A Guide to Calcium Silicate Board

Imagine you could wrap your building in a shield. Not just any shield, but one that could stand up to fire, repel intense heat, and shrug off moisture all at the same time. That's exactly what you get with a calcium silicate board—a remarkably tough, high-performance panel that brings incredible durability to modern construction.

Unpacking the Power of Calcium silicate Board

At its heart, a calcium silicate board is a specialized building material engineered to perform where others fail. It’s not just another sheet of drywall. Think of it more as a core component of your building’s safety and integrity system, designed from the ground up to handle extreme conditions.

The secret to its strength is a surprisingly simple formula. Manufacturers take naturally occurring minerals—siliceous and calcareous materials—and blend them with cellulose fibers for reinforcement. This mixture is then subjected to intense heat and pressure in a process called autoclaving, which triggers a chemical reaction. The result is a rock-solid, stable crystalline structure that gives the board its exceptional toughness.

Key Advantages in Modern Construction

The real value of calcium silicate board becomes crystal clear when you see the problems it solves on a real-world construction site. Its built-in properties make it a trusted choice for any project where safety and longevity are non-negotiable.

Here’s where it really shines:

- Enhanced Building Safety: First and foremost, it’s non-combustible. This isn't just a minor feature; it's a critical passive fire protection measure that can contain a fire, protect the building's structural steel, and buy precious time for people to evacuate.

- Improved Energy Efficiency: The board is also a fantastic thermal insulator. By helping to keep indoor temperatures steady, it takes a significant load off the HVAC system. Over the life of a building, that translates directly into lower energy bills.

- Superior Durability: It’s tough. Calcium silicate board stands up to moisture, rot, pests, and physical impact, offering a lasting solution that cuts down on maintenance and replacements—a key concept we explore in our guide on sustainable construction materials.

Simply put, choosing a calcium silicate board is an investment in the building's future. It’s a material that solves immediate construction challenges while delivering long-term protection and efficiency.

Why It Is Gaining Popularity

The entire construction industry is shifting. There's a huge push for buildings that are safer, more resilient, and more energy-efficient, and calcium silicate board hits all three of those targets perfectly. Its ability to act as a fire barrier, insulator, and durable liner all in one makes it an incredibly smart and efficient material.

Especially for builders in demanding climates like the UAE, where high heat and humidity are daily realities, this material is a game-changer. It provides a straightforward solution to complex environmental challenges, proving that sometimes, the simplest materials deliver the most powerful results.

Here is the rewritten section, crafted to sound completely human-written and natural, following all your specified requirements.

The Science Behind Its Superior Performance

So, what gives a calcium silicate board its impressive blend of strength and resilience? The secret isn't one single feature, but a whole collection of properties that work together to create a safer, more durable, and more efficient building.

To really get why it’s a go-to choice for tough construction environments, you have to look past the surface. It's about understanding the core mechanics that make it work. Each property ties directly to a real-world benefit you can see and feel on a project site.

Exceptional Fire Resistance

If there's one quality that puts calcium silicate boards in a class of their own, it's fire resistance. This isn't just a marketing line; it's baked right into the material's DNA. The boards are officially classified as non-combustible, consistently hitting a Euroclass A1 rating—the highest standard for fire safety you can get.

Think of it as a permanent, built-in fire shield for your walls and ceilings. When a fire breaks out, the board simply refuses to burn. It won't produce smoke or release dangerous flaming droplets. Instead, it holds its ground, maintaining its structural integrity and forming a tough barrier that contains the flames and heat. This passive fire protection is absolutely critical for shielding structural steel and keeping escape routes clear.

This ability to contain a fire isn’t just about ticking a box on a building code. It’s about providing real, life-saving protection for the people inside and safeguarding the building itself.

This performance makes the calcium silicate board an essential spec for fire-rated partitions, ceilings, and ductwork, especially in high-rise apartments, commercial towers, and industrial plants where you can't afford to compromise on safety.

Superior Thermal Insulation

Beyond just stopping fire, calcium silicate boards are fantastic thermal insulators. This comes down to their very low thermal conductivity, which is just a technical way of saying they're really bad at letting heat pass through them. The board's internal structure is full of microscopic air pockets that effectively trap thermal energy.

