Electrical insulation tape: Your UAE guide to types and standards

At its heart, electrical insulation tape is a special type of adhesive tape made to insulate wires and other components that carry an electrical current. Think of it as a crucial safety barrier. Its main job is to stop electricity from jumping where it shouldn't, which is how you prevent short circuits, nasty electrical shocks, and even fires. It's one of those fundamental safety items you'll find on any professional construction site.

Why is the right electrical tape critical in the UAE?

For any contractor or engineer working in Dubai and across the Emirates, picking the right electrical tape isn't just a choice—it's a critical responsibility. This seemingly simple roll of tape is foundational to the safety and long-term health of any electrical system, especially on a demanding project site from a trusted supplier in Dubai.

You can think of electrical insulation tape as the first line of defence for every splice and connection. While its most obvious job is to cover exposed wires, its role goes much deeper, particularly when dealing with the unique challenges of our local climate.

How does electrical tape ensure safety and system longevity?

A top-tier electrical tape provides a tough, durable layer of protection that keeps electrical systems running safely and reliably for years to come. The advantages are straightforward: it prevents short circuits, protects against shock, and shields systems from the elements.

- Prevents Short Circuits: It keeps conductors properly isolated, making sure they don't make contact with each other or any grounded metal surfaces.

- Protects Against Shock: It forms a non-conductive shield, protecting technicians, maintenance crews, and building occupants from dangerous currents.

- Shields from the Elements: It effectively seals out moisture, dust, and corrosive agents—all major threats that can degrade electrical systems here in the UAE.

Why is electrical tape a mission-critical component for UAE construction?

On the fast-paced construction sites of the UAE, you simply can't work without quality electrical insulation tape. It's so vital that electrical tapes make up the largest part of the UAE PVC Tape Market, which was valued at a hefty USD 224.8 million. That number alone shows just how essential this product is for protecting the complex electrical networks inside Dubai's skyscrapers and Abu Dhabi's massive infrastructure projects.

And it's only growing. The market is projected to climb to USD 296.3 million by 2033, driven by non-stop urban development and ambitious new mega-projects. You can dig deeper into the data on the UAE's PVC tape market trends.

In a region known for its world-class projects and strict UAE construction standards, this tape isn't just another item on a purchase order; it's a mission-critical safety component. Choosing the correct product from a trusted building materials distributor is the first step towards ensuring compliance and delivering quality work. As a leading supplier in Dubai, we at Yasu Trading Co. get it—we make sure every product we offer has what it takes to perform safely and reliably on your job site.

What are the different types of electrical tape?

When you're on a job site, not all electrical tapes are interchangeable. Choosing the right one is absolutely critical for safety, durability, and a professional finish. A good building materials distributor won't just sell you a roll of tape; they'll offer a range of specialised options for specific tasks.

Think of each tape as a different tool in your toolbox. You wouldn't use a screwdriver to hammer a nail, and you shouldn't use a general-purpose tape for a high-voltage splice. The type of electrical insulation tape you select directly impacts the long-term integrity of your work, especially in the demanding climate of the UAE.

Let's break down the most common types you'll be working with.

What is the most common type of electrical tape?

The most common type of electrical tape is vinyl electrical tape, often called PVC tape, which is ideal for insulating splices and colour-coding wires. Made from stretchy polyvinyl chloride (PVC) with a rubber-based adhesive, its flexibility allows it to conform tightly around wires, making it the standard choice for most low-voltage jobs under 600V.

It’s your everyday workhorse, perfect for insulating splices, patching up minor nicks in cable jackets, and colour-coding wires for quick phase identification. That flexibility is key—it lets you pull it taut and conform it tightly around wires and awkward shapes, creating a secure, lasting wrap. Its all-around solid performance makes it the default choice for the vast majority of low-voltage jobs in residential and commercial buildings.

What is rubber tape used for?

Rubber tape is used for high-voltage applications and for creating completely waterproof seals around electrical connections. Unlike PVC tape, rubber tape is stretched during application, causing it to self-amalgamate and fuse into a solid, seamless, and moisture-proof rubber barrier.

This self-fusing process is essential for:

- Splicing medium-to-high voltage cables: Its superior insulation is a must-have for handling the higher electrical pressures safely.

- Waterproofing outdoor connections: It's perfect for protecting connections in junction boxes or outdoor fixtures exposed to rain and humidity.

- Padding and sealing irregular shapes: It moulds perfectly around bulky connectors, creating a uniform, insulated mass.

