Finding the Best Cable Suppliers in UAE

When you're sourcing cables for a multi-million dollar project in the UAE, you're not just buying a product; you're making a strategic decision. Get it right, and your project runs smoothly. Get it wrong, and the consequences can ripple through every stage of construction, affecting safety, timelines, and your bottom line.

Why Your Choice of Cable Supplier Is So Critical

Think about any major construction project, from a towering skyscraper in Dubai to a sprawling data centre in Abu Dhabi. While the steel and concrete create the frame, it's the electrical and data cables that bring it to life—they're the project's central nervous system.

Choosing a subpar supplier introduces risks that no project manager can afford. We're talking about catastrophic delays, budget blowouts, and even serious safety hazards that could surface years down the track. This isn't just about finding the cheapest price; it's about finding a partner you can trust.

This pressure is amplified by the sheer speed of development here. The UAE's wires and cables market is booming, fueled by massive government and private sector investments. In fact, market analysis predicts the sector will grow at a compound annual growth rate (CAGR) of 12% between 2025 and 2031. You can dig into the numbers in the full UAE wires and cables market report from 6wresearch.

More growth means more suppliers, but it also means you have to be much more careful with who you choose.

The Real-World Challenges of Choosing a Supplier

Project managers on the ground face a distinct set of hurdles when sourcing cables in this market. To navigate it properly, you need to focus on three key areas:

Navigating Complex Quality Standards: The UAE has incredibly strict regulations. Your supplier's products must be certified by local authorities like the Emirates Authority for Standardisation and Metrology (ESMA) and Dubai Civil Defence (DCD), on top of meeting international standards. There’s no room for error here.

Ensuring Supply Chain Reliability: In construction, delays cost a fortune. A truly reliable supplier needs to have their logistics locked down, with solid inventory management to get materials to your site exactly when you need them. One late shipment can bring an entire site to a standstill.

Getting Proper Technical Expertise and Support: The best suppliers don't just take orders. They act as an extension of your team, offering technical advice to make sure you're selecting the right cable specifications for your project's unique demands, whether it’s a high-rise, an industrial plant, or a renewable energy facility.

