Choosing Cable Manufacturers in UAE A Strategic Guide

Picking the right cable manufacturer in the UAE isn't just another item on your procurement list. It's a foundational decision that can make or break your project's success down the line. Given the sheer scale of infrastructure, energy, and tech projects happening across the region, the need for top-tier, compliant cabling is at an all-time high.

Navigating the UAE Cable Manufacturing Market

Finding a dependable supplier is less about ticking boxes and more about a strategic approach to vetting potential partners. The UAE market has its own set of rules, from incredibly strict safety regulations to the practical need for cables that can take a beating from the harsh environment. You're looking for a manufacturer whose commitment to innovation, production capacity, and reliability mirrors your own project's goals for performance and safety.

This isn't just a purchase; it's the start of a partnership that ensures the very backbone of your project is solid.

Understanding the Local Industry Landscape

With the UAE's construction and industrial sectors firing on all cylinders, local cable production is booming right alongside them. To put it in perspective, the cable connector market alone was valued at around USD 1,172.49 million in 2024, and it's only expected to grow. This surge is powered by both established local giants and major international players setting up shop here.

If you're looking for specific insights into applications like data centres or large commercial buildings, a deep dive into structured cabling in Dubai can give you a much clearer picture of the market dynamics you'll be working with.

The real secret weapon of local manufacturers is their on-the-ground knowledge. They get the regional climate challenges and the ins and outs of local regulations in a way an overseas supplier just can't. That kind of expertise is a massive advantage.

The Importance of Regulatory Compliance

In the UAE's building sector, compliance is everything. It’s not a guideline; it's the law. Every single component, right down to the electrical wiring, has to meet rigorous standards for safety and integrity.

Cutting corners with uncertified materials is a recipe for disaster—think project-halting delays, failed inspections, and hefty fines. Any manufacturer you even consider must be ready to show you clear, verifiable proof that they meet all local and international standards.

To get a handle on just how detailed these requirements are, it helps to understand the full picture. You can get up to speed by navigating the regulations for building materials in the UAE. Arming yourself with this knowledge means you can ask the tough, necessary questions and confidently check a supplier's credentials, protecting your project from some very expensive headaches.

Getting to Grips with Quality and Technical Specs

In a market where safety is everything, you can't just take a manufacturer's word on quality. This is more than just a box-ticking exercise during procurement; it's about safeguarding the very core of your project. You have to look past the sales pitch and dive deep into the technical details that separate a reliable product from a liability.

Your first move? Always demand the technical data sheets for every single cable type you're considering. Think of these documents as the cable's passport. They lay out everything from conductor material and insulation thickness to voltage ratings and temperature resistance.

If a supplier gets cagey about providing these, that’s a massive red flag.

What to Look for in Certifications

Certifications are your frontline defence against subpar products. They're independent proof that a manufacturer sticks to stringent production and safety standards. For any serious cable manufacturers in the UAE, a few key certifications are absolutely non-negotiable.

Here’s a quick-reference table to help you cut through the noise and focus on what truly matters when evaluating potential suppliers.

Key Quality Certifications for UAE Cable Suppliers

| Certification/Standard | What It Signifies | Verification Tip |

|---|---|---|

| ISO 9001 | This proves the manufacturer has a solid quality management system covering everything from R&D to final inspection. | Ask for the certificate number and confirm its validity on the ISO database. Ensure it's not expired. |

| BASEC | British Approvals Service for Cables is a globally respected mark. It means the cable has undergone brutal testing for safety and performance, far beyond basic requirements. | Look for the BASEC mark printed directly on the cable sheath itself, not just on the documentation. |

| EQM (Emirates Quality Mark) | A mandatory mark for many products sold in the UAE, this confirms compliance with national safety and quality rules. It’s a clear sign the product is approved for the local market. | Check the ESMA (Emirates Authority for Standardization and Metrology) website to verify the manufacturer's certification. |

Verifying these is straightforward. A quick check on the issuing body's public database using the certificate number can save you from a world of trouble down the line. To really get into the weeds on this topic, it's worth learning more about the role of https://yasutrading.com/blog/quality-assurance-in-dubais-construction-yasu-trading-co-llcs-commitment.

Don't Just Trust the Paperwork

Certifications are essential, but nothing beats seeing and feeling the product yourself. Always, always ask for samples. This gives you a chance to check the build quality, feel the flexibility, and inspect the markings with your own eyes.

