Your Guide to Fire Rated Gypsum Board

When you hear "drywall," you probably picture the standard, paper-faced panels used in most homes. But there's a specialized version designed for a much more critical job: fire rated gypsum board.

This isn't your average wall panel. It's engineered specifically to resist and slow down the spread of fire and intense heat. The secret is in its core, which contains chemically bound water. When exposed to fire, this water is released as steam, actively cooling the panel and buying critical, life-saving minutes for people to evacuate. This one feature makes it fundamentally different from standard drywall.

How Fire Rated Gypsum Board Works

It helps to think of fire rated gypsum board less like a simple wall covering and more like a passive fire protection system, just waiting to be activated by heat. Its real strength lies in its chemical makeup.

The board’s gypsum core holds a surprising amount of water in a crystalline form—a process called hydration. You can imagine it as a solid, compressed sponge tightly holding onto water molecules.

When a fire breaks out and the board is hit with extreme heat, a chemical reaction known as calcination kicks off. This is where the magic happens. The heat forces the gypsum to release all that trapped water as steam. This is incredibly effective for two key reasons:

- The steam creates a protective barrier, physically pushing back against the flames and heat.

- The process of converting water into steam absorbs a massive amount of thermal energy, which actively cools the side of the wall not exposed to the fire.

This reaction dramatically slows the temperature rise on the other side of the wall assembly. It prevents heat from transferring through and igniting flammable materials in the next room or corridor. It’s this built-in, water-based defense that gives fire rated gypsum its life-saving power, turning a simple wall into a formidable fire barrier.

The Role of Reinforcements

To bolster this natural fire resistance, manufacturers mix special reinforcements into the gypsum core. Tiny glass fibers are evenly distributed throughout the mixture.

During a fire, as the water turns to steam and the gypsum begins to dehydrate, these glass fibers act like a tough skeleton. They hold the board together, preventing it from cracking, shrinking, or crumbling under the intense heat. This structural integrity is absolutely crucial for ensuring the wall maintains its protective barrier for its full fire-rated duration.

The core principle is beautifully simple: as long as water is being converted to steam, the temperature on the unexposed side of the board will stay close to 100°C (212°F)—the boiling point of water. This single factor delays both structural failure and the spread of deadly heat.

This quick comparison table breaks down the key differences between the drywall you see every day and its fire-rated counterpart.

Standard Drywall vs Fire Rated Gypsum Board

| Feature | Standard Gypsum Board (Drywall) | Fire Rated Gypsum Board (Type X) |

|---|---|---|

| Composition | Gypsum core with paper facing. | Gypsum core reinforced with non-combustible glass fibers. |

| Fire Resistance | Offers limited fire resistance, typically 20-30 minutes. | Designed to resist fire for at least 1 hour (60 minutes). |

| Primary Use | General interior walls and ceilings in residential settings. | Walls and ceilings in multi-family housing, commercial buildings, and garages where fire codes require a specific rating. |

| Thickness & Density | Typically lighter and available in 1/4", 3/8", and 1/2" thicknesses. | Thicker and denser, most commonly found in 5/8" thickness. |

In short, while both products look similar, Type X gypsum is a purpose-built safety material. Its reinforced core is what gives it the strength to stand up to fire long enough to make a real difference.

