A Guide to Fire Resistant Wallboard in Construction

Fire resistant wallboard is a highly specialised building material, mostly made from gypsum, engineered to slow down the spread of fire and heat. Think of it as a passive fire protection system that buys a critical window of time for people to evacuate and for emergency services to arrive.

Your Building’s First Responder

It's helpful to see fire resistant wallboard not just as a product, but as an engineered safety system built right into your walls and ceilings. It’s your building’s silent first responder, always on guard. While it might look a lot like standard plasterboard on the surface, its core is completely different—it's designed from the ground up to perform under the intense stress of a fire.

The main job of this material isn't to be "fireproof," which is a common misunderstanding. No building material is truly immune to fire. Its real purpose is containment. It creates fire-rated compartments inside a building, stopping flames, smoke, and dangerously high temperatures from racing from one area to another.

The Science Behind It: Gypsum and Water

The secret to its fire-fighting power is a simple but incredibly effective chemical reaction involving its key ingredient: gypsum. Gypsum, chemically known as calcium sulphate dihydrate (CaSO4·2H2O), is a mineral that naturally holds about 21% water by weight, locked into its chemical structure.

Picture millions of microscopic water molecules trapped inside the board’s crystalline core. When a fire starts and the wallboard’s surface hits 100°C (the boiling point of water), this trapped water starts turning into steam. This process is called calcination.

Calcination is the engine driving fire resistance. As the water turns to steam, it soaks up a huge amount of heat energy from the fire. This dramatically slows down how quickly the temperature rises on the other side of the wall. In a way, the wall is sweating to keep the structure cool.

This clever conversion provides two immediate safety benefits:

- Absorbing Heat: The change from liquid water to steam uses up a lot of thermal energy, essentially starving the fire of the heat it needs to punch through the wall.

- Creating a Barrier: The steam that’s released forms a protective layer on the fire-facing side of the wall, which adds another layer of insulation against the intense heat.

How It Buys You Precious Time

This reaction keeps going as long as there is water left in the gypsum core. For a typical 5/8-inch fire-rated board, this process can hold back extreme temperatures for an hour or even longer, depending on the exact product and how it's installed. The fire has to methodically boil off all the water, layer by layer, before the gypsum itself starts to break down and the temperature on the non-fire side begins to climb.

This built-in delay is what earns the wallboard its fire-resistance rating. It’s not about stopping a fire forever; it's about managing it. This controlled delay can be the difference between a small, contained incident and a full-blown catastrophe. It protects critical structural elements like steel beams, which can lose their strength at high temperatures.

By keeping escape routes clear and containing the blaze where it started, fire resistant wallboard gives us the invaluable gift of time—the single most important factor in any fire emergency. Understanding this is fundamental for anyone designing, building, or managing safe structures in the UAE.

Decoding Fire Ratings and Wallboard Types

When you're looking at a stack of wallboards, it’s tough to tell them apart. But on the inside, where it counts, they can be worlds apart in terms of fire performance. Choosing the right one isn't just a suggestion—it's a critical safety decision based on specific classifications and fire-resistance ratings.

A fire-resistance rating is pretty straightforward: it tells you exactly how long a complete wall or ceiling system can hold up against a fire in a controlled test. You’ll see ratings like 60-minute or 120-minute. Think of it as a crucial safety buffer, giving occupants a clear window of time to evacuate and for emergency services to arrive.

It's important to remember this rating isn't just for the board itself. It's for the entire assembly—the framing, the fasteners, the joint compounds, and the wallboard working together as a single, tested unit.

Understanding Type X and Type C Wallboard

Walk onto any job site, and you’ll hear talk of Type X and Type C boards. These aren't just brand names; they signify specific formulas designed to beef up the fire resistance of the gypsum core far beyond standard plasterboard.

Type X wallboard is your go-to, foundational fire-rated option. It's usually 5/8-inch thick and has special glass fibres mixed right into its gypsum core. When things get hot, these fibres act like rebar in concrete, holding the board together as the water chemically bound in the gypsum turns to steam. This reinforcement is what helps a single layer achieve a solid one-hour fire rating in many assemblies.

