Fiber Cement Boards: The Best Choice for Modern Construction

Ever seen a building material that acts like concrete but works like wood? That's the magic of fiber cement boards. They're a composite material, essentially a high-tech blend of cement, sand, and cellulose fibers, and they’ve become a go-to for modern construction because of their remarkable durability and incredible versatility.

Unpacking the Power of Fiber Cement Boards

So, what's inside these boards? The recipe is deceptively simple but incredibly effective. You start with Portland cement for strength and water resistance, mix in sand for bulk and stability, and then add the secret ingredient: cellulose fibers. These tiny threads of wood pulp weave through the mixture, acting like a reinforcement grid. This prevents the board from becoming brittle and gives it an impressive ability to flex without breaking.

This combination creates a material that neatly sidesteps the problems of its competitors. It won’t rot or attract pests like wood, and it’s far more resilient than vinyl, which can easily crack under extreme temperature swings.

Why Is It Gaining Popularity?

The popularity of fiber cement boards has absolutely exploded, and it’s easy to see why. Builders and homeowners are on a constant search for materials that look great and last a lifetime, especially in demanding climates. Fiber cement delivers on both counts, offering a rock-solid shield against intense sun, high humidity, and fluctuating temperatures, all while looking fantastic.

A huge part of its appeal is the low-maintenance lifestyle it offers. Forget about the endless cycle of painting and staining that comes with wood siding. Fiber cement holds its finish for years, and a simple wash-down is usually all it needs. It's this "install it and forget it" quality that really resonates with people.

Imagine a building material with the toughness of concrete but the workability of wood. That is the essential promise of fiber cement—a product engineered to endure decades of environmental stress while maintaining its structural integrity and appearance.

A Market on the Rise

The regional construction industry has definitely caught on. Valued at roughly USD 215.85 million in 2021, the Middle East fiber cement board market is expected to climb to USD 314.91 million by 2028. This surge is being driven by large-scale commercial projects that demand materials that are tough, fire-resistant, and can stand up to anything the weather throws at them. You can dig into the specifics of this market forecast on ResearchAndMarkets.com.

This upward trend signals a real shift in how we think about building. As project standards for safety and durability get higher, materials like fiber cement are moving from being a niche alternative to the first choice for creating resilient, long-lasting structures. Plus, its ability to be shaped and finished to look like anything from classic painted wood to sleek, modern panels gives architects a huge amount of creative freedom without ever having to compromise on performance.

The Core Advantages of Building with Fiber Cement

When you're choosing building materials, it always comes down to a juggle between performance, how long it will last, and the overall value you get for your money. Fiber cement boards consistently come out on top because they deliver where many traditional materials just can't keep up. They offer a powerful blend of strength and resilience that translates into real, tangible benefits for any property.

But instead of just rattling off a list of features, let's look at how these advantages actually perform in the real world, especially in tough environments. This material isn't just another option; for a lot of projects, it’s a massive upgrade.

Unmatched Durability Against Harsh Elements

Think of a building's exterior as its armor. In climates with brutal sun, stifling humidity, and biting sand, materials like wood will inevitably warp, crack, and fade. Vinyl gets brittle and breaks down. Fiber cement, on the other hand, was born for this kind of punishment.

Because it's made from cement and sand, it’s incredibly stable. It doesn't really swell or shrink when the temperature and humidity swing wildly. This stability is what prevents the warping and cracking that plagues other materials, keeping the building’s protective shell tight and secure for decades.

One of the biggest wins for fiber cement is its ability to handle extreme weather cycles without falling apart. It just shrugs off relentless UV rays, moisture, and wind-driven sand, making it a no-brainer for coastal and desert climates.

This resilience means you can stop worrying about seasonal damage. It means a longer life for your building's exterior, protecting your investment year after year.

Superior Fire and Pest Resistance

In construction, safety and structural integrity are everything. This is an area where fiber cement offers genuine peace of mind. Wood is fuel for a fire, but fiber cement boards are non-combustible. Most products easily earn an A1 fire rating—the highest classification you can get—which means they simply will not burn.

