Fasteners Dubai: Your Expert Guide to Quality & Compliance

Dubai's incredible skyline didn't just appear out of the sand. It’s a testament to bold vision, of course, but it’s also held together by millions of high-performance components from fasteners Dubai suppliers. Getting this choice right isn't just a box-ticking exercise; it's a foundational decision that impacts the safety, longevity, and ultimate success of any project in this demanding environment.

The Foundations of Fastener Success in Dubai

Anyone working in Dubai knows the challenges go far beyond what you'd read in a standard textbook. You're not just putting up a building; you're fighting corrosive coastal air, navigating strict Dubai Municipality regulations, and dealing with extreme temperatures. The stakes couldn't be higher, as the integrity of the entire project often comes down to these small but critical components.

Think of this guide as your on-the-ground manual for getting it right. We'll break down the factors that truly matter when you're sourcing and using fasteners here in the UAE. Understanding this isn't just about passing inspections—it's about building with confidence and a quality that lasts.

Core Concepts for the UAE Market

To really succeed, you have to stop seeing fasteners as simple commodities. They are engineered solutions, each designed for a specific job under specific conditions. Let's look at the key pillars you need to master.

- Material Selection for Climate: We'll explore why materials like marine-grade 316 stainless steel are absolutely essential for coastal projects, and how coatings such as hot-dip galvanisation are your first line of defence against punishing heat and humidity.

- Navigating Local Codes: Getting to grips with the specific requirements from Dubai Municipality and other local authorities is non-negotiable. It's the only way to avoid expensive delays and guarantee every connection is up to code.

- Building a Reliable Supply Chain: Your quality control starts and ends with your supplier. Partnering with a reputable source that provides certified, traceable materials is the bedrock of any secure project.

The real shift in mindset is to start viewing every bolt, screw, and anchor not as a cost, but as a long-term investment in structural integrity and safety. This is how your work becomes part of the world-class construction legacy that Dubai is known for.

Making smart choices begins with understanding the full range of products available. As you map out your next project, taking a broader look at all your hardware options is a huge advantage. For a more complete picture, check out our detailed guide to construction hardware in the UAE, which offers more context on sourcing all your essential materials. When you put quality and compliance first, you're setting the stage for a successful build that will truly stand the test of time.

Understanding Core Fastener Types and Their Jobs

If you want to build structures in Dubai that last, you can't think of fasteners as just bits of hardware. They are precision-engineered tools, and each one has a very specific job to do under incredible stress. A simple way to start is to think of a bolt and nut as a powerful, removable clamp, and a screw as a wedge that threads its own way into a material. Getting this distinction right is the first step to making smarter, safer choices on any project.

This basic knowledge is what separates a standard job from a truly solid one. Take the high-tensile structural bolts used in the steel skeletons of our skyscrapers. Their one job is to create immense clamping force, squeezing beams and columns together in a grip so tight it resists any force trying to pull them apart or slice them sideways. This is a world away from what a simple screw is designed for.

Bolts and Screws: The Clamp vs. The Wedge

It’s easy to get bolts and screws mixed up, but their functions are completely different. A bolt is designed to pass through a smooth, unthreaded hole and be tightened with a nut on the other end. All its strength comes from that clamping action, which pulls two surfaces together.

A screw, on the other hand, is built to cut its own threads into a material. It acts like a wedge, pulling itself deeper to hold things in place. This is perfect for jobs like fixing drywall to studs or securing timber decking. Using a screw where a high-strength bolt is needed isn't just a mistake—it's a dangerous one.

