Cement Price UAE: Latest Trends & Pricing Insights

If you're in the construction game in the UAE, you know that the price of cement is one of the most fundamental numbers you need to track. Right now, a standard 50kg bag of cement will set you back somewhere between AED 12 and AED 16.

That seemingly small figure is the bedrock of project budgeting, whether you're a major developer plotting a new skyscraper or a homeowner planning a simple extension.

An Overview of Cement Costs in the UAE

Getting a handle on cement costs is ground zero for any construction budget. The price per bag might not seem like much on its own, but those costs multiply quickly and can make or break your financial plan.

That price tag isn't just plucked out of thin air. It’s a direct reflection of complex market forces, raw material grades, and where different suppliers sit in the pecking order. For anyone planning a project, knowing these numbers isn't just helpful—it's absolutely critical. Think of it like this: you can't bake a cake without knowing the price of flour. It's the core ingredient, and without that baseline, your final cost estimate will always be off the mark.

Baseline Prices for Common Cement Types

So, let's get straight to the numbers. To give you a clear, practical starting point, we'll break down the average costs for the two workhorses of the UAE construction industry: Ordinary Portland Cement (OPC) and Sulphate Resisting Cement (SRC).

Each has its own job to do, and that specialisation is reflected in its price.

- Ordinary Portland Cement (OPC): This is your everyday, go-to cement. It's the versatile all-rounder used for everything from concrete slabs and blocks to mortar and plastering.

- Sulphate Resisting Cement (SRC): As the name suggests, this is a specialist product. It's engineered to protect structures from sulphate attack, making it essential for foundations, coastal projects, and any concrete that will be exposed to aggressive soil or water.

To make this even clearer, here’s a quick look at the current prices you can expect to find in the market.

Average Cement Prices in the UAE by Type

This table gives you a snapshot of the estimated price range for a standard 50kg bag of the most common cement types available across the UAE.

| Cement Type | Average Price Range (per 50kg bag) | Common Applications |

|---|---|---|

| Ordinary Portland Cement (OPC) | AED 12.50 – AED 14.00 | General construction, mortars, concrete blocks, plastering |

| Sulphate Resisting Cement (SRC) | AED 14.50 – AED 16.00 | Foundations, coastal structures, sewage systems, basements |

As you can see, the specialised nature of SRC comes with a slightly higher price tag. Knowing which type your project requires is the first step to building an accurate and reliable budget.

The Engine Room of the UAE’s Construction Boom

To really get a handle on cement prices in the UAE, you have to look past the cost of a single bag. We need to zoom out and see the sheer scale of the industry itself. Cement isn't just another building material here; it’s the bedrock of the nation's incredible ambition and its world-famous architectural wonders.

From the dizzying heights of the Burj Khalifa to the ever-expanding metro lines and sprawling new communities, cement is the quiet hero holding it all together. It's the essential ingredient in the UAE's recipe for progress.

Think of the UAE's construction sector as a colossal, high-performance engine. This engine is always running, powered by visionary national development plans, a steady flow of foreign investment, and a drive to build a futuristic urban landscape. In this analogy, cement is the high-octane fuel it guzzles. Whenever the engine roars to life for a new mega-project, the demand for this fuel skyrockets, and that has a direct impact on its price.

Market Size and What's on the Horizon

The numbers behind this "engine" are genuinely staggering. They paint a vivid picture of its immense power and influence on the national economy. We're talking about a multi-billion-dollar industry that is anything but static; it’s constantly expanding.

This non-stop growth creates a classic supply-and-demand scenario where production has to race just to keep pace. The UAE cement market was valued at roughly USD 1.97 billion in 2024. Projections show it growing at a compound annual growth rate (CAGR) of 5.2% over the next several years, expected to hit a market size of around USD 3.10 billion by 2033. For more detail, you can dig into the UAE cement market forecast on imarcgroup.com.

This constant forward momentum means that today's price isn't just about current costs—it’s also heavily influenced by what the market expects to need tomorrow.

How National Ambition Shapes the Price Tag

The UAE's grand strategic vision directly influences the cost of every bag of cement sold. Government-backed initiatives and massive developments create a predictable, long-term demand that suppliers have to plan for years in advance. These projects don't just need cement; they need mind-boggling quantities of it, setting a baseline of demand that underpins the entire market's stability and pricing structures.