It works a lot like a high-end insulated flask. Here in the UAE, it’s a game-changer for keeping the blistering outdoor heat from seeping into the building, while also stopping your expensive, cooled air from escaping. This helps create a much more stable and comfortable indoor environment, which in turn drastically cuts down the load on your AC systems. The payoff? Lower energy bills and reduced running costs for years to come.

Impressive Moisture Resistance

Moisture is the silent enemy on any construction project, leading to mold, rot, and all sorts of material breakdown. Because a calcium silicate board is made from inorganic materials, it's naturally resistant to moisture. Unlike wood or even standard plasterboard, it gives mold nothing to feed on and won't rot or fall apart when exposed to high humidity.

This makes it the perfect material for those tricky, high-humidity spots, including:

- Bathrooms and Kitchens: Where steam and condensation are a daily reality.

- Soffits and Eaves: Areas that are constantly exposed to the elements.

- Mechanical Rooms: Often home to equipment that produces a lot of moisture.

Unwavering Dimensional Stability

Another key advantage is its dimensional stability. In simple terms, the board doesn't change its size or shape, even when temperatures and humidity levels are all over the place. It won’t warp, swell, or shrink like so many other building materials are prone to do. This stability is what keeps your paint finishes pristine and the joints between boards tight and seamless over the long haul.

That kind of reliability is a huge deal in climates with extreme temperature swings, guaranteeing a durable, low-maintenance finish that lasts. This robust nature is a big reason why its market is growing. The global calcium silicate insulation market—a core use for these boards—was projected to be worth USD 320 million by 2026, all driven by this powerful combination of thermal performance and strength. You can dive deeper into the market forces influencing high-performance building materials on marketsandmarkets.com.

Where Calcium Silicate Board Shines in Construction

Knowing the properties of a calcium silicate board is one thing, but seeing where it really proves its worth on a job site is something else entirely. This isn't just a material that looks good on a spec sheet; it's a genuine problem-solver, stepping up in situations where other boards would quickly fail. Its incredible versatility lets it go from protecting structural steel to lining a humid mechanical room without missing a beat.

Think of it as the specialist you bring in for the most critical plays. In modern building, especially for high-stakes projects like commercial towers or industrial plants, its unique blend of fire resistance, toughness, and stability makes it an indispensable part of the toolkit.

Building Fire-Safe Compartments

One of the most important jobs for calcium silicate board is creating fire-rated partitions and ceilings. The entire strategy for fire safety in large buildings hinges on compartmentation—the idea of dividing the structure into smaller, sealed-off zones to stop a fire in its tracks. Calcium silicate board is purpose-built for this.

When you use it for walls and ceilings, it creates a tough barrier that can hold back a fire for a specific amount of time, often up to two hours or even more. This is absolutely critical in places like:

- Commercial and Residential High-Rises: Protecting vital escape routes like stairwells and corridors.

- Hospitals and Schools: Giving vulnerable occupants the time they need to get to safety.

- Data Centers: Shielding mission-critical servers and equipment from catastrophic fire damage.

The board’s ability to keep its shape and strength under intense heat is what ensures these fire compartments actually work when you need them most. It buys precious time for evacuation and for firefighters to arrive and do their job.

Durable Linings and Soffits

But the board's toughness isn't just for fires. It’s also a fantastic choice for internal wall linings in high-traffic areas where things tend to get banged up. Its high mechanical strength means it can take a hit from a cart or a careless shoulder far better than standard drywall, making it perfect for busy hallways, public lobbies, and industrial workshops.

On top of that, its impressive moisture resistance makes it a far better option for soffits and eaves. These outdoor areas are constantly exposed to humidity and changing weather, but a calcium silicate board won't rot, warp, or become a breeding ground for mold. You get a clean, low-maintenance finish that lasts. This kind of resilience is a major reason for its growing popularity, a trend we're seeing among the top trending construction materials in Dubai and across the region.

Key Insight: The real value of calcium silicate board is that it's a multi-tool. A single panel delivers fire protection, moisture resistance, and a durable finish, which simplifies your material list and speeds up installation.

High-Temperature Industrial Insulation

Now let's step into the industrial world, where the demands get even tougher. In factories, power plants, and processing facilities, you have high-temperature pipes, ducts, and machinery that need serious insulation to keep processes efficient and protect workers.

