Guide to gypsum board cost: Dubai Edition

When you're putting together a budget for a construction project, the installed gypsum board cost in Dubai typically falls somewhere between AED 35 and AED 75 per square metre. Of course, this isn't a fixed number. The final price tag will shift depending on the exact type of board you need, how complex the job is, and the going rate for labour. Think of this range as your starting point for a more detailed cost breakdown.

Understanding Gypsum Board Installation Costs in Dubai

Figuring out the true cost of a gypsum board installation goes far beyond the price of the panel itself. It's a bit like baking a cake – the flour is the main ingredient, but you can't forget the eggs, sugar, and the oven to bake it in. In the same way, a finished gypsum wall needs a whole system: the metal framing, all the fasteners and tapes, and crucially, the skilled hands to put it all together.

As a leading building materials distributor here in the region, we see contractors navigating these costs every single day. The initial quote you get from a supplier in Dubai is for the boards, but a truly comprehensive budget has to account for the entire system to prevent any nasty surprises down the line.

What Is the Average Cost for Gypsum Board Projects?

The total project cost is heavily influenced by which type of board is chosen to meet specific UAE construction standards. For a quick at-a-glance idea, let's look at the typical price ranges you can expect for different gypsum boards, covering both the material and the installation.

Estimated Gypsum Board Supply and Install Costs in Dubai

This table provides a quick reference for average project costs, breaking down the price ranges for different types of gypsum boards commonly used in Dubai construction projects.

| Gypsum Board Type | Average Cost per Board (AED) | Estimated Installed Cost per m² (AED) |

|---|---|---|

| Standard Gypsum Board | 20 - 30 | 35 - 50 |

| Moisture-Resistant Board | 30 - 45 | 45 - 60 |

| Fire-Rated Board | 35 - 55 | 55 - 75 |

These numbers give you a solid baseline for any initial estimates. Now, we'll dig deeper into what actually makes up these figures—from the raw materials to the labour involved—so you can build a precise and reliable budget for your next project.

What Factors Determine Gypsum Board Prices?

Figuring out the total gypsum board cost for a project is a bit like putting together a puzzle. The board itself is the biggest piece, sure, but there are several other essential parts you need to complete the picture. If you want to budget accurately, you have to look beyond the price per board and consider three core areas: the materials, the labour, and all the little accessories.

By breaking down these elements, you can see exactly where your money is going. This isn't just about accounting; it's about making smarter decisions when you're sourcing materials. Let's peel back the layers of the final price tag to understand what’s really driving the cost.

How Do Material Choices Impact the Total Price?

The type of gypsum board you choose is, without a doubt, the biggest factor shaping your material costs. It's easy to think all boards are the same, but they're not. Each type is engineered for a specific job, and its price tag reflects that specialisation.

Your project's unique needs will ultimately guide your hand. For example, staying compliant with UAE construction standards and local building regulations will often dictate exactly what you need in terms of fire safety or moisture resistance, which in turn affects your material choices.

Here’s a look at how different factors come into play:

- Board Type: A standard 12.5mm board is your most budget-friendly option. For areas like bathrooms and kitchens, you'll need moisture-resistant boards, which come at a premium. Then there are the fire-rated boards, which are crucial for meeting safety codes in both commercial and residential buildings. Their specialised composition means they are priced higher still.

- Board Thickness: While 12.5mm is the workhorse of the industry, some projects demand more. If you need better soundproofing or a higher fire rating, you might step up to 15mm boards, which will naturally increase the material cost per square metre.

- Brand and Origin: It’s no surprise that boards from well-known manufacturers often cost a bit more. What you're paying for is consistency, quality, and proven performance. Where the board comes from also matters, as import duties can easily inflate the price of materials sourced from outside the region.

When you're mapping out the budget, you have to get specific about what each area needs. To get a better handle on fire safety requirements, it’s worth checking out our in-depth guide: https://yasutrading.com/blog/your-guide-to-fire-rated-gypsum-board.