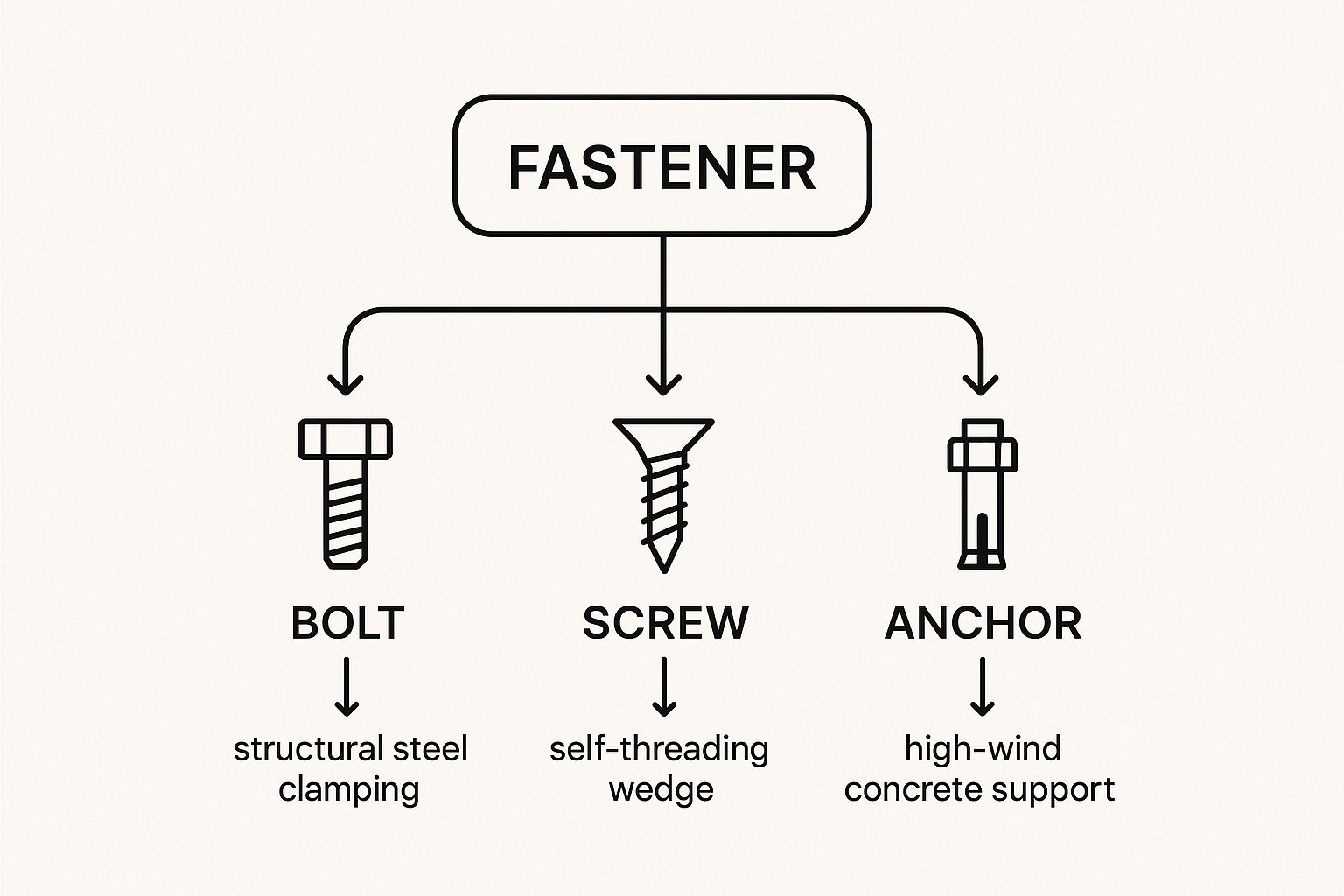

This infographic breaks down the main roles of the fasteners you’ll see on any Dubai project site.

As you can see, each type—bolt, screw, and anchor—is engineered for a specific mechanical purpose, from structural clamping to resisting pull-out forces.

The sheer scale of construction here magnifies these differences. The metal screw market in the Middle East alone was valued at USD 954.2 million in 2024, thanks to the huge urban expansion and infrastructure work happening in places like the UAE. This figure shows just how many screws are used in everything from interior finishing to roofing, and why picking the right type and material is so critical for every single application. You can explore more data on the regional market over at Grand View Research.

Anchors and Rivets: Holding Fast in Concrete and Steel

Beyond the basics of screws and bolts, other fasteners play just as vital a role, especially in Dubai where concrete is king.