Type C wallboard takes it a step further. It's an enhanced version of Type X, packing in even more glass fibres plus other additives that are engineered to reduce shrinkage. Under intense heat, these additives actually cause the core to expand slightly, fighting back against the board's natural tendency to shrink and crack. This makes Type C incredibly resilient, especially in ceilings where the board is fighting gravity while being exposed to fire.

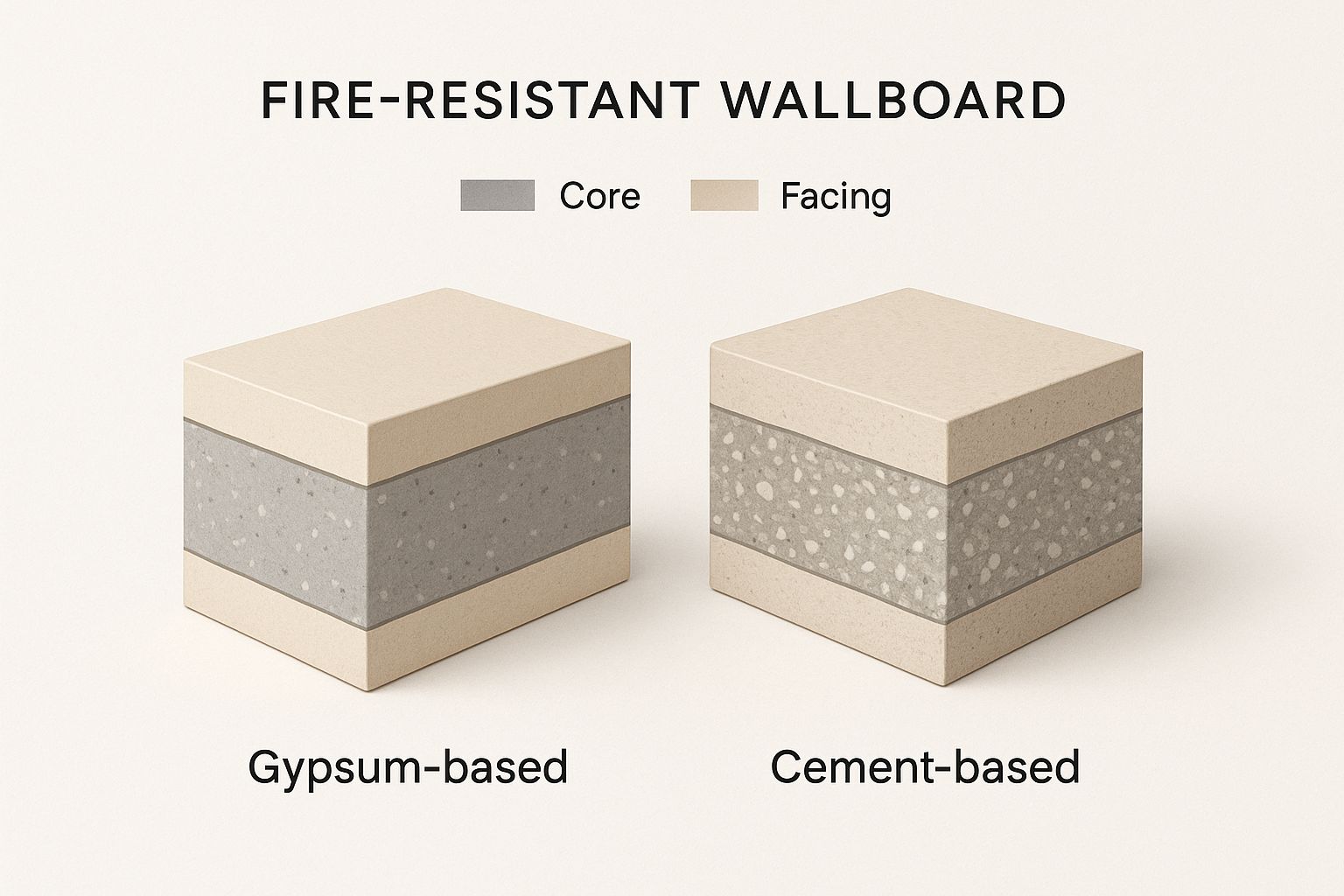

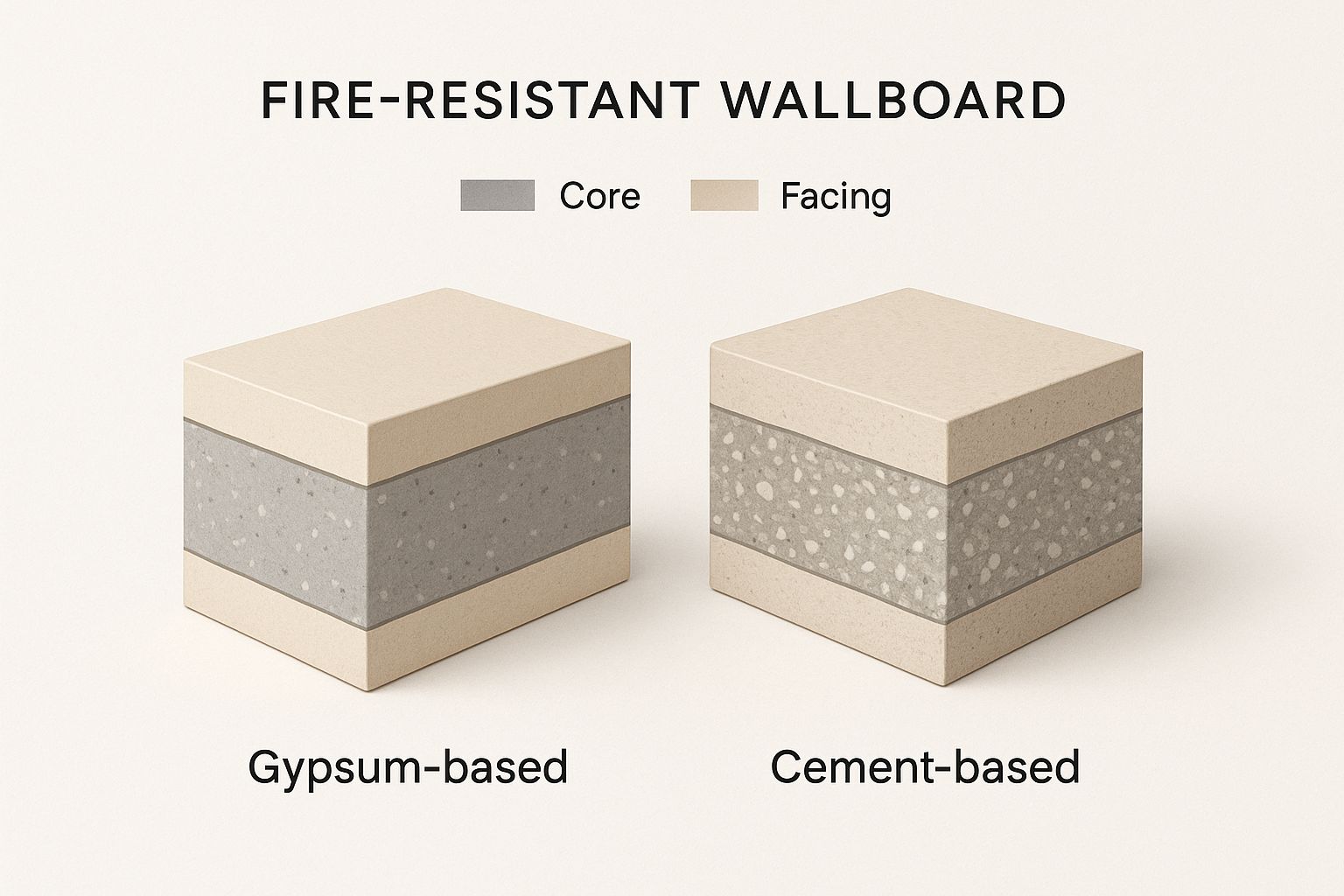

The image above gives you a clear look at the dense, reinforced core that makes this material so effective. You can see how its engineered composition is fundamentally different from other materials, and that structure is the secret to its performance.