Understanding Core Cable Types for UAE Projects

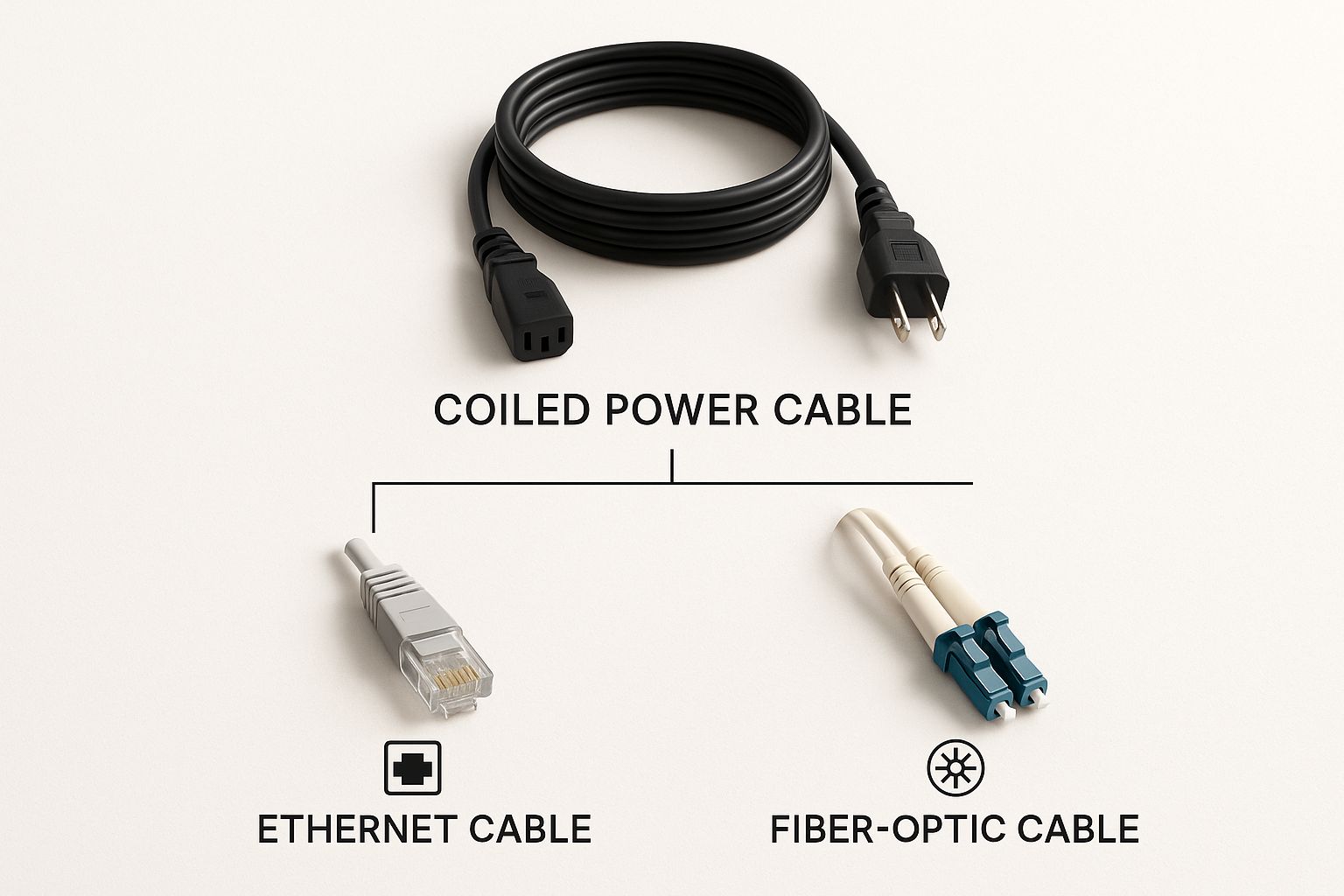

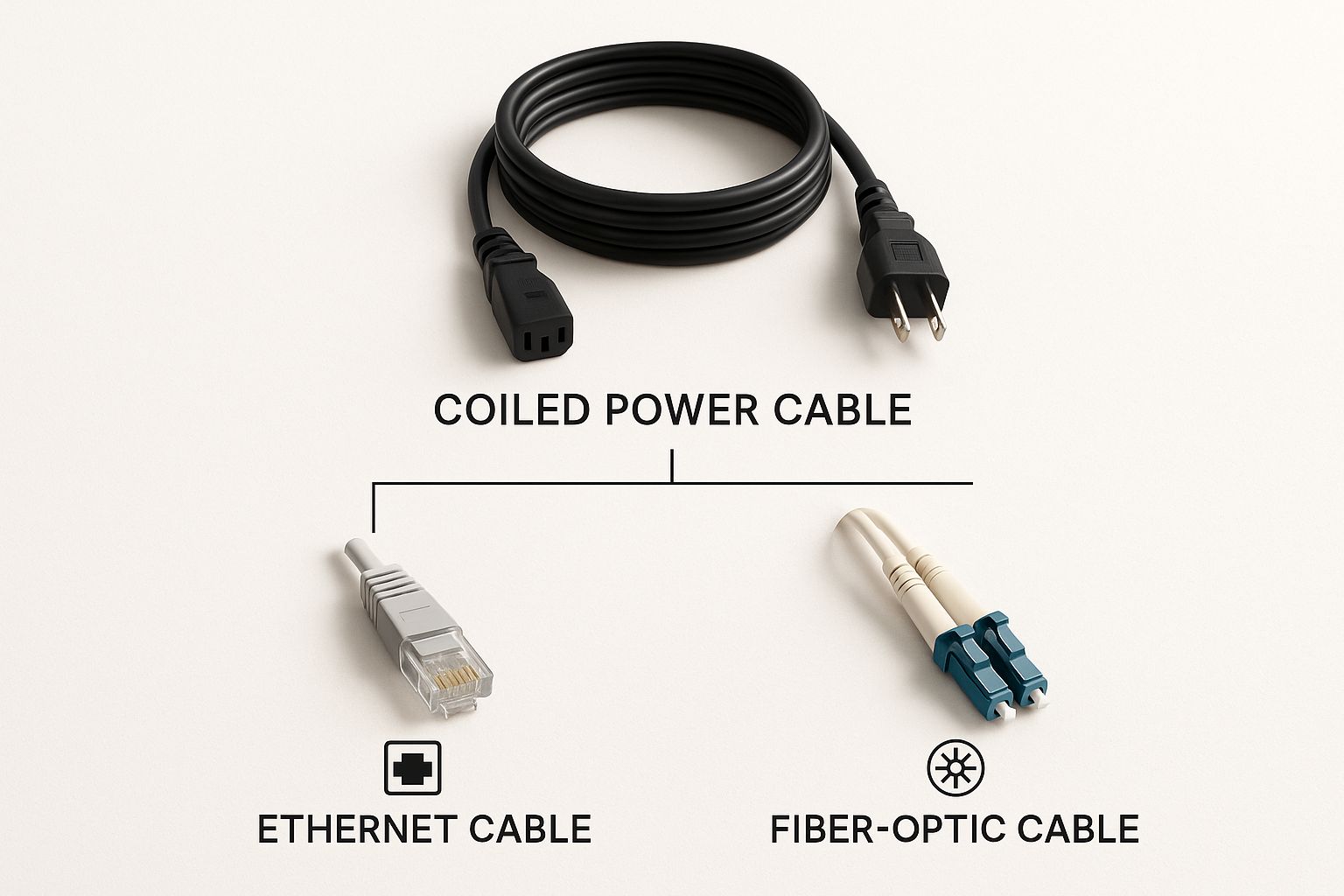

Getting the cabling right on any project is fundamental. Think of it this way: power cables are the main arteries, pumping the lifeblood—electricity—throughout a building. At the same time, data and fibre optic cables act as the central nervous system, transmitting critical information in a flash. For any project in the UAE to succeed, grasping these core differences is the very first step toward building a reliable and future-proof infrastructure.

Let’s use a simple analogy for power cables. Low Voltage (LV) cables are like the local plumbing in your house, perfect for the final connections to lights, sockets, and appliances. Medium Voltage (MV) cables are more like the main water lines running under your street, distributing power across a whole neighbourhood or a large commercial complex. Finally, High Voltage (HV) cables are the massive transmission lines, carrying bulk power over long distances from a power plant to a city substation.

This image gives a great visual overview of the main cable families you'll encounter.

Each type, from a heavy-duty power line to a delicate fibre optic strand, plays a unique and essential role in a project's ecosystem.

To give you a clearer picture, this table breaks down the most common cable types and where you'll typically see them used across the UAE.

Common Cable Types and Their UAE Applications

| Cable Type | Primary Function | Common UAE Project Application |

|---|---|---|

| Low Voltage (LV) Power | Final power distribution | Residential towers, office fit-outs, retail spaces, villas |

| Medium Voltage (MV) Power | Primary distribution within a site | Large industrial plants, university campuses, data centres |

| High Voltage (HV) Power | Bulk power transmission | National grid infrastructure, connecting power plants |

| Instrumentation | Transmitting sensor/control signals | Oil & gas facilities, manufacturing plants, process automation |

