Choosing Construction Safety Equipment Suppliers in the UAE

Your construction safety equipment supplier isn't just another vendor on your list. They’re your most important partner in managing risk on the job site. The quality of their gear and their reliability have a direct, real-world impact on every single person on your crew. Honestly, picking the right one is one of the most critical decisions a project manager can make.

Why Your Supplier Is Your Most Critical Safety Partner

Picture your safety plan as a chain. Every single link—from the site foreman down to the newest hire—depends on the one before it for support and security. Your construction safety equipment suppliers are the very first, most foundational link in that chain.

If that first link is weak, everything that follows is at risk. Think about it: a faulty harness, a subpar helmet, or uncertified gear compromises your entire safety structure before anyone even clocks in. This isn't just about a product failing; it's about preventing a potential catastrophe.

This reality puts a lot of pressure on project managers, especially in the fast-paced UAE construction market. You have to sort through a sea of suppliers to find someone who is more than just a salesperson. You need a partner who doesn’t just take orders but delivers peace of mind, genuine expertise, and certified gear that protects your people, your project, and your reputation.

The Growing Demand for Reliable Partners

The stakes have never been higher. With massive infrastructure projects and tougher safety laws, the regional market for personal protective equipment (PPE) is booming. It was valued at over US$ 3.9 billion in 2022 and is expected to climb to nearly US$ 6 billion by 2030. The UAE is at the forefront of this push for stricter safety enforcement.

This massive growth highlights a clear and urgent need: we need suppliers who are not just reliable, but who can keep up with the increasing demand and ever-changing compliance rules. You can get a better sense of this trend from a detailed market analysis on the industrial PPE sector.

A great supplier relationship is more than just a transaction. It’s a true partnership. Your supplier should understand the unique hazards of your project and deliver solutions that are a core part of your risk management strategy, not just an afterthought.

From Vendor to Strategic Ally

The real trick is to stop thinking of your supplier as a cost you have to manage and start seeing them as a strategic asset. A purely transactional view focuses on price and little else. A partnership, on the other hand, is built on value, trust, and expertise.

A true partner brings a lot more to the table:

- Certified and Compliant Gear: They won't just say their products are good; they'll provide clear proof that everything meets or exceeds both local and international safety standards.

- Technical Expertise: Their team should be able to give you solid advice on the right equipment for specific, high-risk jobs, whether it's working at heights or in confined spaces. To make sure you have all your bases covered, take a look at our complete guide on essential safety equipment for construction sites.

- Inventory and Logistics: A good partner keeps plenty of stock and delivers on time, every time. This prevents those frustrating and costly project delays that happen when you're waiting on critical equipment.

In the end, choosing from the many construction safety equipment suppliers out there is one of the most impactful decisions you'll make. It’s a direct investment in your team’s safety and the smooth success of your project.

Decoding UAE Safety Standards and Certifications

Trying to understand safety regulations can feel like learning a new language. For construction safety gear in the UAE, this language is spoken through certifications. Think of these standards as a mandatory passport for your equipment. Without the right stamp, it simply isn't allowed on a compliant worksite.

These certifications are your guarantee that a product has been put through its paces and meets specific performance benchmarks. They’re what separates a simple hard hat from a life-saving tool backed by serious science and engineering. Any construction safety equipment suppliers worth their salt will make these certifications a top priority and readily provide proof.

When you start looking at equipment, you'll run into a few key international certifications that are recognized and respected across the UAE’s construction sector. Each one comes from a different part of the world, but they all share the same goal: confirming a product is safe, reliable, and does what it says it will do.

Understanding Key Global Certifications

Getting a handle on the alphabet soup of safety standards is your first real step toward compliance. While countless standards exist for specific gear, three main bodies really set the tone for quality and safety around the globe. For any project manager, knowing what they stand for is non-negotiable.

- ANSI (American National Standards Institute): This is the gold standard in the United States. If you see an ANSI rating on a helmet or a pair of safety glasses, it’s been through the wringer of American testing for things like impact resistance.

