Cordless vs. Corded Tools: Which Should Contractors Choose in 2025?

For contractors in 2025, the debate isn't about whether cordless or corded tools are better anymore. It's about strategy. The smartest approach is building a hybrid fleet—using corded tools for the heavy-lifting, stationary jobs and letting cordless tools handle everything that requires movement, access, and finesse. This guide isn't about picking a favourite; it's about building an intelligent asset plan for your business.

The Contractor’s Power Tool Decision in 2025

Choosing between cordless and corded tools comes down to more than just personal preference. You need to look at the total cost of ownership, the latest leaps in battery tech, and what your job sites actually demand day-to-day. The end goal is simple: give your teams the right tools to maximise performance and profitability.

For most contractors here in the UAE, that means investing in both systems. This way, you're covered for every scenario, from smashing through concrete in a heavy demolition job to a technician handling delicate finishing work.

The market numbers back this up. The Middle East and Africa power tools market is on track to hit US$1.88 billion by 2032, fuelled by the massive infrastructure projects we see all around us. While both tool types are crucial, cordless is gaining ground fast. That’s because modern lithium-ion batteries now deliver longer runtimes and unmatched portability—absolute game-changers on large or remote sites. You can get more details on the regional power tool market growth and trends.

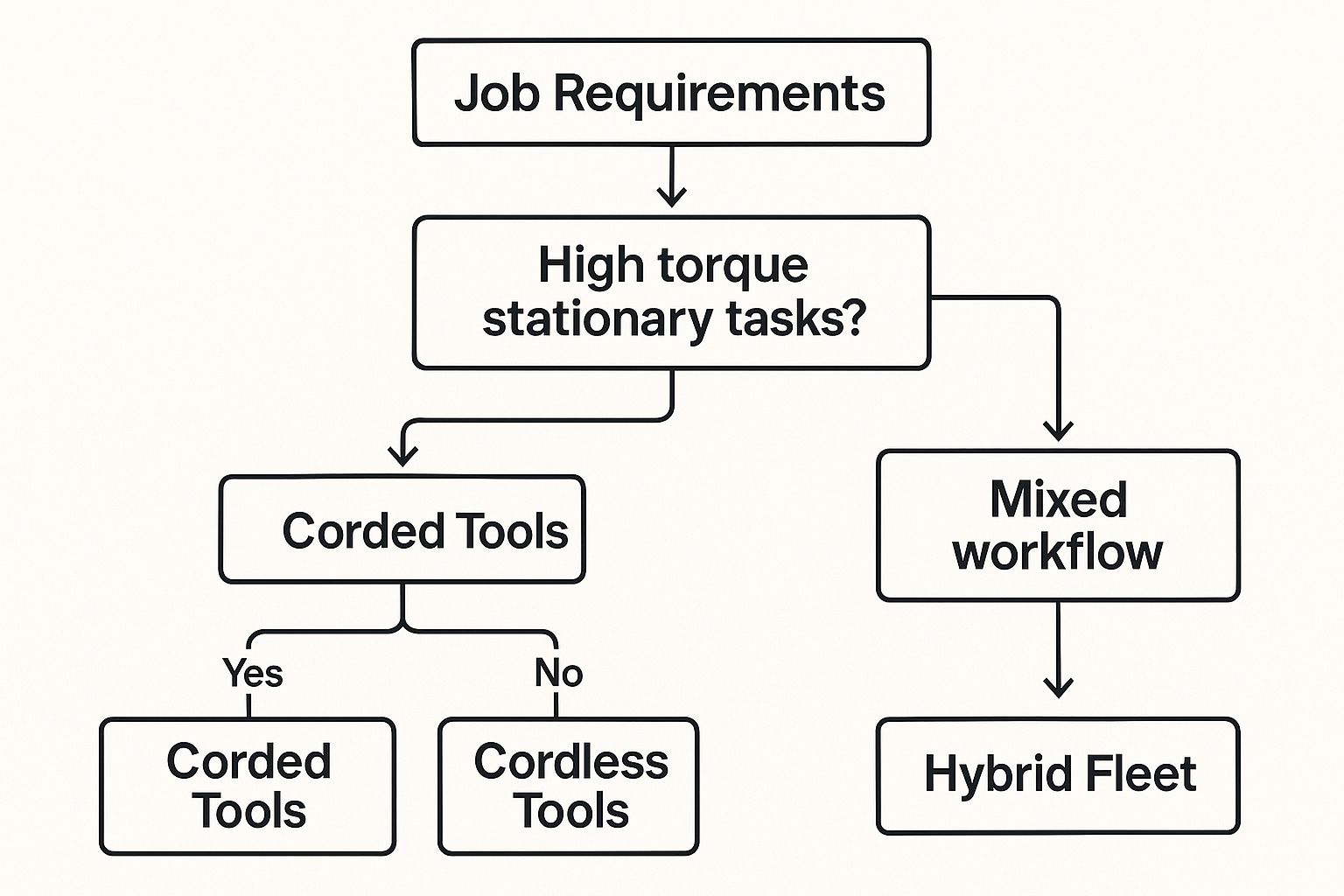

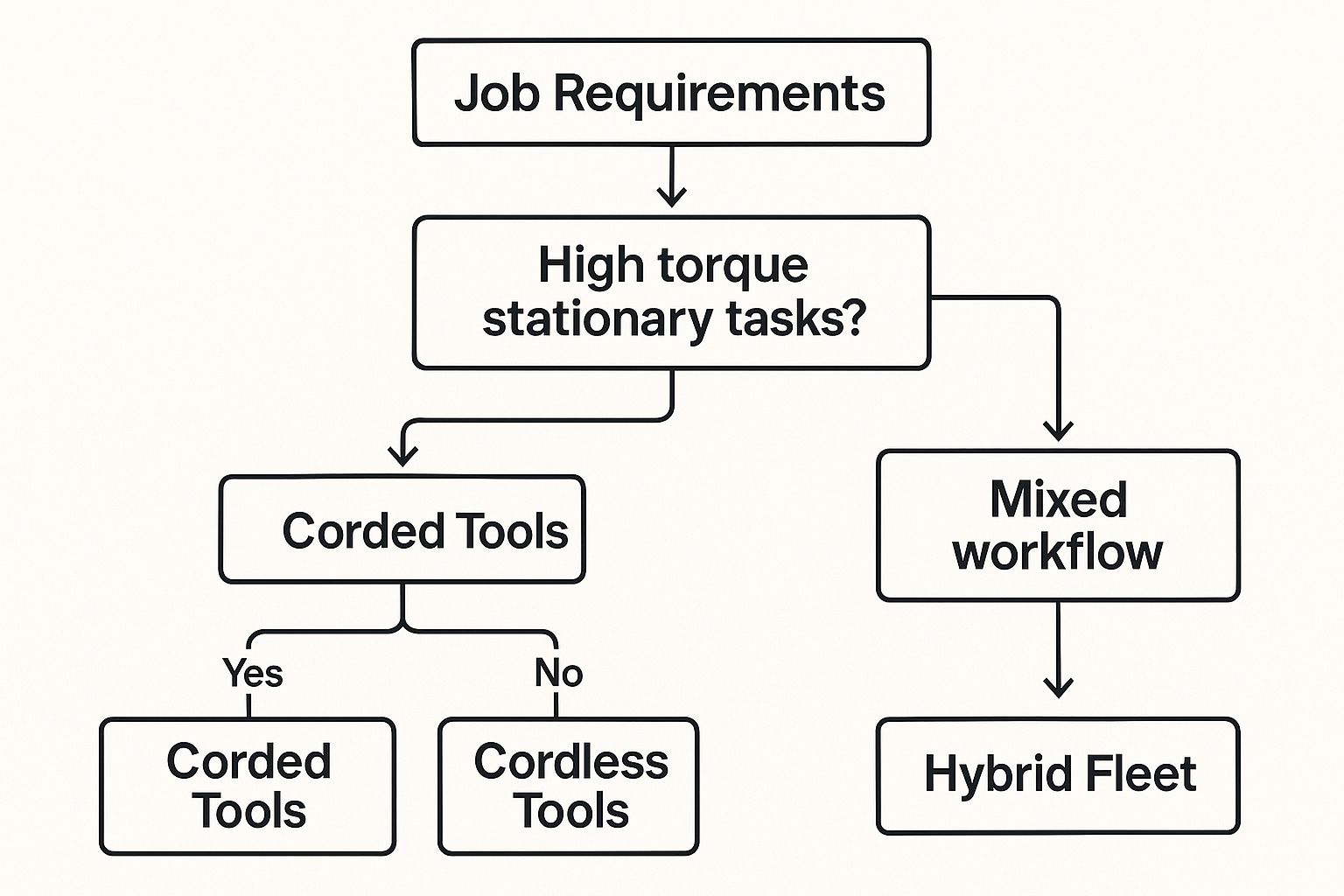

This decision tree helps cut through the noise and points you in the right direction based on your immediate needs.

As the infographic shows, it’s all about the job at hand. If you need relentless power for a big, tough task, plug it in. If you need to move freely and get into awkward spots, go cordless.

