The Essential Guide to Hardware Building Materials

Hardware building materials are the nuts and bolts of any construction project—literally. From the massive steel beams that form a skyscraper's skeleton to the tiny screws holding a cabinet together, these components provide the strength, stability, and function that bring a structure to life.

Think of them as the connective tissues of a building. They are what hold everything together, ensuring safety, durability, and a finished product that works as intended.

Unlocking the World of Hardware Building Materials

Let's use an analogy. If a building were a human body, the concrete and steel frame would be the skeleton, providing the core structure. The hardware building materials—the fasteners, anchors, nuts, and bolts—are the ligaments and tendons holding that skeleton together. Then you have the functional pieces like hinges, locks, and handles, which act like the body's joints, allowing for movement and daily use.

When you look at it that way, you see how every single piece, no matter its size, is critical. A building's integrity relies just as much on the high-tensile bolts as it does on the massive I-beams they connect. For anyone in the construction world, from a project manager on a major development to a homeowner tackling a weekend DIY project, understanding this relationship is absolutely essential.

Why a Deep Understanding Is Crucial

Knowing your hardware isn't just about picking items off a shelf; it's about guaranteeing the safety, longevity, and overall success of your project. The right material in the right place makes all the difference. For instance, if you use a standard interior screw for an outdoor deck, you're inviting rust and, eventually, structural failure.

Getting this right from the start empowers you to:

- Ensure Structural Safety: Choosing the correct load-bearing hardware is non-negotiable. It’s what prevents catastrophic failures down the line.

- Maximize Longevity: Using materials with the right properties, like corrosion-resistant stainless steel in coastal areas, can add years or even decades to a structure's life.

- Improve Project Efficiency: When you have the right components on hand, the building process is smoother, faster, and less labor-intensive.

- Control Budgets: Smart material choices help you avoid the high cost of rework, repairs, and premature replacements.

At its core, mastering hardware building materials is about mitigating risk. Every choice, from a wall anchor to a structural I-beam, is a decision that impacts the final outcome's safety, durability, and overall quality.

This guide is your map for navigating the often-complex world of construction hardware. We'll break down the different categories, explain where and why they're used, and give you the confidence to make the right call for your next project.

If you're looking for a deeper dive into specific components, check out our overview of essential building materials for construction projects in Dubai. This knowledge ensures that what you build isn't just built—it's built to last.

Decoding the Core Categories of Building Hardware

To get a real handle on hardware building materials, you first need to understand how they’re organized. It’s a bit like a chef’s pantry. You don't just toss everything in randomly; you group things by function. Spices go in one rack, oils on another shelf, and grains in their own bins. Building hardware is sorted in the same way, with logical categories based on what each piece actually does on a job site.

This organizational system is a lifesaver. It cuts through the noise of what can feel like a bottomless catalog of parts and pieces. By breaking it all down into functional groups, you can zero in on exactly what you need for a specific task, whether that’s pouring a foundation or just hanging the last door.