To make selection a bit easier, here’s a quick breakdown of the common types of fire resistant wallboard.

Comparison of Fire Resistant Wallboard Types

| Wallboard Type | Core Composition | Typical Fire Rating (Single Layer) | Best Use Cases |

|---|---|---|---|

| Standard Gypsum | Gypsum plaster core between paper facings | 20-30 minutes | Non-rated walls and ceilings in residential settings. |

| Type X | Gypsum core with non-combustible glass fibres | 60 minutes (1 hour) | Single and multi-layer walls, shafts, and stairwells. |

| Type C | Enhanced gypsum core with more glass fibres and shrinkage-compensating additives | 60+ minutes (superior performance) | Ceilings, and in assemblies requiring higher fire ratings. |

This table shows that while Type X is a massive step up from standard board, Type C offers that next level of performance needed for the most demanding fire safety designs.

Key Factors Influencing Fire Ratings

The final fire rating of an assembly isn't just about slapping up a sheet of Type X. Several pieces have to come together perfectly to create a truly fire-resistant barrier.

- Board Thickness: Thicker is better. A 5/8-inch board simply has more mass and more chemically-bound water to fend off heat compared to a 1/2-inch board.

- Number of Layers: Stacking layers is a proven strategy. If one layer gets you a one-hour rating, a second layer can often double it to two hours.

- Framing and Fasteners: The devil is in the details. The type of steel studs, their spacing, and even the length and pattern of the screws are all specified in tested assembly designs. Get any of it wrong, and you could compromise the entire system.

There's a common rule of thumb on sites that Type C is for ceilings and Type X is for walls. While that's often true, the real answer depends entirely on the specific, tested, and approved assembly design. Always, always check the manufacturer’s specs and the local building codes first.

If you want to dig deeper into the nuts and bolts, you can learn more about the properties of fire rated gypsum board in our detailed guide. Making the right choice means carefully matching the board's tested capabilities with your project's safety needs and regulations to build a structure that’s genuinely safe.

Meeting UAE Fire Safety Codes and Standards

In the UAE's fast-paced construction world, following the rules isn't just about ticking a box on a form. It's the very bedrock of a safe, successful project. For anyone involved in building here—be it a developer, contractor, or architect—getting to grips with regulations like the UAE Fire and Life Safety Code of Practice is non-negotiable.

These codes are tough for a good reason. They're designed to make sure every building offers the absolute best protection for the people inside. That’s why authorities like the Dubai Civil Defence (DCD) are so strict about using building materials that have been put through the wringer and properly certified.

The Critical Role of Third-Party Certification

Think of a third-party certification as a product’s passport. It’s undeniable proof that the material has been independently tested and will perform exactly as promised when a fire breaks out. Globally respected organisations like Underwriters Laboratories (UL) or those setting British Standards (BS) conduct these gruelling tests, which act as a universal benchmark for safety.

When you specify a fire resistant wallboard that carries a UL or BS certification, you're not just taking the manufacturer's word for it. You're providing verifiable proof that it meets the high bar set by UAE authorities. It’s a layer of trust and accountability that’s essential for getting any project approved.

This focus on certified materials is only getting stronger across the region. As building codes tighten, particularly in the Middle East and Africa, the demand for proven fire resistance in gypsum board technology is soaring. This shift is reshaping construction standards and opening up the market, a trend highlighted in recent analysis of the Africa drywall market from ResearchAndMarkets.com.

Why the Entire Assembly Matters

Here’s a common and very expensive mistake: assuming that just using a certified fire-resistant board is enough to be compliant. It’s not. Fire safety codes don’t look at a wall or ceiling as just a collection of parts; they see it as a complete, integrated assembly.

A fire-rated assembly is like a chain; it is only as strong as its weakest link. The fire resistant wallboard is a crucial link, but so are the studs, fasteners, insulation, and joint compounds. If one component fails, the entire system fails.

Every single piece of that assembly has to be specified and installed exactly as laid out in the tested design. This includes everything:

- Steel Studs: The right gauge and spacing are fundamental. Get this wrong, and the wall’s structural integrity is compromised under heat.

