AI in Building Materials: How ML Optimises Design & Supply Chains

When people talk about AI in building materials, they're really talking about using machine learning to sift through massive amounts of data. This allows us to discover stronger, greener material formulas and build incredibly efficient, predictive supply chains. It's a technology that helps construction move past old-school methods, directly tackling stubborn problems like material waste and project delays by rethinking both design and logistics from the very beginning.

The New Blueprint for Construction

Think about the difference between building a modern skyscraper with a hand-drawn map versus a real-time 3D model that predicts structural stress and calculates exact material needs. That’s the kind of jump we're seeing as artificial intelligence enters the building materials industry. AI and machine learning are quickly evolving from buzzwords into practical tools you can find on construction sites and in fabrication labs.

For decades, the construction world has been wrestling with the same old headaches. Material waste, unexpected project delays, and budgets that spiral out of control have almost become accepted as the cost of doing business. But AI is stepping in as the ultimate co-pilot for architects, engineers, and supply chain managers, giving them a completely new way to handle all that complexity.

Turning Industry Challenges Into Opportunities

Machine learning algorithms can analyze datasets far bigger than any human team could ever manage. By doing so, they aren't just tweaking existing processes—they're unlocking entirely new ways of working and solving core problems with pinpoint accuracy.

Here are a few key areas where this is making a real difference:

- Material Innovation: AI can digitally simulate and test thousands of chemical compounds, drastically speeding up the discovery of stronger, more sustainable, and cost-effective building materials.

- Predictive Logistics: Instead of just reacting to supply chain disruptions, AI models can forecast demand, anticipate potential shipping delays, and optimize delivery routes to make sure materials show up exactly when they're needed.

- Waste Reduction: AI helps minimize over-ordering and waste, which can account for up to 30% of total material volume on some jobs. It does this by generating precise design specifications and fine-tuning the procurement process.

- Smarter Decision-Making: Project managers get data-backed insights, helping them make informed calls that prevent expensive mistakes and keep the project on track.

By laying the groundwork for a smarter, more resilient construction industry, AI is helping to build the future more efficiently. It turns reactive problem-solving into proactive strategy, ensuring projects are built on a foundation of data-driven certainty.

Let's take a closer look at how AI intervenes across the entire lifecycle of a building material. The table below breaks down the before-and-after picture, showing how machine learning is turning old pain points into new opportunities for efficiency and innovation.

How AI Is Reinventing the Building Material Lifecycle

| Lifecycle Stage | Traditional Challenge | AI-Powered Solution |

|---|---|---|

| Material Design | Slow, trial-and-error R&D process for new materials. | Rapid digital simulation and analysis to discover optimal formulas. |

| Procurement | Guesswork in demand forecasting leads to over-ordering or shortages. | Predictive analytics forecast precise material needs based on project data. |

| Logistics | Reactive management of shipping delays and supply chain disruptions. | Real-time route optimization and disruption prediction for on-time delivery. |

| On-Site Use | High material waste from cutting, installation, and miscalculations. | AI-driven BIM models calculate exact quantities, minimizing on-site waste. |

Ultimately, this transition is about more than just adopting new technology. It’s about building a more predictable and sustainable future. As machine learning refines everything from concrete formulas to the ins and outs of building materials trading, it’s creating a new blueprint where efficiency is built-in from day one.

Designing Smarter Materials with AI

Think of a digital alchemist who can test thousands of formulas for a new type of concrete in the time it takes a lab technician to mix a single physical batch. That's essentially what’s happening in material science right now. Machine learning is optimizing design by finally moving us past the slow, expensive, and often unpredictable world of trial-and-error. AI is completely rethinking how we discover and create the materials that build our world.

So, how does it work? At its core, this process involves feeding machine learning algorithms massive datasets about existing materials. The AI sifts through everything—chemical compositions, molecular structures, and performance stats like tensile strength, thermal resistance, and environmental impact. Armed with that knowledge, it can accurately predict how a new combination of elements will behave before anyone even steps into a lab.