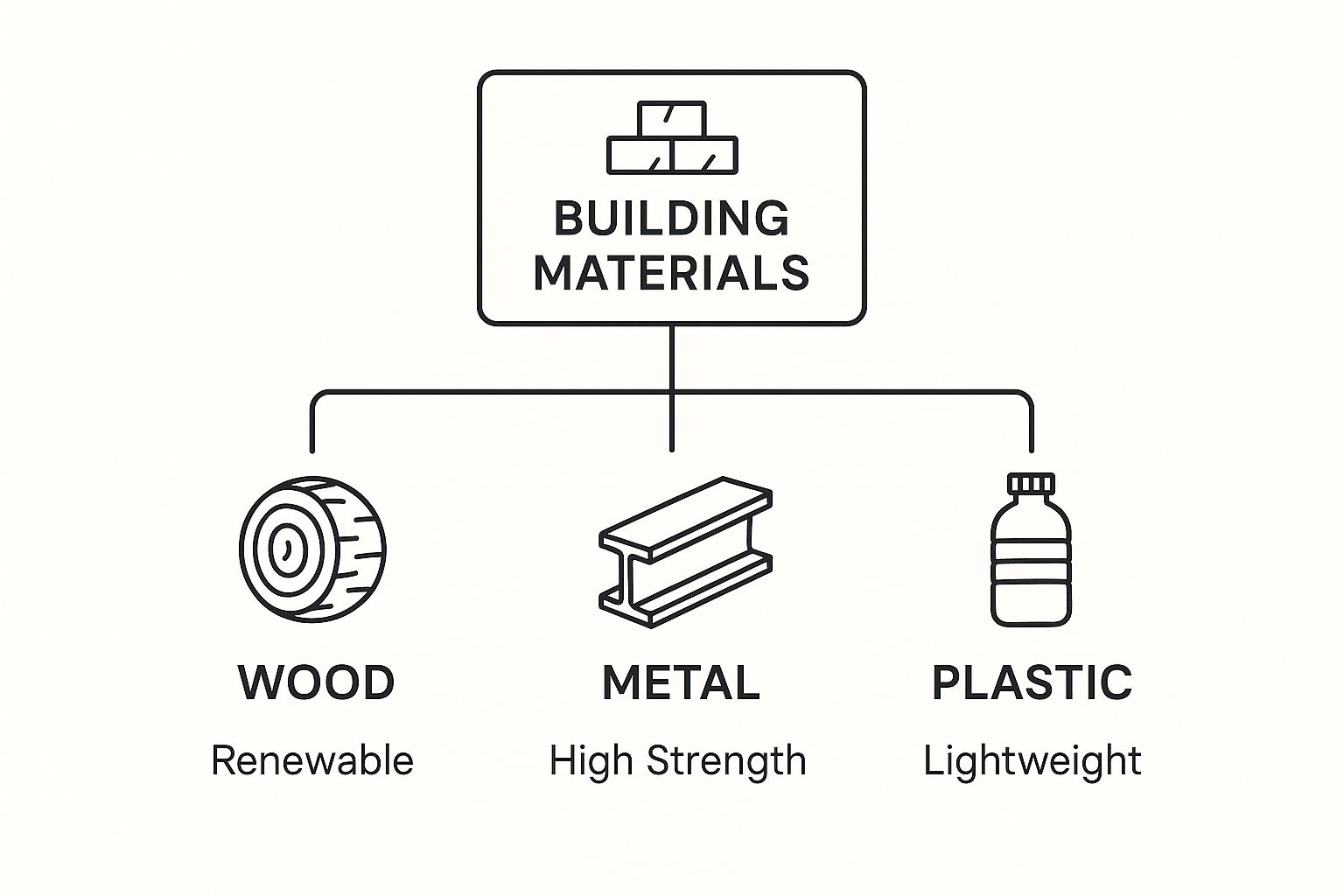

This infographic gives a great visual breakdown of the main types of building materials and how they all connect.

You can see how fundamental materials like wood, metal, and plastic, each with their own unique properties, serve as the building blocks across all the different hardware categories.

Structural Hardware: The Backbone of Construction

Structural hardware is the real heavy lifter on any project. These are the components that bear the load, providing the core strength and stability that keeps a building standing. They're the skeleton that holds everything else up, from the roof and walls right down to the floors.

We’re talking about things like steel I-beams, the rebar (reinforcing bars) you see embedded in concrete, and hefty engineered wood beams. Their entire job is to fight back against forces like tension, compression, and shear, making sure the structure holds its own against gravity and whatever the environment throws at it.

A few examples of structural hardware include:

- Rebar and Wire Mesh: These give concrete incredible tensile strength, stopping it from cracking under load.

- Structural Steel Beams and Columns: This is the primary framework you see in large commercial buildings and major infrastructure projects.

- Joist Hangers and Post Anchors: These are the essential metal connectors that create strong, secure joints in wooden framing.

Choosing the right structural hardware isn’t a guessing game. It’s a matter of pure engineering and safety, almost always spelled out in architectural plans and dictated by strict local building codes.

Fasteners and Fixings: The Connective Tissue

If structural hardware is the skeleton, then fasteners and fixings are the ligaments and tendons holding it all together. This category covers a massive range of items—all designed to join materials securely. They might be small, but you can't overstate their importance. A single failed fastener can compromise an entire section of a build.

These components are chosen based on the materials they’re joining, the load they need to carry, and the environment they'll be exposed to. A drywall screw, for instance, is a world away from a beefy lag bolt designed to anchor a heavy deck ledger board to the side of a house.