For high-stakes projects, sending those samples for independent third-party testing is a smart move and a worthy investment.

We once saw a contractor try to save 15% by going with an unverified supplier. The cables looked fine, but they failed the on-site insulation resistance tests. The result? A full rip-and-replace job that cost three times the initial 'savings' and pushed the project back by six weeks.

The wider UAE wires and cables market is gearing up for significant growth, with experts forecasting a CAGR of around 12% between 2025 and 2031. This boom is fuelled by huge investments in infrastructure and renewables, which puts even more pressure on sourcing top-tier, compliant materials like fire-resistant cables.

Understanding the critical benefits of fiber optic cable is also key, as it shows whether a manufacturer is keeping up with modern demands.

Finally, a truly reputable manufacturer will have no problem with material traceability. They should be able to trace the raw copper or aluminium right back to its source, proving its purity and quality. Don't be afraid to ask.

Matching Manufacturer Capabilities to Your Project

It’s easy to assume all cable manufacturers can handle any job, but that’s a rookie mistake. The truth is, they're not all built the same, and their specialities can make or break your project. Moving beyond basic quality checks means aligning a supplier’s specific expertise and production capacity with what your project actually demands.

You're not just looking for a parts supplier; you need a partner who gets it.

Think about it this way: a massive data centre build-out absolutely requires a partner with deep, proven expertise in high-performance structured cabling—think fibre optic and Cat6A cables. Their entire operation, from machinery to quality control, is fine-tuned for things like data integrity and blistering-fast transmission speeds.

On the other hand, a major industrial plant needs a manufacturer who lives and breathes heavy-duty, armoured high-voltage cables designed to take a beating from harsh environments. Putting a generalist on a specialist's job is a gamble you just can't afford.

Gauging Production Capacity and Specialisation

The first question is always the most direct: can they actually handle your volume without cutting corners? A manufacturer might make fantastic cables, but if their production lines are already running at full tilt, your project is the one that’s going to face delays.

Don't be shy. Ask them straight up about their current production schedule and what realistic lead times look like for an order of your size. This is non-negotiable for any project on a tight deadline. You need rock-solid assurance that your order won’t be squeezed through an overloaded system, because that’s precisely when quality control starts to falter.

A huge part of this assessment is understanding their core business. Take the UAE's structured cabling market—it's a niche segment projected to hit USD 549.1 million by 2033. That growth is fuelled by data centres and smart building projects, which demand a specific skillset many general cable manufacturers in uae simply don't have. You can get more details on the structured cabling market on Grandview Research.

Here’s a pro tip: a bulletproof way to gauge a manufacturer's real capability is to ask for case studies on projects just like yours. If they can't show you two or three relevant examples—complete with project scale and the challenges they overcame—it’s a major red flag. They might not be the right fit.

Key Questions for Potential Partners

To get past the glossy sales pitch, you need to dig deeper. Asking probing questions about their operations reveals their true capabilities and whether they're genuinely suited for your specific needs.

Arm yourself with these questions for your next conversation:

- Machinery and Technology: What specific equipment do you use for drawing, stranding, and insulating the types of cables we need? How modern is it, and what’s your maintenance schedule like?

- Raw Material Sourcing: Where do you get your primary raw materials, like copper and aluminium? Can you provide documentation on material purity and your sourcing ethics?

- Project Experience: Walk me through your experience with projects of our exact size and technical complexity. What were the challenges?

- Customisation Ability: If our project has unique specs, what's your process for developing and testing a custom cable solution?

By asking these pointed questions, you change the dynamic. It stops being a sales pitch and becomes a technical evaluation, ensuring you find a manufacturer whose capabilities are a perfect match for your project's demands.

Evaluating Supply Chain and Logistics Reliability

A world-class cable is worthless if it's stuck in a warehouse while your project grinds to a halt. The best cable manufacturers in UAE know that production quality is only half the battle; rock-solid logistics make all the difference. Their ability to deliver on time, every time, is just as critical as the technical specs on the data sheet.

Picture this: your crew is on-site, ready to pull cables through the conduits of a new commercial tower. It's a critical path activity before the interior fit-out can even start. But the cable shipment is a week late because of the supplier's shoddy inventory management. Now you have a team of expensive electricians sitting idle, your project timeline is in tatters, and those delay penalty clauses in your contract are starting to look very real. This isn't just a hypothetical problem—it's a costly reality for projects that overlook the supply chain.