The constant pipeline of national projects—from new airports and transport hubs to entire sustainable cities—acts as a powerful economic stabiliser for the cement industry. This ensures a consistent demand that keeps production facilities humming and investment flowing, but it also sets a pretty high floor for pricing.

So, when you see the cement price in the UAE, what you're really seeing is a reflection of this vibrant national ecosystem. The cost is inextricably tied to the pace of development. As long as the UAE continues to build its future, the cement industry will remain the powerful, indispensable engine driving it forward—and its price will reflect that crucial role.

What Really Drives Cement Prices Up or Down?

Ever wondered why a bag of cement costs one price today and something completely different tomorrow? The cement price in the UAE isn't a fixed number; it’s constantly moving, reacting to a whole network of economic pressures. Getting a handle on these drivers is the key to predicting costs and keeping your project budget on track.

Think of it like the price of fresh fish at the market. The cost can change daily based on the catch, the price of fuel for the boat, and whether there's a big public holiday increasing demand. It’s the same with cement. The price is tied to its core ingredients, the energy needed to make it, and the overall pulse of the construction market.

These moving parts create a fluid landscape. A shift in one area can send ripples all the way down the supply chain, ultimately changing the price you pay at the checkout.

The Cost of Core Ingredients

At its heart, making cement is all about raw materials. The main ingredient is limestone, which has to be dug out of the ground, crushed, and moved to the factory. Any bump in quarrying fees, labour wages, or transport costs for these raw materials inevitably gets passed on to the final product.

It’s not just limestone, either. Other materials like clay, shale, and iron ore are mixed in with precision. The availability and cost of these additives are just as important. If there's a shortage of one, or its price suddenly jumps, it throws off the entire cost formula and pushes up the market price for a bag of cement.

Energy and Production Expenses

Manufacturing cement is an incredibly energy-hungry process. We’re talking about heating massive kilns to temperatures hotter than 1,450°C to cook the raw materials into 'clinker'—the backbone of finished cement. This requires a huge amount of fuel, usually natural gas or coal.

Volatile energy markets have a direct and immediate impact on the cost of cement production. A sudden spike in global fuel prices acts like an unexpected tax on every bag produced, forcing manufacturers to adjust their pricing to maintain profitability.

It’s a bit like how a surge in petrol prices makes your online shopping delivery more expensive. The higher the cost to power the operation, the more the end-user has to pay.

Demand from Mega-Projects and Government Vision

The UAE’s ambitious national vision is a massive driver of cement demand. When a new metro line, airport expansion, or landmark development gets the green light, it instantly creates a colossal, long-term need for building materials.

This constant buzz of activity puts a healthy pressure on local supply chains, which in turn affects the overall cement price in the UAE. Suppliers have to scale up to fulfil these huge orders, and that can sometimes tighten up availability for smaller, everyday projects. This classic supply-and-demand tug-of-war is always at play.

On top of local factors, international economic pressures also have a say. Global trade dynamics, like tariffs and import duties, can influence material costs across the entire industry. To get a better sense of this, you can learn more about how US tariffs impact the UAE construction industry in our detailed article.

Choosing the Right Cement Brand and Type

Picking the right cement is far more than just ticking a box on a purchase order. It's a foundational decision that directly affects your project's structural integrity, budget, and even its timeline. Here in the UAE, the market is filled with options, from global powerhouses like Lafarge to highly respected local manufacturers.

It helps to think of it like choosing fuel for a car. You could put standard petrol in a high-performance sports car, and it would probably run. But you wouldn't get the performance it was built for, and you might even cause damage over time. The same logic applies to cement. Using a basic, all-purpose cement for a highly specialised job can lead to serious durability issues and expensive fixes later on.

Differentiating Key Cement Types

Before you even start comparing brands, you need to get familiar with the main types of cement on the market. Each one is engineered for a specific job, and knowing the difference is key to avoiding overspending on a product you don't need—or worse, using the wrong one for a critical application.

Ordinary Portland Cement (OPC): This is the go-to, the all-rounder of the cement world. It’s perfect for most general construction work like concrete slabs, mortar, and plastering. For everyday building needs, OPC offers solid, reliable strength.