- Fasteners: The type, length, and even the spacing of screws are meticulously detailed in certified designs. The wrong screws can lead to a catastrophic failure, fast.

- Joint Compounds: Your standard joint compound will crumble in a fire. You must use specified fire-rated taping compounds to keep the barrier intact.

- Penetrations: Any hole for pipes, ducts, or wires has to be sealed with approved firestopping sealants. Otherwise, you’re just creating a highway for smoke and flames.

Avoiding Pitfalls and Ensuring Project Success

Ignoring the full, certified assembly design is a recipe for disaster. It leads to failed inspections, expensive rework, and massive project delays. This is about more than just paperwork; it’s about making sure the system actually works when lives are on the line.

Understanding the whole picture, including how these material choices affect your budget, is crucial. You can get a clearer idea of the numbers by checking out our comprehensive guide on gypsum board prices.

By focusing on the entire system—from the board itself to the very last screw—you ensure your project doesn’t just meet the UAE’s tough fire codes, but that it delivers genuine, life-saving protection. That holistic approach is what separates the pros from the amateurs in this region.

Benefits Beyond Simple Fire Protection

While its primary job is holding back a fire, modern fire resistant wallboard delivers much more. It's easy to just see it as a mandatory safety item, but that would be missing the bigger picture. These boards are multifunctional assets that boost occupant comfort, improve the building’s overall performance, and add long-term value that goes far beyond their fire rating.

One of the most immediate—and appreciated—of these extra benefits is how well it handles sound. The dense gypsum core that’s so good at resisting fire is also fantastic at dampening noise travelling between rooms. This makes it a go-to choice for any space where peace, quiet, and privacy are non-negotiable.

Creating Quieter Spaces

Think about a bustling hotel, a block of apartments, or a busy corporate office. In places like these, noise control isn't a luxury; it's essential for a good experience. A wall system built with fire resistant wallboard can dramatically improve its Sound Transmission Class (STC) rating, which is the industry measure for how well a wall blocks airborne sound.

The higher the STC rating, the quieter and more comfortable the space feels. It’s the difference between hearing every word from the hotel room next door and enjoying your own private space. It’s what keeps a sensitive boardroom discussion from being overheard in the hallway. This acoustic insulation is what turns a functional space into a genuinely liveable and productive one.

A common misconception is that fire safety and occupant comfort are separate design goals. In reality, materials like fire resistant wallboard prove they can be achieved simultaneously, adding value without adding complexity to the project.

Enhancing Durability and Sustainability

On top of sound control, fire resistant wallboard offers real advantages in toughness and environmental responsibility. This makes it a smart pick for any high-traffic area or future-focused project.

- Improved Durability: The dense, reinforced core of Type X and Type C boards gives them far greater impact resistance than standard plasterboard. They can take the knocks. This is why you’ll often see them specified for busy corridors, lift lobbies, and other public areas where walls get their fair share of bumps and scrapes.

- Thermal Performance: That same dense core also helps with thermal efficiency. It acts as another layer of insulation, slowing down heat transfer—a massive plus in the UAE climate. Over the life of a building, this can mean less reliance on air conditioning and, consequently, lower energy bills.

- Sustainability: Gypsum itself is an abundant, naturally occurring, and non-toxic mineral. What's more, the wallboard is highly recyclable. Scrap from construction sites can be gathered and ground down to make new boards, which helps cut down on landfill waste and preserve natural resources.

At the end of the day, specifying fire resistant wallboard isn't just about ticking a safety box. It’s a strategic decision that makes a building quieter, tougher, more energy-efficient, and more sustainable. This changes the material from being a simple cost of compliance into a valuable, long-term investment in the quality of the entire structure.

Proper Installation for Guaranteed Performance

Here’s the hard truth: even the best fire-resistant wallboard on the market is only as good as its installation. All those performance guarantees and impressive fire ratings? They depend entirely on the whole assembly being put together exactly as specified. One small shortcut, one overlooked detail, and you've just created a weak link that compromises the safety of the entire building.