This means scientists and engineers can now define a specific goal for a new material, like lower carbon emissions or superior heat resistance, and let the AI generate novel formulas that fit the bill. It's an approach that not only speeds up innovation but also uncovers solutions a human might never have considered.

The Power of Generative Design

One of the most exciting developments here is generative design. I like to think of it as a creative partner for material scientists. Instead of just analyzing what's already been done, generative algorithms actively dream up countless new material variations, each one built to meet a specific set of needs.

For example, imagine an engineer needs a new composite material. It has to be lightweight enough for a high-rise facade but also tough enough to withstand extreme weather. A generative design model would simulate thousands of potential fiber-and-resin combinations, ultimately delivering a shortlist of the best options optimized for both properties. This doesn't just save a ton of time; it opens the door to creating materials with performance characteristics we once thought were impossible.

This is especially critical for intricate components like fasteners or structural bolts, where material integrity is everything. You can get a deeper look at how this technology is applied in our guide on smart fasteners and 3D-printed bolts.

The result is a much faster path to breakthrough materials that are stronger, lighter, more sustainable, and often cheaper to produce. AI essentially compresses years of traditional R&D into a matter of weeks or even days.

Driving Economic and Sustainable Growth

The economic implications are huge. By 2030, artificial intelligence is expected to add around $320 billion to the Middle East economy, which is about 11% of the region's GDP. A big chunk of that growth will come from sectors like construction, where machine learning is ironing out kinks in both design and supply chain management.

We're already seeing this in action. For instance, Saudi Arabia's Smart Housing Project used AI to cut material wastage by 18%, which translated into massive savings on procurement.

Ultimately, AI-driven material design isn't just about making better "stuff." It’s about building a more resilient and efficient future. By fine-tuning materials right from the molecular level, we can create structures that last longer, use fewer resources, and leave a smaller environmental footprint. It’s truly paving the way for the next generation of architecture and infrastructure.

Building a Predictive Supply Chain

Think of a traditional supply chain as a fire brigade—always reacting to emergencies. An AI-powered supply chain, on the other hand, is more like a fire prevention system, designed to stop problems before they even start. We're seeing a fundamental shift away from the old "break-fix" model of logistics, where teams constantly scramble to solve problems that have already derailed a project. Machine learning is stepping in to untangle the massive complexity of moving building materials, replacing guesswork with genuine foresight.

Instead of just responding to a delay, AI models sift through huge amounts of data to see it coming. This allows for a much more proactive stance, flagging potential bottlenecks and suggesting alternative plans before they can ever touch a project's schedule or budget. It’s the difference between getting a furious call from a site manager about a missing shipment and receiving an automated alert a week beforehand with a new route already mapped out.

From Reactive to Predictive Procurement

One of the biggest game-changers is in predictive procurement. For decades, purchasing managers have relied on a mix of old data and gut feelings to decide when to buy materials like steel, lumber, or cement. This approach is a gamble, often resulting in paying peak prices or, worse, facing shortages that bring work to a standstill.

Machine learning completely flips the script. These algorithms look at a much bigger, more dynamic picture in real-time:

- Market Trends: They constantly watch global commodity prices and supply chain hiccups.

- Project Timelines: Orders are automatically aligned with the specific phases of construction.

- Geopolitical Factors: The AI keeps an eye on global events that could mess with shipping lanes or factory output.

- Weather Patterns: It can even forecast weather that might delay a crucial delivery.

By crunching all this data, the AI can pinpoint the best possible time to buy, locking in better prices and guaranteeing materials will be there when needed. This isn't just about small savings; it's a strategic move that can slash costs across an entire project.

Intelligent Inventory and Route Optimization

But buying smarter is only half the battle. AI also brings a whole new level of intelligence to managing and moving those materials. Intelligent inventory management uses machine learning to keep stock levels just right—no more capital tied up in a mountain of unused rebar, and no more idle crews waiting on a late delivery.

