Cement Price in UAE: Affordable Rates & Trends

If you're trying to nail down your project budget, one of the first questions you'll ask is, "What's a bag of cement going to cost me?" In the UAE, a standard 50kg bag of Ordinary Portland Cement (OPC) will generally set you back somewhere between AED 12 and AED 16.

For more specialised jobs requiring Sulphate Resisting Cement (SRC), you can expect to pay a bit more, typically from AED 14 to AED 18. Of course, these are just ballpark figures. The final price you pay will always depend on who you're buying from, how much you're buying, and where your site is located.

A Snapshot of Current UAE Cement Market Prices

Getting a handle on the current cement price in the UAE is fundamental to any successful project. Think of these numbers as a solid starting point for your initial cost estimates, but remember they aren't set in stone. The market is constantly moving, influenced by a whole host of economic and supply chain factors that we’ll dig into later.

The UAE’s construction industry is the engine driving this demand. The cement market itself is a heavyweight, valued at roughly US$1.2 billion in 2024. It's not slowing down, either. Projections show it’s on track to hit US$1.48 billion by 2029, a clear sign of the non-stop development happening across the country. You can get a more detailed look into the UAE cement market's projected growth on IndexBox.

Average Cost Breakdown by Cement Type

To give you a clearer picture, it helps to break down the costs by the type of cement you'll actually be using.

The table below gives you a quick look at the average price ranges for the most common types of cement, sold by the 50kg bag. Keep in mind these are just estimates to help you with preliminary planning.

Average Cement Prices in the UAE (Per 50kg Bag)

A summary of estimated market prices for common types of cement available across the UAE. Prices are approximate and subject to change.

| Cement Type | Average Price Range (AED) |

|---|---|

| Ordinary Portland Cement (OPC) | AED 12 – AED 16 |

| Sulphate Resisting Cement (SRC) | AED 14 – AED 18 |

| White Cement | AED 35 – AED 45+ |

As you can see, there's a range for each type. The final invoice will be shaped by a few key variables:

- Location: Getting materials to a site in Dubai is a different ball game than delivering to Ras Al Khaimah. Logistics costs matter.

- Order Volume: This is a simple one—the more you buy, the better the per-bag price you'll get. Bulk orders always win.

- Supplier: You'll find different prices from the big manufacturers compared to local distributors or trading companies.

At the end of the day, the price you pay is never fixed until you have a quote in hand. Shop around and get a feel for the market before you commit.

Decoding the Factors That Drive Cement Costs

Trying to get a firm grip on the cement price in the UAE can sometimes feel like chasing a moving target. Prices seem to hold steady for a while, and then, almost overnight, they shift. But these fluctuations aren't random at all; they’re the result of a few key economic and logistical pressures working behind the scenes.

Think of it this way: the price on a bag of cement is like the final bill at a restaurant. It’s not just one item, but a combination of ingredients, preparation costs, and service charges. The main ingredients are the raw materials—limestone and clinker—which form the very foundation of cement. The global market price for these, plus the costs to quarry and process them, sets the baseline.

The Core Production Costs

From there, you have the manufacturing process itself, which is a real energy hog. Making cement means firing up a kiln to temperatures that soar past 1,450°C. That kind of heat requires a massive amount of electricity and fuel. So, whenever global or local energy prices spike, you can bet those extra costs will find their way into the cement price.

Then comes the journey from the factory to your site. Cement is heavy stuff. Moving it from the plant to a project in Dubai or Abu Dhabi isn't cheap. You have to factor in fuel for the trucks, vehicle maintenance, and the wages for the drivers. Every single one of those costs gets baked into the final price tag.

