Construction Logistics UAE: Your Complete Strategy Guide

Understanding Construction Logistics In The UAE's Dynamic Market

Construction logistics in the UAE presents a unique set of opportunities and obstacles. This fast-paced market, known for its ambitious projects and rapid growth, requires careful planning and execution. Understanding the complexities of this environment is essential for project success.

The UAE: A Regional Logistics Hub

The UAE's strategic location and advanced infrastructure position it as a key logistics center for the region. This provides substantial benefits for construction projects. These advantages include efficient import and export procedures and access to a large network of suppliers.

Dubai's extensive port facilities and efficient transportation networks, for example, enable the smooth movement of construction materials. The country's open economic policies further encourage international trade and investment. This creates a competitive marketplace for construction supplies.

Navigating The Regulatory Landscape

Successfully managing the UAE's regulatory system is critical for efficient construction logistics. This involves a clear grasp of permit requirements, customs procedures, and local building codes.

Staying informed about these regulations can minimize delays and help ensure projects run without a hitch. Compliance with safety standards and environmental regulations is also paramount in the UAE’s construction sector.

Cultural Considerations and Regional Factors

Cultural nuances and regional influences play a significant role in construction logistics within the UAE. Building strong relationships with local stakeholders is vital for effective communication and collaboration.

Understanding local business practices and cultural sensitivities, for instance, can have a considerable impact on project timelines. Furthermore, accounting for regional aspects like climate conditions and local holidays is essential for precise planning and scheduling.

The UAE construction sector is a major driver of the region’s logistics market. Dubai alone announced a 16 billion AED roads development plan in 2025 to support urban and infrastructure growth. This investment reflects a broader trend. The UAE’s construction industry is projected to grow by 4.2% in 2025 and maintain a steady 4% Compound Annual Growth Rate (CAGR) from 2026 to 2029. You can find more detailed statistics here.

Practical Approaches To Construction Logistics

Effective construction logistics in the UAE requires practical strategies for material sourcing, inventory management, and site coordination. This includes using reliable inventory control systems to reduce waste and guarantee the prompt delivery of materials.

Optimizing transportation routes and using technology for real-time tracking can greatly improve efficiency. Careful coordination between various parties, including suppliers, contractors, and project managers, is also essential for smooth project execution. All these factors contribute to successful project completion within the UAE's competitive construction industry.

Digital Transformation That Actually Works In Construction

The UAE's construction industry is embracing new technologies to improve processes and increase efficiency. This move toward digital solutions is changing construction logistics. Companies can now use technology for better project results. Let's look at the digital tools making a difference in the UAE.

AI Tracking Systems: Smarter Logistics In Action

AI-powered tracking systems provide real-time information on the movement of materials and equipment. This technology helps optimize delivery routes, anticipate potential delays, and enhance project scheduling.

Imagine a project in Dubai using AI to track concrete deliveries. The system analyzes traffic and adjusts routes instantly, ensuring on-time delivery and minimizing delays. This reduces the risk of budget overruns and project setbacks.

IoT Monitoring: Real-Time Insights For Better Control

The Internet of Things (IoT) connects devices and equipment to the internet for a constant flow of data. In construction logistics, IoT sensors can monitor temperature, humidity, and vibration during transport.

IoT devices also track equipment location and status, helping prevent theft. This real-time information enables proactive maintenance and better resource allocation.

Blockchain Supply Chain Management: Enhancing Transparency And Trust

Blockchain technology can reshape construction logistics with transparent and secure supply chains. By recording each transaction on a shared, unchangeable record, blockchain builds trust between stakeholders.

The origin and movement of materials become easily verifiable. This removes discrepancies, reduces counterfeit materials, and improves accountability across the supply chain.

Emerging Tools: Drones And Predictive Analytics

Digital transformation in construction logistics goes beyond existing technologies. Drone monitoring gives aerial views of sites, allowing for progress tracking and issue identification. Predictive analytics uses data to forecast future trends and anticipate potential delays.

Choosing The Right Digital Solutions: A Practical Approach

The variety of available technologies can feel overwhelming. Choosing the right tools for your construction project doesn't have to be. Start by pinpointing your specific needs and challenges.

For example, if your project has complex deliveries across many locations, AI tracking and IoT monitoring could be important. The global logistics industry is growing rapidly, predicted to jump over 50% between 2020 and 2025, from $8 trillion to over $12 trillion. The UAE plays a key role in this growth, with construction logistics at the forefront. Find more statistics here. Next, evaluate available solutions based on cost, implementation time, and training needs.