For any major MEP project, like a high-rise tower or industrial facility, rubber tape is often specified by name to meet strict UAE construction standards for high-voltage applications.

When should you use mastic tape?

You should use mastic tape when you need the ultimate defence against moisture, corrosion, and chemicals, particularly for underground or direct-burial splices. This tape features a thick, pliable mastic compound that flows into every gap to create an impenetrable seal, offering unbeatable protection against harsh elements.

Imagine mastic tape as an impenetrable shield for your most vulnerable connections. Its soft, putty-like consistency allows it to flow into every tiny gap and void, completely locking out water and other contaminants. It provides excellent electrical insulation and serious mechanical protection.

In the coastal environment of Dubai, where high humidity and salinity can wreak havoc on electrical systems, mastic tape is indispensable. It's the best way to protect buried conduits or outdoor lighting connections, ensuring the system remains reliable for years to come.

What are other specialised electrical tapes?

Beyond the three main types, other specialised tapes exist for unique jobs, such as heat-resistant glass cloth tape for motors or puncture-resistant varnished cambric tape. A knowledgeable supplier in Dubai can help you source the right product for any specific project requirement.

- Varnished Cambric Tape: Made from a fine-weave cotton fabric coated in a yellow electrical varnish, this tape offers fantastic puncture resistance and dielectric strength. It’s often used in motor repairs.

- Glass Cloth Tape: This one is built for extreme heat. With a woven fibreglass backing, it can handle temperatures that would melt standard vinyl tapes, making it ideal for wiring inside furnaces, ovens, and other high-heat equipment.

Choosing the right tape isn't just about getting the job done—it's about ensuring safety and compliance. This quick table can help you make the right call on the fly.

How do electrical insulation tape types compare?

Here's a straightforward table to help you compare the most common electrical tape types at a glance. For contractors in the UAE, this can be a quick reference to ensure you're picking the right product based on material, primary use, and what makes it unique.

| Tape Type | Backing Material | Primary Application | Key Feature |

|---|---|---|---|

| Vinyl (PVC) | Polyvinyl Chloride | General-purpose insulation, wire bundling, and colour-coding. | Flexible, stretchy, and versatile for everyday low-voltage work. |

| Rubber | Ethylene Propylene Rubber | High-voltage splicing and creating waterproof seals. | Self-amalgamating; fuses to itself to form a seamless rubber barrier. |

| Mastic | Mastic Compound on Backing | Moisture and corrosion sealing for buried or exposed connections. | Excellent adhesion and sealing properties; flows into gaps. |

| Glass Cloth | Woven Fibreglass | High-temperature applications like motors, ovens, and furnaces. | Superior heat resistance and high tensile strength. |

Having a clear understanding of these options ensures you can tackle any electrical task with confidence, knowing your work is secure and built to last.

How do you choose the right electrical tape for your project?

Choosing the right type of electrical tape is just the starting point. For any site engineer or procurement manager here in the UAE, the real story is in the technical specs. This isn't just about ticking boxes; it's about understanding the language of safety and ensuring the product you select can handle the job without a single point of failure.

Let's break down the critical numbers you'll find on a data sheet. Think of these not as abstract figures, but as a performance guarantee. They tell you exactly how a tape will hold up under the electrical stress, extreme heat, and physical strain that are all part of a normal day on a UAE construction site.

What is dielectric strength and why does it matter?

Dielectric strength is a measure of how well an electrical tape can resist high voltage before breaking down, making it the single most important electrical property. The higher the number (measured in volts per mil), the better the insulation, ensuring the tape provides a strong barrier against electrical pressure to prevent failures.

This isn't just a nice-to-have technical detail. It’s a fundamental safety requirement under local regulations from authorities like DEWA and ADDC, who mandate specific insulation levels for different jobs. A professional vinyl electrical tape, for instance, might have a dielectric strength of 1,000 volts per mil.

What is the best temperature rating for the UAE climate?

For the UAE climate, the best electrical tape should have a temperature rating of at least 90°C to withstand soaring ambient heat and the heat generated by the current itself. This rating ensures the tape's adhesive and backing will not degrade, providing reliable, long-lasting insulation in demanding environments like enclosed panels or sun-exposed conduits.

Using a tape with a lower temperature rating is a massive risk; it can lead to adhesive failure, unwrapping, and dangerously exposed live conductors.

For any building materials distributor in the region, stocking tapes with a high temperature rating is standard practice. It’s a fundamental requirement to meet UAE construction standards and ensure the longevity of electrical installations in our challenging climate.