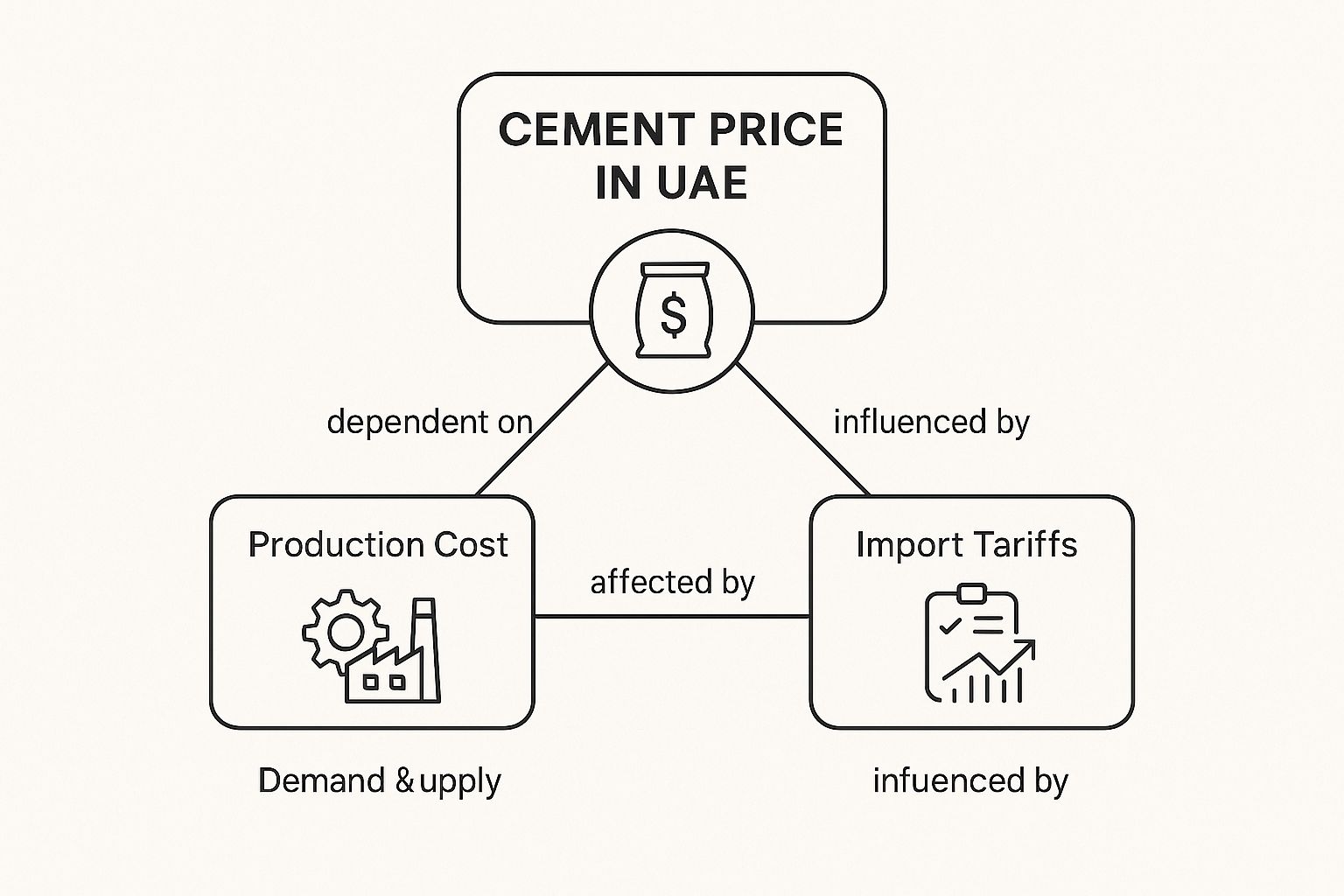

This infographic breaks down the main forces that shape what you pay for cement, from the factory floor to market dynamics.

As you can see, it’s a mix of production overheads, the classic push-and-pull of supply and demand, and even government policies that all come together to set the final price.

Market Forces: Supply and Demand

At the end of the day, simple economics is probably the biggest driver. When the UAE’s construction sector is booming—think major infrastructure rollouts or the lead-up to a global event—demand for cement goes through the roof. If suppliers can't keep up, prices inevitably climb.