That’s why you need to dig into a manufacturer's logistical capabilities with the same rigour you use for their quality certifications. Their warehouse locations, inventory strategy, and distribution network aren't just minor details; they are fundamental to the service you're paying for.

Assessing a Manufacturer's Logistical Strength

First things first, get a map out. A manufacturer with strategic warehouse hubs in places like Dubai and Abu Dhabi is far better positioned to serve projects across the country than one operating from a single, remote factory. This simple geographic advantage can slash delivery times and reduce transport risks.

Next, you need to get under the hood of their inventory management. Are they using modern systems to track stock levels in real time? Can they give you clear, data-backed lead times for both standard and custom orders? A supplier who offers a vague "a few weeks" is a red flag. You need firm commitments you can bank on.

A strong logistical partner will be an open book. Ask them to walk you through their entire process, from the moment an order is confirmed to the final delivery on-site. For a deeper dive into what a solid process looks like, our practical guide on https://yasutrading.com/blog/ensuring-timely-delivery-of-construction-materials-a-practical-guide is a great resource.

Here’s a tip from seasoned project managers: a supplier's past performance is the best predictor of their future reliability. Don't be shy about asking for delivery metrics or references from projects similar in scale to yours. A truly reliable partner will have this data on hand and be proud to show it off.

Finally, talk about their transport partners and, more importantly, their contingency plans. What's the backup if a truck breaks down or a major route is closed? A prepared manufacturer has Plan B and Plan C ready to go, ensuring a hiccup on the road doesn't derail your entire schedule. If you want to get more technical on this, resources on Mastering Supply Chain Visibility can be incredibly insightful. Asking these tough questions upfront helps you secure a partner who won't let you down when it matters most.

Moving Beyond Price for a True Cost Analysis

It's tempting, isn't it? That quote lands in your inbox, and the price per metre looks fantastic. But focusing only on that number is a classic trap, one that can seriously jeopardise your project's financial health down the line. When you’re evaluating bids from cable manufacturers in the UAE, you have to look past the sticker price and conduct a proper total cost of ownership (TCO) analysis.

This is where you dig deeper to uncover the hidden costs that always come with cheap, subpar cables. I'm talking about the real-world expenses of rework, constant maintenance, and the enormous risks—both financial and safety-related—that come with premature electrical failures. You’ll often find that a slightly higher initial investment pays for itself many times over throughout the project's life.