| Fibre Optic | High-speed data transmission | Telecom networks, smart building infrastructure, CCTV systems |

| Fire-Resistant | Maintaining power in a fire | Emergency lighting, fire alarm systems, public address systems |

As you can see, the application dictates the technology. A high-rise in Downtown Dubai and a processing plant in Jebel Ali have vastly different requirements, and the right cable choice is critical for both.

The Foundation: Power Cables

Power cables are the absolute backbone of any electrical system. Picking the wrong one doesn't just lead to poor performance; it can create serious safety hazards. It all comes down to the scale and demands of the application.

Here’s how it usually breaks down on the ground:

- Low Voltage (LV) Cables: These are the workhorses you see everywhere, from wiring homes and offices to powering machinery in smaller industrial settings.

- Medium Voltage (MV) Cables: Step up a level, and you find MV cables distributing power from a main substation to smaller, local ones. Think large industrial plants, sprawling university campuses, and utility networks.

- High Voltage (HV) Cables: These are the heavy lifters for transmitting bulk power over long distances. They’re essential for the national grid, connecting major power stations to cities.

Specifying these cables correctly starts with a thorough analysis of your power needs. For a closer look at this process, our guide on how to perform an https://yasutrading.com/blog/electrical-load-calculation/ walks you through the essential steps to get it right from day one.

The Brains: Data and Specialised Cables

Power is just one part of the equation. Today’s projects in the UAE are smart and connected, demanding a sophisticated network for data and communication. This is where specialised cables come in, ensuring everything from your internet connection to your fire alarm system works without a hitch.

In a modern smart building, the quality of your data network is just as vital as the power supply. A slow or unreliable network can grind a business to a halt just as quickly as a power cut.