Quick Decision Matrix For Cordless vs Corded Tools

When you're on the spot and need to make a fast call, this table breaks it down. Use this summary to match the job site requirement to the best tool type without overthinking it.

| Scenario | Recommended Tool Type | Primary Justification |

|---|---|---|

| Continuous, heavy demolition | Corded | You need raw, uninterrupted power for maximum torque and runtime. No battery swaps. |

| Working at height or in tight spaces | Cordless | Cords are a major trip hazard and a nightmare to manage in cramped areas. |

| Remote job sites without grid power | Cordless | The tool is its own power source, giving you total freedom to work anywhere. |

| Repetitive, high-volume production | Corded | Delivers consistent, reliable performance all day long without downtime for charging. |

| Finishing and snagging lists | Cordless | Perfect for moving quickly between dozens of small, scattered tasks. Quick setup, no fuss. |

| Mixed-use daily workflow | Hybrid Fleet | The best of both worlds. The raw muscle of corded combined with the agility of cordless. |

Ultimately, having both types of tools on hand means you’re never caught unprepared, no matter what the job throws at you.

Comparing Raw Power and Sustained Performance

The heart of the cordless vs. corded debate has always been power. For years, the rule of thumb on any job site was simple: if you needed serious, uncompromising muscle, you found a socket. While that’s still the case for some of the biggest jobs, the performance gap is closing fast, forcing us to look closer at what "power" really means in 2025.

The biggest advantage a corded tool brings to the table is its sustained performance. It's plugged directly into a constant, unlimited source of electricity. That means it can hold peak torque and RPM for hours on end, without a single drop in power. This isn't just a minor perk; for certain demanding tasks, it’s absolutely essential.

When Corded Power Is Unbeatable