On the flip side, when construction activity cools down, demand drops. Suppliers suddenly have more stock than buyers, and they'll often lower their prices to stay competitive and move their product. That's when contractors can find some great deals.

The price of cement is a direct reflection of the UAE's construction pulse. A surge in new projects immediately tightens the market, while a slowdown provides breathing room and often, better pricing for contractors.

Finally, you can't ignore government rules and import policies. These regulations are there to ensure all building materials meet crucial safety and quality standards, but complying with them adds to the manufacturer's costs. You can get a much clearer picture by navigating the regulations for building materials in the UAE in our guide. All these pieces—from a quarry in Ras Al Khaimah to a high-rise project in Dubai—fit together to determine the price of this essential material.

A Look Back at Cement Price Trends

To get a real grip on today's market, you have to look at where it's been. The story of the cement price in UAE is a rollercoaster, closely following the nation's ambitious growth. Think of it as a direct reflection of the construction industry's pulse.

When you look back, you can see clear patterns. Remember the massive construction boom leading up to iconic projects like the Burj Khalifa? The demand for building materials went through the roof. This created a classic seller's market—suppliers just couldn't keep up, and prices naturally shot up. It's a perfect example of how quickly things can change when major developments get underway.

On the flip side, we've also seen the market cool down. During global economic lulls or right after a wave of huge projects wraps up, construction activity slows. This takes the pressure off supply chains, and suddenly, pricing becomes much more competitive as suppliers vie for business.

From Price Peaks to Troughs

These cycles aren't just lines on a graph; they have a real impact on project budgets. The market has seen some wild swings over the years. We've gone from prices as low as US$2.40 per bag back in 2003 to highs of around US$6.80 per bag in the years that followed. That's a nearly threefold jump! This massive increase was driven by a combination of skyrocketing local demand and broader inflationary pressures, a story well-documented in reports like this one on the UAE cement sector's history from Global Cement.

Knowing this history is vital. It shows just how volatile the market can be and reminds us that today's prices are part of a much bigger, ongoing economic story.

When you understand these historical cycles—the construction booms that send prices soaring and the quiet spells that bring them back down—you can stop reacting to costs and start planning for them.

Making History Work for You Today

This isn't just a history lesson; it's a playbook for smart planning. By seeing how prices reacted to past events, contractors and developers can get much better at forecasting what might happen next.

This knowledge gives you a serious edge when making purchasing decisions. For instance:

- Spotting Price Hikes: Hear about a new mega-project announcement? That’s your cue that demand—and prices—are likely about to climb.

- Finding Buying Windows: During quieter construction periods, you'll likely find better prices and have more room to negotiate with suppliers.

- Smarter Budgeting: When you factor potential price swings into your project budget from the start, you build in a resilience that protects your bottom line.

This forward-thinking approach is crucial, especially when you're juggling costs for all the different materials a modern project requires. For a wider perspective, check out our guide on trending construction materials in Dubai. By learning from the past, you arm yourself with the foresight to navigate the current and future cement price in UAE with confidence.

Choosing the Right Cement for Your Project and Budget

Picking the right cement isn't just a technical detail—it's a critical decision that directly hits your project's structural integrity and your wallet. Get it wrong, and you could be looking at expensive repairs or a finish that just doesn't meet expectations. To really get a handle on the cement price in UAE, you first need to know what you're buying.

Think of it like choosing tools from a toolbox. You wouldn't use a sledgehammer for a delicate job, right? In the same way, you don’t need premium architectural cement for a simple foundation. Each type is engineered for specific jobs, different environments, and particular aesthetic goals.

Ordinary Portland Cement (OPC): The Industry Workhorse

Ordinary Portland Cement, or OPC, is the stuff you see on practically every construction site across the UAE. It's the dependable, all-purpose choice for a huge range of general construction work, from residential slabs and columns to massive infrastructure projects. Its wide availability and solid, all-round performance make it the most cost-effective option out there.