Think of it like building a watertight boat. You can use the most advanced, expensive materials available, but if you leave a single unsealed seam, the whole thing will fail when it’s needed most. Installing a fire-rated system is no different—it's a job of absolute precision where every single component has a critical role to play.

This isn't just about hanging up some plasterboard. It's about constructing a seamless, code-compliant fire barrier. Success comes down to fully understanding the approved assembly design and having the discipline to follow every step to the letter.

Mastering the Fundamentals of Fastening

How you attach the fire-resistant wallboard to the framing is one of the most critical parts of the job. It’s about much more than just keeping the board on the wall; it’s about making sure it stays there under the intense stress of a fire. It’s a sad fact that incorrect fastening is one of the most common—and easily avoidable—points of failure in fire-rated assemblies.

Stick to these golden rules for your fasteners:

- Correct Type and Length: Always, without exception, use the specific screw type (Type S for steel studs, for instance) and length demanded by the tested assembly design. Screws that are too short simply don't have enough bite to hold the board when things get hot.

- Precise Spacing: Fire-rated designs have exact screw spacing for a reason—it’s often much closer than what you’d see on a standard wall. This pattern is carefully engineered to distribute the load and stop the board from pulling away as it's exposed to heat.

- Proper Depth: You need to drive the screws so they sit just below the paper surface without breaking it. An overdriven screw crushes the gypsum core, and its holding power drops dramatically.

To get this right every time, specialised tools like drywall guide tip bits are invaluable. They help you avoid over-driving the screws, ensuring each fastener gives you the maximum support it was designed for.

The Critical Art of Joints and Penetrations

Once your boards are securely fastened, the next challenge is creating that truly seamless fire barrier. Every joint, every corner, and every single penetration for services is a potential highway for fire and smoke. Sealing them correctly isn't just good practice; it's non-negotiable if you want to maintain the assembly's fire rating.

Staggering your joints is a foundational technique, especially when working with multi-layer systems. By making sure the seams on one layer never line up with the seams on the layer below, you eliminate a direct path for heat to punch through. It’s a simple step that massively boosts the wall's overall resilience.

A fire-rated wall is a complete system. Using standard joint compound on a fire-rated assembly is like patching a firefighter's suit with cotton thread—it will fail at the first sign of heat. Always use specified fire-rated taping and joint compounds.

Beyond the joints, every single opening for pipes, cables, or ductwork must be sealed with approved firestopping materials. This is not a job for standard caulk. Proper firestopping sealants are engineered to expand when heated, swelling up to completely choke off any gaps and block the passage of flames and deadly smoke. If you skip this step, you’ve effectively made the entire fire-rated wall useless.

Executing these installation practices correctly is what turns a collection of individual parts into a cohesive, reliable fire protection system. For those exploring other high-performance materials, our article on https://yasutrading.com/blog/calcium-silicate-board/ offers some great insights into another excellent fire-rated option.

The Future of Fire Safety in MEA Construction

Look at the skyline across the Middle East and Africa, and you’ll see a story of ambition written in steel and glass. This isn’t just construction; it’s a full-blown boom, driven by massive government projects and a population that just keeps growing. With all this rapid development comes a huge demand for smarter building materials, and right at the top of that list is fire resistant wallboard. It’s no longer just a box to tick for compliance; it's becoming a fundamental part of building safely and efficiently.

This isn't just about putting up more buildings. It's about building them better. As architects push the boundaries of design and building codes get stricter, the way we think about passive fire protection has to evolve. The market is already responding, with new innovations popping up that are paving the way for the next generation of fire safety.

Key Drivers Shaping the Market

So, what’s really pushing fire resistant wallboard into the spotlight across the MEA? A few powerful forces are at play. The incredible scale of development is the most obvious one—we're talking about new cities and commercial hubs that need millions of square metres of high-performance walls.

The numbers back this up. The drywall market in the Middle East and Africa, which leans heavily on fire-rated gypsum boards, is on a serious growth trajectory. It’s projected to jump from around USD 4.7 billion in 2025 to a massive USD 8.6 billion by 2031. That’s a compound annual growth rate of roughly 10.2%. You can explore more data on this regional expansion and see for yourself what's fuelling the need for faster, more effective construction.

