Aluminum sandwich panel: Expert Guide to Selection and Installation

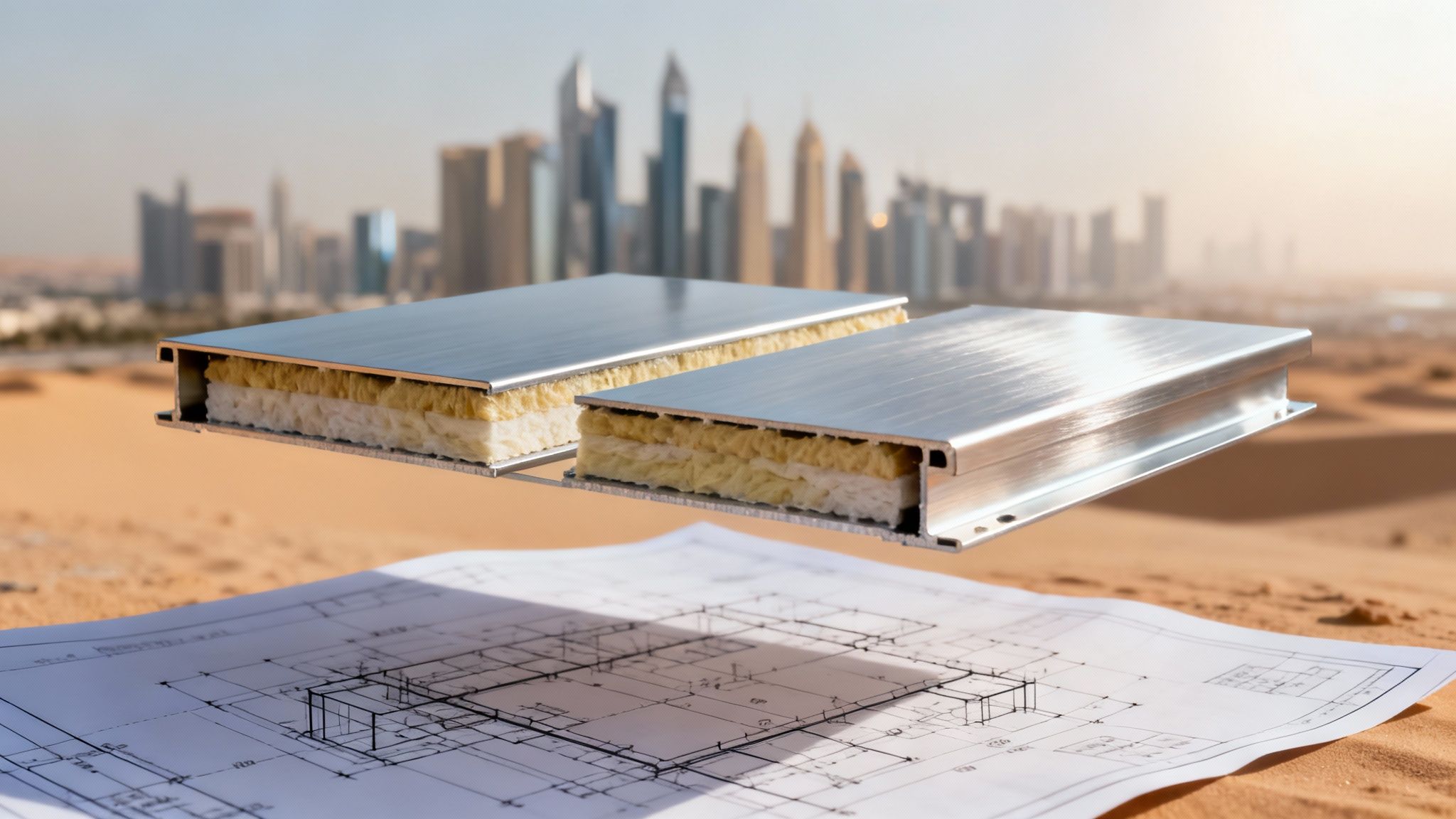

At its most basic, an aluminum sandwich panel is a composite material. It’s made of two aluminium sheets permanently bonded to a central, insulating core.

