Drill and Hammer: UAE's Guide to Power Tools

When you’re gearing up for a project here in the UAE, one of the first decisions you'll face is whether to grab a standard drill or a hammer drill. At a glance, they look similar, but their mechanics are worlds apart. A standard drill is all about rotation, making it your go-to for drilling into softer materials like wood or plastic.

The hammer drill, however, brings something extra to the table: a powerful, pulsating hammering action that works in tandem with the rotation. It's this one-two punch that lets you power through the tough masonry and concrete so common in our local construction.

Choosing the Right Tool for UAE Projects

Knowing the difference isn't just academic—it's about getting the job done right, without wrecking your materials or your tools. Whether you’re a pro on a high-rise site or a DIYer hanging shelves in your apartment, the right choice saves you time, money, and a whole lot of frustration.

This isn't just about simple definitions. It's about practical know-how for picking the perfect tool for the job you’re actually doing. The power tools market in our region is booming, valued at around USD 3.72 billion in 2021 and expected to hit USD 5.31 billion by 2029, with drilling and fastening tools right at the forefront.

Direct Comparison: Drill vs. Hammer Drill

So, which one do you need? It all comes down to the material you’re up against. Here’s a quick head-to-head comparison to make the choice clearer.

| Feature | Standard Drill | Hammer Drill |

|---|---|---|

| Primary Action | Purely rotational | Rotation + rapid hammering |

| Best For | Wood, plastic, metal | Concrete, brick, masonry |

| Typical Use | Assembling furniture | Anchoring into block walls |

| Torque Focus | Consistent turning force | High-impact percussive force |

This distinction is absolutely vital when you're working with the diverse building materials found throughout the UAE, from timber framework in a villa to the reinforced concrete of a skyscraper. A standard drill gives you precision and control. A hammer drill gives you the raw power needed to conquer the toughest surfaces.

2. The Mechanics: What's Happening Inside the Tool?

To really get why these tools are different, you have to look past the plastic casing and get into the guts. It’s all about the engineering inside. The fundamental difference isn't just what they do, but how they do it.

A standard drill is beautifully simple. Its motor spins a set of gears, delivering pure rotational force to the chuck. Think of it as a relentless, smooth twisting motion. This is exactly what you want for drilling clean, precise holes in materials like wood, metal, or plastic. No fuss, just spin.

A hammer drill, on the other hand, adds a clever bit of brute force to the mix. Inside, it features two interlocking, ridged discs or rings. When you flip the switch to hammer mode, these discs engage. As they spin, the high points on one disc ride up and slam down against the other, creating thousands of tiny, rapid-fire forward blows. This percussive action pulverises tough materials like concrete or block right at the tip of the spinning drill bit, allowing it to chew through masonry.

This single mechanical distinction is why one tool is your go-to for joinery, and the other is a must-have for foundation work. One glides, the other demolishes.

As you can see, matching the tool’s power and core action to the material is everything.

Drill vs Hammer Drill Core Mechanical Comparison

To put it plainly, here’s a breakdown of what’s happening mechanically.

| Attribute | Standard Drill | Hammer Drill |

|---|---|---|

| Primary Action | Pure Rotation (Torque) | Rotation + Percussion (Hammering) |

| Key Mechanism | Geared Motor | Geared Motor + Cam-Action Discs |

| Force Type | Twisting/Shearing | Twisting + Forward Impact |

| Resulting Capability | Drills through softer materials | Powers through hard, brittle materials |

This table cuts right to the chase: a standard drill only twists, while a hammer drill twists and punches.

Why This Matters on a UAE Job Site

The constant innovation in this space tells you how critical these tools are. For instance, the market for advanced hammer drills was valued at USD 2.5 billion in 2024, a figure that's only expected to climb. This isn't just about adding more power; it's about making the tools more efficient and durable for the kind of demanding work we see every day in the UAE.

The core takeaway is simple: a standard drill applies torque (rotational force), while a hammer drill applies both torque and percussion (forward thrusts). That dual action is non-negotiable for anyone working with the concrete and masonry that form the backbone of construction here.