But it’s not just about volume. Other key drivers are making a big impact:

- Modular Construction: The shift to building off-site is a game-changer. This method needs materials that are light, easy to work with, and deliver predictable performance. Fire resistant wallboard is a perfect fit, helping to speed up project timelines without cutting corners.

- Stricter Regulations: After seeing what can go wrong, authorities in the UAE and across the region are tightening up fire and life safety codes. This means higher standards for passive fire protection are now non-negotiable for almost any building.

- Sustainability Goals: Everyone’s talking about green building, and for good reason. Gypsum is a natural, recyclable material, which makes fire resistant wallboard a smart, environmentally-friendly choice that helps projects earn those valuable sustainability certifications.

Innovations on the Horizon

The industry isn't sitting on its hands. Manufacturers are constantly in the lab, cooking up new products to meet the real-world demands of MEA construction sites. The goal is to create wallboards that are more than just fire-resistant—they need to perform better, be easier to install, and solve multiple problems at once.

The next wave of fire resistant wallboard is all about integrated performance. We are moving beyond single-function panels towards smart materials that solve multiple challenges at once, from fire and acoustics to moisture and impact resistance.

New technologies are starting to change what’s possible. Soon, you’ll see more lightweight boards that give you incredible fire ratings without the back-breaking weight, which is great for both the building’s structure and the workers on site. We're also seeing boards with built-in moisture and mould resistance become the new standard, giving you a complete wall solution that’s perfect for the region’s diverse climates. It’s this kind of forward-thinking that ensures the future of construction in the MEA isn't just bigger, but fundamentally safer and more resilient.

Got Questions About Fire Resistant Wallboard?

Even with a good grasp of the basics, a few specific questions always seem to pop up on site. Knowing the answers is crucial for keeping your installation safe, compliant, and up to code. Let's tackle some of the most common ones so you can build with confidence.

Is Fire Resistant Wallboard Actually “Fireproof”?

That’s a common mix-up, but no, it's not. "Fireproof" implies something is completely immune to fire, which isn't realistic for any building material.

The correct term is fire-rated. Fire resistant wallboard is engineered to hold back fire and stop it from spreading for a specific amount of time—say, 60 or 120 minutes. This creates a vital window for people to evacuate safely and for first responders to arrive. It resists fire; it doesn't ignore it.

Can I Just Use My Regular Joint Compound on These Walls?

Absolutely not. This is a mistake that can have serious consequences. A fire-rated wall is an entire system, not just a board. Every single part, down to the screws and mud, has to be up to the task.

Standard joint compound will crack and crumble under intense heat, creating a weak spot where fire and smoke can breach the wall. You must use a specially formulated fire-rated joint compound to ensure the whole assembly holds together when it matters most.

Using the wrong joint compound is one of the quickest ways to fail an inspection. Remember, the boards, fasteners, and finishing compounds are all part of one certified system. Treat them that way.

How Does It Stack Up Against Concrete Blocks for Fire Safety?

Both are excellent fire barriers, but they have different strengths. Concrete blocks are undeniably tough, but a properly constructed fire-rated drywall system often has the edge in other areas.

For starters, it's much lighter, which means less load on the building's structure and potentially lower costs for the foundation. Drywall systems are also far quicker and cleaner to put up, and it's a breeze to run plumbing and electrical lines through the wall cavity. In many situations, a fire-rated wall can provide the same—or better—fire rating as a block wall, but in a more practical and cost-effective package.

Will Painting the Wall Affect Its Fire Rating?

A normal coat of paint won't cause any issues. A thin layer of standard latex or acrylic paint doesn't interfere with the board's ability to resist fire, which comes from the water chemically trapped in its gypsum core.

That said, you should steer clear of very thick, textured finishes or any flammable coatings that could contribute to flame spread across the surface. If you're ever unsure, the best bet is to check the manufacturer's guidelines and the UAE Fire and Life Safety Code.

For all your projects requiring certified, high-performance building materials, Yasu Trading Co. LLC is your trusted partner. We provide a complete range of fire resistant wallboard and accessories to ensure your construction meets the highest standards of safety and compliance. Request a quote today and build with confidence.