Mastering Project Cargo And Heavy Equipment Logistics

Transporting heavy equipment and oversized cargo in the UAE demands careful planning and specialized expertise in construction logistics. It's like orchestrating a complex symphony: every element, from cranes and trucks to permits, must be perfectly coordinated for a successful delivery. This involves managing numerous moving parts, encompassing route planning and customs clearance, to keep your project on schedule.

Route Planning And Infrastructure Considerations

While the UAE boasts a modern infrastructure, transporting oversized loads presents unique challenges. Route planning must account for road weight restrictions, bridge clearances, and potential traffic bottlenecks. For instance, moving a large prefabricated building section through Dubai might necessitate permits for nighttime travel and specialized escort vehicles. This proactive approach minimizes costly delays and ensures the safe transport of valuable cargo.

Permit Acquisition And Stakeholder Alignment

Securing necessary permits in the UAE can be intricate. Successfully navigating this process requires a thorough understanding of local regulations and close collaboration with relevant authorities. This includes coordinating with municipalities, police departments, and road authorities for timely approvals. Furthermore, maintaining open communication with all stakeholders, from suppliers to contractors, is essential for seamless execution.

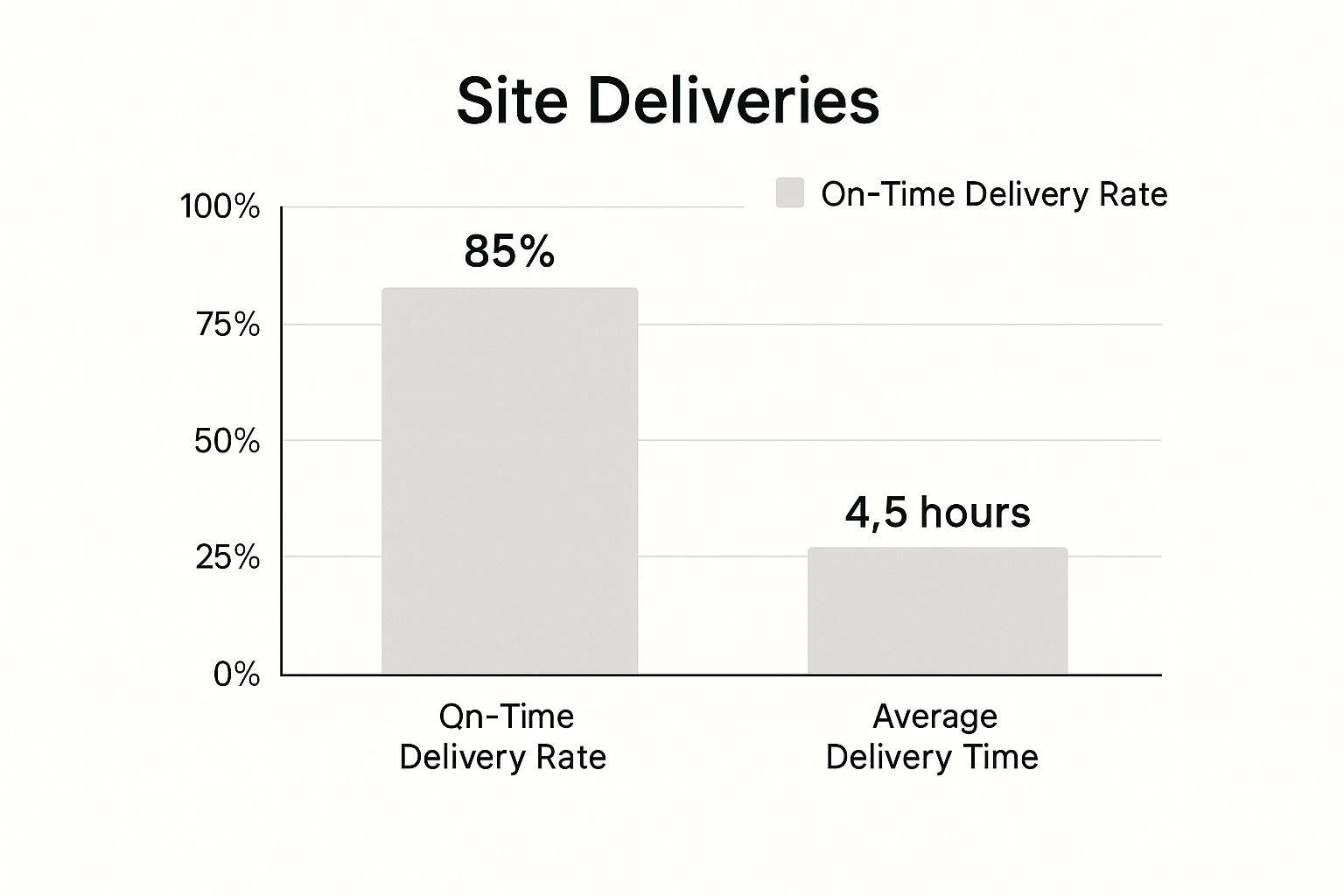

The infographic above illustrates on-time delivery rates and average delivery times for construction site deliveries. Achieving an on-time delivery rate of 85% while maintaining an average delivery time of 4.5 hours demonstrates the efficiency possible with well-executed construction logistics. This data highlights the importance of optimized processes in this dynamic industry.

Risk Management And Insurance

Transporting high-value project cargo inherently carries risks. Robust risk management strategies are crucial for protecting your investment. This includes comprehensive insurance coverage tailored to the specific cargo and chosen transport method. Contingency plans are also essential to mitigate potential disruptions from unforeseen events, such as unexpected weather delays or port closures.

Project Cargo Growth in the Middle East

Saudi Arabia and the UAE are leading the Middle East in construction logistics, with the UAE's focus on digital advancements setting it apart. The demand for specialized project cargo solutions is rapidly growing, with heavy cargo volumes increasing by over 10% in recent years. The UAE is projected to handle over 8 million tons of project cargo by 2030, primarily related to construction. For further insights, explore more about construction logistics in the Middle East here.

Working With Ports, Customs, And Specialized Providers