What Is the Role of Labour and Finishing?

Labour is the next major piece of your total gypsum board cost. In a fast-paced market like Dubai, installation rates aren't fixed; they can shift based on how complex the job is and the level of finish your client expects.

Think about it: putting up a simple, straight wall in a warehouse is a straightforward job. It's going to cost a lot less than installing a complex, curved partition with multiple openings in a five-star hotel. The required finish—from a basic Level 1 for concealed areas to a flawless, paint-ready Level 5 for high-end interiors—also has a huge impact on labour hours and, consequently, your final bill.

Why Are Accessories and Fasteners Important?

Finally, let's talk about the accessories. These are the small, often-overlooked items that are absolutely vital for a solid and secure installation. They are just as critical as the boards themselves and need to be factored into your budget from day one.

It’s like the supporting cast in a film; without them, the main star can’t do their job properly. The smart move is to partner with a comprehensive building materials distributor. This way, you can source everything from a single supplier in Dubai, which simplifies your logistics and usually helps you get better overall pricing.

Your shopping list of key accessories will include:

- Metal Framing: The steel studs and tracks that create the skeleton of the partition.

- Jointing Compounds: The "mud" used to tape and finish the seams between boards for a smooth surface.

- Screws and Fasteners: You'll need specialised screws to fix the boards securely to the metal frame.

- Corner Beads and Tape: These are essential for creating durable, crisp corners and reinforcing the joints.

How Does the UAE Market Influence Gypsum Costs?

If you want to get your procurement right, you need to understand the local market. It’s your secret weapon. The final gypsum board cost you see on an invoice isn’t just about the material itself; it’s deeply connected to the unique economic pulse of the UAE. To navigate this well, you have to look at the specific regulations, supply chain quirks, and economic trends that shape construction here.

Dubai's construction scene is a world of its own, with its own set of rules and logistical challenges. Think about it—from tough building codes to the sheer volume of materials flowing through its ports, a dozen local factors can push your project expenses up or down. Getting your buying strategy in sync with these market forces is absolutely key to keeping your budget and schedule from going off the rails.

How Do UAE Construction Standards Affect Material Choice?

UAE construction standards directly impact material choices by setting strict regulations for fire safety and sustainability. These rules often mandate the use of specialised, higher-cost materials like premium fire-rated or moisture-resistant boards, particularly in high-rise buildings, making them non-negotiable requirements rather than optional upgrades. This ensures buildings are safe and durable but also raises the baseline project cost from the beginning.

A decade ago, you might have gotten away with basic boards for a standard office fit-out. Not anymore. Today, the rules often demand specific fire-resistance ratings for partitions, particularly in commercial towers. This naturally pushes contractors towards more expensive, certified materials. This regulation-driven demand is a massive factor in local pricing.

To give you an idea of the scale, the UAE gypsum board market was valued at around USD 443.4 million in 2023. It’s expected to explode to USD 1,082.7 million by 2030, which is a compound annual growth rate of 13.6%. You can learn more about these market trends and their impact on pricing.

What Is the Impact of Supply Chains and Local Manufacturing?

Regional supply chains, import duties, and shipping logistics all add layers of cost to a gypsum board's final price. Any disruption, such as a port delay or truck shortage, can cause price spikes, which is why a reliable supply line from a good supplier in Dubai is essential for budget stability.

Thankfully, the strong presence of local and regional manufacturers helps keep prices more stable and ensures boards are actually available when you need them. This is where your choice of supplier really matters. Partnering with an established supplier in Dubai who has solid relationships with these factories can protect your project from the chaos of international supply issues. A good building materials distributor with a well-stocked warehouse acts as a buffer, shielding you from shortages and often securing better rates through their bulk purchasing power.

Choosing the right partners is everything. You can get a head start by exploring our detailed overview of the leading gypsum board manufacturers in Dubai to make a more informed choice. A smart approach here builds a resilient supply chain that protects both your budget and your timeline.