Of course, the tool is only half the battle. To truly get the most out of that hammering action, you need bits that can take the punishment. Using the right specialized SDS Plus drill bits and chisels is essential. They're specifically engineered to withstand the intense, repetitive impacts on materials like reinforced concrete and stone, preventing breakage and ensuring the force is delivered right where you need it.

Real-World Uses in UAE Construction

Knowing the mechanics is one thing, but seeing how a standard drill and hammer drill perform on a real UAE job site is where their true value comes to light. Each tool is a specialist, and its role is dictated entirely by the material you're working with. Getting that choice right is everything for efficiency.

The standard drill is your go-to for tasks that need precision and a delicate touch rather than sheer brute force. Think of the detailed work in interior fit-outs, where finesse is the name of the game.

- Assembling Furniture: Driving screws cleanly into wood or MDF for custom cabinetry and wardrobes.

- Kitchen Installations: Drilling perfect pilot holes for handles on laminate or wooden cabinet doors without splintering.

- Partition Walls: Fastening lightweight metal studs for drywall partitions in office towers and apartment buildings.

In these situations, you need accuracy to avoid wrecking expensive materials. The standard drill delivers just that.

When the Hammer Drill Takes Over

But the moment your job involves concrete, blockwork, or masonry, the standard drill gets put back in the toolbox. The hammer drill steps up to handle the tough surfaces that are the backbone of UAE construction, from villa walls to high-rise concrete slabs. Its powerful hammering action makes tough jobs possible.

Project Snapshot: Renovating a Downtown Dubai Apartment

Imagine you need to mount a heavy, designer air conditioning unit on a solid concrete block wall. A hammer drill isn't just a good idea—it's essential. Its percussive blows pulverise the masonry just enough for the bit to advance, creating a deep, secure hole for an anchor that can safely take the unit's weight. A standard drill would just burn out.

It's the same story for a villa extension in a community in Sharjah or Ras Al Khaimah, where the hammer drill becomes the MVP of your tool kit.

- Electrical Channelling: Cutting clean channels into blockwork to run electrical conduits without shattering the surrounding wall.

- Securing Balcony Fixtures: Anchoring safety railings or satellite dishes directly into poured concrete balconies for a rock-solid installation that will withstand the elements.

- Foundation Work: Drilling into concrete footings to install heavy-duty anchor bolts for steel beams or timber frames.

For these jobs, the hammer drill’s one-two punch of rotation and impact is the only way forward. It transforms what would be a long, frustrating struggle into a quick, straightforward task, perfectly illustrating why these two tools are worlds apart.

A Framework for Selecting Your Power Tool

Choosing the right power tool isn't just about picking a "drill" or a "hammer drill." It's about matching the tool to the reality of your work. The perfect choice nails that balance between power, portability, and how often you'll actually be using it. A pro working on a high-rise in Dubai has completely different needs than a homeowner putting up shelves on a Friday afternoon.

So, where do you start? First, be honest about your workload. Is this a tool for daily, heavy-duty punishment, or is it for the occasional odd job? Answering that one question cuts through half the noise and stops you from either buying a beast of a machine you don’t need or a tool that will burn out on its first real test.

Then, think about the work itself. The diameter and depth of the holes you need are everything. Drilling a few small pilot holes for screws is one thing; boring deep channels for anchor bolts into solid, reinforced concrete is a different world entirely.

Key Selection Criteria

Your answers here will point you straight to the right tool for your kit.