The massive urban growth across the Middle East is pushing the demand for these high-performance materials. The UAE is leading the charge with huge investments in commercial and industrial zones that require tapes for cable splicing that can withstand 90°C temperatures and offer 10kV dielectric strength. This need is fuelled by Dubai's non-stop construction, from huge hospitality projects to essential infrastructure upgrades. You can find more insights on the growing electrical tape market on grandviewresearch.com.

Why do material thickness and adhesion strength matter?

Material thickness provides physical protection against abrasion and punctures, while adhesion strength ensures the tape stays securely wrapped without "flagging" or unravelling over time. A thicker tape (measured in mils) offers better mechanical durability, and strong adhesion is vital for maintaining a tight, long-lasting seal, especially in environments with temperature fluctuations.

Backing Thickness: A standard tape might be 7 mils thick, but for tougher jobs, heavy-duty versions can be 8.5 mils or more, giving you that extra mechanical strength.

Adhesion Strength: This measures how well the tape sticks—both to a surface and to its own backing. It’s usually shown in ounces per inch width. A strong adhesive bond is what keeps the insulation intact and protects the connection for years to come.

As a trusted supplier in Dubai, we know these specifications aren't just numbers; they are your assurance of quality and safety. They link directly to project compliance and the overall integrity of your electrical work. For a deeper dive into wiring components, have a look at our guide on selecting wires and cables in Dubai. After all, choosing the right tape is just as important as choosing the right cable.

What is the correct way to apply electrical tape?

Having the best electrical insulation tape on the market means nothing if it’s put on the wrong way. Even a premium tape can fail if it's applied poorly, leading to dangerous connections and frustrating project delays. Getting the application right is a core skill that guarantees a secure, lasting, and compliant job every single time.

Your goal isn't just to cover an exposed wire. It's to build a new, seamless protective jacket that’s just as tough as the original cable insulation. That means paying close attention to the details, like surface prep, wrapping technique, and tension control.

How do you properly wrap electrical tape?

To properly wrap electrical tape, use the half-lapping method, where each new wrap overlaps the previous one by half its width to create a seamless, uniform covering. Start on the cable's original insulation, apply slight and consistent tension as you wrap over the connection, and finish on the clean insulation on the other side.

This technique ensures there are absolutely no gaps and creates a smooth, uniform thickness across the entire splice. Be careful not to overstretch the tape, as that can weaken it.

Why is consistent tension important when applying tape?

Consistent tension is critical because it activates the tape's elastic memory, causing it to grip the wire tightly and create a void-free seal that locks out moisture. Proper tension ensures the tape conforms to every contour, but overstretching can thin the tape and reduce its insulating properties. For the final wrap, use no tension to prevent the end from lifting or "flagging" over time.

As a rule of thumb, a properly tensioned and half-lapped wrap should make the insulated area at least 1.5 times thicker than the cable’s original insulation. This is a common benchmark that helps you meet strict UAE construction standards and guarantees you've created a truly robust connection.