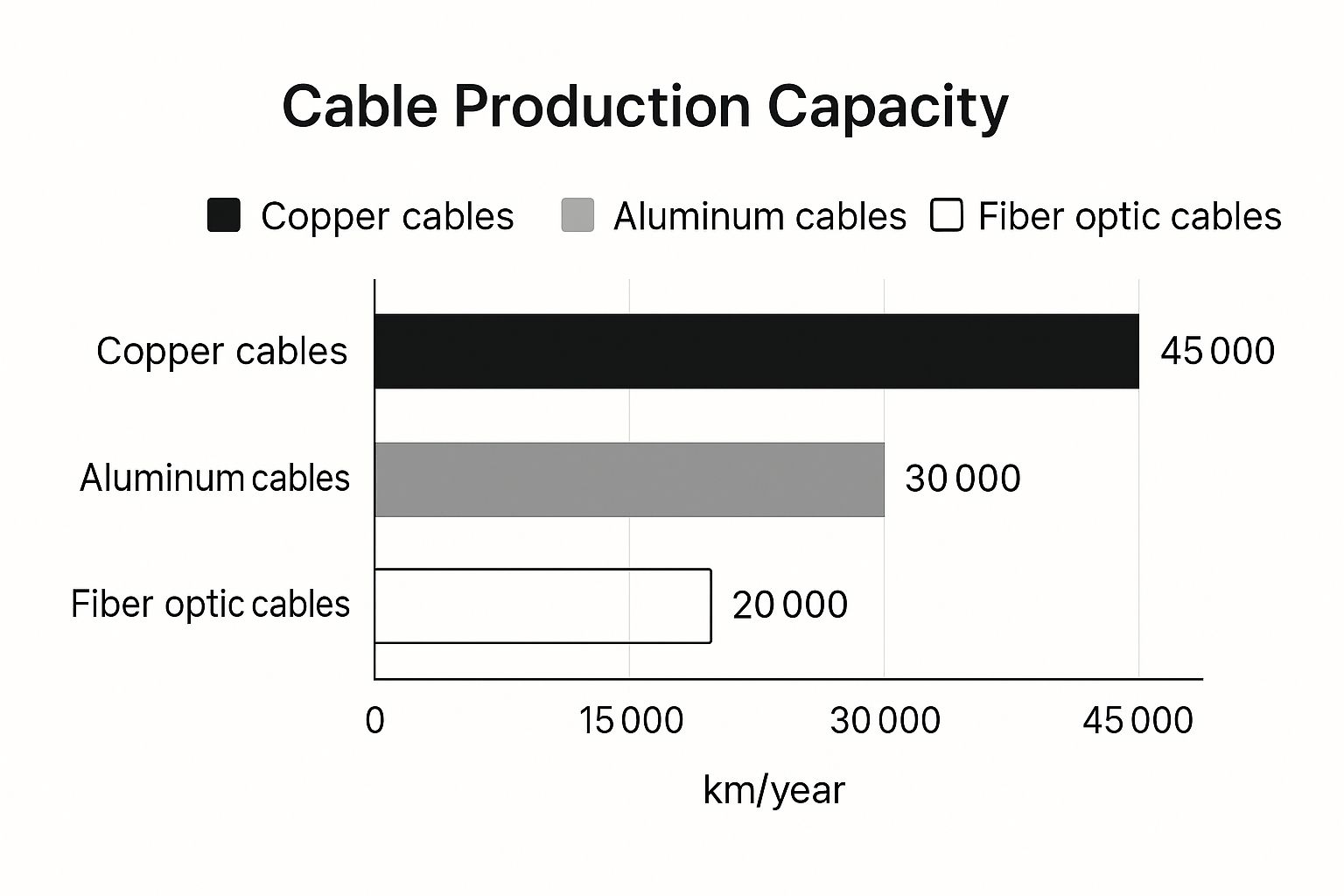

The chart below gives you a good sense of scale for what different manufacturers might produce annually. It helps you understand where their focus and expertise might lie.

As you can see, standard copper and aluminium power cables usually have much higher production volumes than specialised products like fibre optics. This is a crucial detail when you're gauging a manufacturer's core capabilities.

Uncovering the Hidden Costs

So, when you’re laying those quotes side by side, what should you be looking for beyond the price? Here are the factors that have a direct and significant impact on your total cost.

- Material Quality & Copper Purity: Sure, lower-grade copper or aluminium might save you a few dirhams upfront. But it’s a false economy. These materials have higher resistance, which means more energy loss and a greater risk of overheating. That inefficiency costs you money on your utility bills every single day.

- Warranty Terms & Guarantees: A solid warranty from a reputable manufacturer isn't just a piece of paper; it’s your financial safety net. When one supplier offers a 1-year warranty and another offers a 10-year one, they're sending a very clear message about their confidence in the product's quality.

- After-Sales & Technical Support: What’s the plan when your team runs into an issue during installation? A value-focused supplier will have responsive technical support ready to help, but a low-cost vendor might just leave you stranded. Those delays get expensive, fast.

A true cost analysis isn't just about saving money. It's about mitigating risk. The potential cost of a single electrical fire caused by a non-compliant, cheap cable can easily wipe out an entire project's budget and ruin a company's reputation.

Comparing Cable Manufacturer Bids

To really see the difference, let’s compare two typical bids. This table breaks down how to evaluate suppliers based on total value, not just the initial quote.

| Evaluation Criteria | Supplier A (Low Price) | Supplier B (Value-Focused) |

|---|---|---|

| Initial Cost | 20% Lower | Higher Initial Outlay |

| Material Quality | Basic grade, vague specs | High-purity copper, fully documented |

| Certifications | Meets minimum standards | Exceeds standards (e.g., BASEC, LPCB) |

| Warranty | 1-Year Limited | 10-Year Comprehensive |

| Technical Support | Email-only, slow response | Dedicated support, on-site assistance |

| Long-Term Risk | High risk of failure, replacement costs | Low risk, proven reliability |

| Total Cost | Potentially 2-3x higher over lifetime | Lower TCO due to reliability & efficiency |

The takeaway here is clear. The initial saving offered by Supplier A is quickly erased by the hidden costs and massive risks it introduces. Supplier B delivers genuine value and long-term security.