Think of it like a high-performance structural sandwich. The aluminium sheets are the ‘bread,’ giving the panel its durability and weather resistance. The inner core is the ‘filling,’ providing all the thermal insulation and rigidity. This simple concept creates a material that is both incredibly lightweight and exceptionally strong.

What's Inside an Aluminum Sandwich Panel?

So, what exactly are these panels, and why are they popping up on virtually every major construction site across the UAE? They are a fantastic example of composite engineering, combining the sleek, corrosion-resistant nature of aluminium with the insulating and structural muscle of a lightweight core.

This elegant structure is what gives the panel its key advantages, especially for projects here in our demanding climate. Of course, getting the right quality is everything, which is why sourcing from a specialised building materials distributor is non-negotiable.

The Anatomy of a High-Performance Panel

Let’s break it down. You take two thin, yet strong, sheets of aluminium and fuse them to a thicker, less dense material in the middle. This simple combination is what unlocks the panel's unique performance characteristics:

- The Faces: These are the outer aluminium skins. They’re typically coated with incredibly durable finishes, like PVDF, which are essential to stand up to the relentless UAE sun, humidity, and abrasive sand. The faces provide both the look and the first line of defence.

- The Core: This is the heart of the panel. It’s the central layer that delivers the rigidity, insulation, and, crucially, the fire-resistant properties. The choice of core material is one of the most important decisions you'll make when specifying.

- The Bond: A high-strength adhesive layer is used to fuse the core and faces together. This creates a single, unified unit that performs as one solid structural element, preventing any delamination over time.

This composite design means the panel performs far better than the sum of its parts. It allows us to create those large, perfectly flat, and dimensionally stable surfaces you see on modern building facades, roofs, and even interior partitions.

For us in the Emirates, the real value is getting that clean, modern aesthetic while simultaneously hitting the stringent UAE construction standards for energy efficiency and fire safety. Any reputable supplier in Dubai will be able to provide panels fully certified to meet these local codes.

The demand for these panels isn't just anecdotal; it's booming. The Middle East and Africa sandwich panel market was recently valued at USD 270 million and is projected to grow at a compound annual rate of 8.5%. This growth is being fuelled by the massive infrastructure and real estate projects across the GCC, with the UAE leading the charge. You can dig deeper into the numbers in the complete research about the regional sandwich panel market.

What Are the Main Core Types for Panels?

The performance of an aluminum sandwich panel really comes down to what’s on the inside. The core material is the heart of the panel, and it dictates everything from thermal insulation to fire resistance—two non-negotiable factors under UAE construction standards.

Think of the core as the panel's engine. You wouldn't put the same engine in a race car as you would in a heavy-duty truck, right? The same logic applies here. You choose a core based on what the building needs to do. A skyscraper in Downtown Dubai has a completely different set of demands than a cold storage facility out in Jebel Ali.