Sulphate Resisting Cement (SRC): Think of this as the specialist for tough environments. SRC is essential for projects where the concrete will be exposed to high levels of sulphates in the soil or water, like foundations or coastal structures. This exposure can eat away at regular concrete, but SRC is built to withstand it.

White Cement: This one is all about aesthetics. White cement is the top choice for decorative finishes, architectural features, and creating vibrant, coloured mortars. It costs more to produce, so it’s usually reserved for projects where looks are a top priority.

Getting this first step right—matching the cement type to the job—is the smartest way to manage costs. Once you know what you need, you can start looking at suppliers. For a deeper dive, take a look at our ultimate guide to choosing the right building materials supplier in the UAE.

Major Brands and Their Market Standing

With the right cement type in mind, the next step is selecting a brand. The UAE market has a good mix of options at various price points, so you can find the right balance between cost and proven performance.

Choosing a supplier isn't just about the initial cement price in the UAE. It’s about securing a reliable partner who can guarantee consistent quality, timely deliveries, and the technical support your project demands.

To give you a better sense of the landscape, we’ve put together a quick comparison of some of the top cement brands you’ll find in the UAE. This table outlines their main products and where they typically fit into the market, helping you make a more informed choice.

Comparison of Top Cement Brands in the UAE

A comparative overview of major cement suppliers in the UAE, highlighting their key product offerings and market positioning to aid in purchasing decisions.

| Brand | Key Cement Types Offered | Typical Price Point | Best For |

|---|---|---|---|

| Lafarge | OPC, SRC, White Cement | Premium | Large-scale infrastructure projects and specialised applications requiring high performance and consistency. |

| Jebel Ali Cement | OPC, SRC | Mid-Range to Premium | Projects prioritising locally-sourced materials with a strong reputation for reliability and strength. |

| Union Cement | OPC, SRC, Oil Well Cement | Mid-Range to Premium | A wide range of construction, from residential buildings to demanding industrial and oil field applications. |

| National Cement | OPC, SRC | Competitive | General construction projects where a balance of cost-effectiveness and trusted quality is essential. |

| Fujairah Cement | OPC, SRC | Competitive | High-volume projects that need consistent supply and reliable performance without a premium price tag. |

Each brand has carved out its own niche, whether it's through specialised products like oil well cement from Union Cement or the cost-effective reliability offered by National and Fujairah Cement. Your final decision will depend on your project's specific technical requirements, your budget, and the level of service you expect from a supplier.

A Look Back at Cement Price Trends

To get a real feel for where cement prices might be heading, it pays to look at where they’ve been. The cement price in the UAE has never been static; it’s a story of constant flux, pushed and pulled by economic cycles, massive construction booms, and major global events. When you look back, you see a clear pattern of volatility, which is just part of the game in this industry.

Think of it like a ship's captain studying old nautical charts. Knowing where the hidden reefs and strong currents were in the past helps you navigate the waters ahead with much more confidence. The same idea applies here. Understanding past price swings gives you crucial context for what's happening in the market today.

The last two decades, in particular, tell a fascinating story. Take the run-up to a major event like Expo 2020, for example. Demand for cement went through the roof, which naturally put a lot of upward pressure on prices as suppliers scrambled to keep up with frantic construction schedules.

From Then to Now

This history really highlights how much things can change. Over the past twenty years, cement prices in the UAE have shifted dramatically. Back in 2003, you could pick up a bag of cement for as little as US$2.40. Fast forward to today, and that same bag costs nearly triple that, hovering around US$6.80.

This isn't just a random jump. That steady climb reflects everything from inflation and the rising cost of raw materials to the incredible, non-stop demand driven by the UAE's rapid urban expansion. For a deeper dive into this history, you can find some great insights into the long-term price evolution on globalcement.com.