At the same time, dynamic route optimization makes sure materials get to the job site on time and at the lowest cost. AI algorithms calculate the fastest, most efficient delivery routes by looking at live traffic, weather reports, and even unexpected road closures. This doesn't just save on fuel; it dramatically improves the reliability of your delivery schedule. Getting all these moving parts to work in harmony is the core challenge of modern construction logistics, and this technology is completely reshaping the field.

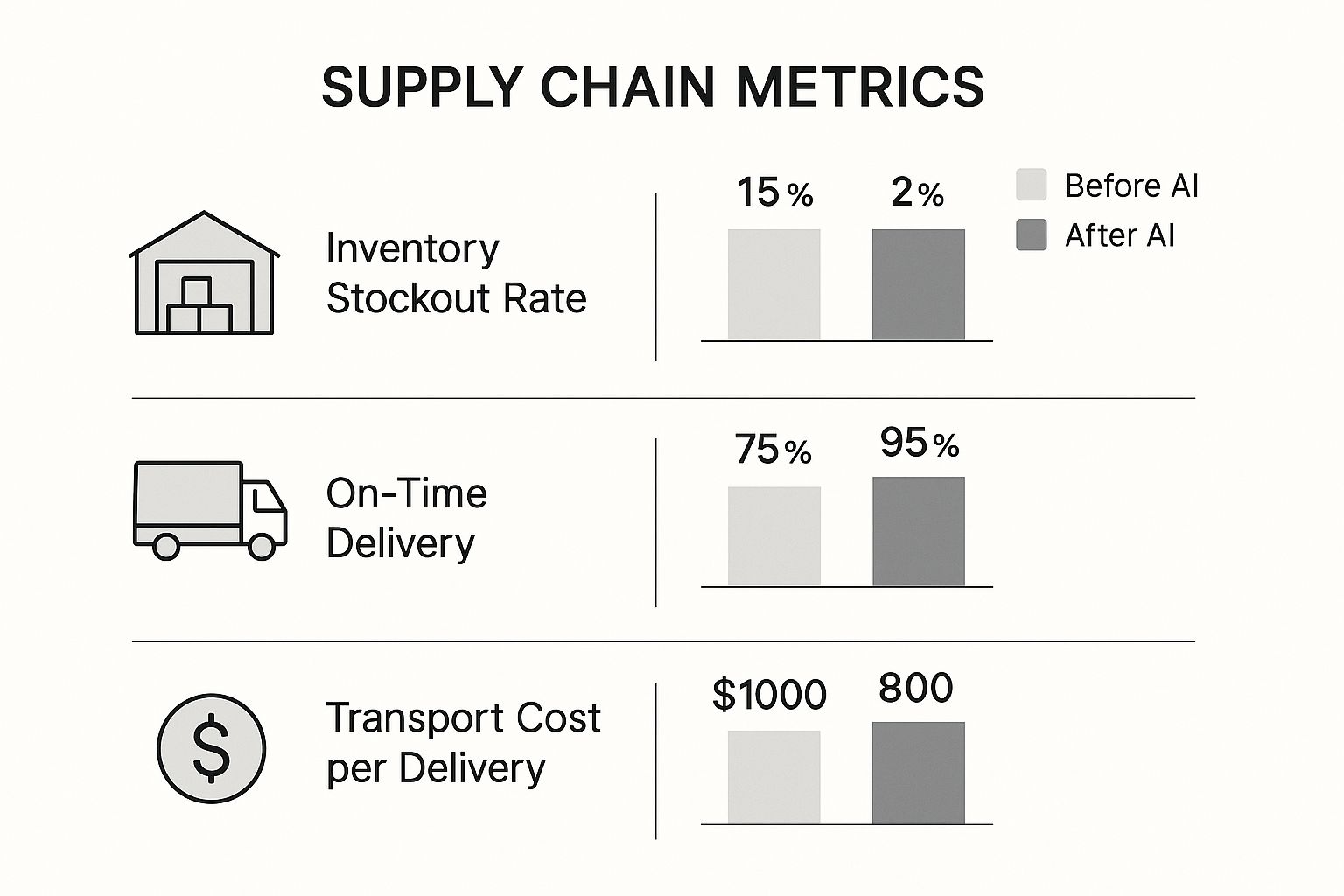

The infographic below shows the kind of real-world results companies are getting by making this switch.