Because it's made in such huge volumes, OPC benefits from economies of scale, which helps keep the price down. It delivers reliable strength and durability for most everyday building needs, making it the true foundation of the construction industry.

Sulphate Resisting Cement (SRC): The Essential Protector

Now, when your project involves structures that will be exposed to aggressive soil or groundwater, Sulphate Resisting Cement (SRC) is non-negotiable. Many areas in the UAE have high sulphate levels in the soil and water, which can literally eat away at standard concrete over time. This chemical attack can seriously compromise the integrity of foundations and anything else underground.

SRC is specifically formulated to stand up to these harsh conditions. Of course, the specialised manufacturing process and added resilience mean SRC costs more than standard OPC. But that extra cost is an investment, not an expense—it’s an insurance policy against long-term decay, protecting the lifespan of the entire structure.

Choosing SRC for foundations in sulphate-rich ground isn't an upgrade; it's a necessity. The slightly higher upfront cost prevents catastrophic and eye-wateringly expensive structural failures down the line.

White Cement: The Architectural Finish

For projects where looks are everything, White Cement is the only way to go. Unlike the usual grey cements, it's produced from raw materials with extremely low iron content, giving it a clean, brilliant white finish. You'll see it used for high-end decorative work, terrazzo flooring, architectural concrete, and premium tile adhesives.

The careful selection of raw materials and the specialised production process make White Cement the most expensive option by a wide margin. Its price tag simply reflects its role as a premium finishing product, designed for visual impact rather than just brute strength.

Comparison of Common Cement Types in the UAE

To help you see the differences at a glance, we've put together a simple table. This should make it easier to match your project's technical needs with your budget.

| Cement Type | Primary Use Case | Key Feature | Relative Price |

|---|---|---|---|

| OPC | General construction, concrete slabs, beams | Versatile and widely available | $ |

| SRC | Foundations, coastal structures | High resistance to sulphate attack | $$ |

| White Cement | Decorative finishes, architectural features | High aesthetic quality and brightness | $$$ |

As you can see, the right choice really boils down to balancing performance requirements with cost. From the affordable versatility of OPC to the essential protection of SRC and the visual appeal of White Cement, there's a specific product for every application.

Navigating the UAE's Leading Cement Brands

When you start sourcing materials for a project in the UAE, you’ll quickly notice that a handful of big names dominate the cement market. Getting to know who they are and what they offer is your first step toward making a smart purchase. The cement price in UAE isn't just a number on an invoice; it's tied to the brand's reputation, consistency, and sheer production scale.

Think of these brands as tiers. You've got your premium players, the go-to for high-spec, landmark projects. Then there are the solid, mid-range workhorses that deliver a fantastic balance of performance and price. And, of course, you have budget-friendly options that help you stay on track for less critical applications.

Key Players in the UAE Cement Industry

The UAE is home to several massive cement producers, many of whom literally laid the foundation for the country's incredible growth. These companies run huge facilities, especially up in the northern emirates like Ras Al Khaimah, which sits on a goldmine of raw materials for cement manufacturing. Their size alone gives them a major say in market prices and availability.

You’ll see these names pop up again and again:

- RAK Cement: A powerhouse out of Ras Al Khaimah, known for its massive output and a distribution network that stretches across the region. They're a reliable, mainstream choice for many contractors.

- Union Cement Company (UCC): Also based in Ras Al Khaimah, UCC is one of the oldest and biggest producers in the game. They have a rock-solid reputation for quality you can count on.

- National Cement Co.: This Dubai-based company is a major supplier, especially for projects inside the emirate. They offer a whole range of products for different construction needs.

- Star Cement: As part of a larger international group, Star Cement has a strong foothold here, recognised for its modern plants and high-grade cement.