Some jobs just demand that constant, brute force only a corded tool can deliver. Think about a crew tasked with breaking up a thick concrete slab. A corded demolition hammer will pound away with the same relentless impact from the moment you start until the day is done. No battery swaps, no fading power—just pure, uninterrupted work.

Corded is still king in a few key scenarios:

- Continuous Concrete Demolition: Jackhammers and heavy-duty rotary hammers need that non-stop energy to chew through dense material efficiently.

- Large-Scale Metal Fabrication: If you're running a high-amperage angle grinder on thick steel all day, it needs a level of sustained power that would kill even the best battery packs in no time.

- Stationary Production Work: Masons using large wet tile saws or carpenters running a mitre saw in a workshop depend on that all-day-long, consistent performance.

For these high-demand, marathon jobs, a corded tool isn't just an option—it's a necessity. The ability to run at 100% output indefinitely translates directly into getting the job done faster and more reliably.

The Rise of Cordless Peak Performance

But the conversation flips when we talk about tasks that need quick bursts of high power instead of sustained grunt work. This is where modern cordless tools, with their advanced brushless motors and high-output batteries, have completely changed the game. A top-of-the-line cordless circular saw or impact wrench today can often match, or even beat, the peak torque of its corded counterpart. It just does it for shorter periods.

This shift is changing how contractors approach everything from structural framing to mechanical installations. A roofer with a cordless nail gun can work faster and safer, without worrying about a tangled air hose. An electrician on a scissor lift installing overhead lights can move freely, without a dangerous cord dangling below. For a deeper dive, check out our guide on the differences between drills and hammer drills on our blog.