The numbers speak for themselves. AI directly leads to better performance, with huge drops in stockouts and costs, plus a major improvement in on-time deliveries.

To see the contrast more clearly, let's compare the old way of doing things with the new, AI-driven approach.

Comparing Supply Chain Management Approaches

| Supply Chain Function | Traditional Reactive Approach | AI-Powered Predictive Approach |

|---|---|---|

| Demand Forecasting | Relies on historical sales data and manual analysis, often leading to inaccuracies. | Uses ML models to analyze dozens of variables (market trends, weather) for highly accurate predictions. |

| Inventory Management | Fixed reorder points; prone to stockouts during demand spikes or overstocking in lulls. | Dynamic inventory levels adjust in real-time based on predictive analytics, minimizing waste and shortages. |

| Procurement | Manual purchasing based on intuition and past prices; vulnerable to market volatility. | Identifies optimal purchasing times based on predictive cost modeling, securing better prices. |

| Route Planning | Static, pre-planned routes that don't account for real-time disruptions like traffic or accidents. | Dynamic route optimization adjusts paths in real-time, ensuring faster, cheaper, and more reliable deliveries. |

| Disruption Handling | Scrambles to find solutions after a problem occurs, causing significant delays and cost overruns. | Identifies potential risks before they happen and suggests proactive solutions to avoid disruption. |

This table makes it clear: the move to an AI-powered system isn't just an upgrade, it's a complete overhaul of how supply chains operate, building in resilience and efficiency from the ground up.

By transforming a reactive supply chain into a resilient, proactive system, AI provides the tools needed to navigate modern logistical challenges. It’s about creating a network that doesn't just respond to change but actively anticipates it.

Ultimately, by connecting all these different data points into one smart network, AI ensures the right materials get to the right place, at the right time, and for the right price. For a deeper dive into how this works in practice, this resource on 5 AI use cases for supply chain data integration is a great read. It's about building a foundation of pure efficiency for any construction project.

Real-World Examples of AI in Construction

It’s one thing to talk about how machine learning can theoretically improve supply chains or material design. It’s another thing entirely to see it in action. The best arguments for AI in the building materials space come from real companies solving real problems and getting tangible results.

These aren’t abstract algorithms floating in the cloud; they’re tools translating into stronger concrete, faster deliveries, and safer job sites. Let's dig into a few stories of companies that faced a persistent challenge, brought in an AI solution, and saw a genuine impact.

Pioneering Low-Carbon Concrete

A major cement manufacturer found itself under immense pressure to go green. The goal was to create a new concrete mix with a much lower carbon footprint, but without sacrificing strength or durability. Anyone in the industry knows that’s a tough nut to crack. The old-school R&D method of physically mixing and testing batch after batch was just too slow and costly to get them there.

So, they turned to a machine learning platform. They fed the AI a massive amount of historical data—thousands of different concrete formulas and their performance stats. The system then ran millions of digital simulations, far more than a human team ever could. It eventually pinpointed a novel combination of recycled materials and admixtures that kept the concrete strong while drastically cutting the carbon-heavy clinker content.

The results were impressive:

- A commercially viable, low-carbon concrete mix was ready in just six months, smashing the original two-year projection.

- The final product cut the carbon footprint per cubic meter by over 30%.

- The AI-powered R&D process slashed costs by nearly 40%.

Optimizing Logistics for a Materials Distributor

Here’s another great example from a large building materials distributor drowning in logistics headaches. Late deliveries, sky-high fuel costs, and unreliable ETAs were becoming the norm, frustrating contractors and holding up projects. Their system simply couldn't keep up with real-time traffic, sudden weather changes, or last-minute adjustments to orders.