This is where industrial-grade calcium silicate really excels. It can be easily fabricated into custom shapes to wrap around things like:

- High-Pressure Steam Pipes: To stop heat loss and keep energy costs down.

- Furnace Linings: Providing a stable, heat-resistant barrier against extreme temperatures.

- Exhaust Ducts: Protecting the surrounding structure from damaging heat.

This wide range of uses, from commercial construction to heavy industry, is fueling some serious market growth. The global calcium silicate board market was valued at around $919.3 million and is expected to hit $1.39 billion by 2034. That expansion, especially here in the Middle East, is being driven by new infrastructure projects and a sharp focus on high-performance, fire-safe building materials. From protecting skyscrapers to insulating factory pipes, its value is clear.

Choosing the Right Panel for Your Project

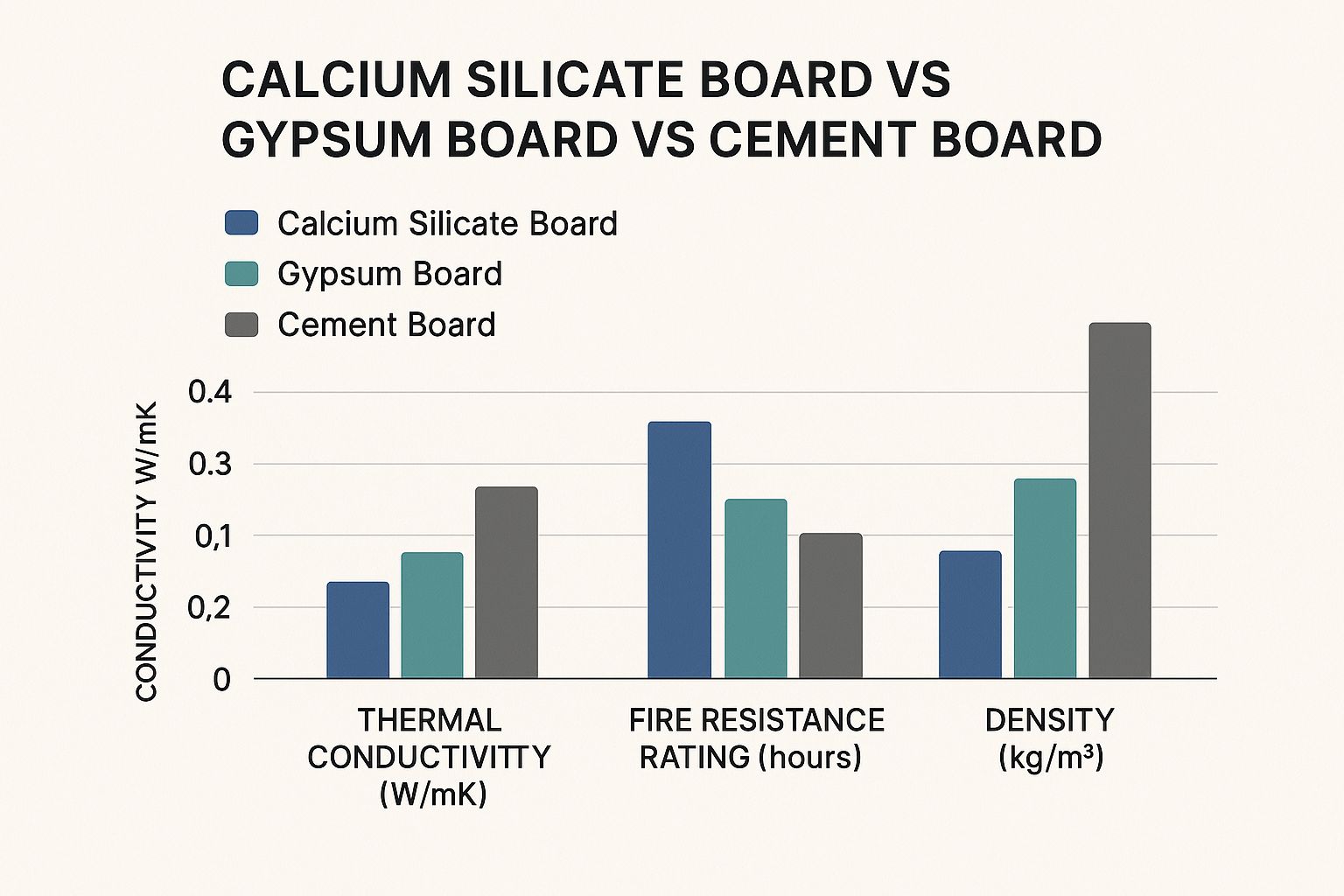

Picking the right building panel is one of those make-or-break decisions that ripples through the entire project, affecting safety, long-term durability, and of course, the budget. A calcium silicate board is a fantastic all-rounder with top-tier fire and moisture resistance, but it’s not the only player in the game. To make a smart call, you need to see how it stacks up against common alternatives like gypsum, fibre cement, and magnesium oxide (MgO) boards.

There’s no single "best" panel for every job—that’s a myth. The real goal is to match the material’s strengths to what the project demands. Sometimes, the low cost of one board is the deciding factor. In other situations, you simply can't compromise on fire performance or moisture resilience, and that's where the investment in a premium board pays for itself.

Performance Comparison of Building Boards

To give you a clearer picture, let's look at how these materials compare side-by-side. This table breaks down the key performance metrics for the most common building panels, helping you see where each one shines.

| Feature | Calcium Silicate Board | Gypsum Board (Plasterboard) | Fibre Cement Board | Magnesium Oxide (MgO) Board |

|---|---|---|---|---|

| Fire Resistance | Excellent (Non-combustible, A1 rated) | Poor to Fair (Fire-rated versions available) | Good (Non-combustible) | Excellent (Non-combustible) |

| Moisture Resistance | Excellent (Hydrophobic, dimensionally stable) | Poor (Prone to swelling, mould growth) | Excellent (Weather and water-resistant) | Excellent (Does not support mould) |

| Thermal Insulation | Excellent (Low thermal conductivity) | Poor (Low R-value) | Fair (Better than gypsum, not a primary insulator) | Good (Better than fibre cement) |

| Durability & Impact | Very Good (High impact resistance) | Poor (Easily damaged) | Excellent (Very robust and durable) | Good (Can be brittle) |