How to Calculate Total Gypsum Project Costs Accurately

The difference between a profitable job and a financial headache often comes down to one thing: turning a rough guess into a solid, reliable budget. Let’s walk through how to build a proper cost calculation for your next gypsum project, making sure every last screw and off-cut is accounted for from day one. Getting this right is what keeps your project on track and your budget in the black.

It all starts with getting the measurements right. You need to calculate the total surface area—walls and ceilings—that you plan to cover. Once you have that number in square metres, you can figure out how many gypsum boards you’ll need. And here's a pro tip: always, always add a buffer for waste. This covers everything from awkward cuts and simple mistakes to boards that get damaged during transport.

How Much Waste Should You Factor In?

A waste factor of 10% to 15% is a safe and standard industry practice for gypsum board jobs. For simple, rectangular rooms, a 10% buffer is usually sufficient, but for projects with complex layouts, curved walls, or numerous openings, it is safer to lean towards a 15% allowance.

Once you’ve nailed down the board count, it’s time to think about all the accessories. This means calculating the linear metres of metal framing, figuring out how many screws you'll need per board, and estimating the amount of jointing tape and compound required for that perfect, seamless finish. A good building materials distributor can often give you handy estimation guides based on your total square meterage.

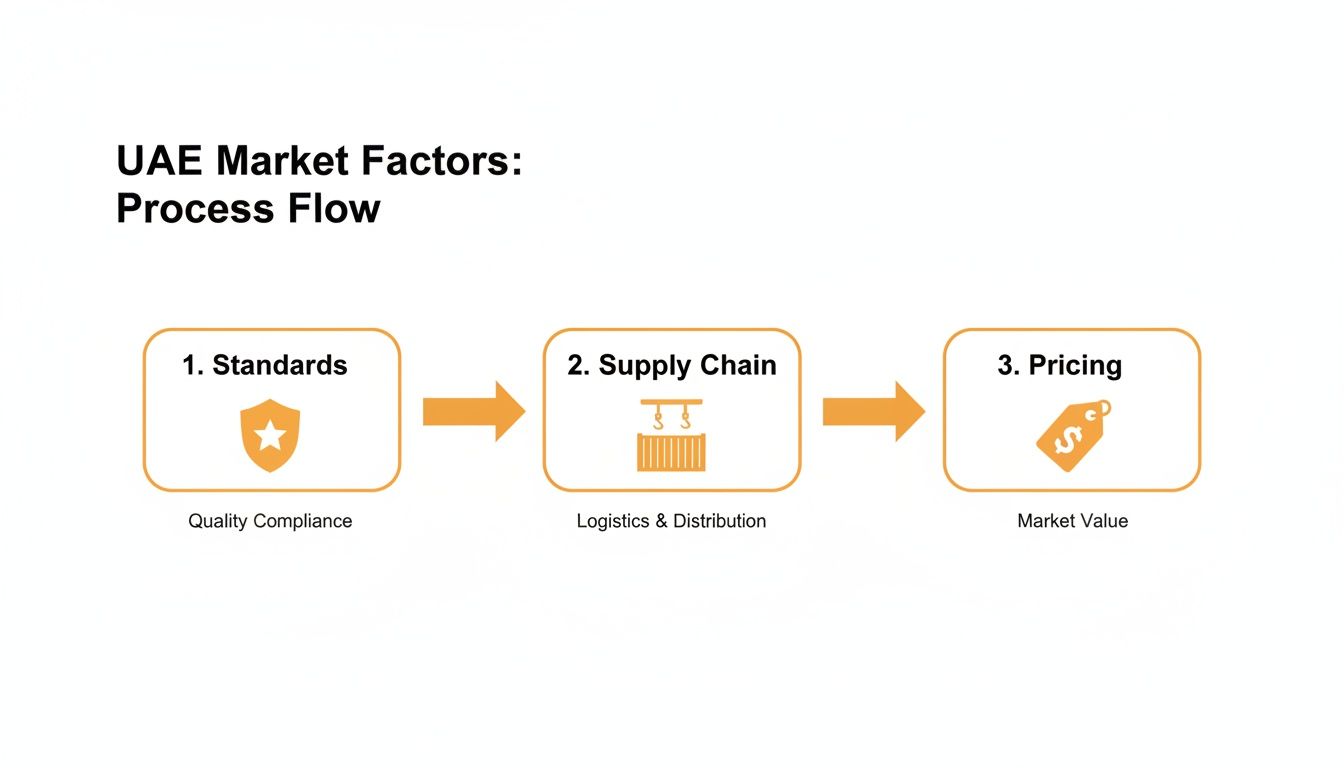

The infographic below shows how different UAE market factors—from regulations to logistics—play a role in the final price you'll pay for these materials.

As you can see, everything from mandatory UAE construction standards to the complexities of the local supply chain and pricing models has a direct impact on your final material costs.

What Does a Sample Calculation Look Like?

Let's put this into practice and work up a quick estimate for a standard office partition in Dubai. Imagine a wall that is 10 metres long, 4 metres wide, and 3 metres high. This will help make the numbers feel a bit more real.

- Calculate Total Area: A 10m x 3m wall is 30 m². A 4m x 3m wall is 12 m². That's a total of 42 m² per side. Since we're building a partition, we need to cover both sides, bringing our total area to 84 m².

- Determine Board Quantity: A standard 1.2m x 2.4m board covers 2.88 m². For our 84 m² area, we’ll need 29.1 boards. It’s always best to round up, so let's call it 30 boards.