The company brought in an AI logistics platform to sort out the mess. This new system analyzed delivery schedules, truck capacity, and live traffic data to map out the most efficient routes for the entire fleet on the fly. It also got much better at predicting demand, making sure the right materials were already waiting at the right distribution centers.

This overhaul paid off big time. Within the first year, the distributor saw a 20% reduction in transportation costs and a 15% boost in on-time delivery accuracy.

Automating Quality Control with Computer Vision

In manufacturing, quality control often comes down to a pair of human eyes, which can be slow and inconsistent. A company making prefabricated wall panels knew they needed a better way to catch defects like tiny cracks or incorrect dimensions before panels shipped out.

Their fix was an AI-powered computer vision system. They installed high-resolution cameras along the production line and trained a machine learning model to recognize even the most subtle flaws. Now, the system automatically scans every single panel, flagging defects in real time. Not only did this improve product quality, but it also generated data that helped them fine-tune their manufacturing process to prevent those errors from happening again. This is a clear case where technology like AI-driven predictive maintenance can extend a material's lifespan and cut down on waste.

These real-world applications show that AI in building materials is not a distant concept; it's a practical tool delivering a competitive edge today. From sustainability to efficiency, machine learning is rebuilding the industry from the ground up.

This trend is picking up speed, especially in rapidly developing regions. The Middle East & Africa's Artificial Intelligence in Construction market is set to grow at a compound annual growth rate (CAGR) of 30.1% from 2024 to 2030—a pace that leaves many other global markets in the dust. This rush to adopt is fueled by the need for advanced tech to manage massive urban developments and smart city projects, where AI’s ability to optimize resources is absolutely critical. You can explore more data on these regional trends in this detailed market analysis.

The Technology Powering Construction AI

Artificial intelligence in construction isn't some magic black box. It’s a powerful engine, and like any high-performance engine, it needs the right fuel and a solid chassis to do its job. What you see on the surface—the optimized schedules or predictive models—is just the final output. Behind the scenes, a whole digital ecosystem is working in concert to make it happen.

The fuel for this engine is big data. Without a constant flow of high-quality, well-organized information, even the most sophisticated algorithm is just spinning its wheels. This data pours in from everywhere—job sites, supply trucks, material labs—creating the rich context AI needs to spot patterns and make smart decisions.

The Core Components of the AI Engine

To actually make sense of this flood of data, the industry relies on a few key technologies that have become the backbone of construction AI. Each one plays a critical role in turning raw numbers into real-world action.

- Cloud Computing: This is the massive, on-demand horsepower needed for heavy AI calculations. Instead of building their own costly server farms, companies can tap into the cloud for the processing power and storage they need, when they need it.

- Specialised Processors (GPUs): You can thank the gaming industry for these. Graphics Processing Units are fantastic at running the millions of simultaneous calculations required for machine learning. They can simulate thousands of material formulas or map out complex logistics scenarios in the blink of an eye.

- IoT Sensors: These are the eyes and ears on the ground. Internet of Things (IoT) sensors are embedded in everything from concrete mixers and delivery vehicles to warehouse shelves, feeding back a live stream of data on location, temperature, machine health, and more.

When you put these pieces together, you get a powerful feedback loop. IoT sensors gather the raw data, the cloud provides the space to store and manage it, and GPUs do the heavy lifting to train the machine learning models.

Successful AI implementation is less about finding a single piece of software and more about building a connected digital ecosystem. It’s the seamless flow between data, computing power, and smart algorithms that truly unlocks new levels of efficiency.

Building the Digital Backbone for a Smarter Region

This need for a strong digital foundation isn't just a theory; it's driving massive infrastructure investment. Regional leaders know that to lead in AI, you first have to build the right digital highways.