| Workability | Good (Can be cut with standard tools) | Excellent (Very easy to cut and install) | Fair (Requires specialised cutting tools) | Good (Relatively easy to work with) |

| Cost | High | Low | Moderate | Moderate to High |

As you can see, the trade-offs are clear. While gypsum is budget-friendly, it falls short in wet or high-risk areas. On the other hand, calcium silicate justifies its cost with superior performance where it matters most: fire safety, moisture control, and insulation.

Calcium Silicate Versus Gypsum Board

Almost everyone in construction knows gypsum board, or plasterboard. It's the go-to for interior walls in countless projects, mainly because it's cheap and incredibly easy to install. It gives you a smooth finish that’s ready for paint, and its light weight means crews can put it up fast.

But its weaknesses show up quickly when conditions get tough. Standard gypsum board hates water. Get it wet, and it will swell, start to crumble, and become a perfect breeding ground for mould. Even the fire-rated versions of gypsum can’t truly compete with the level of passive fire protection and high-temperature stability you get from a calcium silicate board.

So, the choice is pretty straightforward. For standard, dry interior walls on a tight budget, gypsum works. But for any space that needs serious fire separation, moisture proofing, or impact strength—think mechanical rooms, commercial kitchens, or life-safety corridors—calcium silicate is the only reliable choice.

Calcium Silicate Versus Fibre Cement Board

Fibre cement board is another tough contender, known for its sheer durability and ability to stand up to the weather. It shares some great traits with calcium silicate, like being resistant to moisture and pests. That's why you often see it used for external siding and facade panels that have to endure years of sun and rain.

Where they differ is in their DNA and what they do best. Fibre cement is a heavier, denser material, which can make it tougher to cut and handle on site. And while it has good fire resistance, a calcium silicate board is a far better thermal insulator and holds its own more consistently at extreme temperatures. This makes it the superior option for critical life-safety systems and industrial fire protection.

This data shows it perfectly. Fibre cement is the heavyweight champ in density, but calcium silicate strikes the ideal balance between low thermal conductivity and exceptional fire resistance.

Calcium Silicate Versus Magnesium Oxide (MgO) Board

Magnesium Oxide (MgO) boards are another modern panel that also delivers excellent performance against fire and water. In many ways, MgO is the closest rival to calcium silicate, since both are inorganic materials built for demanding environments. MgO boards are also often lighter, which can make them a bit easier to handle during installation.