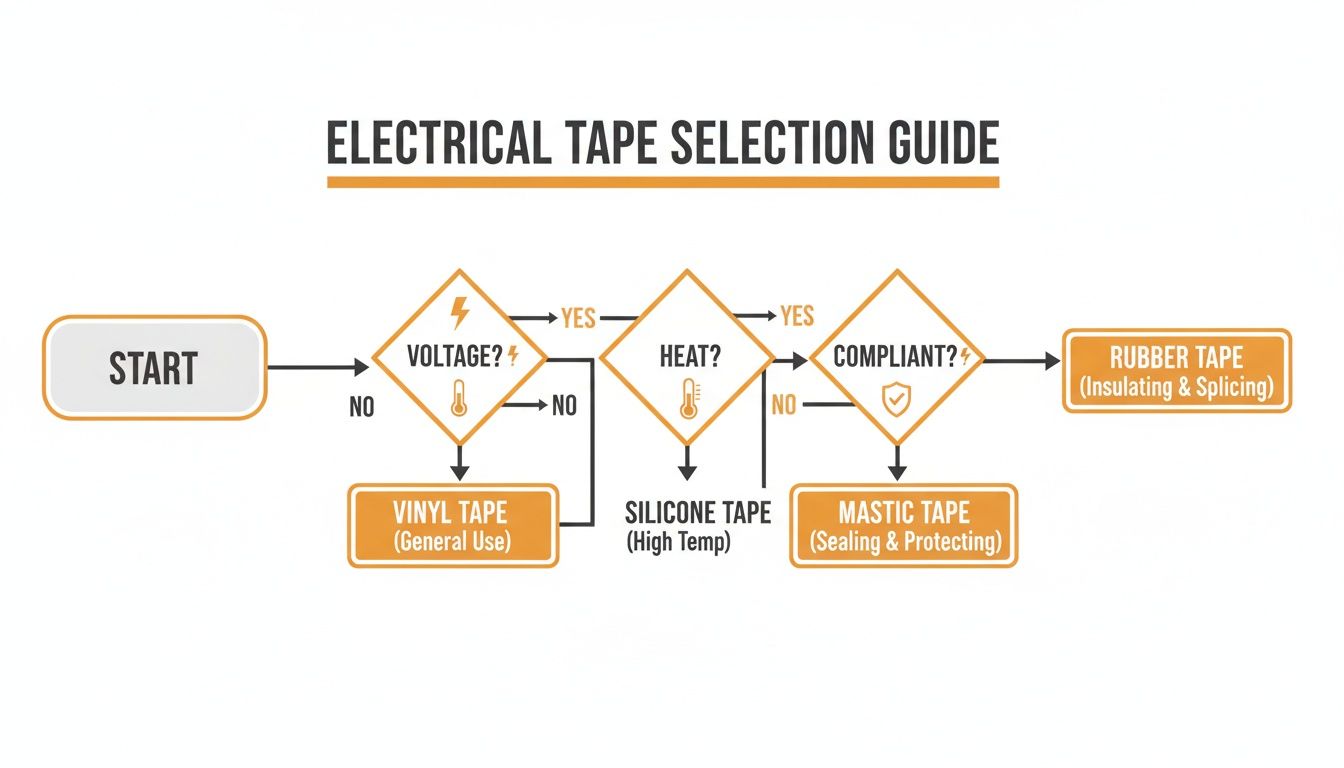

This flowchart can help you think through the selection process, making sure you start with the right tape for the job based on voltage, heat, and compliance needs.

The main takeaway here is that your project's specific needs for voltage, heat exposure, and local standards should always guide your choice. This prevents you from either over-spending or, far worse, making an unsafe selection.

What are common mistakes to avoid on site?

Common mistakes include applying tape to dirty or moist surfaces, using too few layers, leaving gaps or wrinkles in the wrap, and using the wrong type of tape for the job. As a leading building materials distributor, we see the results of both good and bad practices firsthand. Avoiding these common mistakes will make a huge difference in the quality and safety of your work.

Here’s what to watch out for on site:

- Applying Tape to Dirty Surfaces: Dust, oil, or moisture are the enemies of good adhesion. The tape’s adhesive needs a clean, dry surface to create a proper bond, so always give the area a quick wipe first.

- Using Too Few Layers: Don't be stingy with the tape. A single layer just isn't enough for proper protection. If you don't build up the tape to that required 1.5x thickness, you're leaving the connection vulnerable.

- Leaving Gaps or Wrinkles: Rushing the wrap often leads to gaps, or "holidays," and wrinkles. These create weak spots in the insulation, giving moisture and electrical shorts an easy way in.

- Using the Wrong Type of Tape: This is a critical safety error. Grabbing a general-purpose tape for a high-voltage or high-temperature application is asking for trouble. Always match the tape's specs to the job's demands.

After your work is done, verifying your electrical insulation with a ground fault test is a crucial final step to ensure the connection is solid. Mastering the right application technique is a true mark of professionalism. For any supplier in Dubai, providing top-quality materials is only half the battle; ensuring they are used correctly is what ultimately leads to safe, successful projects.

How do you meet UAE standards for electrical safety?

In the UAE's tightly regulated construction industry, compliance is the bedrock of every project. When it comes to electrical insulation tape, using the right product is essential for meeting demanding local requirements from authorities like DEWA and ADDC. This ensures every connection meets safety and quality standards, passes inspections, and avoids costly rework.

This is precisely why having a building materials distributor who knows the local landscape is so crucial.

What certifications should you look for?

When buying electrical tape in the UAE, you should look for certifications from globally respected bodies like UL (Underwriters Laboratories) and ASTM. These international standards are often required in local project specifications and guarantee the tape has been rigorously tested for flame resistance, adhesion, and dielectric strength.

Here in the UAE, local bodies like DEWA (Dubai Electricity and Water Authority) and ADDC (Abu Dhabi Distribution Company) set their own specific rules. A compliant electrical tape must meet these local regulations, which often build upon or even surpass international standards. This is a non-negotiable part of UAE construction standards.

Why is using compliant tape so important?