The market data tells the same story. While corded tools are still a staple on large industrial projects in the UAE, their growth is slowing. Corded tool sales in the MEA region are projected to grow at a 5% CAGR from 2025 to 2033. In contrast, cordless tools are growing at a much faster 7% CAGR, as seen in recent analyses of global power tool market trends. The trend is clear: battery power is taking over more and more applications.

Performance Verdict: It’s All About the Situation

So, which is more powerful? That's the wrong question. It’s about matching the right type of power to the specific task at hand.

Corded tools deliver that unrelenting, sustained force, making them the undisputed champions for heavy, continuous demolition and fabrication. They are the workhorses.

On the other hand, modern cordless tools offer incredible peak power combined with total freedom. They excel where you need mobility and short, powerful bursts of action—think assembly, finishing, and overhead work. For any serious contractor in 2025, a truly optimised toolkit has both. You deploy the raw, sustained energy of corded for the big breakdown jobs and the agile, peak performance of cordless to build it all back up.

Maximising Mobility and Job Site Efficiency

Raw power is one thing, but the real value of a tool is how it impacts the daily rhythm of your job site. When you’re weighing up cordless vs. corded, efficiency isn't just about motor speed. It's about workflow, safety, and all the little moments of saved time that add up across a project. This is where cordless tools really start to shine, completely changing how crews get things done in complex environments.

The freedom from a cord is the most obvious perk, but what that means in practice is huge. You cut out the need to find a power source, run extension leads, and navigate around cables. Right away, setup time for any task gets slashed. That "pick up and go" ability lets workers move from one job to the next without missing a beat, which is a massive productivity boost, especially during finishing stages with lots of small tasks all over the site.

The True Cost of Being Tethered

The price you pay for a corded tool at the counter is just the beginning. The real expense comes from the "hidden costs"—all the subtle, time-wasting activities that slowly eat away at your project's bottom line. Every minute someone spends hunting for a working socket, untangling a knotted extension cord, or moving cables out of the way is a minute you're paying for with zero output.

Just think about these everyday headaches:

- Sourcing Power: On a new build or a sprawling site, power points can be few and far between. A worker can easily waste 10-15 minutes just finding a plug and running a lead to where they need to be. Multiply that across a whole crew, and the lost time skyrockets.

- Cable Management: Cords are a trip hazard and need to be managed. That means taping them down, running them overhead, or constantly shifting them around, all of which breaks the flow of work.

- Limited Reach: Even with a long extension lead, you can only go so far. Working on rooftops, scaffolding, or in wide-open spaces often means having to stop and move your power source, causing yet another delay.

The real win with cordless tools isn't just about speed. It's about getting rid of the dozens of tiny, unproductive tasks that come with managing a power cord. It frees up your team to just focus on the job.

Enhancing Access and Safety on Site

Modern construction sites in the UAE, from towering skyscrapers to complex commercial fit-outs, throw some serious access challenges at you. In these situations, cordless tools aren't just a nice-to-have; they’re essential for getting the job done efficiently and, more importantly, safely.

Picture a team of glaziers installing façade panels on a high-rise. Trying to manage extension cords dangling hundreds of feet in the air is not just a logistical nightmare—it’s a major safety risk. Give them a cordless impact driver, though, and they can work freely, securely, and much more quickly. The same goes for an MEP technician in a cramped plant room; they can get into tight spots with a cordless drill far more easily than if they were dragging a cord behind them.

This freedom directly leads to a safer site. Extension cords are one of the biggest culprits for trips and falls on any job site, a risk that a cordless fleet completely removes. On top of that, you get rid of cords that can scratch up finished surfaces like flooring or painted walls during the final fit-out stages.

A Practical Scenario Comparison

Let's look at what this means in the real world. Imagine a two-person roofing crew that needs to cut and install flashing.

Corded Tool Workflow:

- Find a power outlet on the ground floor.

- Grab a heavy-duty, 50-metre extension cord and connect it.

- Haul the cord up to the roof, making sure it's secured so it doesn't fall.

- Plug in the corded circular saw.

- Constantly stop to reposition the cord to reach different parts of the roof.

- At the end of the day, lower the cord and coil it up for storage.

Cordless Tool Workflow:

- Carry the cordless circular saw and a spare battery to the roof.