Effective project cargo management hinges on seamless collaboration with various entities. This involves close coordination with port authorities for efficient loading and unloading procedures. Navigating customs regulations requires meticulous documentation and adherence to import/export requirements. Choosing reputable specialized transport providers with experience handling oversized loads is critical for safe and timely delivery. You might also find helpful information on how to master construction waste disposal. Ultimately, effective coordination among all parties ensures your vital project components arrive on schedule and in optimal condition.

The following table provides a breakdown of different project cargo categories and their transportation requirements in the UAE:

Project Cargo Categories and Transportation Requirements

Comparison of different types of construction cargo, their specific handling requirements, and transportation considerations in the UAE market

| Cargo Type | Weight Range | Special Requirements | Transportation Method | Lead Time |

|---|---|---|---|---|

| Steel Beams | 10-50 tons | Crane lifting, secure lashing | Heavy-duty flatbed trucks | 7-10 days |

| Concrete Pipes | 5-20 tons | Specialized cradles, careful handling | Low-loader trailers | 5-7 days |

| Prefabricated Units | 20-100+ tons | Escort vehicles, route surveys | Modular trailers, SPMTs | 10-14 days |

| Generators | 2-10 tons | Climate control, vibration protection | Flatbed trucks, enclosed trailers | 3-5 days |

| Construction Equipment (Excavators, etc.) | 10-50 tons | Secure fastening, ramps | Low-loader trailers, RORO vessels | 7-10 days |

This table summarizes the diverse nature of project cargo and the specific considerations for each type, highlighting the importance of specialized equipment and logistical planning. Understanding these factors is crucial for successful project execution in the UAE's construction sector.

Building Supply Chains That Actually Deliver

Robust supply chains are the backbone of any successful construction project in the UAE. These intricate networks aren't established overnight. They require careful strategic planning and the cultivation of strong relationships with reliable partners. By learning from leading UAE construction companies, we can explore practical strategies for building supply chains that consistently deliver.

Supplier Selection and Contract Negotiation

Choosing the right suppliers is paramount. This involves a thorough assessment of potential suppliers based on several key factors. These include their track record, financial stability, and demonstrated commitment to quality. Think of it as carefully selecting ingredients for a complex recipe: high-quality inputs are essential for a successful final product.

Contract negotiation is equally important. Clear and comprehensive agreements should be established from the outset, outlining deliverables, payment terms, and dispute resolution processes. This establishes a solid foundation for a strong and mutually beneficial partnership.

Local Sourcing vs. International Networks

Balancing local sourcing with international suppliers can offer distinct advantages. Local suppliers often provide benefits such as shorter lead times and a deeper understanding of the UAE market.