The integrity of a structure is often only as strong as its smallest connections. Fasteners and fixings are the unsung heroes that provide the critical links between larger structural elements, ensuring everything works as a cohesive unit.

Finishing Hardware: Where Functionality Meets Aesthetics

After the structure is up and everything is locked together, it's time for the finishing hardware. This category is all about the components that make a building usable and livable for the people inside. It’s where raw function meets polished design.

This is the hardware you see and touch every single day: door handles, locks, hinges, window latches, and cabinet pulls. Of course, they have to be durable enough to handle constant use, but their look and feel are just as important. They play a huge role in the interior design and overall aesthetic of a building.

To tie it all together, here’s a quick look at how these major hardware categories fit into a construction project.

Key Building Hardware Categories and Their Uses

This table summarizes the main hardware groups, the materials they're typically made from, and where you'll find them on a job site.

| Hardware Category | Common Materials | Primary Application Examples |

|---|---|---|

| Structural Hardware | Steel, Engineered Wood, Concrete | Beams, rebar for foundations, joist hangers. |

| Fasteners & Fixings | Stainless Steel, Galvanized Steel, Brass | Screws, nails, bolts, anchors for joining materials. |

| Finishing Hardware | Brass, Chrome, Stainless Steel, Bronze | Door handles, locks, hinges, cabinet pulls. |

| Plumbing & Electrical | Copper, PVC, Brass, Aluminum | Pipes, fittings, conduit, wiring connectors. |

As you can see, each category of hardware building materials serves a distinct but interconnected purpose—from guaranteeing the building's foundational strength to adding the final functional touches. You truly need every category to get from a blueprint to a finished, successful build.

The Powerhouse Materials: Steel and Concrete

In the world of construction, steel and concrete are the undisputed heavyweights. On their own, each is a truly formidable material. But bring them together, and you get a partnership so effective it has become the bedrock of modern architecture, from the tallest skyscrapers to the most expansive infrastructure projects.

This powerhouse duo works in perfect harmony, with each material making up for the other's shortcomings. It's a classic case of synergy where the combination is far more powerful than the individual parts. Grasping this relationship is the first step to understanding why these hardware building materials form the structural backbone of almost every major development today.

Their combined strength is what allows us to build structures that are not only massive but also incredibly resilient against the forces of nature, making them essential for any demanding environment.

The Perfect Partnership Of Strengths

To really get why steel and concrete work so well together, just think of them as having complementary superpowers. Concrete is a champion of compressive strength; it can handle immense crushing forces without breaking a sweat. Imagine stacking colossal weights on a concrete column—it’s not going anywhere.

But concrete has an Achilles' heel: it's incredibly weak when put under tension. Try to bend or stretch it, and it cracks almost immediately. This is where steel swoops in to save the day. Steel boasts incredible tensile strength, meaning it’s a master at resisting pulling and stretching forces. This is precisely why we embed steel rebar (reinforcing bars) inside concrete.

When a load presses down on a reinforced concrete beam, the concrete on top gets squeezed while the steel rebar at the bottom gets stretched. The concrete handles the crushing, the steel handles the pulling, and together they create a perfectly balanced and incredibly strong structural element.

This symbiotic relationship is the magic behind reinforced concrete. It’s the material that gives architects and engineers the freedom to design buildings with vast open spaces, long, unsupported spans, and complex shapes that would be unthinkable with either material alone.

Choosing The Right Grade and Mix

Of course, not all steel and concrete are created equal. The specific demands of a project—like its required load capacity, exposure to the elements, and fire resistance standards—will dictate the exact specifications of the materials you need.

Picking the right grade and mix isn't just a suggestion; it's a critical engineering decision. For example, a high-rise tower in an earthquake zone needs a very different grade of steel and a more flexible concrete mix than a simple single-story warehouse built in a stable climate.

Here are a few factors that come into play:

- Structural Steel Grades: Different grades offer varying levels of yield strength and ductility. The highest grades are reserved for columns and beams that have to support extreme loads.

- Concrete Mix Designs: The ratio of cement, water, and aggregates (like sand and gravel) can be tweaked to achieve specific properties, such as faster curing times, better workability, or enhanced resistance to water and chemicals.