- EN (European Norm): This is the harmonized standard used all across Europe. EN standards are incredibly specific, often breaking down into detailed codes for different types of protection—like EN 388 for gloves or EN 361 for fall-arrest harnesses.

- CE (Conformité Européenne): This mark shows a product meets the EU’s strict health, safety, and environmental protection rules. For personal protective equipment (PPE), the CE mark is basically a manufacturer's promise that the item ticks all the necessary boxes.

Here in the UAE, gear that meets any of these major international standards is typically good to go, as our local rules are built on these same global best practices. This principle doesn’t just apply to PPE, either. You can learn more by navigating the regulations for building materials in the UAE to see how this plays out across the entire industry.

How to Verify Genuine Certifications

Here’s the hard truth: counterfeit gear with fake certification labels is a massive risk. A fraudulent sticker offers precisely zero protection when things go wrong. That means you have to be relentless about checking that a supplier's claims are legitimate.

A real certification isn't just a label stuck on a product; it’s documented proof that the equipment passed specific, rigorous tests. Never, ever take a sticker at face value.

To keep your team and your project safe, build a simple verification habit. First, always ask your supplier for a formal Certificate of Conformity for the specific batch you’re buying. A reputable supplier will have this ready for you, no questions asked.

You can also do a little digging yourself by cross-referencing the product model number and certification details on the public database of the organization that issued it (like ANSI or a CE-notified body). Finally, a huge sign of authenticity is buying from an authorized distributor for major safety brands. These distributors are held accountable by the manufacturers themselves, which gives you a powerful extra layer of trust.

A Practical Framework for Vetting Suppliers

Choosing from a list of construction safety equipment suppliers is about more than just comparing price tags. You're not just buying a product; you're looking for a partner. The best suppliers act more like consultants, guiding you to the right equipment for specific job site hazards and making sure your crew is genuinely protected.

This isn't something you can do on the fly. You need a solid framework to look past the sales pitch and size up what really matters: their product range, how much they keep in stock, and whether their delivery trucks show up on time. A supplier who can't get certified gear to your site when you need it is a liability, plain and simple.

The goal here is to shift your mindset. Stop thinking of procurement as just another purchase order. Instead, view it as building a strategic alliance that underpins the long-term safety and success of your projects. That means doing your homework on their reputation, their quality control, and the support they offer after they’ve made the sale.

Evaluating Product Range and Expertise

First things first, take a hard look at what they actually sell. A top-tier supplier doesn’t just have a random assortment of gear. They offer a carefully curated selection from reputable, certified brands. They should be a one-stop shop, covering everything from the basics like hard hats and hi-vis vests to more specialized gear like fall protection systems and respiratory equipment.

This is a huge deal in the UAE’s demanding construction environment. The building boom, supercharged by massive projects for events like Expo 2020, sent the demand for reliable safety equipment through the roof. Back in 2015, the Middle East's construction pipeline was already poised to deliver projects worth an incredible USD $500 billion. This forced suppliers to source products suited for local challenges like extreme heat and to partner with global brands to meet rigorous safety standards. You can learn more about the evolution of PPE in the Middle East to get the full picture.

But it’s not just about the products. You need to gauge the expertise of their team. Can they confidently answer your technical questions about EN or ANSI standards? Can they explain why you need one type of respirator for silica dust and another for chemical fumes? A supplier with a knowledgeable team is an asset you can’t put a price on.

Assessing Inventory and Logistical Strength

A beautiful catalog is useless if the items are always out of stock. Before you sign any contracts, you need to dig into their inventory management and logistics. Delays in getting your hands on critical safety gear can bring a project to a grinding halt, costing you both time and money.

Don't be shy about asking direct questions:

- Stock Levels: How much inventory do you typically carry for essential items like helmets, gloves, and harnesses?

- Delivery Speed: What’s your standard delivery window for orders within Dubai or Abu Dhabi? Can you handle an urgent, next-day request if we’re in a bind?