- Concrete Anchors: These are the unsung heroes holding everything together. They secure heavy machinery to factory floors and brace curtain walls against high winds. Specialised expansion anchors and chemical anchors are designed to form an incredibly strong bond with concrete, giving them amazing resistance to being pulled out.

- Rivets: Think of a rivet as a permanent fastener. It starts as a smooth metal pin with a head on one end. Once it’s put in place, the other end is formed into a second head, locking it permanently. This creates a powerful, vibration-proof join, which is why you see them used so often in steel fabrication.

Choosing the right fastener is really about understanding the forces at play. Is the connection being pulled apart (tensile force), sliced (shear force), or shaken by vibration? Your answer will tell you if you need the clamping power of a bolt, the grip of a screw, or the permanence of a rivet.

The material of the fastener is just as crucial as its design. For instance, using plain mild steel bolts near the coast would be asking for rust and failure. Our guide on the differences between MS and GI coatings on bolts and nuts digs deeper into how material choice affects performance. This knowledge is non-negotiable for ensuring connections last in the harsh UAE climate, preventing failure and protecting the integrity of your entire structure.

Selecting Materials Suited for the UAE Climate

Choosing a fastener in Dubai is about far more than just size and strength; it’s a constant battle against the environment itself. The unique combination of intense solar radiation, high humidity, and airborne salinity—especially near the coast—creates one of the most aggressive corrosive environments on the planet.

Getting the material selection wrong isn’t just a simple mistake. It’s a guarantee of premature failure, unsightly rust staining, and, most critically, compromised structural integrity.

Think of your fastener’s material as its shield. An ordinary steel fastener in this climate is like bringing a wooden shield to a dragon fight—it just won’t last. The UAE’s climate demands specialised materials engineered to withstand this relentless chemical assault. This is where a real-world understanding of stainless steel, galvanised steel, and other alloys becomes an essential skill for any construction professional in the region.

The Stainless Steel Showdown

When it comes to fighting corrosion, it's crucial to know that not all stainless steel is created equal. For projects involving fasteners Dubai professionals understand the choice often boils down to two primary grades: 304 and 316. They might look identical, but their performance in the local climate is worlds apart.

Grade 304 Stainless Steel: This is the workhorse of the stainless steel family. It offers good corrosion resistance in most environments, making it an excellent choice for indoor applications or projects situated well inland, far from the coast's salty air.

Grade 316 Stainless Steel: Often called "marine-grade," this is the undisputed champion for any coastal application. Its secret weapon is molybdenum, an element that gives it superior resistance to chloride corrosion—the specific type of decay caused by saltwater. For any structure on the Palm, in Dubai Marina, or near the coastline, 316 stainless is non-negotiable.

Trying to save a few dirhams by using 304 grade where 316 is required will inevitably lead to pitting and crevice corrosion, which will severely weaken the fastener over time. That small initial saving is quickly wiped out by the high cost of replacement and potential structural damage.

Hot-Dip Galvanised Steel: A Cost-Effective Defender

While stainless steel offers premium protection, it also comes with a premium price tag. For many inland projects, hot-dip galvanised (HDG) steel provides a robust and more economical alternative. The process involves coating a steel fastener in a thick layer of molten zinc, creating a durable, sacrificial barrier.

The zinc coating on a galvanised fastener acts like a bodyguard. It corrodes first, sacrificing itself over many years to protect the steel core underneath. This is a powerful defence against the general humidity and heat found across the UAE.

It's vital, however, to understand its limits. HDG is highly effective against general atmospheric corrosion but is not a substitute for 316 stainless steel in direct contact with saltwater or heavy coastal spray. It provides a tough, abrasion-resistant coating that’s ideal for structural steel, infrastructure, and general construction away from the immediate shoreline. For a deeper look into this, you can explore more on sustainable fasteners and coatings designed to fight corrosion in challenging climates.

Comparing Your Material Options

Making the right choice means carefully balancing performance, application, and budget. To help clarify where each option fits best, we've put together a simple comparison for common scenarios in Dubai.