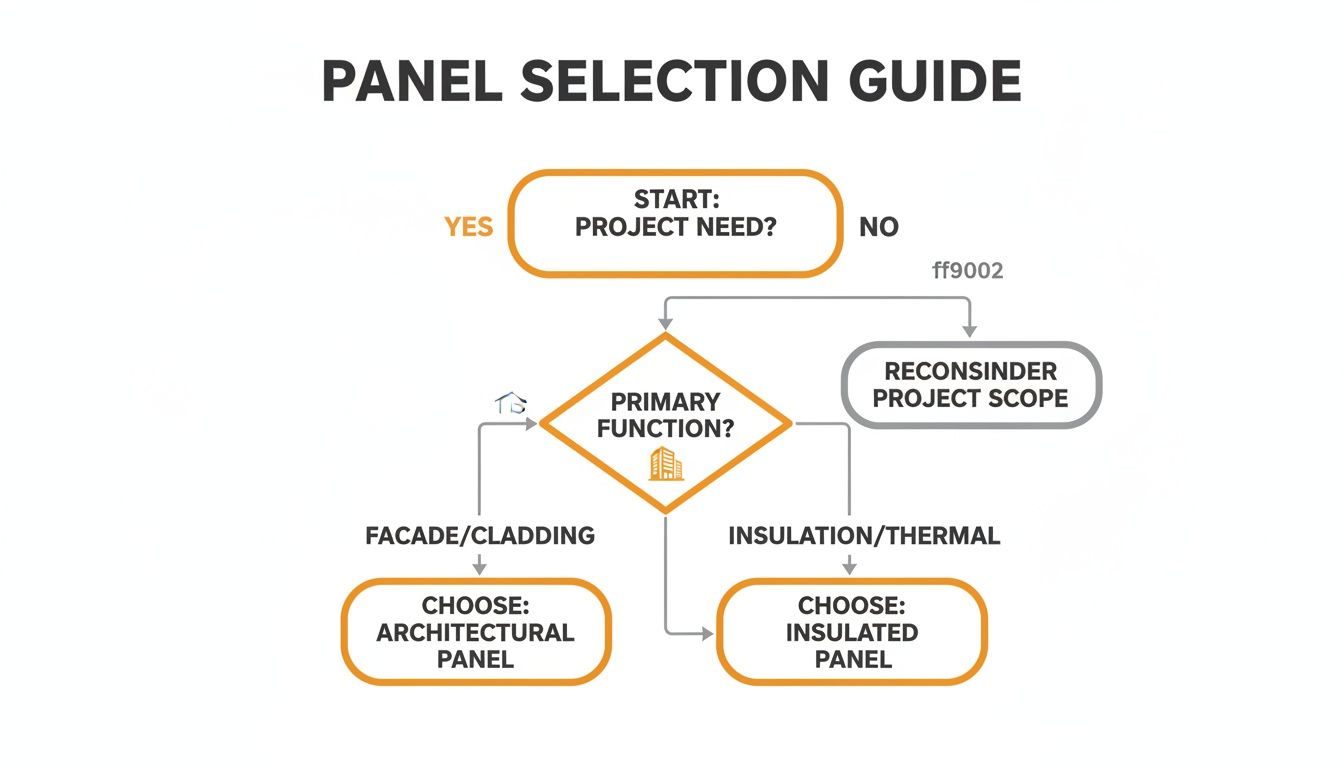

Let's break down the most common core types you'll encounter from any reputable supplier in Dubai. This will help you match the right "engine" to your project's specific requirements. This flowchart offers a great starting point, helping you think through the decision based on your primary goal.

As you can see, the choice starts with a simple question: is your main objective aesthetic and architectural, or is it purely about maximising insulation?

What Is a Mineral Wool Core?

A Mineral Wool (MW) core is the answer when fire safety is your absolute top priority. It’s made from spun molten rock fibres, which makes the core completely non-combustible and prevents it from fueling a fire, making it an essential specification for high-rise buildings, hospitals, and any public space where life safety comes first.

Picture it as a fireproof shield built directly into your building's envelope. If exposed to flames, an MW core holds its structure for a significant amount of time, effectively containing a fire and stopping its spread. This is exactly the kind of performance needed to meet the strict fire codes mandated by the UAE Civil Defence.

What Are PUR and PIR Cores Best For?

Polyurethane (PUR) and Polyisocyanurate (PIR) cores are best for thermal insulation. These rigid foam cores are exceptional at preventing heat transfer, which directly translates to keeping buildings cool and slashing air conditioning costs in the scorching UAE climate.

Think of a PUR or PIR core like the insulation in a high-end thermos flask. Its closed-cell structure traps gas, creating an incredibly effective thermal barrier. PIR takes it a step further by offering better fire performance than standard PUR, making it a very popular, well-balanced choice for a huge range of commercial and industrial buildings.