- Supply Chain Integrity: Where do you get your products? Are you an authorized distributor for the brands you sell?

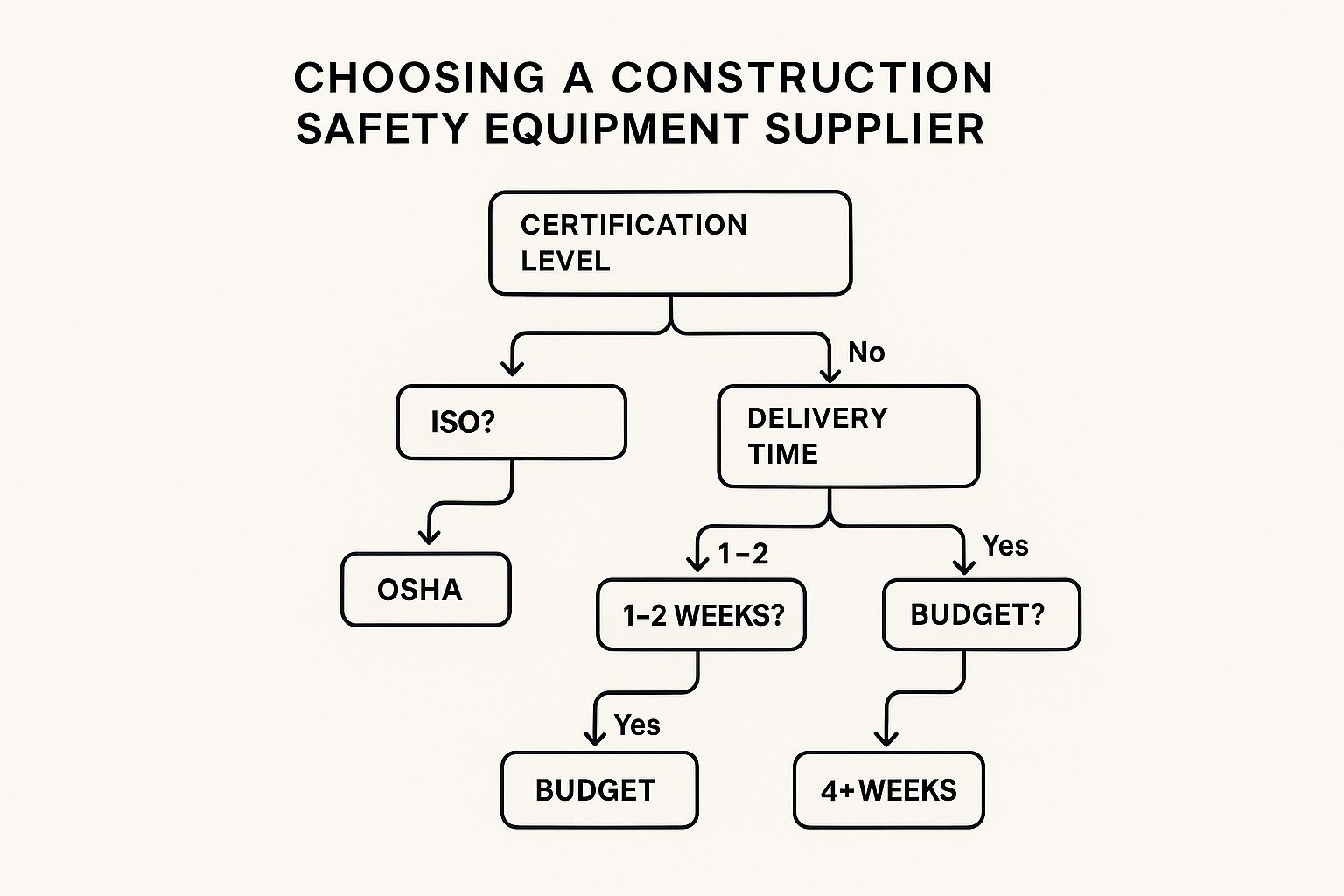

This entire process can feel overwhelming, but a simple decision tree can help cut through the noise. This visual guide helps you weigh the key factors—certification, delivery speed, and cost—against your project's specific needs.