Fastener Material and Coating Comparison for Dubai's Climate

This table gives a comparative overview of common fastener materials and coatings, evaluating their suitability for the different environmental exposures found across the UAE.

| Material/Coating | Corrosion Resistance | Strength | Cost | Ideal Dubai Application |

|---|---|---|---|---|

| 316 Stainless Steel | Exceptional | Very High | High | Coastal projects, marine structures, and high-salinity areas. |

| 304 Stainless Steel | Good | High | Medium | Indoor use, non-coastal urban areas, and architectural finishes. |

| Hot-Dip Galvanised | Very Good | Very High | Medium-Low | Inland structural steel, infrastructure, and general construction. |

| Plain Carbon Steel | Poor | High | Low | Temporary structures or dry, controlled indoor environments only. |

In the end, specifying the correct material is a foundational step in ensuring the longevity and safety of any build in the UAE. By matching the material's defensive capabilities to the specific environmental threats of your project's location, you are investing in durability that will withstand the region's demanding climate for decades to come.

Making Sense of Dubai Municipality and Industry Standards

In Dubai’s high-stakes construction world, meeting standards isn’t just a box to tick at the end; it's the very foundation of a project. It’s not enough to just pick the right material. Every single fastener, especially those holding the structure together, has to meet a tough set of local and international rules.

Getting your head around these regulations can feel like a maze at first, but it's the only way to sidestep expensive delays, failed inspections, and the nightmare of rework. Think of these standards as the official rulebook for safety and quality. They guarantee that every connection—from a simple screw on a building’s facade to a high-tensile structural bolt—will perform exactly as designed, especially under Dubai’s demanding climate.

Dubai Municipality’s Role in Quality Control

The main authority setting the bar for building safety here is the Dubai Municipality (DM). They don't hand out a list of "approved brands." Instead, they take a performance-based approach, requiring all critical building materials, fasteners included, to comply with internationally recognised standards.

This puts the responsibility squarely on the shoulders of contractors and suppliers to prove their products are up to scratch. For anyone buying fasteners Dubai projects demand, this means one thing: paperwork is king. If you can't produce the right certificates during an inspection, your entire project can grind to a halt.

The Key International Standards You Must Know

Dubai Municipality’s rules point directly to a handful of globally trusted standards. If you’re specifying or installing fasteners in the region, knowing these is non-negotiable.

- ASTM (American Society for Testing and Materials): This is the big one, especially for structural bolts like the ASTM A325 and A490. These specs lay out everything from the bolt's chemical makeup to its exact tensile strength and hardness.

- ISO (International Organisation for Standardisation): Standards like ISO 898 define the mechanical properties of fasteners. They provide a universal benchmark, ensuring a bolt made in one country performs identically to one made elsewhere.

- DIN (Deutsches Institut für Normung): These German standards are also a common sight, particularly for specific metric fasteners and components.

Following these standards isn't about bureaucracy. It’s about ensuring predictable performance. When you use a bolt certified to a specific ASTM grade, you know exactly the load it can handle. That certainty is what keeps a structure safe and sound.

This focus on certified products is fuelling major growth. The Middle East and Africa industrial fasteners market was valued at USD 6.55 billion in 2024 and is expected to climb to USD 10.42 billion by 2033. This surge is powered by the very mega-projects that depend on unwavering quality. You can dive deeper into the market drivers in a comprehensive report from Straits Research.

Why Documentation and Traceability Are Everything

Proof of compliance is just as crucial as the physical fastener. Any reputable supplier in Dubai must provide specific documents to back up the quality and origin of their products, especially for anything structural.

The Two Documents You Absolutely Must Have:

- Material Test Certificate (MTC): This is the fastener's birth certificate. Often called a Mill Cert, it traces the product back to its manufacturing batch and provides detailed chemical and mechanical test results, proving it meets the specified standard (like ASTM A325).

- Certificate of Conformity (CoC): This is a formal declaration from the supplier or manufacturer, confirming that the product meets all relevant standards and regulations.

Together, these documents create an unbreakable chain of accountability from the steel mill right to your job site. Without them, you have no verifiable proof that the fasteners you're installing are safe. Choosing a supplier who gets this and provides the paperwork without a fuss is one of the most important calls you'll make.