A Real-World Comparison

Let's put this into a practical scenario. Imagine you're sourcing fire-resistant cables for the emergency systems in a new commercial tower—a critical application where failure is not an option.

You get two quotes.

Supplier A comes in 20% cheaper. Their cable meets the most basic specifications on paper, but it lacks any credible third-party fire-resistance certification from an authority like BASEC. The warranty is limited and they can’t provide clear material traceability.

Supplier B, on the other hand, provides a fully certified, fire-resistant cable with all the documentation to back it up. Their initial cost is higher, but the product comes with a comprehensive warranty, verifiable copper purity, and access to their technical support team.

Choosing Supplier A might make the procurement manager look good on the initial budget sheet, but it's a huge gamble. If that cable fails during a fire, the consequences are catastrophic. Even before that, it could easily fail a consultant's inspection, forcing a complete and incredibly expensive replacement that wipes out any initial savings.

In contrast, Supplier B's product gives you peace of mind. You get guaranteed compliance and long-term reliability. That slightly higher upfront cost is really an investment in safety, performance, and the integrity of your entire project, delivering a far lower total cost of ownership in the end.

Common Questions About UAE Cable Suppliers

When you’re sourcing from cable manufacturers in UAE, you’re bound to have questions. It’s a critical decision. Getting the right answers upfront saves a world of headaches down the line, so let's tackle some of the most common queries I hear from project managers and engineers.

Local Versus International Suppliers

This is a big one: should you stick with a local UAE manufacturer or look abroad?

Frankly, for most projects here, local is the way to go. A manufacturer like Ducab isn't just physically closer; they have an ingrained understanding of our regional standards and the harsh environmental realities we build in. That local knowledge translates into shorter lead times, faster deliveries, and technical support that can actually show up on-site when you need it. The logistical simplicity is a massive advantage.

Of course, international suppliers have their place, especially if you need a highly specialised or niche cable that just isn't made here. But be prepared to navigate a minefield of extra costs—shipping, import duties, and the very real risk of customs delays that can throw your entire project timeline into chaos. For the vast majority of jobs, a reputable local partner offers a far more stable and cost-effective supply chain.

Evaluating a Manufacturer's Project Portfolio

How much does a supplier's past work really matter? Everything. It's the only real proof you have of their capabilities and reliability in the field.

But don't just skim the project names. Dig deeper. If you're building a new data centre, you need to see their track record on similar high-tech infrastructure projects, not residential villas. The technical demands are completely different.

Don't be shy about asking for detailed case studies or even client references. Seeing their name attached to iconic UAE landmarks like the Burj Khalifa or Dubai Metro tells you one thing very clearly: they can perform under pressure and meet the absolute highest standards.

Requesting Custom Cable Solutions

What if your project has very specific, non-standard needs? This is where top-tier cable manufacturers in the UAE really stand out. Many have impressive R&D teams ready to engineer custom solutions.

Whether you need specialised insulation to withstand corrosive chemicals, unique colour-coding for a mind-bogglingly complex system, or a composite cable that bundles power and data, bring it up early. A good partner will welcome the challenge.

Ask them to walk you through their process for custom jobs:

- How do they handle the initial design and engineering?

- What specific performance and safety tests will the cable undergo?

- How is the final product certified to meet all necessary standards?

A clear, confident answer to these questions is a great sign you're dealing with a true expert.

Red Flags to Watch Out For

Knowing what to look for is only half the battle. You also need to know what to avoid. I’ve seen enough projects go sideways to know the warning signs.

Be immediately suspicious of any supplier who is cagey about providing certification documents or won't give you straight answers about their raw material sourcing. A price that seems way too low is almost always a red flag for corner-cutting—think lower-purity copper or dangerously thin insulation.

Other warning signs include a flimsy online presence or a portfolio full of projects you can’t verify. Trust your gut. If a supplier hesitates to give you technical data sheets or send over physical samples for you to inspect, it's time to walk away. In this business, a deal that looks too good to be true almost always is.

For all your projects, from large-scale developments to specialised installations, Yasu Trading Co. LLC provides a comprehensive range of certified building materials and electrical essentials to ensure your success. Discover our full catalogue and request a competitive quotation by visiting us at https://yasutrading.com.