As the infographic shows, it’s all about finding the right balance. Sometimes you need premium, certified gear no matter the cost, while other times budget and timeline are the driving forces.

A supplier's warehouse and delivery fleet are just as important as their showroom. Their ability to consistently and reliably get you what you need, when you need it, is a direct measure of their value as a partner.

To make this evaluation more structured, use a checklist to compare potential suppliers side-by-side. This ensures you're asking the same critical questions of everyone and making a decision based on facts, not just feelings.

Supplier Vetting Checklist

| Evaluation Criteria | Questions to Ask | Ideal Response/Indication |

|---|---|---|

| Certifications & Compliance | Can you provide documentation for ANSI/EN certifications for your products? | Yes, readily available and up-to-date documentation for all relevant items. |

| Product Range & Quality | Do you stock a comprehensive range of PPE from reputable brands? | A wide selection from well-known, trusted manufacturers. |

| Inventory & Availability | What are your typical stock levels for high-demand items? | Large, consistent inventory to prevent backorders on critical equipment. |

| Logistics & Delivery | What is your average delivery time? Do you offer expedited shipping? | Clear timeframes (e.g., 24-48 hours locally) with options for urgent needs. |

| Technical Expertise | Can your team advise on the right product for specific site hazards? | Knowledgeable staff who can provide technical guidance and recommendations. |

| Reputation & References | Can you provide references from other contractors in our industry? | Willing to share positive client testimonials and has a strong market reputation. |

| After-Sales Support | What is your policy on warranties, returns, and defective products? | A clear, fair, and hassle-free process that shows they stand by their products. |

Using a checklist like this helps you standardize your approach, ensuring no stone is left unturned in your search for a true safety partner.

Investigating Reputation and After-Sales Support

Finally, it’s time to check their reputation. What are other contractors and project managers saying about them? A solid reputation in this industry isn't bought; it's earned through years of consistent, reliable performance.

Hunt for online reviews, ask for a list of client references, and check how long they’ve been operating in the UAE. A company with deep roots in the local market usually has a much better grasp of the specific challenges and requirements here.

Just as important is what happens after the transaction. Does the supplier offer clear warranty policies? Is their process for returning defective items straightforward? This kind of after-sales support is the hallmark of a company that’s in it for the long haul—a true safety partner who stands behind their products.

Calculating the True Cost of Safety Gear

When you're sourcing safety equipment, it’s easy to let the price tag do all the talking. But that initial number? It’s only a tiny piece of the financial puzzle. A smart procurement strategy digs deeper, looking at the Total Cost of Ownership (TCO) to understand the real impact of your choices down the line.

Think about it like buying a car. You could grab a cheap, beat-up vehicle and save a bundle upfront. But after you factor in the constant repairs, awful gas mileage, and the inevitable day it leaves you stranded, you realize you would have been far better off with a more reliable model. Safety gear is no different—the cheapest option is almost never the most cost-effective one.

Any construction safety equipment suppliers worth their salt know this. They'll guide you to see safety gear not as a disposable line item, but as a critical investment in your people, your productivity, and the overall stability of your project.

The Hidden Costs of Low-Quality Gear

Going for budget equipment almost always backfires, introducing a whole raft of hidden costs that can quietly drain your project’s budget. These expenses don't always show up on a spreadsheet, but they hit your bottom line hard.

They usually fall into three buckets:

- Frequent Replacements: Cheap gear just doesn't last. A low-grade hard hat might crack after one minor knock. A flimsy harness could fail an inspection after just a few months. Suddenly, you're buying the same items over and over again.

- Lost Productivity: Uncomfortable or poorly designed PPE is a productivity killer. When workers are wrestling with stiff gloves or fighting off a headache from an unbalanced helmet, they’re slower, more distracted, and get tired faster. That lost time adds up.