Saudi Arabia, for instance, is making a serious play to become a regional AI hub by massively expanding its data center capacity. As of early 2025, the Kingdom already had over 300 megawatts (MW) online, with plans to add an incredible 2,200 MW more. That’s over four times the planned expansion of the UAE. This kind of infrastructure is exactly what’s needed to run the powerful machine learning models that can optimize everything from material design to supply chain logistics. To learn more, you can discover insights about AI advancements in the Middle East and their impact on construction.

The Future of AI-Driven Construction

As we've seen, weaving AI into building materials isn't just a minor upgrade. It’s a ground-up reinvention of how we design, source, and build. Machine learning is moving beyond simply tweaking old methods; it’s unlocking entirely new possibilities. Think about discovering new sustainable material formulas or creating supply chains that see disruptions coming and react before they hit.

That’s the new foundation for construction, and the pace of change is only picking up steam. As artificial intelligence merges with other powerful tech, the industry is headed for an even more connected, automated future. We're right on the edge of breakthroughs that will completely redraw the boundaries of what's possible.

Emerging Frontiers in Construction Tech

The next big leap will come from pairing digital brains with physical brawn. The real magic happens when AI starts directing the machinery. Here are a couple of trends to watch closely:

- AI and Robotics Integration: Picture a factory floor where autonomous robots, guided by AI, churn out custom building components with flawless accuracy. This combo is the key to automated fabrication, which means less human error and much, much faster production cycles.

- Digital Twin Supply Networks: Soon, companies will be able to build a complete virtual copy—a digital twin—of their entire supply chain. This lets them run stress tests and what-if scenarios, simulating everything from a sudden port closure to a spike in material costs, all without a single real-world consequence.

The future of construction is intelligent, sustainable, and automated. It’s no longer a question of if AI will reshape the industry, but how fast leaders can adapt to make the most of it.

Honestly, this journey is just getting started. For those leading the way, getting on board with this shift isn't just about getting a leg up on the competition—it's about survival. By investing in the tools that sharpen both material design and supply chains, the industry as a whole can build a more efficient, innovative, and resilient future.

Common Questions About AI in Building Materials

It's natural to have questions when new technology like artificial intelligence starts changing an industry as established as construction. Let's break down some of the most common queries about how AI is actually being used with building materials.

How Does AI Really Design a New Building Material?

It's a great question, because AI doesn't "design" things with human-like creativity. Instead, think of it as a super-powered scientist running millions of experiments in a digital lab at incredible speeds.

First, you give the AI a massive library of information on existing materials and all their properties—compressive strength, thermal conductivity, environmental impact, you name it. Then, you tell it what you want the new material to do. From there, the AI churns through a mind-boggling number of molecular structures and composite blends, simulating how each one would perform until it finds promising candidates that a human researcher might never even consider.

What’s the Biggest Hurdle for AI in Supply Chains?

Hands down, the single biggest challenge is data quality and integration. An AI model is a powerful engine, but it runs on data—and if the fuel is bad, the engine won't work.

The reality of a building materials supply chain is that information is scattered everywhere. It's stuck in different systems, used by different companies, and formatted in completely different ways. Before you can even think about using AI for something like logistics, you have to do the hard work of gathering, cleaning, and standardizing all that messy data. It’s the essential, non-negotiable first step.

Any AI project for a supply chain lives or dies by its data. Turning fragmented, messy information into a clean, unified resource is the foundation for success. Without it, even the most powerful algorithms are useless.

Is AI Only for Big Construction Giants?

Not at all, and that's a common misconception. Years ago, this was true, but the game has changed. Thanks to cloud computing and a whole new market of AI-as-a-Service (AIaaS) platforms, powerful tools are no longer out of reach.

Smaller and mid-sized companies can now subscribe to software that handles specific, high-value tasks, like predicting inventory needs or finding the most efficient delivery routes. The smart way to start is to pick one specific problem—like cutting fuel costs—and apply a focused AI tool to solve it. This way, you get a clear return on your investment without needing a massive budget, making it possible for any business to compete.

At Yasu Trading Co. LLC, we provide the high-quality building materials and hardware that form the foundation of successful construction projects. Explore our extensive product range and see how we can support your next build.