International suppliers, on the other hand, may offer access to specialized materials or more competitive pricing. The optimal balance depends on the specific project needs and priorities. This could involve sourcing basic materials locally while importing specialized components from international suppliers.

Inventory Management and Just-In-Time Delivery

Effective inventory management is crucial for controlling costs and minimizing waste. Just-in-time (JIT) delivery is a valuable strategy that aims to deliver materials precisely when they are needed on-site. This approach reduces storage costs and minimizes the risk of material damage or obsolescence.

Implementing JIT effectively requires meticulous planning and collaboration with dependable suppliers. It's a carefully choreographed process where every step needs to be synchronized to avoid disruptions.

Collaborative Planning and Quality Assurance

Collaboration with suppliers is essential for a smoothly functioning supply chain. Sharing project schedules and forecasts allows suppliers to anticipate your needs and optimize their production and delivery schedules. This proactive approach helps maintain project momentum and minimize potential delays.

Quality assurance processes should be implemented throughout the supply chain. Regular inspections and clearly defined quality standards help ensure that materials meet project specifications and all relevant regulatory requirements. This proactive approach reduces the risk of costly rework and project delays.

Building Resilience in Your Supply Chain

Supply chain disruptions are an inevitable part of the construction industry. Building resilience is crucial for navigating these unexpected challenges. This includes having backup suppliers, diversifying sourcing locations, and nurturing strong relationships with your primary suppliers.

These strategies act as a safety net, allowing you to adapt and maintain project momentum even when faced with unforeseen circumstances.

Vendor Relationship Management: Creating Competitive Advantages

Effective vendor relationship management can create significant competitive advantages in the construction industry. Building strong relationships with key suppliers fosters a sense of partnership and a shared commitment to project success.

This collaborative approach leads to improved communication, faster problem-solving, and greater flexibility in meeting evolving project needs. Ultimately, strong vendor relationships improve efficiency and contribute to overall project success while maintaining effective cost control.

Warehouse Management That Supports Project Success

Your warehouse operations are essential to successful construction logistics. A well-managed warehouse can significantly influence project timelines and overall success, especially in a fast-paced market like the UAE. This involves ensuring the right materials are available at the right time and in the right location. Let's explore how to optimize warehouse operations for maximum efficiency and project success.

Designing For Efficiency: Layout And Space Optimization

The layout of your warehouse significantly impacts its efficiency. Carefully plan the flow of materials, from the moment they are received to when they are dispatched. Vertical stacking and narrow aisle racking can maximize space utilization while ensuring accessibility for forklifts and other equipment. Think of it as a well-organized kitchen, where everything is in its designated spot and easily accessible.

Security And Environmental Control: Protecting Your Assets

Proper storage is crucial, especially given the UAE's climate. Implementing climate control protects sensitive materials like adhesives, paints, and certain types of wood from extreme temperatures and humidity. Security measures, such as CCTV cameras, access control systems, and regular inventory checks, are vital for preventing theft and loss.

Inventory Tracking: Real-Time Visibility And Control

An effective inventory management system is essential for modern warehouse operations. Real-time tracking provides clear visibility into stock levels, material location, and anticipated needs. This prevents stockouts, minimizes waste, and ensures efficient resource allocation. Integrating this system with your project schedule ensures materials are available precisely when and where needed.

Quality Control: Preventing Costly Mistakes

Quality control within the warehouse is just as crucial as quality control on-site. Establish clear procedures for inspecting incoming materials, identifying defects, and ensuring proper storage. This proactive approach prevents costly delays and rework later on. Imagine discovering damaged tiles after they've been delivered to the site – a significant and avoidable setback.

Integration and Synchronization: Connecting Warehouse With Project Schedule

Integrating warehouse operations with your project schedule is key for synchronized construction logistics. This ensures materials are available when needed, eliminating delays and keeping projects on track. This synchronization streamlines logistics and speeds up project completion. Leading construction companies in the UAE are using integrated systems for real-time communication between the warehouse and project sites. For more insights on materials, see our guide on essential building materials for construction projects in Dubai.

Flexibility and Adaptability: Responding To Changing Requirements

Construction projects rarely proceed exactly as planned. Your warehouse operations must be flexible enough to handle unexpected changes in project scope or timeline. This requires adaptable storage solutions, responsive inventory management, and open communication with all stakeholders. This adaptability keeps logistics efficient even when project requirements shift.