- Get to work.

The difference in time is plain to see. The cordless crew cuts out several slow and hazardous steps, letting them finish faster and with a lot less hassle. When you multiply that time saving across every trade on your site, the case for bringing cordless tools into your workflow for any job that requires movement becomes impossible to ignore.

Calculating the Total Cost of Ownership

When you're trying to decide between cordless and corded tools, the price tag on the box is just the beginning of the conversation. To make a truly smart decision for your contracting business in 2025, you have to look beyond the initial purchase and calculate the Total Cost of Ownership (TCO). It’s a simple concept: add up every single cost tied to that tool over its entire working life, not just what you hand over at the counter.

It's easy to be tempted by a lower upfront price. A corded tool might look like the cheaper option at first glance, but the costs creep up on you. Think about the constant need for heavy-duty extension cords, the potential for generator hire on certain UAE sites, and the money you lose when a cable gets damaged. These are the operational costs that rarely make it into a quick price comparison but can seriously dent your profits over time.

Breaking Down the Corded Investment

On the surface, the financial side of corded tools seems straightforward. You buy the tool, you plug it in, and with a bit of care, it can run for years. The problem is, you're not just buying the tool; you're buying into an ecosystem that has its own hidden costs.

For example, a good quality, 50-metre industrial extension lead isn't cheap, and a busy crew will likely need several. Worse, when someone inevitably drives over a cord or it gets snagged and damaged, you're not just paying for a replacement. You're paying for downtime while that crucial tool is out of commission. These "small" expenses really start to add up over the life of a project.

The real TCO for a corded tool isn't the tool itself. It's the tool plus the price of every extension cord, every generator you have to hire, and every dirham you lose to cord-related downtime and repairs.

Understanding the Cordless Financial Model

The cordless world runs on a completely different financial model. The initial hit to your wallet is almost always higher, especially if you're buying a kit that includes a few batteries and a charger. Here, your main costs are the "bare tool" (the tool without a battery), the batteries themselves, and the chargers needed to keep them topped up.

The biggest long-term cost to plan for is battery replacement. A professional-grade lithium-ion battery doesn't last forever. Under heavy daily use, you can expect about three years or a certain number of charge cycles before it starts to lose its punch. This means you need to budget for replacing your entire fleet of batteries every few years, which can be a significant expense. Knowing the current drilling machine price in Dubai helps with the initial comparison, but smart contractors always factor in the long-term battery costs.

The Strategic Value of a Single-Battery Platform

This is where committing to a single-battery ecosystem becomes one of the smartest financial moves you can make. When you stick with one pro-grade brand—whether it's DeWalt, Makita, Bosch, or another—you can run dozens of different tools off the same set of batteries. Your drill, your circular saw, your angle grinder, and even your site lights all share the same power source.

This approach massively cuts your long-term TCO. Instead of getting a new battery and charger with every single tool you buy, you start purchasing the "bare tool" only. This slashes your acquisition costs, makes managing your tool inventory a whole lot simpler, and pretty much guarantees your team will always have a charged battery ready to go. A well-managed battery platform turns your tools from a collection of individual expenses into a streamlined, cost-effective system.

Three-Year Cost of Ownership A Carpentry Crew Case Study

Let's put some numbers to this. Here’s a rough breakdown of the potential three-year costs for a small, three-person carpentry crew. This is where you can really see how a lower initial price doesn't always mean a lower long-term cost.

| Cost Component | Corded Tool Ecosystem (AED) | Cordless Tool Ecosystem (AED) | Notes |

|---|---|---|---|

| Initial Tool Purchase | 10,000 | 15,000 | Assumes purchasing equivalent saws, drills, and impact drivers for three workers. |

| Power Accessories | 2,500 | 0 | Includes heavy-duty extension cords and power splitters for the corded setup. |

| Batteries & Chargers | 0 | 9,000 | Initial cost for six high-capacity batteries and three fast chargers. |

| 3-Year Battery Replacement | 0 | 9,000 | Budgeting for a full replacement cycle of all six batteries. |

| Estimated Cord Repair | 750 | 0 | Minor repairs or replacement of one damaged cord over three years. |

| Total 3-Year TCO | 13,250 | 33,000 | A clear look at the long-term financial commitment for each system. |

Looking at the numbers alone, the corded setup seems like the obvious winner. However, this table can't put a price on the massive productivity gains, job site mobility, and improved safety that going cordless brings. For many businesses, the efficiency and flexibility a cordless system provides will more than justify the higher investment, delivering a much better return in the long run.