Using compliant electrical tape is important because it prevents insulation failure, short circuits, and fire hazards, ensuring project safety and avoiding failed inspections. Non-compliant materials can lead to stop-work orders, expensive repairs, and damage to your company's reputation. A reliable supplier in Dubai will stock municipality-approved products to protect clients from these risks.

To keep your projects on track, always check for these key compliance factors:

- Verified Performance: Certifications are your guarantee that the tape’s voltage and temperature ratings are accurate and have been independently tested.

- Traceability: Compliant products are clearly marked with manufacturer details, making documentation and quality control straightforward.

- Safety Assurance: Using approved materials shows you’re serious about safety, protecting both your crew and the people who will eventually use the building.

At the end of the day, selecting certified tape is a fundamental part of professional electrical work. Of course, once you have the right tape, you also need to know how to use it for different jobs, like when you need to know how to wire a ceiling fan switch. Here at Yasu Trading Co., we guide our clients through these complex standards, ensuring every roll of tape we provide is fully compliant and ready for any project in the UAE.

How do you find the right electrical tape supplier in Dubai?

Finding the right electrical insulation tape specialist in the UAE is about securing quality, compliance, and on-time delivery, not just the lowest price. A dedicated B2B specialist and building materials distributor like Yasu Trading Co. offers a curated selection of compliant, top-tier brands backed by full warranties, ensuring every roll meets strict UAE construction standards.

Why partner with a specialist supplier?

Partnering with a specialist supplier gives you access to technical expertise, ensures product compliance, and guarantees reliable, timely delivery to your job site. A specialist acts as an extension of your procurement team, offering practical advice, streamlined sourcing, and the logistical support needed to prevent costly project delays.

- Speedy Delivery: Getting same-day or next-day delivery to your site in Dubai, Abu Dhabi, or Sharjah keeps the work moving.

- One-Stop Sourcing: Bundling all your electrical supplies from a single source streamlines your purchasing and cuts down on paperwork.

- Real Expertise: You get immediate access to technical advice, ensuring you're not just buying tape, but buying the right tape.

Working with a supplier that maintains a deep inventory of certified materials is your best defence against subpar products. It protects your project from failed inspections and safeguards the long-term integrity of your electrical installations.

At the end of the day, your choice of a supplier in Dubai has a direct impact on your project's quality and efficiency. An established distributor offers competitive wholesale pricing, robust logistical muscle, and the technical know-how to guide you through complex job requirements. They are a critical partner in keeping your project on track.

You can learn more by exploring our detailed guide on what to look for in an electrical supplies distributor in Dubai. Partnering with an expert ensures you get the right materials, precisely when you need them.

Frequently Asked Questions

Got questions? You're not alone. When it comes to the finer points of electrical work, even seasoned professionals want to double-check the details. Here are some of the most common questions we hear from contractors and engineers on sites across the UAE.

What is the best electrical tape for high temperatures in the UAE?

For most jobs in the UAE, the best electrical tape is a high-quality vinyl tape rated for at least 90°C. For extreme heat applications near motors or in direct sun, specialised tapes like glass cloth or silicone rubber are necessary as they are designed to withstand high temperatures without degrading.

How many layers of electrical tape are needed for a safe splice?

For a safe low-voltage splice (under 600V), you need enough layers of electrical tape to make the final wrap at least 1.5 times the thickness of the cable's original insulation. This is typically achieved by using the "half-lapping" technique, where each wrap overlaps the previous one by half its width, ensuring a durable and compliant connection.

Following this isn't just good practice; it's essential for meeting UAE construction standards and ensuring every connection is safe, durable, and ready for inspection.

Can you use duct tape instead of electrical tape?

No, you absolutely cannot use duct tape instead of electrical tape for any wiring application. Duct tape has no dielectric (insulating) properties, its cloth backing can absorb moisture, and its adhesive is not rated for voltage, creating a serious risk of short circuits, electric shock, and fire. Always use properly certified electrical tape from a trusted building materials distributor.

Does electrical insulation tape expire?

Yes, electrical insulation tape does expire, typically having a shelf life of about 5 years from its manufacture date if stored correctly. Over time, the adhesive degrades and the backing can become brittle, compromising its ability to insulate and stick properly. Always check the manufacture date before use, as a good supplier in Dubai will ensure their stock is fresh.

For all your project needs, from high-performance electrical tapes to a full range of construction hardware, trust the experts. Yasu Trading Co. LLC is your dedicated partner, providing municipality-compliant materials and reliable site-direct delivery across the UAE.

Request a quote or browse our full catalogue of building materials today.