For projects where energy efficiency is a key driver, specifying a PIR core is one of the most effective ways to lower a building's operational carbon footprint. Its excellent insulation-to-thickness ratio allows for slimmer wall profiles without sacrificing thermal performance.

When Should You Use an EPS Core?

You should use an Expanded Polystyrene (EPS) core for a lightweight and cost-effective solution. The core is made of expanded polystyrene beads fused together, making it light, easy to handle, and simple to install, which can speed up construction timelines and trim labour costs.

While its thermal performance is decent, it doesn't quite match up to PUR or PIR. Critically, its fire performance is lower than both PIR and Mineral Wool. This often limits its use to low-rise industrial buildings, internal partitions, or applications where fire regulations are less demanding. It's a practical, budget-friendly choice when a high fire rating isn't a primary concern.

To make the choice clearer, let’s put these core materials head-to-head.

This table breaks down the key performance characteristics of common core materials to help specifiers in the UAE select the right panel for their projects.

Comparing Core Materials for Aluminum Sandwich Panels

| Core Material | Primary Benefit | Thermal Insulation (U-value) | Fire Rating | Best Application |

|---|---|---|---|---|

| Mineral Wool (MW) | Superior Fire Resistance | Moderate | Excellent (Non-combustible) | High-rise buildings, hospitals, schools |

| Polyisocyanurate (PIR) | Excellent Thermal Insulation | Excellent (Very Low) | Good (Fire-retardant) | Warehouses, commercial buildings, roofs |

| Polyurethane (PUR) | High Thermal Insulation | Excellent (Low) | Fair | Cold storage, industrial facilities |

| Expanded Polystyrene (EPS) | Cost-Effective & Lightweight | Good | Poor | Internal partitions, low-rise structures |

Ultimately, choosing the right core is about balancing performance with project-specific needs. A solid understanding of these materials ensures your building is not only compliant but also performs exactly as intended for years to come.

How do you read a panel's technical data sheet?

To choose the right aluminium sandwich panel, you must look beyond the glossy finish and understand its technical data sheet. This spec sheet contains the critical data that dictates how a panel will perform in the real world, ensuring compliance with UAE construction standards and the building's longevity.

Knowing how to read these metrics isn't just good practice—it's absolutely critical for anyone building in the region.

U-Value: Your Defence Against the Heat

For any project in the UAE, the U-value is one of the first specs you should look for. It’s a straightforward measure of thermal efficiency: the lower the U-value, the better the insulation. A low number means less heat will transfer through the panel and into your building.

Think of it as a barrier against our relentless summer heat. A panel with a good U-value keeps the cool, conditioned air in and the scorching ambient air out. This has a direct impact on the building’s operational costs, as the AC systems won't have to work nearly as hard. That translates to significant energy savings over the building’s entire lifecycle.

Fire Rating: A Non-Negotiable Safety Metric

A panel's fire rating tells you exactly how it will behave when exposed to flames. These ratings aren't just suggestions; they are mandated by authorities like the UAE Civil Defence to protect lives and property.

The core material is the key player here. A Mineral Wool (MW) core, for instance, is non-combustible and achieves the highest fire classifications, making it a mandatory choice for high-rise towers and other critical buildings. Polyisocyanurate (PIR) offers excellent fire-retardant properties, while other foam cores might provide less resistance. Always cross-reference the panel's rating with local building codes.

Always insist on seeing the official fire safety certificate for any aluminium sandwich panel you specify. A reputable building materials distributor will provide this documentation upfront, giving you the proof you need for your project's compliance.

Structural Load Capacity: Standing Strong Against the Elements

Structural load capacity is all about strength—how much force a panel can handle before it bends, buckles, or fails. In a place like Dubai, where we see impressive high-rises and occasional strong winds, this is a vital statistic, particularly for facades.