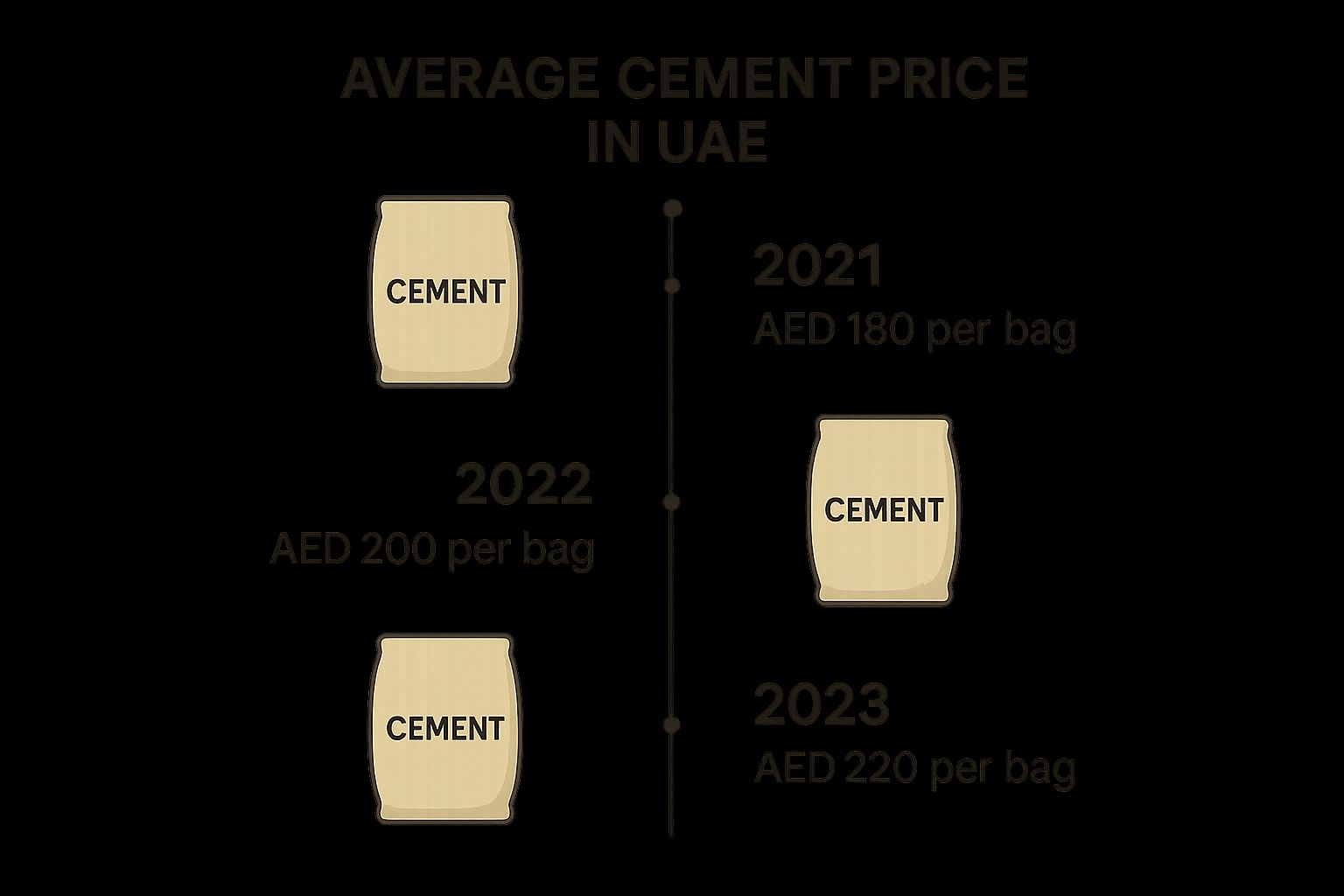

This simple graphic shows just how much the average price has increased over the last three years alone.

The data paints a clear picture: a consistent upward trend, showing how various market pressures have steadily pushed costs higher. By studying these patterns—both the long-term shifts and the recent year-on-year increases—you get a much better sense of the market's rhythm, helping you plan your project budgets with a sharper eye.

Smarter Ways to Source and Manage Cement Costs

Knowing the market is one thing, but turning that knowledge into actual savings is where the real skill lies. A proactive approach to how you buy cement can seriously slash your expenses and shield your budget from those unpredictable market swings. Smart sourcing isn't just about chasing the lowest cement price in the UAE; it's about fine-tuning your entire purchasing process to get the best possible value.

Think of it like doing the weekly grocery shop for a massive family. Popping out for a single carton of milk every day is a waste of time and money. Buying in bulk and planning meals ahead, however, saves on both fronts. The very same logic applies to construction materials, where buying at scale is the key to unlocking significant savings.