When you're working with materials this tough, having the right concrete and asphalt cutting tools is just as important as the materials themselves. Precision is key, both during installation and for any later modifications.

A Foundation For Regional Growth

The dominance of steel and concrete is especially clear in rapidly developing regions. Concrete, in particular, is a foundational material in the Middle East and Africa, underpinning the region’s incredible urban growth and infrastructure boom.

Ultimately, the correct specification and application of steel and concrete are fundamental to structural integrity. These materials aren't just components in a build; they are the assurance of safety, longevity, and the ambitious possibilities of modern construction.

Choosing the Right Hardware for Your Project

Getting the hardware selection right is probably the most make-or-break moment for any project. This is where a blueprint’s potential either comes to life or gets fatally kneecapped. A bad choice here can spiral into budget blowouts, missed deadlines, and even long-term structural problems or safety issues.

Think of it like cooking. You wouldn't swap salt for sugar and expect a gourmet meal. In the same way, using an interior-grade fastener for an outdoor deck is just asking for trouble. Let’s walk through a practical framework to help you make smart choices and avoid those expensive mistakes.

Evaluating Load-Bearing Requirements

First things first: what kind of weight does the hardware need to hold up? And it’s not just about the static weight of the structure itself, what we call the dead load. You also have to factor in the live loads—all the variable forces from people walking around, furniture, equipment, and even things like a heavy snowstorm or strong winds.

Engineers and architects spend a lot of time calculating these forces to make sure they specify hardware with the right tensile and shear strength. The bolts holding a balcony to the side of a building, for example, have to support the balcony's own weight plus the weight of every single person who might pile onto it during a party.

A project's structural integrity is only as strong as its weakest connection. Overlooking load-bearing specifications is not just poor practice; it's a significant safety risk that can have catastrophic consequences.

Responding to Environmental Factors

Where your project is located has a massive impact on which materials you can use. A beachfront villa in Dubai is constantly getting blasted with salt spray and humidity—a perfect storm for corrosion. Using standard carbon steel hardware in that kind of setting would be a huge mistake; it would rust out and fail in no time.

This is where the properties of the material itself become critical. For that coastal home, you’d want to specify stainless steel (usually grade 316) or hot-dip galvanized hardware. Both are champs at resisting corrosion. On the other hand, a warehouse built inland in a dry climate probably doesn't need those premium, pricier materials, letting you make a more cost-effective choice.

To get a handle on the environmental demands, ask yourself these questions:

- Moisture and Humidity: Is the hardware going to be exposed to rain, condensation, or just plain damp air?

- Chemical Exposure: Could it come into contact with industrial chemicals, pollutants, or harsh cleaning agents?

- Temperature Fluctuations: Will the hardware have to deal with extreme heat and cold? That can cause materials to expand and contract, putting stress on the connections.

Ensuring Material Compatibility

It’s also surprisingly easy to forget that different materials don’t always play nice together. There's a nasty little phenomenon called galvanic corrosion that can happen when two different metals touch each other while wet. It’s an electrochemical reaction that makes one of the metals corrode way faster than it normally would.

A classic mistake is using galvanized steel screws to attach a copper fixture. The steel will corrode at an alarming rate, and before you know it, the connection is compromised. The fix is simple: always use fasteners made from a compatible metal, or use something like a nylon washer to create a barrier between them. That little bit of attention to detail goes a long way in ensuring your connections last. When you're renovating, a complete shower door buying guide can help you select compatible finishing hardware for wet environments.

Adhering to Building Codes and Standards

Last but certainly not least, every material choice has to follow local and national building codes. These aren't just friendly suggestions; they're legally enforced rules designed to keep people safe. For any project in the UAE, for example, you have to stick to the specific guidelines from the Dubai Municipality and other authorities.

These codes cover everything from the type of fire-rated hardware you need in a commercial building to the specific anchors required in an earthquake-prone area. Always, always check the latest local building codes before you sign off on your material list. For a closer look at these requirements, you can check out our ultimate guide to choosing building hardware in Dubai, which gets into the specifics for the region.

The Rise of Smart Building Hardware

We're witnessing the next major leap in construction. It's a shift away from purely static materials and into an era of truly intelligent buildings. The traditional hardware building materials we've relied on for centuries are now being fused with technology, giving our structures something akin to a central nervous system.

