, not the midday peak.

Getting these details right is vital for any waterproofing project. For more tips, especially when dealing with roofs and other flat surfaces, it's worth learning about the techniques for a waterproof roof coating. At the end of the day, it’s this thoughtful, skilled application that turns a quality product into a solution that truly lasts.

Advanced Applications in Specialised UAE Industries

While hybrid sealants are making a huge impact in everyday construction, their real power comes to light in some of the UAE’s most specialised and demanding industries. Think aerospace and marine – sectors where performance isn't just a nice-to-have; it's a matter of safety and operational survival. Standard materials just don't stand a chance here, which is why advanced hybrid formulations are absolutely vital.

These high-tech fields push sealants to their breaking point. We're talking about materials that have to endure intense mechanical stress, harsh chemical exposure, and environmental extremes that go far beyond what you'd ever see on a typical building site.

Aerospace Engineering in Extreme Heat

Let’s look at the aerospace sector. Picture an aircraft sitting on the tarmac at a UAE airport. The surface temperature of that plane can soar past 80°C. The sealants holding it all together need incredible thermal stability to avoid breaking down, stay flexible, and maintain a perfect seal under that kind of punishing heat.

This is where specialised hybrid formulations come in. They are engineered to handle this resilience, resisting everything from hydraulic oils and jet fuel to the constant expansion and contraction of different materials like aluminium alloys and advanced composites.

You simply can't compromise on this level of performance. A sealant failure in an aerospace application could be catastrophic, which is why only the most robust, rigorously tested materials make the cut for these high-stakes jobs.

The aerospace sector is growing fast in the UAE, and with it, the demand for these high-performance hybrid adhesive and sealant formulations. This trend is driven by the UAE's strategic push for more fuel-efficient aircraft and stronger structural integrity, where material selection is directly shaped by the region’s climate. You can dive deeper into the aerospace adhesives and sealants market on databridgemarketresearch.com.

Marine Durability Against Saltwater Corrosion

The marine industry is another battleground for materials. Equipment on ships, offshore platforms, and coastal structures is in a constant fight against corrosive saltwater, high humidity, and non-stop UV radiation. This trifecta of challenges quickly destroys conventional waterproofing, paving the way for rust and structural failure.

Hybrid sealants formulated specifically for marine environments offer a different story. Their unique chemistry creates a tough, waterproof bond that shields metal and other surfaces from the relentless attack of salt and moisture. This is crucial for protecting the lifespan and safety of the UAE’s critical marine assets, making these advanced sealants & waterproofing: hybrid formulations for UAE climate a key part of the nation’s economic diversification strategy.

Got Questions About Hybrid Sealants? We've Got Answers.

When you're dealing with advanced materials like hybrid sealants, especially in a place as demanding as the UAE, a few questions are bound to pop up. It's smart to get clear answers before you start, so your project goes off without a hitch. We've heard just about every question in the book, so here are some of the most common ones we get.

"Can I paint over it?" This is probably the number one question. With pure silicones, paint just beads up and won't stick. But with most hybrid sealants, the answer is yes—they are fully paintable once cured. This is a massive plus for achieving that perfect, seamless finish on façades and around trim, giving you total creative control.

Are Hybrid Sealants Safe to Use?

Safety and environmental impact are always big concerns, and rightly so. You'll be glad to know that quality hybrid sealants are formulated to be low in Volatile Organic Compounds (VOCs) and are typically solvent-free. This makes them much safer for the crew applying them and for anyone who will eventually occupy the building, fitting perfectly with the UAE's push for greener construction.

"How long will it actually last?" is another common one. While every project is different, a well-applied hybrid sealant can easily last for over 20 years. In the UAE, where the sun and temperature swings are relentless, this is huge. They hold up against UV rays and extreme heat without cracking or shrinking away, unlike many older sealant technologies. It’s an investment that pays for itself in durability.

People often assume that once a sealant is cured, they're all pretty much the same. That's a huge misconception. The genius of hybrid chemistry is that it gives you both flexibility and strength—a combination that single-polymer products just can't deliver under constant stress.

Finally, the big question for applicators: "Do I always need a primer?" Honestly, not always. One of the best things about hybrid sealants is their incredible ability to stick to just about anything. They’ll often bond directly to common building materials like aluminium, concrete, and glass with no primer needed. But—and this is important—for tricky surfaces or a high-stakes application, always double-check the technical data sheet. It’s better to be safe than sorry.

For all your construction material needs, from advanced sealants to essential safety gear, trust the experts at Yasu Trading Co. LLC. Explore our extensive range of high-quality products and request a quote today at https://yasutrading.com.