The data sheet will specify the panel's ability to resist wind pressures, which constantly push and pull on a building's exterior. Choosing a panel with an inadequate load capacity could lead to rattling, visible deflection, or, in a worst-case scenario, complete failure during a storm. This spec ensures your building envelope remains tight and secure, no matter what the weather throws at it.

PVDF vs. Polyester Coatings: The Face You Show the World

The coating is the panel's first line of defence, protecting it from intense UV radiation, humidity, and airborne sand and salt. The two main players you'll encounter are PVDF (Polyvinylidene Fluoride) and Polyester.

- PVDF Coatings: This is the top-tier choice. PVDF offers outstanding resistance to UV rays, which prevents colour fading and chalking. It’s the go-to for the harsh UAE climate, ensuring a building’s facade looks pristine for decades.

- Polyester Coatings: A more budget-friendly option, polyester still provides good durability but doesn't have the same long-term UV resistance as PVDF. It’s often a perfectly fine choice for interior applications or projects in less exposed environments.

The market here in the UAE leans heavily on aluminium-based panels for a reason—they simply perform better in our hot, arid climate where thermal efficiency and moisture resistance are everything. You can find more details in this analysis of the competitive landscape of the multi-metal aluminum sandwich panel market.

Where are sandwich panels used in UAE construction?

You will see aluminium sandwich panels used everywhere in major UAE cities. They are a true workhorse of modern construction, providing practical solutions for design and engineering challenges on everything from iconic skyscrapers to vast industrial estates.

Their most obvious use is for building exteriors, giving architects the tools to create stunning, contemporary facades. The panels’ ability to stay perfectly flat over huge surfaces is why we see so many smooth, almost seamless designs on commercial towers, five-star hotels, and premium apartment buildings. It’s the go-to material for that clean, futuristic look.

But their value goes much deeper than just aesthetics. Think about roofing. The lightweight nature of these panels is a massive benefit, especially for wide-span structures like warehouses, airport terminals, and exhibition centres. A lighter roof means less stress on the structural frame, which can translate into real cost savings on steel and a significantly faster installation schedule.

What’s the best panel for a building facade?

The best panel for a building facade in the UAE is an aluminium sandwich panel with a tough PVDF coating and a fire-retardant core, typically Mineral Wool (MW) or PIR. This specific combination provides a sleek finish, long-term resilience against sun and sand, and crucial compliance with the UAE's strict fire safety codes for high-rise buildings.

Beyond the glamorous exteriors, these panels are essential in highly controlled environments where temperature and cleanliness are non-negotiable. Their smooth, non-porous surfaces are a breeze to clean and don’t give mould or bacteria a foothold, making them the default choice for:

- Cold Storage Facilities: The insulation is second to none for maintaining exact low temperatures.

- Clean Rooms: Perfect for creating sterile environments in pharmaceutical or electronics manufacturing.

- Food Processing Plants: They provide hygienic surfaces that easily meet stringent health and safety regulations.

- Data Centres: They help maintain the stable, cool temperatures vital for protecting sensitive IT hardware.

Why are they used for cold storage and clean rooms?

They are used for cold storage and clean rooms because the insulated core delivers brilliant thermal control, while the smooth aluminium faces create a hygienic, non-porous surface. This combination provides temperature stability and a contamination-resistant barrier in one product, making it a perfect match for these demanding, highly controlled spaces.

Any good supplier in Dubai will tell you the same thing: demand for insulated panels, especially for logistics hubs and cold chain facilities, is booming. It's a direct reflection of the UAE's growing importance as a global trade and commerce centre.

This isn't just anecdotal, either. The numbers back it up. The Middle East and Africa sandwich panel market was valued at USD 248.73 million in 2022 and is on track to hit USD 386.52 million by 2029. This incredible growth shows just how much the region is investing in infrastructure that relies on these advanced materials. You can find more analysis on the driving factors in the MEA sandwich panel market.

How do you choose the right panel for your project?