This resistance can seriously slow the spread of a fire, buying precious time for people to get out safely and for emergency crews to arrive. It’s a vital safety feature that adds a critical layer of protection to any building, whether it's a home or a commercial property.

And it’s not just fire. Fiber cement boards are totally immune to the pests that destroy organic materials.

- Termite-Proof: The cement-based recipe offers nothing for termites or other wood-boring insects to eat, so you can forget about infestations.

- Rot-Resistant: It doesn’t soak up moisture like wood does, so fiber cement will never rot, decay, or grow mold. This is a huge advantage in humid areas or for parts of a building close to the ground.

A Low-Maintenance, Long-Term Solution

The real cost of a building material isn’t just what you pay for it upfront; it’s the total cost over its entire lifespan. And this is where fiber cement really pulls ahead, offering a "set it and forget it" quality that saves a ton of time and money down the line.

Wood siding needs to be scraped and repainted or re-stained every few years to keep it from weathering. That constant upkeep is expensive and a major hassle. By contrast, fiber cement with a quality factory finish can hold its color and look great for 15 years or more with nothing more than an occasional wash.

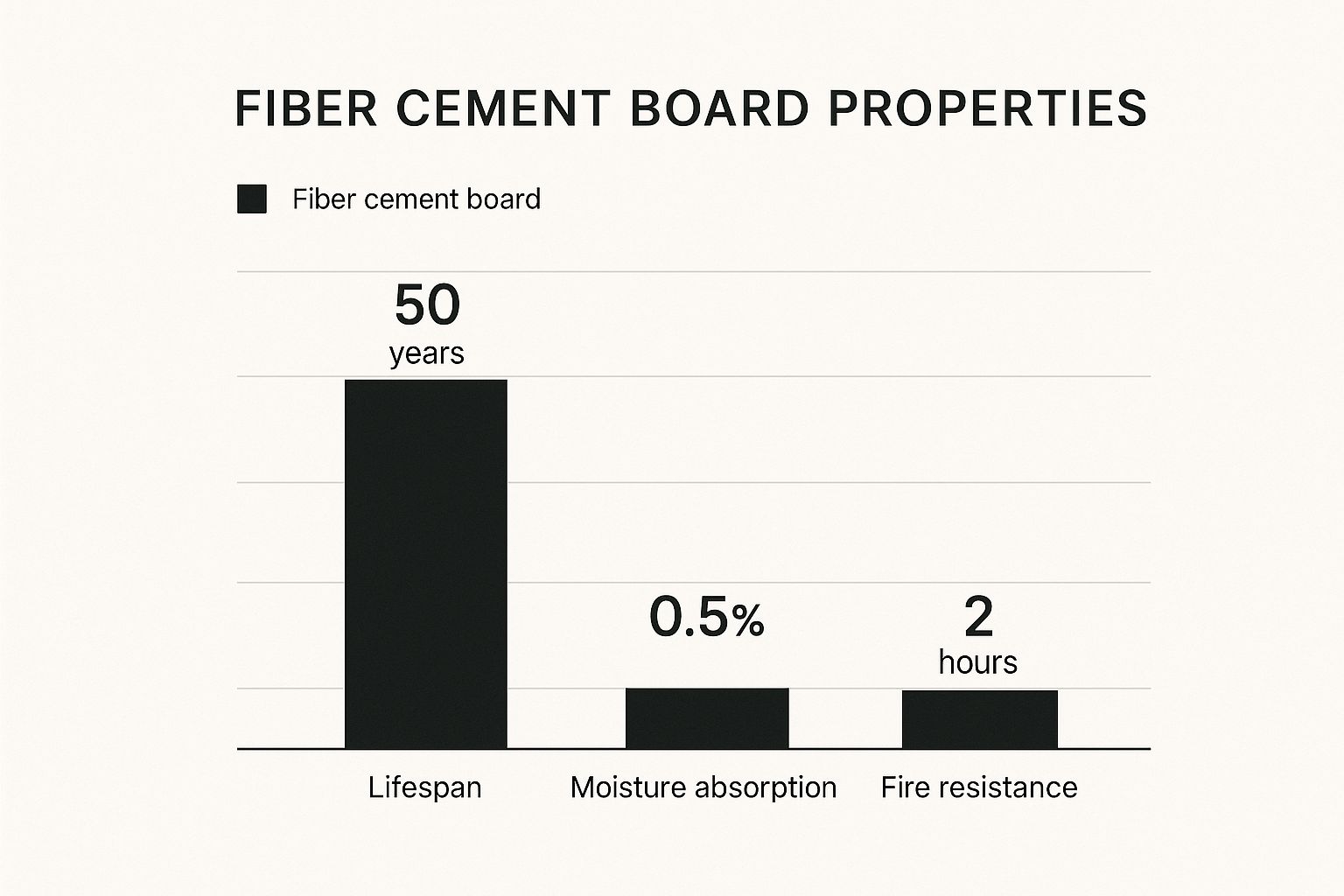

That minimal upkeep frees up money and time that would have been poured into repairs and refinishing. When you factor in its incredible lifespan, which can be more than 50 years, it's easy to see why fiber cement is such a smart financial move. Its durability also makes a building more sustainable by cutting down on the need for frequent replacements. For more on this, check out our guide to sustainable construction materials to see how long-lasting products reduce environmental impact. All told, this long-term reliability makes fiber cement a smart, forward-thinking choice.

How Fiber Cement Stacks Up Against Other Materials

Picking the right siding for a project is always a balancing act—you're weighing looks, performance, and long-term value. While fiber cement boards have a fantastic all-around profile, it helps to see how they really compare to old-school materials like wood, vinyl, and brick. Each has its place, but fiber cement often hits that sweet spot between toughness and design freedom.