- Add Waste Factor: We'll add a 15% waste factor to be safe. That's another 4.5 boards, so our final count is around 35 boards.

- Estimate Labour: If a contractor quotes an installed rate of AED 45/m² (which typically includes labour and materials), the calculation is straightforward: 84 m² x AED 45 = AED 3,780.

This simple calculation gives you a strong baseline. It pulls together the material costs (including waste) and the labour rate to create a reliable, all-in project budget.

Looking at historical data is also crucial for long-term planning, especially for multi-year projects where price increases need to be factored in. In the UAE, gypsum board prices have been on a steady upward trend, typically increasing by 3% to 5% annually between 2018 and 2022. For a deeper dive into these pricing patterns, you can explore the full analysis of market dynamics.

To get even more precise with your material lists and costings, specialised tools like drywall takeoff software can automate these calculations, boosting accuracy and saving a huge amount of time.

How Can Contractors Reduce Gypsum Project Expenses?

Getting a handle on your project budget goes far beyond just chasing the lowest price tag on materials. Real cost control is born from smart planning and even smarter procurement. By focusing on total efficiency—from ordering materials to the final installation—contractors can seriously cut their overall gypsum board cost without ever sacrificing the quality expected by UAE construction standards.

This isn't just about the price per board; it's about seeing the bigger picture. It means cutting down on waste, eliminating costly downtime, and making savvy decisions about which materials to use where. Let’s break down a few practical strategies that can make a real impact on your bottom line.

How Can Bulk Purchasing Reduce Costs?

Bulk purchasing reduces costs by allowing contractors to access volume discounts from a single building materials distributor. Consolidating orders for boards, framing, and accessories into one large purchase strengthens negotiating power and often leads to significantly lower per-unit prices than are available for smaller, separate buys.

This strategy does more than just lower material costs. It simplifies your entire logistics chain, cutting out multiple delivery fees and making site coordination a whole lot easier. Working with a major supplier in Dubai translates to one invoice, one delivery, and one person to call, saving you headaches and administrative overhead.

Why Is an Accurate Material Takeoff So Important?