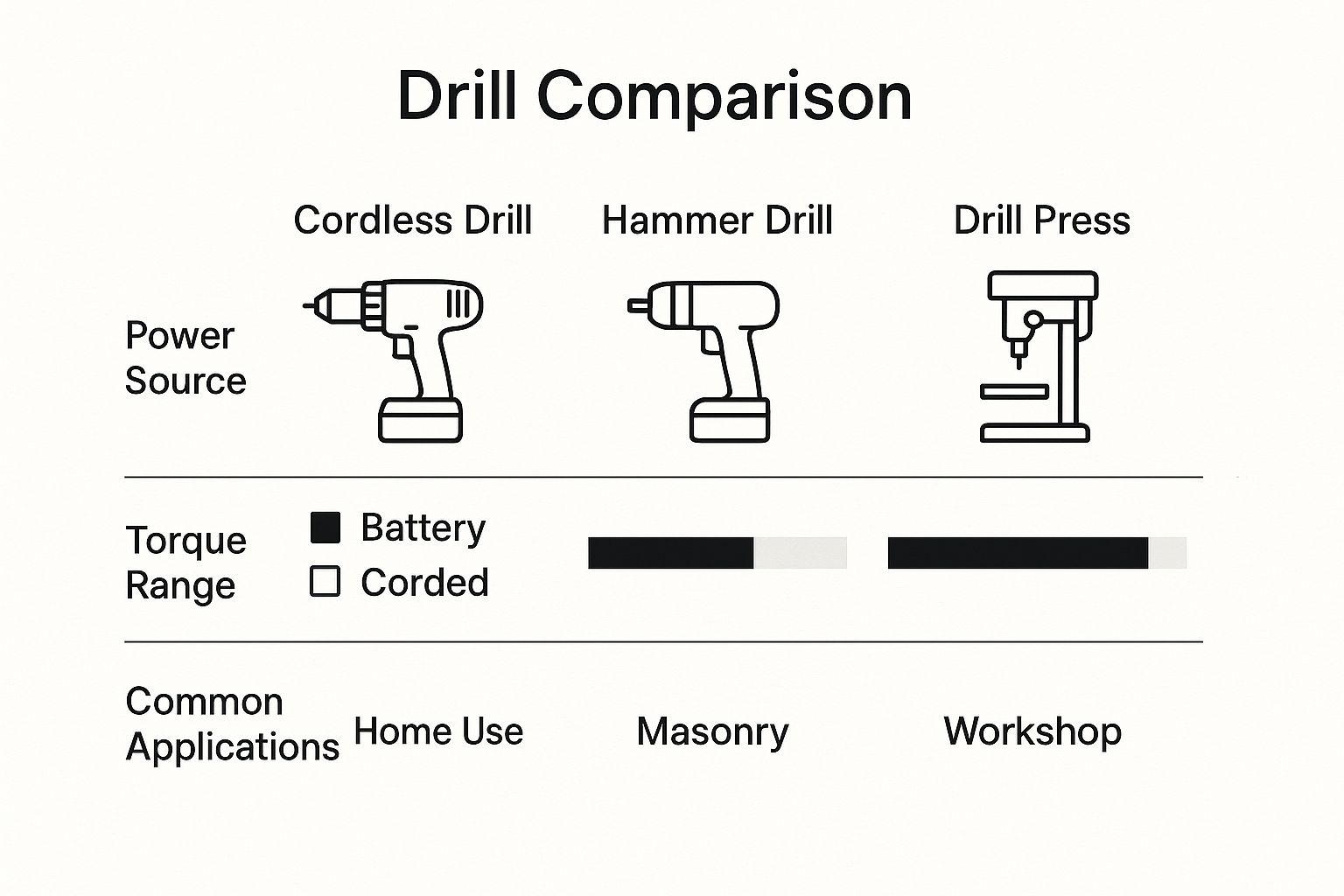

- Frequency of Use: If you’re working with masonry day-in, day-out, a dedicated corded hammer drill is your workhorse. It delivers relentless power and won't let you down. For more varied projects or occasional drilling into blockwork, a versatile cordless combi drill is a much more practical choice.

- Hole Diameter and Depth: A good combi drill can handle small to medium holes in standard blockwork without breaking a sweat. But when you’re facing large-diameter or seriously deep holes in dense concrete, you have to step up. Only a powerful hammer drill or even a rotary hammer will have the guts to get the job done efficiently.

- Power Source: Cordless models give you freedom. That’s a massive advantage when you’re moving around a large, cluttered site without dragging cables behind you. On the other hand, corded tools offer raw, uninterrupted power for those long, demanding jobs where a battery would just get in the way.

To get a broader picture of how these tools fit into a complete professional setup, our guide to essential construction tools in the UAE breaks down the options available.

For frequent work with concrete or brick, a dedicated hammer drill is a non-negotiable investment. For occasional masonry tasks, a combi drill offers superior versatility.