Choosing the right aluminium sandwich panel is a critical technical decision that impacts your project's compliance, durability, and performance in the UAE. Getting it right ensures a smooth project, while getting it wrong can lead to costly rework and compliance issues. The key is to follow a methodical approach based on your building's function, location, and environmental demands.

Following a clear checklist lets you confidently specify a panel that hits that sweet spot between budget, aesthetics, and the UAE's demanding construction standards.

What Is the Panel’s Primary Application?

First things first: where is this panel going? A panel designed for a high-rise facade in Downtown Dubai has a completely different job to do than one lining the inside of a cold storage facility in Jebel Ali. Answering this one question immediately narrows your options and puts you on the right track.

Let's look at the most common scenarios:

- External Facades and Cladding: Here, the enemies are sun and wind. You need excellent UV resistance to prevent fading, the structural integrity to handle high wind loads, and, of course, a top-tier fire rating.

- Roofing Systems: For roofs, it’s all about keeping the elements out and providing structural support. Look for superior water tightness and the ability to span long distances between purlins, which can save on structural steel costs.

- Internal Partitions and Ceilings: Inside a building, priorities shift. You're likely more concerned with acoustic performance to reduce noise transfer, surface hygiene for clinics or kitchens, and achieving the required fire separation between spaces.

- Specialised Environments: Think clean rooms, food processing plants, or cold stores. In these cases, the focus is squarely on thermal insulation (a very low U-value), total airtightness, and having non-porous surfaces that are a breeze to clean.

How Do You Ensure Fire Safety Compliance?

Once you know the application, fire safety is the next critical hurdle. The UAE Civil Defence has some of the most stringent codes in the world, and there’s absolutely no room for error, especially on high-rise and public buildings.

This all comes down to the panel's core. For high-risk applications, a non-combustible Mineral Wool (MW) core is often the only acceptable choice. For many other commercial projects, a high-quality, fire-retardant Polyisocyanurate (PIR) core can provide the necessary compliance while offering excellent insulation.

A word of advice: always demand the official, up-to-date fire safety certificate for any panel you're considering. Don't just take someone's word for it. A reputable supplier will have all the documentation ready to prove compliance with local authorities, making your approval process much smoother.

What Level of Thermal and Structural Performance Is Needed?

Next up, you need to dig into the technical data. A panel's U-value is your key metric for energy efficiency. A lower U-value means better insulation, which translates directly into lower cooling bills over the building's lifetime. When assessing panels, it is also important to consider the impact of poor installation; you can learn more by understanding thermal bridging and how it can undermine the panel's insulating performance.

Just as important is the structural capacity. Your structural engineer will calculate the wind loads your building will face, and the panel you choose must be able to withstand them. This information is all on the technical data sheet, and a good building materials distributor can help you make sense of the numbers. If you need help finding the right local partners, our guide to the top sandwich panel manufacturers in the UAE is a great place to start.

Finally, let's talk about the finish. In the UAE's harsh climate, a PVDF (Polyvinylidene Fluoride) coating is really the only smart choice for exterior panels. It offers the best defence against colour fading and chalking from our intense UV radiation, keeping the building looking sharp for decades.

How do you get installation and maintenance right?

The real-world performance of the best aluminum sandwich panel depends on the quality of its installation. A poor installation will undermine even the most premium panel, leading to issues that can compromise the entire building envelope. Every step, from handling panels at a UAE job site to applying the final sealant, is critical.

For anyone working on upgrading older buildings, it's also worth looking at specialised techniques; modern metal retrofit roofing solutions offer some great insights into current best practices.

What is the most common installation mistake?

The most common and costly installation mistake is improper joint sealing. When a sealant is poorly chosen or incorrectly applied, it creates a direct path for water to enter, leading to leaks, corrosion, and damage to the panel's core and the building's structure over time.

This is a massive issue here in the UAE, where the relentless sun can break down cheap sealants in no time. The non-negotiables are proper surface cleaning, using the right primer for the job, and applying the correct bead size. The goal is to build a seamless, weatherproof barrier that can handle the thermal expansion and contraction cycles without failing.