Take instrumentation cables, for example. They are the sensitive nerve endings in an industrial facility, carrying precise measurement signals from sensors back to the control room. For sheer data speed, nothing beats fibre optic cables. When planning for a new commercial or residential tower, understanding the advantages of fibre broadband is key to delivering the connectivity tenants now expect.

Finally, you have cables that save lives. Fire-resistant cables are a non-negotiable safety feature, engineered to keep critical circuits powered during a fire. They run essential systems like emergency lights and alarms, buying precious time for people to evacuate. Finding the right cable supplier in the UAE means finding a partner who truly understands these critical differences.

Getting to Grips with UAE Cable Certifications and Standards

In the UAE's fast-paced construction world, cutting corners on compliance is a risk no one can afford to take. It’s not about navigating bureaucratic hurdles; it’s about the fundamental safety and legal standing of your entire project. When you source from cable suppliers in UAE who adhere to the strict local and international standards, you're protecting your investment, your reputation, and crucially, the people who will eventually use the building.

Think of these certifications less as red tape and more as a guarantee of quality and safety. A cable without the right approval is a liability waiting to happen. In the UAE, a couple of key local authorities are the gatekeepers for ensuring electrical products are safe and perform as they should.

Who Sets the Standards? Key Local and International Bodies

Before you can comply, you need to know who makes the rules. The standards are set by a mix of powerful local authorities and globally respected organisations.

- Emirates Authority for Standardisation and Metrology (ESMA): As the federal standards body, ESMA is the big one. If a product, including cables, doesn't have ESMA’s seal of approval, it can't legally be sold or used in the UAE. It’s that simple.

- Dubai Civil Defence (DCD): With a laser focus on fire safety, DCD approval is absolutely essential for any component used in fire alarm, detection, or suppression systems. For fire-resistant and flame-retardant cables, DCD certification isn't just a good idea—it's mandatory.

- International Electrotechnical Commission (IEC): This is the gold standard for electrical technologies worldwide. While local approvals are a must, seeing an IEC certification means the cable also meets globally recognised benchmarks for performance and safety.

- British Approvals Service for Cables (BASEC): Widely respected as an independent certifier, a BASEC mark is a clear sign of superior quality control. Suppliers with BASEC-approved cables have put their products through rigorous, ongoing testing.

Always ask for proof. A trustworthy supplier will have no problem providing documentation for ESMA, DCD, and any other relevant certifications. If they hesitate, that's a major red flag.

Why You Can't Afford to Ignore Compliance

The push for certified, high-quality products has only grown stronger with the region's incredible construction pipeline. Think about the boom leading up to major events like Expo 2020 Dubai—it created a massive need for top-tier power cables in countless new developments. This demand has put major players like Dubai Cable and National Cables Industry at the forefront, supplying projects from Abu Dhabi to the Northern Emirates. You can dig deeper into how these events influence the UAE wires and cables market.

Using non-compliant cables isn't just a minor mistake; it can have disastrous consequences. We're talking about inspectors rejecting your project, facing steep fines, and even the nightmare scenario of having to rip out and replace every single substandard wire. Beyond the financial hit, the safety risks are enormous, from simple electrical faults to catastrophic failures during a fire.

Ultimately, choosing certified products from a reputable supplier is the only path to guaranteeing performance, staying on the right side of the law, and delivering a project that is both safe and reliable.

An Overview of Major Cable Suppliers and Manufacturers

The UAE’s cable market is a fascinating mix of powerhouse local manufacturers and big-name international players. Figuring out who's who—what they specialise in and how they're seen in the industry—is the first step to making a smart sourcing decision. It's not just about picking a brand you've heard of; it’s about matching a supplier’s core strengths to the precise demands of your project.

At the heart of the market are a handful of formidable local manufacturers. These companies didn't just pop up overnight; they've spent years building a solid reputation for quality and reliability. They know the region inside and out and have the production muscle to back it up, making them a default choice for many of the UAE's most iconic projects.

Leading Local Manufacturers

When you talk about cable suppliers in UAE, two names inevitably dominate the conversation because of their sheer scale and market influence.

Ducab: A true giant in the Middle East, Ducab is known for its incredibly comprehensive range of high-quality power cables. Whether it's low-voltage wiring for a residential tower or highly specialised high-voltage solutions for national power grids, their products are everywhere. Their entire reputation rests on uncompromising quality control and a deep commitment to meeting both regional and global standards.