The real conversation isn't just about the initial price tag; it's about what it costs you over the next few decades. You have to think about maintenance, how it will hold up to the local climate, and what it does for your property's value. Let's break it down to see where fiber cement shines.

A Head-to-Head Comparison

To get a clear picture, let's put these materials side-by-side. The table below cuts through the noise and compares fiber cement against its most common competitors on the factors that matter most.

| Feature | Fiber Cement Boards | Wood Siding | Vinyl Cladding | Brick Veneer |

|---|---|---|---|---|

| Durability | Excellent; resists rot, fire, pests, and impact. | Poor; susceptible to rot, pests, and fire. | Fair; can crack, warp, or fade over time. | Excellent; extremely durable and long-lasting. |

| Maintenance | Low; requires occasional cleaning and repainting (every 10-15 years). | High; needs regular painting, staining, and sealing. | Very Low; requires only occasional cleaning. | Very Low; may need occasional repointing. |

| Aesthetics | Highly versatile; can mimic wood, stucco, or smooth panels. | Classic, natural look with deep texture. | Can look artificial; limited texture options. | Timeless, traditional appearance. |

| Cost (Initial) | Mid-range; more than vinyl, less than brick. | Varies widely by wood type, but generally mid-to-high. | Low; typically the most budget-friendly option. | High; most expensive material and labor. |

| Fire Resistance | Excellent; non-combustible material. | Poor; highly combustible unless treated. | Poor; can melt and release toxic fumes. | Excellent; non-combustible. |

| Longevity | 50+ years | 20-40 years (with constant maintenance) | 20-30 years | 100+ years |

This comparison makes it clear: fiber cement consistently delivers high performance across the board without the extreme costs of brick or the high maintenance of wood.

Fiber Cement Boards vs. Wood Siding

Everyone loves the classic, natural beauty of wood siding. It's a timeless look, for sure. But that beauty comes with a hefty maintenance commitment. Wood is a magnet for problems—rot, termites, and moisture damage are constant threats, meaning you’re stuck in a cycle of scraping, staining, and painting to keep it from falling apart.

Fiber cement gives you the best of both worlds. It can be engineered to perfectly replicate the texture and grain of real wood, whether you want a clean clapboard look or something more rustic. The big difference? You can basically forget about the upkeep. It’s completely immune to rot and pests and won’t warp or crack when it gets wet. You get the look of wood without any of its headaches.