At the end of the day, it's about matching the tool to the task. By thinking through how often you'll use it, what you'll be drilling into, and where you'll be working, you can confidently pick the right machine. You’ll have the performance you need without paying for power you’ll never use.

Safety and Maintenance in Demanding Conditions

Whether you're using a standard drill or a hammer drill, treating it with respect is non-negotiable. On job sites across the UAE, fine dust and intense heat are part of the daily grind. This makes proactive maintenance absolutely essential if you want your tools to have a long, reliable life.

A simple clean-up after every use can make all the difference. Get a can of compressed air and blow out the air vents to clear away the dust and debris that builds up. It's a small step, but it’s one of the best ways to keep the motor from overheating and burning out. Also, make it a habit to check power cords for frays or damage, and if you’re using cordless models, look after your batteries by keeping them out of extreme heat and avoiding full discharges.

Tool-Specific Care and Safety Protocols

While a quick clean is good for any drill, a hammer drill needs a bit more attention because of the incredible forces it handles. The hammering action puts a massive amount of stress on the internal parts, which makes proper lubrication a critical job.

The chuck mechanism on your hammer drill takes a real beating. Regularly lubricating it is vital to reduce friction and wear on the components that deliver all that impact force. Skip this, and you're looking at premature failure and poor performance on tough masonry.

Your own safety is just as important as the tool's health. The powerful torque on these drills can twist your wrist in a second if the bit suddenly jams. That's what the auxiliary handle is for—always use it to keep a firm, two-handed grip for complete control.

- Gear Up with PPE: Don't even think about starting without safety goggles, protective gloves, and hearing protection, especially when you've got the hammer function engaged.

- Choose the Right Bit: Using the correct masonry bit for the material you're drilling doesn't just prevent the bit from breaking; it makes the work easier and less tiring.

- Keep an Eye on Vibration: Powerful tools mean powerful vibrations. It’s important to monitor and reduce risks like hand-arm vibration. You can easily track your exposure with a hand-arm vibration calculator.

Getting into a structured maintenance routine will keep your tools in top shape for years. If you want to formalise your process, check out this guide on creating a preventive maintenance schedule template.

Answering Your Top Drill Questions

Even after you know the difference between a standard drill and a hammer drill, a few practical questions always pop up on the job site. Getting straight answers builds confidence and makes sure you’re tackling the work safely and with the right tool in hand. Here are some of the most common queries we hear from professionals and DIY enthusiasts alike.

Can I Use a Hammer Drill as a Regular Drill?

Absolutely. In fact, that's one of their biggest selling points. Modern hammer drills almost always come with a mode selector switch.

All you have to do is flick it over to the ‘drill-only’ setting. This turns off the hammering action completely, leaving you with pure rotational force – just like a standard drill. It’s this versatility that makes them perfect for drilling into wood, metal, or plastic, and why combination (or 'combi') drills are a go-to for so many tradespeople.

What's the Real Difference Between a Hammer Drill and a Rotary Hammer?

Both are made for masonry, but they’re in different leagues entirely. A hammer drill uses a mechanical clutch for its rapid, light-tapping action. It’s brilliant for smaller holes in materials like brick and standard concrete blocks.

A rotary hammer, which you’ll often hear called an SDS drill, is a different beast. It uses a powerful electro-pneumatic piston to generate a heavy, thumping blow. This gives it far more impact energy, making it the only real choice for drilling large-diameter holes into dense, reinforced concrete or for tasks like light demolition and chiselling.

The easiest way to think about it is this: a hammer drill is for drilling holes into masonry. A rotary hammer is for powering through and breaking it up.

Do I Need Special Bits for a Hammer Drill?

Yes, and this is non-negotiable for both performance and your own safety. The moment you engage that hammer function, you must use a proper masonry bit. These are specifically built with a tough tungsten carbide tip to handle the brutal, high-frequency impacts.

That reinforced tip is what chews through the hard material. If you try to use a regular wood or metal bit in hammer mode, you won’t just ruin the bit in seconds – you risk it shattering, which is a serious safety hazard.

At Yasu Trading Co. LLC, we stock the high-quality power tools and accessories you need to get the job done right. Explore our extensive collection and find the perfect tool for your next project.