The catch with MgO, however, has been consistency. The market has seen a lot of variation in quality and performance between manufacturers, with some past issues related to unreliable formulas. Calcium silicate, in contrast, is a more mature and standardized technology, so you get predictable, certified performance every time. More importantly, calcium silicate board has lower thermal conductivity, making it a better insulator. When you absolutely need proven passive fire protection and thermal efficiency, the reliability and superior insulation of calcium silicate give it a clear advantage.

Best Practices for Installation and Handling

A high-performance material like calcium silicate board is only as good as its installation. You can have the best board in the world, but if it's handled poorly on-site, you lose all the benefits you paid for. Think of it like a high-end sports car—it needs the right driver and a skilled mechanic to perform at its peak.

Following the right procedures from the moment the boards are delivered to the final coat of paint is non-negotiable. A sloppy job can compromise fire ratings, weaken moisture resistance, and ultimately turn a premium product into a liability. Getting it right the first time isn't just about good workmanship; it's about protecting your investment, saving time, and preventing costly rework down the line.

Essential Safety and Handling On-Site

First things first: safety. While calcium silicate board is non-toxic and contains no asbestos, the dust created when cutting it is the main thing to watch out for.

Always handle the boards with care to avoid chipping the edges or cracking the surface. Store them flat on a dry, level surface—never directly on the ground. Keep them under a cover to shield them from rain and prevent any accidental damage. This simple step keeps the boards in perfect condition right up until they're needed. Picking the right materials is the foundation of any durable project, a topic we explore further in our guide on how to choose reliable construction materials for the UAE climate.

Critical Safety Precaution: The biggest risk during installation is inhaling the fine silica dust from cutting. Anyone cutting the boards must wear proper respiratory protection, like an FFP2 or FFP3 mask. If you have a dust extraction system for your tools, use it. No excuses.

Tools and Techniques for Cutting and Fixing

You need the right tools for the job. Because calcium silicate board is so dense and durable, your standard plasterboard tools might not make the cut—literally.

For clean, straight cuts, a circular saw fitted with a polycrystalline diamond (PCD) blade is your best friend. A PCD blade is designed to handle the abrasive nature of the board, giving you a sharp edge without wearing out after a few uses. For smaller cutouts, like for electrical outlets or pipes, a simple score-and-snap technique with a heavy-duty utility knife works well.

When it's time to fix the boards to the frame, your choice of fastener is crucial. This is where many projects go wrong.

- Fasteners: Use corrosion-resistant, self-embedding head screws made for dense boards. They sink flush with the surface without over-driving and cracking the board.

- Framing: The board is only as strong as the structure behind it. Make sure your steel or timber frame is perfectly plumb, level, and built to spec.

- Spacing: Don't just guess. Follow the manufacturer's guidelines for screw spacing—usually around 200mm centres. This ensures the installation is solid and can handle the natural movements of a building.

Achieving a Perfect Finish with Jointing

The final, and arguably most important, step is the jointing. This is what creates a seamless, monolithic look and maintains the system's fire and acoustic integrity. Rushing this stage is a classic mistake that often results in visible cracks appearing weeks or months later.

Start by filling the tapered board edges with a high-quality, fire-rated jointing compound. Lay jointing tape over the wet compound, press it in firmly, and immediately apply a thin skim coat over the tape. Once it’s fully dry, a light sanding is all it takes to get a perfectly smooth surface, ready for primer and paint. Taking your time here is what separates an average job from a professional one.

Finding the Right Calcium Silicate Boards

Sourcing high-quality calcium silicate board is more than just a simple purchase. Think of it as a crucial investment in your project's safety, durability, and long-term performance. The truth is, not all boards are created equal, and the gap between a premium product and a cheap imitation can have serious consequences down the line. The key is to work with reputable suppliers who are completely transparent about what they're selling.

Any supplier worth their salt will readily provide a certified technical data sheet (TDS) for their boards. This isn't optional; it's essential. The TDS is your proof of performance, detailing everything from fire ratings and board density to thermal conductivity and strength, all backed by independent lab testing. If a supplier is hesitant to provide one, that's a major red flag.