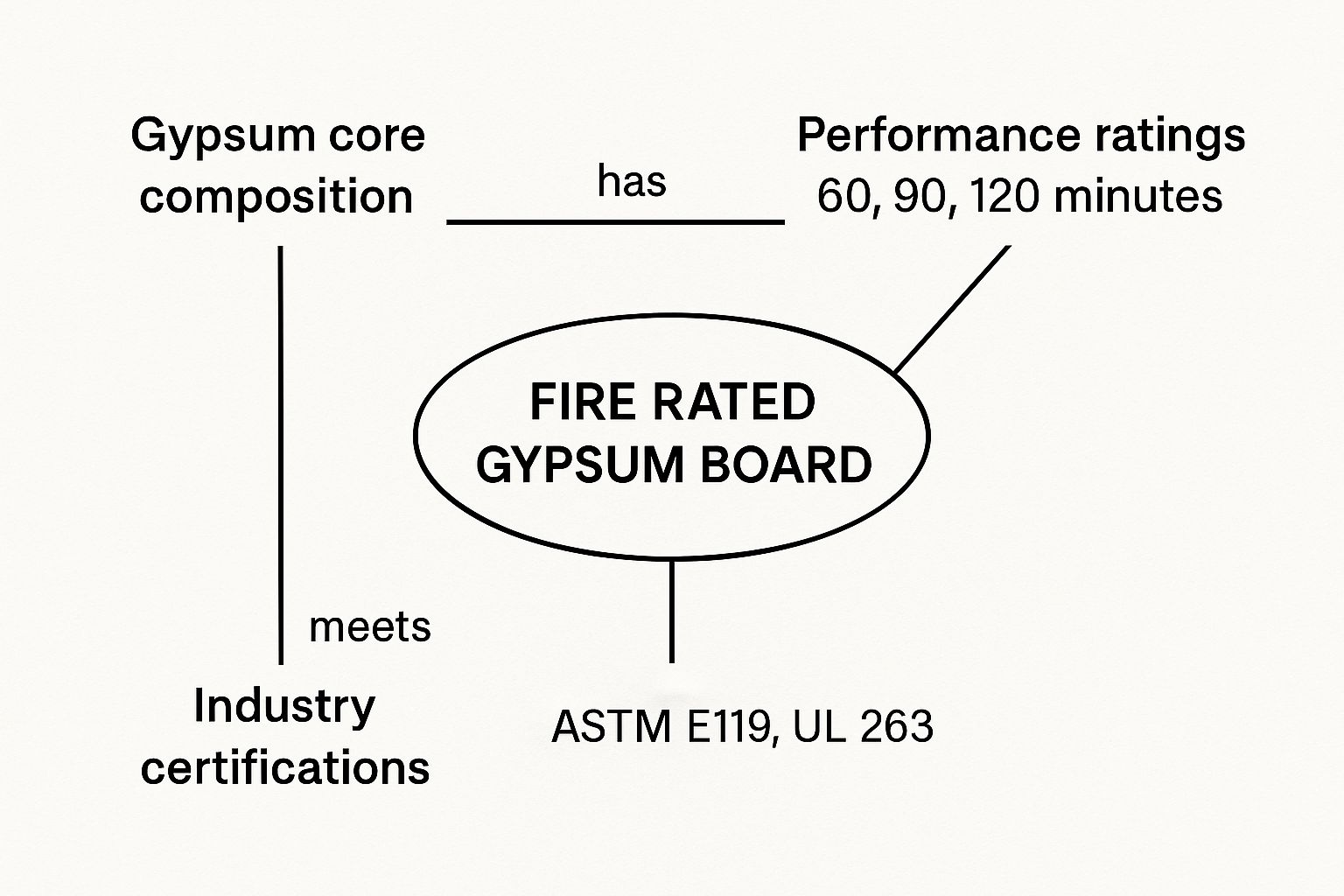

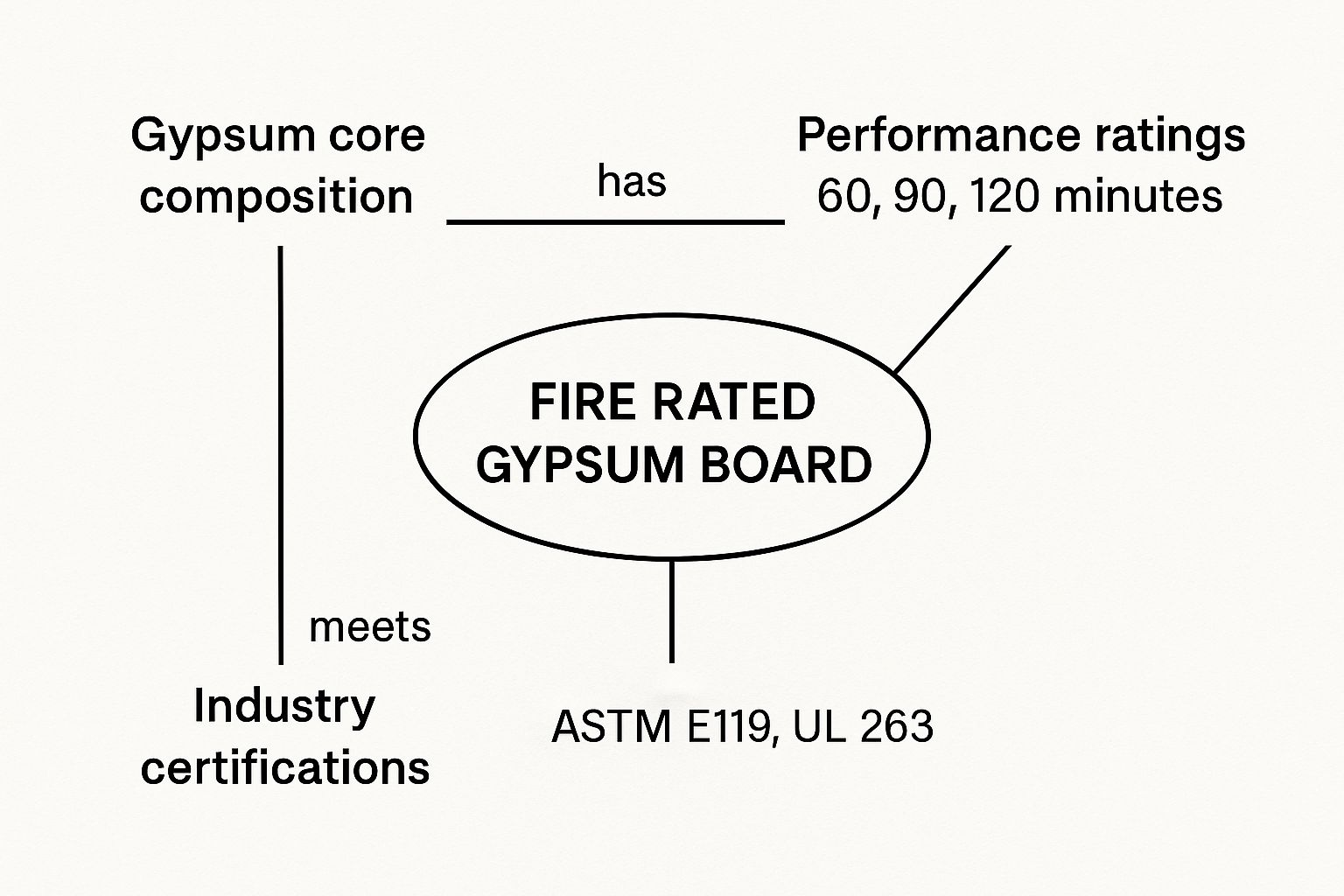

The following infographic shows how the board's unique composition directly influences its performance ratings and the certifications required to validate its safety.

As you can see, the specific formulation—especially the addition of those glass fibers—is what allows the board to achieve performance ratings of 60 or 120 minutes. These ratings are then verified through rigorous testing protocols from organizations like ASTM International and UL Solutions to ensure they perform as promised when it matters most.

Decoding Fire Ratings and Building Codes

When you see a fire rating on a gypsum board, don't just think of it as a technical spec. It’s a promise—a promise of time. That rating tells you exactly how long a wall or ceiling can hold back a fire, buying precious, life-saving minutes for people to get out of a building safely.

A 1-hour or 2-hour fire rating isn't just about the board itself. It means the entire assembly—the gypsum board, the studs, the fasteners, the joint compound—has been tested as a complete system and proven to contain a fire for that amount of time. Think of it as a crucial countdown that only begins when a fire starts. A 1-hour rated wall will maintain its integrity and block intense heat for at least 60 minutes.

This isn’t just a nice-to-have feature; it’s a non-negotiable part of modern building safety. And in places known for their towering high-rises, these rules are rightfully strict.

Connecting Ratings to Regulations

Building codes are what connect these fire ratings to the real world. They dictate precisely where specific fire-rated assemblies must be installed. The whole strategy is to compartmentalize a building, keeping a fire contained where it starts for as long as possible. This approach is what protects escape routes like stairwells and hallways, stops a fire from jumping between apartments, and shields the building's critical structural elements.

Understanding these codes isn't just for architects and engineers. For instance, across the UAE, where fire safety in dense cities is paramount, fire-rated gypsum boards are a cornerstone of building regulations. In fact, fire incident data from the region shows that using fire-resistant materials properly can slash fire-related fatalities and property damage by over 30%.