Choosing Your Power Source: Battery vs. Grid

Deciding between cordless and corded tools is more than just picking a tool; it's a fundamental choice about your power source. Are you tying your workflow to the grid's steady supply, or are you investing in the freedom of a self-contained battery system? For contractors here in the UAE, getting this decision right in 2025 is crucial for keeping a job site running smoothly and profitably.

A battery platform isn't just an accessory anymore—it’s a core business asset. The big names in the industry have built out impressive ecosystems where one battery can power 200+ different tools, from a compact impact driver to a heavy-duty demolition hammer. That kind of interchangeability is a massive win for efficiency on site.

The Modern Battery Ecosystem

The battery tech for 2025 is pushing boundaries like never before. We're now seeing higher amp-hour (Ah) cells that give you longer runtimes and pack more punch, letting cordless tools step into roles that used to be strictly corded territory. Fast-charging technology has also completely changed the game, with some systems juicing up a high-capacity battery in less than an hour.

This progress is directly fuelling market growth. In the residential and light commercial sectors across the MEA region, the shift to cordless is accelerating. The compound annual growth rate for cordless is easily outpacing the rest of the market, thanks to a growing DIY culture and modernising retail channels. While the global cordless market was valued around $15 billion in 2025, the MEA's share is climbing fast as cities like Dubai continue to expand.

For contractors on the ground, here are the key advancements that matter:

- Increased Durability: Better casing and cell protection mean batteries can take a beating from drops and handle the dusty, demanding conditions of a typical UAE job site.

- Smart Technology: Built-in electronics allow the battery, tool, and charger to communicate. This prevents overheating, manages power draw for optimal performance, and ultimately extends the battery's working life.

- Power Stacking: Some brands now let you link two batteries to a single tool, giving you the kind of performance and runtime you'd expect from a corded model.

A well-managed battery platform is a force multiplier. It cuts downtime, simplifies logistics, and ensures every crew member has the power they need, right where they need it.

Reliability and Limits of Grid Power

On the other hand, grid power has one massive advantage: reliability. When you have access to it, it’s an endless, unwavering source of energy. For high-demand, stationary tools set up on a site with temporary power boards, it's perfect. You never have to sweat about a battery dying in the middle of a critical cut.

But that reliability comes with its own set of strings attached—literally. On new construction sites, especially in the early stages, getting reliable grid access is often a challenge. This often means falling back on noisy, fuel-guzzling generators, which adds another layer of cost and maintenance to the project. Even when power is available, managing metres of extension cords across a busy, multi-level site creates trip hazards and slows down the workflow.

For projects where power needs go beyond what the grid or portable generators can offer, looking into larger mobile energy solutions can provide a clearer picture of what’s possible for job site infrastructure. These systems can be a lifesaver for large-scale projects in more remote locations.

In the end, the choice between battery and grid doesn't have to be an either/or situation. The smartest approach for a contractor in 2025 involves weighing the risks and rewards for each phase of a project. You might rely on grid power for heavy-duty foundational work, then go all-in on batteries for framing, MEP, and finishing. It's all about using the strengths of each to make the entire project run better.

So, What's the Final Verdict for Your Tool Fleet?

The old "cordless versus corded" argument is over. There's no single winner anymore. For any contractor looking to stay competitive in 2025, the smartest play isn't picking a side; it's building a hybrid fleet that uses the best of both worlds. The real goal is to have the right tool for the right job, every single time, maximising your efficiency and, ultimately, your profit.

This means you have to stop thinking in terms of personal preference and start thinking about the task at hand. You absolutely need the brute, non-stop power of corded tools for the heavy-lifting and foundational work. But you also need the nimble freedom of cordless systems for everything that comes after. Marrying these two ensures your crews are never caught short, whether they're breaking concrete or fitting out a final snag list.

Your Trade Dictates the Mix

Let's be clear: the ideal blend of corded and cordless tools changes dramatically depending on what you do. A one-size-fits-all approach is a recipe for failure in the demanding UAE market.