Vetting Suppliers and Checking for Quality

When you're shortlisting suppliers, look for companies with a solid reputation here in the UAE. An established player understands the local building codes, climate challenges, and project standards inside and out. Don't be shy about asking for project references or case studies—seeing their materials in action on real-world sites speaks volumes.

It’s also worth considering how you buy. Globally, direct sales accounted for 61.34% of the market in 2024, which tells you that serious buyers prefer to go straight to the source, especially for large orders. This direct-from-supplier approach usually means better pricing and, more importantly, consistent quality control. For the kind of large-scale construction common in the UAE, this is often the smartest route. You can dig deeper into these global market trends and what they mean for the AE region with these insights from Consegic Business Intelligence.

When you get your hands on a sample, really look at it. A good quality board feels solid. It should have smooth, even surfaces, a consistent thickness across the entire board, and clean, sharp edges. Any warping, crumbling, or unevenness is a clear sign of a subpar product.

Matching the Board to the Job

Finally, make sure the board's specs are a perfect match for its intended use. Different applications demand different properties, so you need to get specific.

- For Fire-Rated Partitions: Your primary focus should be the certified fire rating—whether it's 60, 120, or 240 minutes—and the exact board thickness required to achieve it.

- For High-Moisture Areas: Look for a board with higher density and documented moisture resistance. This will prevent it from breaking down in damp environments like bathrooms or basements.

- For Thermal Insulation: The number you care about is the thermal conductivity (W/mK) on the TDS. The lower the number, the better the board is at insulating.

By taking a methodical approach and partnering with proven suppliers, you can ensure the calcium silicate board you specified on paper is the one that shows up on-site—ready to perform exactly as you need it to.

Common Questions About Calcium Silicate Board

Even after getting to grips with all the benefits, a few practical questions always pop up when you're thinking about using calcium silicate board. Let's tackle some of the most common ones head-on to clear up any confusion and help you make a confident decision.

Is Calcium Silicate Board Waterproof?

This is a big one. While standard calcium silicate boards are incredibly moisture-resistant, they aren’t technically waterproof on their own. They're fantastic for high-humidity spots like bathrooms, kitchens, or basements because they simply won't swell up, rot, or grow mold. Since they’re inorganic, mold has nothing to eat.

However, if you're planning to use it somewhere with constant, direct water contact—think inside a shower stall—you’ll want to apply a dedicated waterproofing membrane over the board. This creates a completely sealed, bulletproof system that stops any water from getting through.

Can I Paint Directly Onto Calcium Silicate Board?

Yes, absolutely. In fact, these boards offer a beautifully smooth, stable surface that painters love. Once you’ve properly filled and sanded the joints using the right compound, the board is primed and ready for its final look.

Go ahead and use a standard primer followed by your choice of water-based or acrylic paints. The board’s exceptional stability means no warping or swelling, so you get a professional, durable finish that will look great for years. It makes getting a high-quality finish surprisingly straightforward.

Key Takeaway: With a stable, inert surface and proper jointing, calcium silicate board is one of the best backings you can ask for when you need a top-quality, long-lasting painted finish, especially in tough environments.

Is This an Environmentally Friendly Material?

Calcium silicate board is definitely considered a sustainable choice in the building world. For starters, it’s made from natural, abundant raw materials like silica and lime, and it is 100% asbestos-free.

But its biggest contribution to the environment comes from its performance over time. Because these boards are so durable, they don't need to be replaced as often, which means less waste heading to the landfill. On top of that, their excellent thermal insulation properties help lower a building's energy use day in and day out, reducing its carbon footprint over its entire life.

How Does Its Weight Compare to Plasterboard?

You'll notice right away that calcium silicate boards are denser and heavier than standard gypsum plasterboard of the same thickness. That extra heft comes from their highly compressed and robust makeup.

Sure, this means they take a bit more muscle to handle and install, but the trade-off is more than worth it. That extra weight is exactly what gives them their superior strength, high-impact resistance, and better sound insulation. Think of the added density as a feature, not a bug—it’s what delivers that enhanced durability where standard plasterboard just wouldn't hold up.

When your project demands certified performance and durability that lasts, you need a partner you can trust. Yasu Trading Co. LLC supplies a complete range of premium construction materials, including top-tier calcium silicate boards, to meet the strict standards of any project in the UAE.