Fiber Cement Boards vs. Vinyl Cladding

Vinyl is the go-to choice when budget is the top priority. It's cheap upfront, lightweight, and you never have to paint it. But you often get what you pay for. Vinyl can get brittle and crack in the cold, and it has a tendency to fade or even warp in intense, direct sunlight.

Sure, fiber cement boards cost more at the outset, but they deliver a far more premium look and much greater durability. Fiber cement is significantly thicker and more rigid, giving it better impact resistance and a more solid appearance that adds real curb appeal. Plus, its color holds up for years, and it won't melt or warp from heat.

As you can see, the core properties of fiber cement add up to a tough, long-lasting exterior that has very few weak points.

Fiber Cement Boards vs. Brick Veneer

Brick is the king of durability. It has a classic look, is fantastic in a fire, and can easily last for a century with almost no maintenance. The catch? It’s expensive. Both the materials and the labor cost a pretty penny, as you need a skilled mason to lay it correctly.

This is where fiber cement offers a smart compromise. It gives you comparable fire resistance and toughness at a much more palatable price point. While it can’t perfectly match the three-dimensional texture of real brick, modern manufacturing creates panels that give a very similar visual effect. This makes fiber cement boards a great solution for projects that want that masonry look without the huge cost and structural weight.

The market is taking notice of this balanced approach. In 2022, the fiber cement board market in the Middle East & Africa was valued at around USD 837.6 million, with projections showing it could hit nearly USD 2,400 million by 2030. The high-density board segment, prized for its strength, held a dominant 60.47% share. You can dive deeper into this trend by checking out Grand View Research's analysis.

At the end of the day, every material has its pros and cons. But fiber cement's unique blend of weather resistance, low maintenance, and design flexibility makes it a top-tier contender for almost any modern building project.

Versatile Applications for Modern Construction

When you hear “fiber cement boards,” you probably picture exterior cladding. And you’re not wrong—it’s brilliant for that. But stopping there is like buying a high-end camera just to take selfies. The real magic of this material is just how incredibly versatile it is, giving builders and architects a powerful tool for all sorts of applications, both inside and out.

This flexibility isn’t accidental. It comes directly from its unique recipe: cement, sand, and cellulose fibers. This blend creates a board that’s not only tough as nails but also dimensionally stable and stubbornly resistant to moisture, fire, and pests. It’s this combination that opens up a whole world of uses that traditional materials like drywall or timber simply can’t touch.

From sleek, modern facades to hard-working interior surfaces, fiber cement boards offer a single, reliable solution for a ton of different construction challenges. Honestly, it’s one of the most practical and dynamic materials on the market today.

Expanding Beyond Exterior Walls

While fiber cement is definitely a champion of exterior cladding, its utility stretches to almost every part of a building’s outer shell. Its incredible resistance to weathering and rot makes it the perfect choice for all those finishing touches that are usually the first to show wear and tear.

You'll often see it used for:

- Soffits and Fascia: These areas are critical for protecting your roof structure from the elements. Fiber cement gives you a durable, low-maintenance shield that won’t rot or warp like wood inevitably does.

- Trim and Architectural Accents: Need clean, sharp lines around windows and doors? Fiber cement can be cut and shaped to create beautiful, crisp trims, corner boards, and other decorative elements that really define a building's character.

- Modern Fencing and Screening: For a contemporary look, large-format fiber cement panels are perfect for building stylish, private, and seriously durable fences or privacy screens that laugh in the face of bad weather.

These applications really show how you can use the material’s natural strength for both must-have protection and standout design.

A Powerful Solution for Interior Spaces

The very same qualities that make fiber cement a beast on the outside make it a secret weapon for interiors, especially in places that see a lot of moisture and heavy use. Its ability to stay solid and stable when wet gives it a huge leg up on standard gypsum board.

This is where fiber cement really shines. Think about its moisture resistance—it’s an ideal substrate for tiling in wet areas.