General Contractors: On big builds, a solid inventory of corded gear is non-negotiable. Think heavy-duty breakers, big angle grinders, and stationary saws—these are your workhorses for demolition and the structural phase. At the same time, your finishing teams doing drywall, painting, and snagging should be almost 100% cordless to fly through their tasks without being tethered.

MEP Specialists: Electricians and plumbers, on the other hand, benefit hugely from going nearly all-in on cordless. They're constantly working in cramped spaces, up on ladders, or across sprawling sites where dragging a cord is not just a hassle—it's a safety hazard. For these trades, the ROI on cordless tools, thanks to sheer speed and mobility, is massive.

The smartest investment a contractor can make is in a flexible, hybrid tool fleet. This isn't about replacing corded with cordless; it's about complementing raw power with unmatched mobility to create a more productive and adaptable business.

Final Recommendations for 2025

As you plan your tool buys for the coming year, think strategically. Equip your workshops and demolition crews with the most reliable corded tools you can get your hands on. For continuous, high-demand jobs, you just can't beat their dependability.

For your crews on the move—the ones handling installations, repairs, and finishing touches—invest heavily in a single, top-tier cordless battery platform. Sticking to one brand simplifies everything from charging on-site to managing inventory, saving you a fortune in the long run. As you put together your ideal setup, it's a good idea to start by exploring various tool collections to see the full range of what's available.

Ultimately, the answer to what tools contractors need in 2025 is simple: you need both. A powerful, hybrid fleet is the only way to truly prepare your business for the realities of modern construction. For more specific guidance on sourcing the right gear, our deep dive into essential construction tools in the UAE can help steer your purchasing decisions. By blending the relentless power of corded tools with the go-anywhere freedom of cordless, you’re not just buying tools—you’re building a serious operational advantage.

Frequently Asked Questions

Even after weighing the pros and cons, contractors still have questions before they invest in new gear. It's only natural. Making the right call goes beyond the specs on the box—it's about how these tools perform on a real job site, day in and day out.

Here, we tackle some of the most common queries we get from professionals across the UAE as they decide between cordless and corded tools. Let's get straight to the practical answers you need.

Are Cordless Tools Powerful Enough for Heavy Concrete Work?

For most concrete jobs, yes—with a few important exceptions. Modern cordless rotary hammers and breakers, especially the high-end models, are seriously impressive. They can easily handle tasks like drilling anchor holes, light chipping, and even breaking up smaller sections of concrete without breaking a sweat.

But when you're facing a full day of heavy-duty demolition, like breaking up a thick foundation, a corded tool is still king. You just can't beat its relentless power and unlimited runtime for those marathon jobs. A corded breaker won't slow down or force you to stop and swap out batteries, which makes all the difference when efficiency is key.

What's the Real-World Lifespan of a Professional Cordless Battery?

You can generally expect a professional-grade lithium-ion battery to last about three years, or somewhere between 800 to 1,500 charge cycles under typical job site conditions. It won't just stop working one day. Instead, you'll start to notice it holds less charge and gives you shorter runtimes.

Expert Tip: How you treat your batteries makes a huge difference. To get the most out of them, avoid running them completely dead, keep them stored in a cool place out of the sun, and always use the right charger from the manufacturer. It prevents overheating and protects the cells.

Is Sticking to a Single-Battery Platform Always the Smartest Move?

For most contracting businesses, committing to one battery ecosystem is a brilliant financial strategy. It cuts your long-term costs significantly because you can buy "bare tools" without having to pay for a new battery and charger every time. It also makes life simpler for your crew—everyone knows where to find a compatible power source.

The only real downside is "brand lock-in." You might miss out on a best-in-class speciality tool simply because it's from a different brand. A more balanced approach that we often see work well is to standardise 90% of your tool fleet on one platform for all the common tasks. Then, you can invest in a few specialised tools from other brands where they offer a clear performance edge. This gives you a great mix of cost savings and top-tier capability.

At Yasu Trading Co. LLC, we stock a complete range of both corded and cordless power tools from the world's leading brands. Whatever the job demands, we have the right equipment for you. Explore our selection and request a quote today.