The most important takeaway? The entire assembly gets the fire rating, not just the board. If you use the wrong screws or space them incorrectly, you can compromise the whole system. That fire-rated board becomes ineffective, creating a dangerous weak point.

The Role of Building Codes

Local authorities are the ones who enforce these standards through building codes, which are legal requirements for any new construction or major renovation. These codes tell you the specific fire-resistance ratings needed for different parts of a building, all based on its intended use and how many people will be inside. For example, the wall separating your home from an attached garage almost always requires a specific fire rating for a reason.

These rules dictate exactly what kind of fire-rated gypsum board is needed for different jobs:

- Multi-family homes rely on them for the walls and floors separating individual units.

- Commercial buildings use them to protect corridors and enclose elevator shafts.

- High-rise structures depend on them to keep escape routes clear and safe.

Getting a handle on fire ratings is essential for navigating construction permit requirements and ensuring your project is fully compliant. Following these codes isn't just about passing an inspection; it's a fundamental commitment to life safety. To get a better grasp on the rules in this region, you can explore the specifics of https://yasutrading.com/blog/dubai-building-codes/. Specifying and installing the right fire-rated gypsum board assembly is simply a non-negotiable part of building responsibly.

Choosing Between Type X and Type C Gypsum

When you’re looking at fire-rated gypsum board, you’ll quickly run into the two main players on the field: Type X and Type C. Both are designed to resist fire, but they don't perform identically. Knowing the difference isn't just a technicality—it’s critical for the safety of the building.

Think of Type X gypsum board as the long-standing industry standard. It gets its strength from a gypsum core that's beefed up with glass fibers. In a fire, as the gypsum's water content turns to steam, these fibers act like a rebar skeleton, holding the board together long enough to achieve that crucial 1-hour fire rating in most wall assemblies. It’s a reliable workhorse.

But sometimes, you need more. For more demanding situations, like ceilings or assemblies that require a higher fire rating, Type C is the board for the job.

Understanding Type C Performance

Type C gypsum board is essentially a supercharged version of Type X. It takes the same basic idea but packs in more glass fibers and adds other key ingredients, like vermiculite. These additives are what make all the difference. When they get hot, they actually expand, which helps to counteract the natural shrinkage of the gypsum core as it heats up.

The real magic of Type C is its ability to hold its shape. By shrinking less, the board maintains its integrity for a longer period, preventing gaps from opening up where flames and heat could push through. This is precisely why it’s the go-to choice for ceiling assemblies, where you’re fighting gravity in a fire.

Making the Right Choice

So, which one do you pick? The decision between Type X and Type C isn't about which one is "better" in a vacuum. It’s about what the specific fire-rated assembly you’re building requires. Your choice is dictated by the tested design you have to follow to meet the building code.

- Type X: This is your solution for most standard vertical walls that need a 1-hour rating. Think party walls between apartments or the wall separating a home from its garage.

- Type C: You'll see this specified for higher-performance assemblies, like 2-hour rated walls or nearly all fire-rated ceiling systems where preventing panel collapse is absolutely critical.

At the end of the day, always check the architectural plans and the specific UL or ASTM-tested assembly design for your project. That document will tell you exactly which board to use. Ensuring you have the right board type and dimensions is non-negotiable for compliance and safety. You can learn more about standard gypsum board sizes to better match the materials to your project's demands.

Essential Installation Rules for Fire Safety

Even the best fire-rated gypsum board is only as good as its installation. You can have a premium, top-of-the-line product, but if it isn’t put up correctly, its safety potential is completely lost. That’s because the fire rating applies to the entire assembly—the studs, fasteners, board, and finishing—not just the drywall sheet itself.

Think of it like building a ship. A single weak seam or a missing bolt can be the difference between floating and sinking. In a fire-rated wall, one wrong screw or an improperly taped joint creates a fatal weak point, turning a robust 1-hour fire barrier into a wall that could fail in minutes.

Following the tested assembly designs isn't just about "best practice." It's a non-negotiable part of ensuring the system works to save lives. Details that might seem minor, like screw spacing, have been determined through intense fire testing to make sure the wall holds together when the heat is on.