National Cables Industry (NCI): Operating out of Sharjah, NCI is another key local player with a serious foothold in the market. They manufacture a huge variety of cables—from building wires and power cables to control cables—primarily serving the construction and utility sectors. A relentless focus on consistency has made them a go-to partner for countless contractors.

These homegrown champions bring some serious advantages to the table, like shorter lead times, an intuitive grasp of regional regulations, and solid local support networks you can count on.

Major International Suppliers in the UAE

Standing alongside the local leaders are several global giants. They've established a strong presence in the UAE, bringing their worldwide expertise and often highly specialised product lines right to our doorstep.

The fact that we have strong local and international suppliers here creates a really healthy, competitive market. For buyers, this is fantastic. It means more choice, better access to specialised tech, and more competitive pricing.

These international firms often step in to handle niche or technically demanding applications, like large-scale industrial automation systems or the backbone of advanced telecom networks.

Prysmian Group: This Italian multinational is one of the biggest cable manufacturers on the planet. Here in the UAE, they're the name you hear when it comes to specialised energy and telecom cables. You'll often find their solutions in complex oil and gas projects, renewable energy farms, and data centres where cutting-edge technical specs are non-negotiable.

Nexans: Another global heavyweight, Nexans offers a massive portfolio of cables and complete cabling systems. While their expertise is broad, they're particularly strong in providing solutions for building automation, high-speed data transmission, and tough industrial environments. Their knack for innovation makes them a key supplier for many of the "smart building" projects taking shape.

Ultimately, the choice between a local or international supplier boils down to your project's specific needs, its scale, and its technical complexity. For a side-by-side comparison of the key players, dive into our detailed breakdown of the top cable manufacturers in UAE to find the perfect fit.

A Practical Framework for Choosing Your Cable Supplier

Picking the right partner from the sea of cable suppliers in UAE isn't just another item on your procurement list. It's a strategic move that can make or break your project's timeline, budget, and, most importantly, safety. It's easy to get fixated on the initial cost, but a truly robust evaluation means looking for a supplier who acts more like a partner than just a vendor. You need to dig deeper into their technical know-how, their logistical muscle, and their commitment to you after the sale is complete.

Think of it like hiring a key member of your project team. You wouldn’t just look at their salary demands, would you? You’d scrutinise their experience, their ability to solve problems on the fly, and how they perform under pressure. That’s the exact level of detail you need when selecting the company responsible for your project's entire electrical and data backbone.

Beyond the Price Tag: Technical Expertise and Inventory

A low price might catch your eye, but it’s worthless if the supplier doesn’t have the technical depth to guide you or the stock to deliver what you need. Your project needs a partner who gets the subtle differences between cable specifications and can offer solid advice, preventing you from making a very expensive mistake down the line.

Start by asking some direct questions about their team's background. A quality supplier should be able to confidently discuss the specific demands of your application, whether it's fire-resistant cables for critical life-safety systems or high-performance data cables needed for a smart building integration. This kind of expertise is becoming even more critical, especially when you consider the UAE cable connector market reached USD 1.17 billion in 2024—a testament to the complexity of modern systems. You can get more details from Stellar Market Research's report on this growing market.

Their inventory is just as crucial. A supplier with a deep and diverse stock can get you what you need quickly, which helps slash lead times and keeps your project moving. Don't be afraid to ask:

- Can you give me an immediate stock report for my critical items?

- What’s your typical lead time for cables that aren't in stock or need a custom order?

- Have you supplied projects on a similar scale to this one before?

Assessing Logistical Capabilities and After-Sales Support

You often see a supplier's true colours when things don't go perfectly. Their ability to handle tricky logistics and provide real support after they've made the sale is what separates the great from the good. Construction sites in the UAE are fast-paced, high-pressure environments where one late delivery can trigger a costly chain reaction of delays.

A supplier’s logistical network is the bridge between their warehouse and your worksite. If that bridge is weak, your entire project schedule is at risk. A reliable delivery promise is non-negotiable.

Probe into their delivery processes and support systems. Their answers will tell you everything you need to know about their commitment to being a genuine project partner.

- Material Traceability: Ask, "Can you provide full traceability documents for all materials, right from the manufacturer to our site?" This is non-negotiable for quality control and compliance.

- Urgent Delivery Protocol: Inquire, "What’s your process for handling an urgent, same-day, or next-day delivery to site?" A clear, established plan shows they're organised and prepared.