To further illustrate the importance of choosing the right system for your warehouse, take a look at the comparison table below:

Construction Warehouse Management Systems Comparison: Analysis of popular warehouse management platforms used in UAE construction projects, comparing features, costs, and implementation requirements.

| System Name | Key Features | Project Size Suitability | Integration Capabilities | Cost Range |

|---|---|---|---|---|

| Example System 1 | Inventory tracking, reporting, forecasting | Small to Medium | ERP, Accounting Software | $500 - $1500/month |

| Example System 2 | Advanced analytics, mobile app, multi-warehouse support | Medium to Large | CRM, Project Management Software | $1500 - $5000/month |

| Example System 3 | Customizable workflows, RFID integration, automated replenishment | Large to Enterprise | Supply Chain Management Platforms | $5000+/month |

This table provides a brief overview of some popular warehouse management systems. The specific system that best suits your needs will depend on the size and complexity of your projects, as well as your budget. Choosing the right system can drastically improve efficiency and project success.

Cost Management And Performance Metrics That Matter

Construction logistics isn't simply about moving materials. It's about moving them efficiently and affordably. In the competitive UAE construction market, managing costs and tracking the right performance metrics can significantly impact your project's budget. This means understanding not just what to measure, but how to use those measurements to enhance your overall logistics plan.

Frameworks For Budgeting Logistics Operations

Building a realistic budget for construction logistics requires more than just estimating transportation costs. A robust framework needs to account for variables like changing fuel prices, potential delays, and storage expenses. It's similar to planning a road trip: you factor in not just gas, but also potential tolls, food, and perhaps even a hotel if there are unexpected detours.

Also, consider adding contingency funds for unexpected events. For instance, a sudden spike in demand for certain materials could impact pricing. Having a buffer in your budget lets you adapt to these fluctuations without disrupting the project.

Key Performance Indicators (KPIs) For Project Success

Choosing the right Key Performance Indicators (KPIs) is crucial for assessing the effectiveness of your construction logistics. On-time delivery rates, transportation costs per unit, and inventory turnover rate are just a few examples. These metrics offer valuable insights into areas for improvement.

For example, a consistently low on-time delivery rate might point to problems with your transportation provider or warehouse operations. Tracking these KPIs allows you to proactively address these challenges. You might find this helpful: How to master timely deliveries.

Tracking Systems and Actionable Insights

Modern tracking systems, using technology like GPS and RFID, offer real-time visibility into material movement. This data lets you pinpoint bottlenecks, optimize routes, and boost overall efficiency. Think of it as having a live map of your logistics network, showing you precisely where everything is and how it's moving.

However, data alone isn't sufficient. Turning this data into actionable insights is key. This means analyzing the data to spot trends, understand the root causes of issues, and develop solutions that improve performance.

Benchmarking and Identifying Improvement Opportunities

Benchmarking your logistics performance against industry standards or competitors can reveal where you excel and where you lag behind. This comparison highlights opportunities for improvement and helps you set realistic targets for optimization.

This process involves identifying key metrics, gathering data on your performance, and comparing it against industry averages or top performers. This helps you pinpoint gaps and create strategies to bridge them.

Measuring ROI For Logistics Improvements

When investing in new logistics technologies or processes, it's important to measure the return on investment (ROI). This involves calculating the cost of the improvement and weighing it against the resulting benefits, such as lower transportation costs or faster delivery times. This helps justify investments and demonstrates the value of logistics optimization.

For example, investing in a new warehouse management system might have a significant upfront cost. However, the resulting gains in efficiency and reduced storage expenses could quickly offset that initial investment.

Cost-Saving Strategies Without Compromising Quality

Cost management shouldn't sacrifice quality or safety. Explore cost-saving strategies that maintain these vital standards. This could include negotiating better rates with suppliers, optimizing transportation routes, or implementing more efficient inventory management procedures.

Stakeholder Communication and Reporting

Keeping stakeholders updated on logistics performance is essential for building trust and maintaining alignment. Regular reports, dashboards, and presentations should clearly convey key metrics, progress updates, and areas of focus. This ensures everyone is informed and working towards shared goals.

Effective communication builds confidence and promotes a collaborative approach to problem-solving.

For all your construction hardware and material needs in the UAE, partner with Yasu Trading Co. LLC. Our commitment to quality, competitive pricing, and timely delivery ensures your project's success. Contact us today for a quote and experience the difference.