Optimising Your Procurement Strategy

Getting strategic about how you buy cement involves a few key moves. Each one is designed to tackle a different part of the procurement puzzle, from the initial order right through to final delivery. Putting these into practice can lead to some impressive cost reductions.

Embrace Bulk Purchasing: If you’re running a larger project, ordering cement in bulk directly from the manufacturers or major distributors is almost always going to get you a better price per unit. This simple step cuts out the middleman and means you're paying fewer delivery fees.

Negotiate with Multiple Suppliers: Never just accept the first quote that lands in your inbox. Get in touch with several reputable suppliers to create a bit of healthy competition. This gives you the upper hand to negotiate better terms—not just on the price tag, but on things like payment schedules and delivery options, too.

Schedule Deliveries Wisely: This one is crucial. You need to coordinate your cement deliveries so they arrive exactly when you need them on-site. If materials show up too early, you risk them getting damaged by the elements. If they're late, you're looking at expensive work stoppages. A tight schedule minimises waste and downtime.

Matching the Material to the Mission

A surprisingly common and costly mistake is over-engineering—that is, using a higher-grade, more expensive cement than the job actually calls for. Simply choosing the right type of cement for each specific task is a powerful way to keep costs in check.

Using a specialised Sulphate Resisting Cement for a simple interior plastering job is like using a surgical scalpel to butter your toast. It's an unnecessary expense. Always match the product's specifications to the project's real engineering needs to avoid paying for performance you don't require.

Smart procurement is a fundamental piece of good financial planning for any project. You can dive deeper into these tactics in our guide to https://yasutrading.com/blog/construction-cost-management/. Beyond the cost of materials, a solid grasp of the bigger financial picture is vital. For instance, exploring some general affordability tips for construction projects can help sharpen your overall budgeting skills.

Got Questions About UAE Cement Prices? We've Got Answers.

When you're dealing with a fundamental material like cement, a lot of questions can pop up. Whether you're a project manager, a contractor on the ground, or even a homeowner planning an extension, getting clear answers is key. Here, we tackle some of the most common queries we hear every day.

What’s the Biggest Thing That Will Affect Future Cement Prices?

If you want to get a feel for where cement prices are heading, look no further than the UAE's national infrastructure pipeline. While forecasting is never an exact science, this is the single biggest driver. The country's ambitious development plans create a huge, consistent demand that really sets the tone for the entire market.

Think about it: when a new mega-project gets the green light, it's like a sponge, soaking up massive quantities of materials. This inevitably tightens supply for everyone else, from smaller construction firms to individual builders. So, keeping an ear to the ground for government construction announcements is your best bet for anticipating future price hikes. A boom in large-scale projects almost always leads to a bump in prices across the board.

Can I Get a Better Price if I Buy a Lot?

Absolutely. In fact, you should insist on it. Buying in bulk is one of the smartest ways to bring down your cost per bag. Suppliers are almost always willing to negotiate better rates for large orders because it makes their lives easier—it simplifies logistics and guarantees a sale. For any project bigger than a small DIY job, negotiating a bulk deal isn't just a good idea; it's standard practice.

It's simple economics: buying one bag of cement is a retail transaction. Ordering an entire truckload? Now you're in the wholesale game. The price difference you see is a direct reflection of the supplier's improved efficiency, and they're usually happy to share that saving with you.

How Does the UAE Market Stack Up Against its Neighbours?

The UAE's cement market is arguably the most dynamic in the GCC. It's constantly fuelled by relentless urbanisation and a diversifying economy. The numbers back this up: the market grew at a steady clip of 6.1% annually between 2020 and 2024. Projections show it expanding from a value of US$1.15 billion in 2024 to US$1.48 billion by 2029.

This growth is built on strong demand from residential and commercial building, but the real engine is infrastructure. You can dive deeper into the specifics in this in-depth industry report. While prices here are competitive, they do tend to be a little higher than in neighbouring countries that don't have the same intensity in their construction pipelines.

For reliable building materials at competitive prices and expert advice that fits your project's unique needs, you can count on Yasu Trading Co. LLC. Make your procurement simple by requesting a quote today at https://yasutrading.com.