Sourcing and Procuring Quality Fasteners in Dubai

A project’s structural integrity is only as solid as the supply chain holding it all together. When it comes to sourcing fasteners Dubai contractors know that this process is far more than just ticking items off an order list. It's a strategic operation where the right supplier can be the difference between hitting your milestones and facing costly, project-halting failures.

Finding a dependable supplier in the UAE's bustling market isn't about chasing the lowest price. You need a partner who gets the unique challenges here, from our climate’s impact on materials to the strict municipal codes we work with. A great supplier doesn’t just sell you bolts; they become a technical advisor, helping you sidestep risks before they become problems.

This all comes down to building a smart procurement strategy—one that balances cost, quality, and availability. It’s about creating a resilient supply line that won’t snap under pressure, ensuring the right certified products arrive on your site exactly when they’re needed.

Vetting Your Supplier The Right Way

The first move in creating that strong supply chain is to properly vet potential vendors. Anyone can talk about quality, but only a handful can back it up with transparent processes and solid documentation. When you're assessing a new supplier, your questions should be about proof, not just promises.

Start simple. Ask them for a Material Test Certificate (MTC) for a specific batch of structural bolts. A trustworthy supplier will have this ready to go. Any hesitation or inability to produce it is a massive red flag—it signals a serious lack of traceability in their stock.

Then, ask about how they manage their inventory. Take a look if you can. A well-organised warehouse with clear batch tracking and proper climate control isn't just for show; it's a sign of professionalism. It tells you they take quality control seriously from the moment a product enters their doors until it heads out to your site.

Critical Questions to Ask Every Vendor

To weed out the simple order-takers and find a true partner, you need to dig a little deeper. The goal is to get a real feel for their capabilities, technical know-how, and how they perform when the pressure is on.

Essential Vendor Questions:

- Traceability: "Can you provide full traceability from the mill to our site for this batch of A325 bolts?"

- Lead Times: "What are your standard lead times for bulk orders, and what’s your game plan for an urgent, last-minute request?"

- Custom Orders: "What’s your process for sourcing non-standard or custom-fabricated fasteners for a unique application?"

- Technical Support: "Do you have experts on your team who can advise on the best material for a highly corrosive marine environment?"

A supplier’s real value isn’t just in their catalogue; it's in the expertise they bring to your project. They should be a resource you can call for advice, helping you navigate complex specs and avoid common mistakes.

The industrial fasteners market here is booming. It was valued at USD 216.74 million in 2024 and is expected to reach USD 290.03 million by 2032. This incredible growth highlights just how much demand there is and why a stable supply chain is absolutely critical. You can get more insights into what's driving these UAE fasteners market trends.

Ultimately, sourcing quality fasteners in Dubai means having solid strategies for managing supply chain disruptions that can throw a spanner in the works. Building a resilient procurement plan protects your timelines and budget from unexpected shortages or delays. This is the kind of forward-thinking that separates the amateurs from the pros.

Building with Confidence and Lasting Integrity

As we've seen throughout this guide, fasteners aren't just nuts and bolts—they're the unsung heroes holding Dubai's incredible structures together. Sourcing the right fasteners Dubai projects demand is about more than just ticking boxes; it requires a strategic focus on long-term performance and absolute safety.

The real shift happens in your perspective. Start seeing every screw, bolt, and anchor not as a cost, but as a direct investment in the structural integrity and legacy of your project.

The Pillars of Fastening Success

So, what does this look like in practice? It comes down to getting four key areas right. Think of these as the non-negotiable pillars that support a successful build, ensuring your work not only meets but surpasses the demanding standards of the UAE.

- Matching Type to Application: Are you using the right fastener for the job? It has to be perfectly suited for the specific load and environmental stresses it will endure day in and day out.

- Choosing Climate-Ready Materials: This is crucial. Specifying materials like 316 stainless steel or hot-dip galvanised steel is your first line of defence against the region's corrosive climate.

- Adhering to Local Standards: Every single component must be certified and traceable, meeting all Dubai Municipality requirements. There are no shortcuts here.