- Equipment Failure Catastrophes: This is the big one. When gear fails, the fallout is immediate and severe. It creates a financial ripple effect that can put the entire project, and even the company, in jeopardy.

The real measure of safety equipment isn't what you pay for it, but what it costs you when it fails. Investing in quality from a trusted supplier is your best insurance against catastrophic financial and human loss.

Breaking Down the Financial Fallout

A single incident caused by faulty equipment unleashes a staggering cascade of costs. We're not just talking about a one-off fine; it's a chain reaction of expenses that can cripple a project’s budget and tarnish a company's reputation for years.

The Anatomy of a Failure Event

| Cost Category | Description & Impact |

|---|---|

| Immediate Project Delays | An incident brings work to a screeching halt, leading to expensive downtime for your entire crew and all that idle machinery. |

| Regulatory Fines | The authorities don't take safety breaches lightly. You can expect heavy penalties, often running into thousands of dirhams. |

| Legal & Insurance Costs | Get ready for skyrocketing insurance premiums and the potential for long, draining legal battles that eat up time and money. |

| Reputational Damage | Word gets around. A serious incident makes it much harder to win future contracts and attract the skilled workers you need. |

This is precisely where partnering with a high-quality supplier proves its worth. By providing durable, ergonomic, and fully certified equipment, they help you sidestep these devastating costs. The small premium you pay for quality gear is nothing compared to the immense financial damage of a single failure.

This principle of investing in reliability extends to all site materials, a topic we explore more deeply in our guide to choosing building hardware in Dubai. At the end of the day, smart procurement is about buying certainty and shielding your operation from risks that are entirely preventable.

Best Practices for Equipment Procurement and Management

Getting your equipment procurement right is so much more than just cutting a purchase order. It’s a full-circle process that protects your crew from the moment they step on-site until the job is done. This means thinking about the entire lifecycle of your safety inventory—making sure the right gear is always on hand, in perfect shape, and used correctly.

When you start thinking this way, it completely changes your relationship with construction safety equipment suppliers. You move away from panicked, last-minute phone calls and toward a predictable, streamlined system that anticipates what you’ll need. It’s an approach that cuts down on downtime, reduces waste, and, most importantly, keeps your people safe.

The sheer scale of regional development makes this a critical conversation. We're looking at massive projects like Dubai's announced USD $10 billion infrastructure investment and Saudi Arabia’s USD $267 billion Vision 2030 program. The demand for reliable safety gear is staggering. This boom is pushing suppliers to offer smarter, more integrated solutions, but their value is only as good as their adherence to strict local and international standards. You can get a sense of the market dynamics by reading up on the trends shaping the regional construction equipment market.

Forecasting Needs and Streamlining Reordering

The first step is simply getting ahead of the game. You can't wait until you're down to the last box of gloves before you think about reordering. Instead, you need to forecast your equipment needs based on your project pipeline and the specific phases of each job.

Think it through:

- Project Kick-Off: Will you need fall protection systems right away for the structural steel work?

- Mid-Project: Does the upcoming excavation phase require specialized respiratory gear?

- Finishing Stages: Will grinding and cutting demand specific eye and face protection?

Answering these questions ahead of time lets you build a structured reordering process with your supplier. Many of the best construction safety equipment suppliers will partner with you to set up scheduled or even automated deliveries, transforming procurement from a reactive headache into a smooth, predictable part of your operations. This is how you prevent shortages and avoid getting caught unprepared.

Your inventory system should be as meticulously planned as your construction schedule. It’s not just about what you have; it’s about knowing what you’ll need next week, next month, and for the next phase of the project.

Implementing Robust Inventory and Inspection Protocols

Once the gear is on-site, your job shifts from procurement to management. A solid inventory system is your best friend here. It doesn't have to be some overly complicated software; a well-organized digital spreadsheet can work wonders for tracking what you have, where it is, and its condition.

Just as important are your inspection schedules. These are completely non-negotiable. Every single piece of PPE, from a hard hat to a complex self-retracting lifeline, has to be checked regularly for wear, damage, or an approaching expiration date. Your management plan needs clear, easy-to-follow protocols.