Aligning Brand Choice with Project Goals

Here’s the thing: picking a brand isn't about just finding the cheapest bag. Your project’s specific demands should be your guide. Are you working on a skyscraper or a critical piece of infrastructure? In that case, going with a premium brand known for its strict quality control is worth the extra cost for the peace of mind alone.

The brand of cement you select is a direct reflection of your project's standards. A premium brand offers assurance for high-stakes construction, while a value-focused option can be perfect for projects where budget is the primary driver.

For most residential or commercial builds, a reputable mid-range brand usually hits that sweet spot of proven performance and competitive pricing. The budget-friendly stuff? It’s perfectly fine for simpler jobs like boundary walls or non-structural concrete work where you don't need top-tier strength.

Getting this right is crucial, as cement is just one of many essential building materials for construction projects in Dubai you'll need to source well. Match the brand to your project's needs, and you'll be well on your way to optimising both your budget and the final result.

Smart Strategies for Purchasing Cement

Understanding the cement market is one thing, but actually turning that knowledge into savings? That’s where the real skill comes in. Securing the best cement price in UAE isn’t just about finding the cheapest supplier on a list; it’s a strategic game that protects your budget and keeps your project on track.

Think of these strategies as your go-to checklist every time you need to place a cement order. They’re practical, easy to implement, and designed to give you more control over one of your biggest material costs.

Always Secure Multiple Quotations

This is the oldest trick in the book for a reason: it works. Never, ever accept the first price you’re given. The UAE's cement market is packed with competition, meaning prices for the exact same product can swing wildly from one supplier to the next. Make it a rule to contact at least three to five different vendors—from the big manufacturers right down to local traders.

Doing this doesn't just hunt for the lowest number. It gives you an immediate, real-world snapshot of the current market rate, which is your most powerful negotiation tool. When suppliers know you're shopping around, you’d be surprised how quickly their "best price" gets even better.

Leverage the Power of Bulk Purchasing

Cement is a volume game, pure and simple. Suppliers love big orders, and they reward them with better pricing. If your project schedule and on-site storage can handle it, buying in larger quantities is a no-brainer. Ordering a full truckload instead of a few pallets here and there can shave a significant amount off the per-bag cost, and those savings add up fast.

Get together with your project manager and forecast your cement needs for the next few phases. Bundling those requirements into one larger order is one of the simplest ways to cut costs and reduce the headache of managing multiple deliveries.

Time Your Purchases Strategically

Like any commodity, cement prices ebb and flow with the market. The cement price in UAE feels the pressure of seasonal demand. During the busiest construction seasons or right before a major holiday, demand spikes and prices tend to climb.

Smart procurement is often about timing. Planning your big buys for off-peak periods when things are a bit slower can give you more negotiating power and access to better pricing.

Keep an eye on industry activity and try to schedule your major purchases for these lulls. A little bit of foresight goes a long way. It never hurts to ask your suppliers directly if they offer better rates during certain times of the year, either.

Final Checks Before You Buy

Before you sign off on that purchase order, a few last-minute checks can save you from a world of hurt down the line. This is about making sure you get exactly what you paid for, with no nasty surprises.

- Verify Manufacturing Dates: Cement has an expiry date. Always check the manufacturing date printed on the bags. Fresher is always better, so look for stock that's less than three months old to ensure you're getting optimal strength and workability.

- Clarify Delivery Terms: Don't get stung by hidden fees. Ask if the price includes delivery to your site, unloading, and VAT. A quote that looks like a bargain can quickly become expensive once you factor in all the logistical extras.

- Inspect on Arrival: When the truck pulls up, do a quick spot-check before the driver leaves. Make sure the bags are dry and intact, and that the brand and type match your order. A quick look can prevent a major problem.

By making these simple strategies a part of your regular purchasing process, you can navigate the market with confidence and lock in a fair cement price in UAE on every single project.

For all your construction needs, from foundational materials to finishing hardware, trust Yasu Trading Co. LLC to deliver quality and value. Get a competitive quote for your next project by visiting us at https://yasutrading.com.