By using fiber cement as a tile backer board in bathrooms, kitchens, or laundry rooms, you create a solid, water-durable foundation that prevents common issues like tile pops or grout cracks. It simply will not swell, soften, or disintegrate when exposed to water.

This makes it a far better choice than drywall or even "green board," which can break down over time and lead to expensive, messy repairs. On top of that, its natural mold resistance adds another layer of protection, helping maintain healthier indoor air. We're even seeing architects use large fiber cement panels to create industrial-chic feature walls—a cool, durable focal point that’s both impact-resistant and a breeze to maintain.

When planning any project, it’s crucial to think about how all your materials will work together. For a closer look at foundational products suited for local construction, our guide on essential building materials for construction projects in Dubai is a great resource. This kind of big-picture thinking ensures every component works together seamlessly, and the versatility of fiber cement means it can play multiple roles, simplifying your material list while boosting quality across the entire build.

Best Practices for Installation and Maintenance

The incredible durability of fiber cement boards only truly shines when they're installed correctly. Getting this part right isn't just about a flawless finish; it's fundamental to safety and ensuring the material performs as promised for years to come.

Likewise, once it's up, a simple maintenance routine is all it takes to keep your project looking pristine for decades.

Proper installation starts with respecting the material itself. While it’s incredibly tough once fixed in place, fiber cement can be brittle during handling. This is always a two-person job—at a minimum—to carry and position the panels, preventing any accidental snaps or chipped corners.

This careful approach is vital. Cutting corners during installation can compromise the entire system, leading to performance issues and, more often than not, voiding the manufacturer's warranty. It’s all about building it right from the very start.

Critical Safety and Handling Procedures

Safety is absolutely non-negotiable when you’re working with fiber cement. The biggest concern is the fine silica dust created when cutting the boards. Inhaling this dust is a serious health hazard, which makes the right personal protective equipment (PPE) and cutting techniques mandatory on any job site.

Always stick to these safety protocols:

- Respiratory Protection: A properly fitted respirator mask designed to filter fine particulates is a must.

- The Right Cutting Tools: Use specialized fiber cement shears or a saw equipped with a PCD (polycrystalline diamond) tipped blade running at a low RPM. These tools are specifically designed to minimize dust.

- Good Ventilation: Whenever possible, work outdoors or in a very well-ventilated area to help disperse any airborne dust.

Beyond dust, proper handling protects the integrity of each board. When fastening, always use the corrosion-resistant screws or nails specified by the manufacturer. Be careful not to over-drive them, as this can easily crack the board. Ensuring every step meets high standards is crucial, and you can learn more about the strict building materials quality standards in the UAE to appreciate just how important compliance is.

The Simplicity of Long-Term Maintenance

Here’s the good news: one of the biggest draws of fiber cement boards is how little upkeep they demand. Their tough composition is engineered to stand up to harsh elements with minimal help from you, freeing you from the constant painting, staining, and sealing that comes with materials like wood.

A straightforward maintenance plan is all you need to preserve the material's good looks and integrity for its entire 50+ year lifespan.

The goal with fiber cement maintenance isn't constant repair; it's simple preservation. A gentle annual cleaning and a quick visual check-up are usually all it takes to keep it performing at its best.

This low-maintenance profile is a huge reason for its growing popularity. The Middle East & Africa cement board market, valued at around USD 2,258.20 million in 2022, is set to grow significantly as more projects recognize these long-term advantages. While the initial install cost might be higher, it’s easily offset by decades of minimal upkeep—a key consideration as nations like the UAE and Saudi Arabia champion green building standards in their new smart city developments. You can explore additional market trends and discover more insights on ResearchAndMarkets.com.

For routine care, a simple wash-down once a year with a soft brush, a cloth, and some mild detergent is enough to clear away any dust and grime. It's also a good idea to do a quick visual inspection now and then, checking caulked joints and keeping an eye out for any signs of settlement-related stress to ensure the building's protective envelope remains secure.

Common Questions About Fiber Cement Boards

When you’re looking at a material as solid and versatile as fiber cement, it’s only natural to have a few questions. Builders, architects, and homeowners all need straight answers to make the right call. We'll cut through the jargon and get right to the practical stuff you need to know for your next project.