- Building a Robust Procurement Process: Don't just look for a supplier; find a partner. You need someone who offers genuine technical expertise and can provide verifiable quality assurance.

Prioritising quality and compliance right from the start doesn't just benefit your project. It contributes to the enduring legacy of world-class construction that has put Dubai on the global map.

This dedication to detail has to run through every single part of a structure. For example, the same level of care needed for a flawless skylight installation applies to the fasteners holding it in place. It’s this holistic approach that truly builds confidence and ensures lasting integrity.

Ultimately, this is what separates a good project from a great one. When every element is selected and installed with a clear understanding of its purpose, the entire structure is safer, more durable, and performs better for decades. That’s how you build something that truly stands the test of time.

Your Questions About Dubai Fasteners, Answered

When you're working on projects in the UAE, you'll naturally have some practical questions about getting the right fasteners. I've gathered some of the most common ones I hear from professionals on the ground to give you clear, expert answers. We'll cover everything from choosing the right materials to making sure your supplier is legitimate.

Even the smallest parts can make a huge difference. For instance, people often ask about washers and whether they're truly necessary. Let me tell you, they are absolutely crucial for a solid bolted connection.

What's the Point of Using a Washer with a Bolt?

Washers might look insignificant, but they play several vital roles in protecting the entire assembly. The best way to think of a washer is as a buffer—a small but mighty mediator between the bolt head or nut and the material it's being tightened against.

One of its most important jobs is to distribute the load of the fastener evenly. Imagine tightening a nut without one. All that pressure gets focused on a tiny spot, which can easily crush or damage the surface you're working on. A washer spreads that force out over a much larger area, giving you a far more secure connection.

Beyond that, washers help you hit a few other key goals:

- Preventing Surface Damage: The friction from turning a nut can scratch, dent, or ruin a finished surface. A simple washer acts as a protective cushion, keeping the material looking good and structurally sound.

- Fighting Vibration Loosening: If your assembly is part of a machine or anything that moves, vibrations will eventually work nuts loose. Special lock washers are designed to add tension and friction to stop this from happening.

- Creating a Smooth Tightening Surface: If the surface under the nut isn't perfectly flat, getting the right tightness is just about impossible. A flat washer gives you a consistent, smooth surface, which is essential for accurate and reliable tightening.

Using the right washer isn't just "good practice." It's a fundamental part of building a fastening system that's safe, durable, and will hold up under real-world stress.

How Can I Be Sure a Supplier is Selling Genuine, Certified Fasteners?

When you're sourcing fasteners Dubai projects depend on, verification is everything. The only reliable way to know you're getting authentic, high-quality products is to insist on seeing the paperwork. Don't move forward without it.

For any structural or critical fasteners, there are two documents you absolutely must ask for:

- Material Test Certificate (MTC): Think of this as the fastener's birth certificate. It traces the product all the way back to its manufacturing batch and gives you the exact chemical makeup and mechanical properties. This is how you prove it meets a specific standard, like ASTM A325.

- Certificate of Conformity (CoC): This is a formal declaration from the manufacturer or supplier. It confirms that the product complies with all the necessary industry standards and regulations.

A trustworthy supplier will hand these documents over without a second thought. If you get excuses or delays, that’s a massive red flag. It almost always points to a lack of traceability and poor quality control.

Are There Special Fasteners for Roofing in the UAE?

Absolutely. Roofing in the UAE has its own set of challenges, so you need fasteners designed specifically for the climate and materials. A classic example is the J-Type Roofing Hook, often just called a J-bolt. These are the go-to for fixing corrugated or profiled roofing sheets to the purlins or steel frames underneath.

These fasteners are usually made from mild steel or stainless steel and are almost always galvanised. That coating is essential for providing corrosion resistance against the humidity and occasional rain we see here. Their unique 'J' shape is what makes them work—it hooks securely around the support, holding the roofing sheets down tight against wind uplift, which is a major concern in our region.

For all your construction needs, from certified structural components to specialised hardware, trust the experts. Yasu Trading Co. LLC provides a complete range of high-quality, traceable fasteners and building materials to ensure your project is built with integrity and to the highest standards. Request a quote today and build with confidence.