- After-Sales Support: Finally, question, "What does your after-sales technical support actually cover?" This could be anything from installation advice to helping troubleshoot an unexpected issue.

By using this framework, you shift the conversation from "who's the cheapest?" to "who's the most reliable partner for the job?". For a wider look at sourcing, our guide to finding the best electrical suppliers in Dubai offers even more practical tips for your procurement strategy.

Answering Your Top Questions About Sourcing Cables in the UAE

Even the most experienced project managers run into questions when sourcing materials in a market as fast-moving as the UAE. Getting straight answers is the key to avoiding expensive mistakes and feeling confident in your procurement choices. Let's tackle some of the most common questions that come up when dealing with cable suppliers in the UAE.

What’s the Biggest Mistake to Avoid When Buying Cables?

Without a doubt, the single most damaging mistake is chasing the lowest price at the expense of verified quality and compliance. It’s always tempting to cut costs on what looks like a simple commodity, but grabbing a "deal" on non-certified cables is a massive gamble.

This one decision can lead to your entire installation being rejected by inspectors, racking up huge financial penalties, and creating serious safety hazards that put people at risk.

Your first priority should always be verification. Before you sign anything, insist on seeing up-to-date certification documents from official bodies like ESMA and DCD.

Are International Cable Standards Good Enough for the UAE?

This is a really common point of confusion. While global standards from groups like the International Electrotechnical Commission (IEC) are well-respected and often form the backbone of local rules, they are not a direct replacement for UAE-specific approvals.

A cable can meet every single IEC standard perfectly, but if it doesn't have the mandatory ESMA approval, it is still considered non-compliant for projects in the UAE.

A good supplier will know this inside and out. They should be able to offer products that not only meet international quality benchmarks but also tick every box for the legal requirements here in the UAE.

How Can I Check a Supplier’s Stock and Lead Times for Real?

Empty promises about stock availability can bring a project to a dead stop. To get the real picture, you need to go beyond just taking their word for it and ask for actual proof.

Request a current, dated stock report that shows the specific cables you need are on hand. It's also a smart move to ask for a few references from past clients who handled projects of a similar scale. A trustworthy supplier will have a transparent inventory system and can give you delivery timelines you can actually count on.

For bigger or custom orders, they should have no problem mapping out a clear production and delivery schedule for you.

What Should I Look Out for with Custom Cable Orders?

Many large-scale projects, especially in industrial or high-tech fields, need specialised cables that you just can't buy off the shelf. When you're ordering these, crystal-clear communication is everything.

- Nail Down the Specs: Give them every technical detail you have and ask the supplier to confirm they have the capability to manufacture it precisely.

- Talk Timelines: Custom orders will always take longer. Get a firm production and delivery schedule in writing so there are no surprises.

- Minimum Order Quantities (MOQs): Custom manufacturing runs often require a minimum order. Make sure you confirm this number upfront to see if it fits your project's budget and needs.

Ultimately, you want to partner with a supplier who has a track record of handling custom work. They’ll have the right processes in place to navigate the complexities and get you the exact product you need without throwing your project off schedule.

Frequently Asked Questions

Here are some quick answers to other common queries we hear from project managers and procurement teams sourcing cables in the UAE.

| Question | Answer |

|---|---|

| Why is DCD approval so important? | Dubai Civil Defence (DCD) approval is mandatory for fire-resistant and fire-rated cables used in life-safety systems. Using non-approved cables will cause an immediate failed inspection. |

| Can a supplier help me choose the right cable? | Yes, an experienced supplier should act as a consultant. They can help you select the right specifications based on your project's electrical load, environmental conditions, and regulatory needs. |

| What's the difference between LV and MV cables? | LV (Low Voltage) cables are typically used for power distribution in residential and commercial buildings (up to 1 kV). MV (Medium Voltage) cables handle higher power loads for industrial facilities and distribution networks (1 kV to 35 kV). |

| How do I spot a counterfeit cable? | Look for poor print quality on the sheath, spelling mistakes, flimsy packaging, and an unusually low price. Most importantly, always verify the authenticity of the certification documents directly with the issuing authority. |

Choosing the right supplier means looking for a partner who not only provides materials but also offers genuine expertise and reliability.

For a partner who understands the nuances of the UAE market and provides certified, high-quality materials for projects of any scale, trust Yasu Trading Co. LLC. We offer a comprehensive range of building and construction essentials, backed by expert guidance and reliable delivery. Request your quote today at https://yasutrading.com.