Essential Inspection and Replacement Steps:

- Define Inspection Frequency: Set daily checks for high-use items like harnesses and weekly or monthly checks for others. Always follow the manufacturer's guidelines.

- Assign Responsibility: Make it crystal clear who is responsible for inspections. Is it the individual worker, a site supervisor, or a dedicated safety officer?

- Document Everything: Keep a detailed log of every inspection. This creates a paper trail for compliance and helps you spot recurring problems with certain types of equipment.

- Create Clear Removal Protocols: Have a simple, foolproof process for pulling damaged or expired gear out of service immediately. This could be a "do not use" tagging system or a designated quarantine area to prevent anyone from accidentally grabbing it.

The Critical Role of Worker Training

Finally, never forget that the best equipment on the planet is worthless if your crew doesn't know how to use, inspect, and care for it properly. Your management plan has to circle right back to your team. Training isn’t an optional add-on; it’s a vital part of the equipment's lifecycle.

Ask your supplier if they offer product training or on-site demonstrations. Make sure your team understands not just the "how" but the "why" behind each piece of equipment. When a worker truly gets how a particular harness feature keeps them safe or why a perfect respirator seal is so important, they become an active partner in their own safety. That’s when the whole system comes together.

Frequently Asked Questions

When it comes to safety equipment, there are no stupid questions. Getting the right answers is what keeps your people safe and your project compliant. We hear a lot of the same queries from project managers and procurement teams across the UAE, so we’ve answered the most common ones right here.

Think of this as your quick-reference guide to cutting through the noise and making confident decisions when you're vetting construction safety equipment suppliers.

How Can I Verify a Supplier's Equipment Meets UAE Safety Standards?

Don't just take their word for it—ask for proof. Start by requesting the compliance certificates for recognized standards like ANSI, CE, or EN. These are the global benchmarks used right here in the UAE.

A reliable supplier won't blink an eye when you ask for a formal Certificate of Conformity for the specific gear you're buying. If they hesitate or make excuses, that’s your cue to walk away. You can even double-check the product model against the issuing body’s public database for an extra layer of confidence.

A supplier’s hesitation to provide certification is the biggest red flag you can encounter. Transparency is non-negotiable when it comes to safety documentation.

Another good sign is if they are an authorized distributor for major international brands. This usually means they have a direct line to the manufacturer and a serious commitment to authenticity.

What Is the Difference Between a Supplier and a Distributor?

It’s a subtle but important distinction. A distributor typically has a formal, direct relationship with a few specific manufacturers. They are the official channel for those brands and hold a large inventory of their products.

A general supplier, on the other hand, might source from various distributors and manufacturers to offer a wider catalog. Think of them as a curator, pulling the best items from different places.

For critical safety gear, an authorized distributor can offer peace of mind about authenticity and direct manufacturer support. However, a great supplier can be a fantastic 'one-stop shop.' The title matters less than their track record, expertise, and ability to prove every single product is genuine.

Should We Buy Safety Equipment in Bulk to Save Money?

Buying in bulk looks good on a spreadsheet, but it can be a costly mistake on the ground. While the per-unit price drops, you introduce two major risks: expiration and degradation.

Safety harnesses, respirator cartridges, and many other items have strict expiration dates. Overstocking is a surefire way to end up with a storeroom full of useless, non-compliant equipment. You also have to consider the harsh UAE climate. Without proper, climate-controlled storage, heat and sunlight can degrade materials, rendering them unsafe long before their expiry date.

A much better strategy is to negotiate a long-term supply agreement. You can lock in great pricing but arrange for 'just-in-time' deliveries. This way, you get fresh, compliant stock exactly when you need it, without the headache and risk of managing a massive inventory.

At Yasu Trading Co., we believe in clarity and compliance. We provide certified, high-quality safety equipment backed by the documentation you need to run a safe and successful site. Let us help you protect your crew.