A perfectly sealed joint is the single most important factor in guaranteeing the longevity and water tightness of an aluminum sandwich panel system. A reliable building materials distributor will always recommend sealants specifically tested for performance in high UV and high-temperature environments.

How to Handle Panels On-Site

Treat the panels carefully to avoid scratches, dents, or other damage to the factory finish. Always store them flat on level supports, keeping them slightly off the ground. That protective film on the surface? Leave it on for as long as you possibly can during the installation—it’s the best defence against site damage.

Never drag panels across each other or over abrasive surfaces. When you need to lift them, use the right gear and make sure the panel is supported along its length to prevent it from bending or buckling. Following these simple rules keeps the panels looking pristine and ensures they fit together perfectly.

What Goes into a Solid Maintenance Plan?

A straightforward and regular maintenance plan makes a huge difference in a panel's lifespan and appearance. It primarily involves two simple actions: cleaning and inspecting.

- Regular Cleaning: At least once a year, give the panels a good wash with mild detergent and water. This gets rid of the dust, sand, and pollutants that can wear down the surface coating over time.

- Annual Inspections: Make a habit of visually checking all the sealant joints. You’re looking for any cracking, shrinking, or signs that the sealant is pulling away from the panel. If you see any issues, re-seal them immediately.

- Fastener Checks: Every so often, take a look at the visible fixings to make sure they haven’t worked loose from thermal movement or vibrations.

This proactive mindset is far cheaper than dealing with major repairs later on and ensures the building facade performs as it should, meeting all UAE construction standards.

What are common questions about aluminium sandwich panels?

Here are straight answers to the queries we hear most often from contractors and architects specifying aluminium sandwich panels in the UAE.

Which panel is best for coastal areas like Dubai Marina?

For humid, salty environments like the coast, the best panel is one finished with a high-performance Polyvinylidene Fluoride (PVDF) coating. This coating offers superior defence against corrosion, salt spray, and UV damage, protecting the aluminium and preventing colour fade.

When you're specifying for a coastal project, make sure to request a PVDF coating and always check with your supplier in Dubai that the manufacturer’s warranty specifically covers coastal installations.

Do these panels meet UAE fire safety codes?

Yes, they can meet UAE fire safety codes, but compliance depends on choosing the right core material. For the highest level of fire resistance, especially in high-rise buildings, you must use panels with a Mineral Wool (MW) core as per UAE construction standards. Panels with a Polyisocyanurate (PIR) core also offer solid fire performance for other applications.

It's absolutely critical to get the official fire safety certificate for any panel you choose, approved by authorities like the Dubai Civil Defence (DCD). A trustworthy building materials distributor will have these compliance documents ready for you without any fuss.

Getting this paperwork sorted from the start ensures your project is fully compliant and avoids any potential headaches down the line.

What is the lifespan of a panel in the UAE climate?

A top-quality aluminium sandwich panel, when installed and maintained properly, can last 25 to 40 years or even longer in the UAE's harsh climate. The lifespan is primarily determined by the quality of the outer PVDF coating, the condition of the joint sealants, and a routine cleaning schedule. Sourcing panels from a reputable supplier ensures they are engineered to handle our region’s intense heat and UV exposure.

Can aluminium sandwich panels improve a building's energy efficiency?

Absolutely. The panel's insulated core creates a powerful thermal barrier that dramatically reduces heat transfer from the outside. This helps maintain a stable interior temperature, which means air conditioning systems don't have to work as hard, leading to significant savings on energy bills over the building's life. Opting for a panel with a low U-value is one of the most effective ways to boost energy performance in the UAE.

For all your project needs, from high-performance panels to essential sealants and fasteners, trust Yasu Trading Co. LLC. We provide municipality-compliant building materials with reliable, site-direct delivery across the UAE. Explore our complete range of construction supplies at https://yasutrading.com.