An accurate material takeoff is crucial because it prevents both over-ordering, which leads to wasted materials and money, and under-ordering, which causes costly work stoppages and expensive rush deliveries. By precisely calculating the required materials upfront, contractors can ensure project efficiency and avoid unnecessary expenses that erode profit margins.

A meticulous takeoff is a non-negotiable part of project planning. Preventing just a few hours of labour downtime due to a material shortage can often pay for the entire cost of the extra boards you might have ordered as a buffer.

Does Selecting the Right Board Type Save Money?

Yes, selecting the right board type saves money by avoiding over-specification. Instead of using expensive high-performance boards everywhere, contractors can match the board to its specific application—using standard boards for general areas, moisture-resistant boards only in wet zones, and fire-rated boards strictly where codes require them. This targeted approach ensures compliance without paying for unnecessary features.

- Standard Boards: These are your workhorses, perfect for general living areas, bedrooms, and office partitions where no special protection is required.

- Moisture-Resistant Boards: Reserve these for wet areas only. Think bathrooms, kitchens, and laundry rooms.

- Fire-Rated Boards: Use these strictly where safety regulations demand them, like in corridors, lift shafts, and fire-rated partitions between apartments.

This targeted approach ensures you’re not spending extra on performance you don’t need. A good supplier can be your best ally here, offering guidance to help you make the most cost-effective choices while staying fully compliant with local codes. By putting these strategies into practice, you can boost efficiency and lower the final gypsum board cost on every single project.

Answering Your Top Questions About Gypsum Board Costs

Even with the best plans in hand, questions always pop up on site. Here are some quick, straight-to-the-point answers to the most common queries we hear from contractors about gypsum board projects in the UAE. Think of this as your go-to reference for making smart decisions on the fly.

What Is the Standard Gypsum Board Thickness for Walls in the UAE?

The standard gypsum board thickness for most interior walls in the UAE is 12.5mm, which is suitable for general residential and commercial spaces. However, for projects requiring enhanced fire resistance or soundproofing to meet stricter UAE construction standards, 15mm boards or multiple layers are often specified.

Always double-check your project specs to make sure you're compliant.

Does the Gypsum Board Cost Include Framing and Accessories?

No, the quoted cost for gypsum board from a supplier in Dubai almost always covers the boards only. The metal framing, jointing compounds, tape, screws, and other accessories are typically priced and sold as separate items from a building materials distributor.

A critical tip when hiring a subcontractor: nail down exactly what their per-square-metre rate covers. Is it an all-in price for supply and installation, or are materials a separate line item? Clarifying this upfront will save you from some nasty surprises down the line.

Getting this wrong can wreck your budget. A quote that looks incredibly cheap might just be for the boards, leaving you to scramble for all the other essential components from a building materials distributor.

How Much Waste Should I Budget for When Ordering Gypsum Board?

You should budget for a waste factor of 10% to 15% when ordering gypsum board. A 10% allowance is generally sufficient for simple projects with straight walls, while a 15% factor is recommended for more complex designs with curves, angles, or multiple openings to cover off-cuts and potential damage.

It feels much better to have a little extra than to be forced into placing a small, last-minute order that costs a premium in both time and money.

Are There Cheaper Alternatives to Gypsum Board for Partitions?

While alternatives like cement fibre boards or plywood exist, gypsum board is generally the most cost-effective solution for interior partitions in the UAE. Other materials typically have a higher initial cost per sheet, require more labour-intensive installation, and involve more complex finishing processes.

For getting a smooth, paint-ready surface quickly and affordably, nothing really beats gypsum board in the UAE construction scene. It hits that sweet spot of low material cost, fast installation, and a great-looking finish, making it the go-to for interior walls and ceilings.

For all your project needs, from gypsum boards and accessories to a full range of construction supplies, trust Yasu Trading Co. LLC to deliver quality materials and reliable service. We ensure your project stays on schedule and within budget.

Explore our complete range of building materials at Yasu Trading