Fasteners: The Foundation of Integrity

The fasteners are what physically hold the fire-rated board to the framing, making them the assembly's first line of defense. It’s a common and incredibly dangerous mistake to use the wrong screw type or length. The whole point is to keep the board firmly attached to the framing for the full duration of its fire rating.

Here are the hard and fast rules for fasteners:

- The Right Type: Use Type S screws for steel studs and Type W screws for wood studs. No exceptions. They are specifically engineered for this job.

- The Right Length: Screws have to penetrate the framing by a minimum depth, which is always specified in the tested assembly design. If they're too short, they won't have the grip to hold the board when it’s under the stress of a fire.

- The Right Spacing: The screw pattern isn't just a suggestion. A common requirement is to place screws every 200-300mm (8-12 inches) along the framing. This specific pattern is designed to distribute the load evenly and stop the board from warping and pulling away from the studs.

If you deviate from that pattern, you risk the board failing far too early, which allows fire and heat to break through the barrier.

A fire-rated wall is a chain where every link must be strong. A screw that is too short or spaced too far apart is a weak link, waiting to break under pressure and compromise the safety of the entire building.

Finishing Joints: The Final Seal

The joints between the gypsum boards are another critical point of failure. If they aren't finished correctly, these seams can crack and open up in a fire, creating a direct highway for smoke and flames. This is why the finishing products you use are just as important as the board itself.

For any fire-rated wall, you must use a setting-type joint compound, which you might know as "hot mud." Unlike the standard ready-mix bucket stuff, setting-type compounds harden through a chemical reaction. They're mostly made of gypsum, so they shrink far less and offer much better heat resistance. This is what keeps the joints sealed and solid.

Make sure any gaps wider than 3mm (1/8 inch) are pre-filled with this setting-type compound before you apply the tape. This extra step ensures there are no hidden weak spots in the wall's surface. By meticulously following these rules, you turn individual parts into a complete, life-saving system that you can count on.

Common Applications in Modern Buildings

So, now that we've covered the technical details and installation basics, where does fire-rated gypsum board actually show up in the real world? The truth is, it’s all around us. It’s one of those unsung heroes of modern construction, quietly making our homes, offices, and public spaces safer every single day.

At its core, fire-rated drywall is a cornerstone of passive fire protection. The whole strategy is to build fire-resistant compartments within a building. Think of them like bulkheads in a ship. If a fire breaks out, these barriers contain it, slow its spread, and most importantly, keep escape routes clear long enough for everyone to get out safely. You’ll find it used most often in places where fire risk is high and containment is everything.

Protecting Homes and Families

When it comes to our homes, this isn't just a "nice-to-have"—it's an absolute necessity, especially in buildings where multiple families live side-by-side.

- Party Walls: Ever wonder what separates your apartment from your neighbor's? It's almost always a wall assembly built with fire-rated gypsum board. This is what stops a fire in one unit from tearing through the entire building.

- Attached Garages: The wall between a house and an attached garage is a major weak point. Garages often store flammable materials like gasoline and paint, not to mention the vehicles themselves. Building codes demand a fire-rated barrier here to keep a potential garage fire from reaching the main living area.

These aren't just suggestions from a contractor; they are strict requirements baked into building codes, all designed to buy precious, life-saving time during an emergency.

Safeguarding Commercial and Public Spaces

The scale gets much bigger in commercial buildings, but the principle remains the same: compartmentalize and protect. The applications are extensive, with a heavy focus on high-traffic areas and the building's essential systems.

In any commercial space, the number one priority is to defend the escape routes. A protected hallway or stairwell is what allows for a calm, orderly evacuation instead of a catastrophe.

You'll see it used everywhere:

- Corridors and Stairwells: These are the arteries of escape. Fire-rated gypsum board is used to line them, ensuring they stay clear of fire and smoke for a specified amount of time.

- Elevator Shafts and Utility Chases: These vertical openings can act like chimneys in a fire, allowing it to race between floors. Encasing them in fire-rated assemblies effectively chokes off that path.

This intense focus on safety is a huge driver of market growth. In fact, the Middle East and Africa gypsum board market, where fire rated gypsum board is a key product, is projected to climb past USD 7 billion by 2029. This boom is fueled by massive construction projects in the UAE and surrounding GCC nations. If you're planning a project, our guide on gypsum board prices can offer some valuable financial perspective. This material is also critical after a disaster; understanding what’s involved in professional fire restoration services really highlights how important these boards are in getting a building back to a safe and usable state.