From paint colors and eco-credentials to what it really takes to install, let's dig into the details that come up time and time again when people consider this fantastic building material.

Can You Paint And Customise Fiber Cement Boards?

Absolutely. One of the best things about fiber cement is how much you can do with it, design-wise. You can get boards that come pre-finished from the factory in a huge variety of colors, often with a warranty that can last 15 years or more. This is a great choice if you want a perfect, durable finish right out of the box.

Or, you can get the boards primed and ready for painting on-site. This opens up a world of possibilities, giving you total freedom to match any color palette or architectural style you have in mind.

For a finish that truly lasts, you’ll want to use a high-quality, 100% acrylic exterior paint. This flexibility means you can get the classic look of painted wood, the clean feel of stucco, or a sharp, modern aesthetic—all with the tough-as-nails resilience of fiber cement underneath. The material holds paint incredibly well, so you get a vibrant finish that resists chipping and fading for years.

Are Fiber Cement Boards An Eco-Friendly Option?

Yes, fiber cement is definitely considered a sustainable building material, and for good reason. It’s made from simple, natural ingredients like cement and sand, and the cellulose fibers often come from sustainably managed forests.

But the biggest environmental win? Its incredible lifespan. When installed correctly, fiber cement boards can last for 50 years or even longer. That kind of durability means fewer replacements over the life of a building, which saves a ton of resources and keeps waste out of landfills.

A material's true environmental impact is measured not just by what it's made of, but by how long it lasts. The longevity of fiber cement means fewer resources are consumed for repairs and replacements over decades, making it a fundamentally sustainable choice.

On top of that, its natural resistance to rot and pests means you can skip the harsh chemical treatments. This makes it a smart choice for green building projects focused on creating healthier spaces without all the volatile organic compounds (VOCs).

How Does The Cost Of Fiber Cement Compare?

When you’re thinking about cost, it’s really important to look at the whole picture, not just the price tag. The upfront material cost for fiber cement boards usually falls somewhere in the middle—it’s more affordable than brick or premium wood, but more expensive than basic vinyl siding.

But just looking at the initial price is misleading. The real value of fiber cement shines through when you consider the total cost of ownership over time. Because it needs so little maintenance, you dodge all the recurring costs that come with other materials.

Think about these long-term savings:

- No Regular Sealing or Staining: Unlike wood, you don't have to constantly treat it to protect against moisture or sun damage.

- No Pest Control: It’s completely immune to termites and other wood-boring bugs, saving you from expensive extermination bills.

- Less Frequent Painting: A quality paint job on fiber cement can easily last 10-15 years, much longer than it would on wood siding.

When you add it all up, the excellent return on investment—plus its superior look and fire resistance—makes the initial cost well worth it. It’s a smart financial move that can also boost a property's resale value by giving it a durable, great-looking exterior.

How Difficult Is Installing Fiber Cement Siding?

Putting up fiber cement siding is a job best left to the pros. The final product is incredibly tough, but the material itself needs a careful touch and the right tools during installation to avoid damage and stay safe.

The boards are heavy and can be brittle before they’re fastened, which is why it always takes at least two people to handle a panel. Trying to lift and position them on your own is a surefire way to end up with a cracked board.

You also need special tools to get clean, precise cuts. Professionals use dedicated fiber cement shears or a special low-RPM saw fitted with a polycrystalline diamond (PCD) blade. Using the wrong tool will just lead to chipped edges and a ton of dust.

Speaking of dust, the silica dust created when cutting is a serious health hazard. Proper safety gear, like respirators and good ventilation, is non-negotiable. Professional installers are trained to manage the dust and follow strict safety rules. Hiring a qualified crew ensures the job gets done right, safely, and in a way that keeps the manufacturer's warranty intact.

At Yasu Trading Co. LLC, we provide a comprehensive range of high-quality fiber cement boards and all the essential building materials your project demands. Our commitment to quality and timely delivery helps you stay on schedule and on budget. Discover our full selection and request a quote today at https://yasutrading.com.