Of course. Here is the rewritten section, crafted to sound like an experienced human expert while adhering to all your requirements.

More Than Just Fire Resistance

It’s easy to think of fire rated gypsum board as a one-trick pony, a material you only reach for when the building code demands it for life safety. But that’s a narrow view. The very same qualities that make this board a beast in a fire—its dense, reinforced core—also happen to deliver some fantastic secondary benefits that elevate the entire building.

Think about it. That dense core doesn't just resist heat; it also creates a surprisingly quiet and private indoor environment. It's an investment that pays dividends in safety, comfort, and overall building performance long after the inspectors have signed off.

A Quieter, More Comfortable Space

One of the most noticeable side-effects of using fire rated board is its acoustic performance. The material’s density acts like a muffler for your walls, deadening airborne noise and significantly reducing sound transmission between rooms or from the outside world. This is a game-changer for creating focused office spaces, serene hotel rooms, or simply a more peaceful home.

But the benefits don't stop at sound. That same density also improves thermal performance. The board's core slows down heat transfer, which helps maintain a more stable and consistent indoor temperature. In a warm climate, the practical advantages are immediate:

- Less Strain on Your AC: Your cooling systems don't have to cycle on and off as frequently to keep the building comfortable.

- Lower Energy Bills: Reduced AC usage translates directly into tangible cost savings over the life of the building.

- Happier Occupants: A consistent, comfortable temperature makes for a more pleasant environment for everyone inside.

When you specify fire rated gypsum board, you're doing more than just meeting a safety requirement. You're actively upgrading the building envelope itself. It's a choice that results in a structure that's quieter, more energy-efficient, and ultimately, more resilient.

This powerful combination of features is exactly why it's becoming a go-to material for both walls and ceilings. You get critical fire endurance plus excellent acoustic and thermal insulation in one package. And as manufacturing technology improves, these boards are only getting more durable and sustainable, perfectly aligning with what modern construction demands. You can learn more about the growing market for these advanced materials and see where the industry is headed.

Got Questions? We've Got Answers.

Even after diving deep into a topic, there are always a few lingering questions. It’s only natural. Here are some of the most common things people ask about fire rated gypsum board, with straightforward answers to help you on your next project.

Can I Paint Fire Rated Gypsum Board Just Like Regular Drywall?

Yes, you absolutely can. The magic of fire rated board happens inside its core, so surface treatments won't interfere with its performance.

Once your boards are installed, taped, and finished with the right joint compound, you're free to prime and paint them just like any other wall. Go ahead and use your preferred interior paint, apply texture, or even hang wallpaper—its fire-resistant capabilities will remain fully intact.

How Can I Tell if Gypsum Board is Fire Rated?

On a busy job site, you need to know what you're looking at, fast. Thankfully, manufacturers make it easy to identify fire rated gypsum board. Just flip it over and check the information printed on the back.

You're looking for specific text that clearly states:

- "Type X" or "Type C"

- The board's specific fire-resistance rating

The thickness is another dead giveaway. The most common thickness for boards like Type X is 15.9mm (5/8-inch), which is noticeably beefier than standard 1/2-inch drywall.

Pro Tip: Always check the stamp on the back of the board before you install it. Thickness alone isn't a guarantee, as some non-rated boards come in similar sizes. That "Type X" or "Type C" marking is your proof.

Is Fire Rated Gypsum Board Waterproof?

No, standard fire rated gypsum board is not designed to be waterproof. Just like regular drywall, both Type X and Type C will get damaged if they're exposed to too much moisture. Water can weaken the gypsum core, invite mold, and ruin the board's integrity.

If you're working on a bathroom, a commercial kitchen, or any other wet area, you'll need a specialized product. Many manufacturers produce boards that are specifically moisture-resistant or mold-resistant, and some even offer products that combine both fire and moisture resistance for those tough spots.

For any project in the UAE, getting your hands on certified materials you can trust is non-negotiable. Yasu Trading Co. LLC stocks a complete range of high-quality, fire-rated construction materials to ensure your project is safe, compliant, and built to last. Request a quote today and build with confidence.