This isn't about slapping a smart thermostat on the wall and calling it a day. We're talking about a fundamental change where passive components like concrete and steel become active systems—able to communicate, monitor, and react to the world around them.

The magic behind this is embedded hardware. Think of tiny sensors, microcontrollers, and actuators built directly into materials during manufacturing or construction. These almost invisible components become the eyes, ears, and reflexes of the building itself, collecting invaluable data and triggering automated responses that once felt like science fiction.

From Passive Structures to Active Systems

At its core, this evolution is about giving materials a voice—the ability to tell us how they're doing. Imagine concrete that can send an alert when it's under too much stress or detect the tiny beginnings of internal cracks long before a human inspector ever could. This is a game-changer for preventative maintenance, helping us head off catastrophic failures and dramatically extend a building's lifespan.

This constant stream of information creates a live feedback loop between the structure and its managers. Instead of relying on scheduled, often infrequent, manual inspections, building operators get a real-time pulse on everything from structural integrity to energy use.

Smart hardware transforms buildings from inert shells into dynamic ecosystems. They can now self-diagnose, optimize their own performance, and create safer, more comfortable environments for people inside.

What we're seeing is the birth of a whole new category of building hardware, one that marries physical strength with digital intelligence.

Real-World Applications of Smart Hardware

This smart integration is already showing up in powerful ways, making buildings more functional and secure. For example, the same principles that enable advanced smart access control systems for custom driveway gates are being scaled up to protect entire facilities.

But it goes much further. Here are just a few applications making a real impact:

- Energy Optimization: Smart windows can automatically tint to block solar heat, while HVAC sensors adjust airflow based on how many people are in a room. The result? A massive reduction in energy waste.

- Enhanced Safety: Modern fire detection can pinpoint a fire's exact origin, while integrated air quality sensors can detect pollutants and trigger ventilation systems automatically.

- Structural Health Monitoring: You'll find embedded sensors in modern bridges and skyscrapers constantly listening for vibrations, strain, and signs of corrosion, providing crucial early warnings about potential issues.

This isn't a niche trend; it's backed by serious investment. The embedded hardware market in the Middle East and Africa, currently valued around USD 2.1 billion, is on track to grow at a compound annual rate of about 5.7% over the next decade. This momentum signals a clear commitment to building the smarter, more resilient structures of the future.

Navigating Procurement and Supply Chain Realities

Even the most buttoned-up project plan can fall apart because of one logistical hiccup. You can have the perfect list of hardware building materials, but getting them to your site on time and on budget? That's a completely different ball game. Today's construction supply chain is a sprawling, intricate web, and it's vulnerable to all sorts of disruptions that can create serious ripple effects.

Think about it: sudden price spikes for raw materials, unexpected shortages of that one critical component, or a simple shipping delay can bring your entire project to a grinding halt. For any project manager or procurement officer, mastering the supply chain isn't just admin work—it's a core strategy for keeping your timeline and budget intact. You have to be proactive to shield your project from these all-too-common hurdles.

Building a Resilient Supply Chain

A truly resilient supply chain is one that can bend without breaking. It's built to anticipate disruptions and has backup plans ready to go, keeping materials moving no matter what. The first, most crucial step? Stop relying on a single source for your most important components.

Supplier diversification is your best line of defense against local shortages or problems with a specific vendor. When you build relationships with multiple suppliers, you give yourself options and flexibility. If one supplier gets held up, you can pivot to another without suffering major downtime. This simple strategy builds redundancy right into your procurement process, turning a potential crisis into a manageable hiccup.

Technology is also a massive game-changer for modern inventory management. Real-time tracking systems and predictive analytics help you forecast your needs with far greater accuracy, letting you maintain just the right amount of stock on hand. This data-first approach cuts down on the risk of running out of essential items while also saving you the cost of overstocking and storing excess materials on-site.

A strong supply chain does more than just deliver materials; it delivers certainty. By diversifying suppliers and using technology, you transform procurement from a reactive process into a strategic advantage that safeguards your project's schedule and budget.

Addressing Broader Market Pressures

Beyond day-to-day logistics, the construction industry is grappling with bigger economic challenges. Large-scale projects are frequently up against significant labor shortages, with some reports showing a staggering 56% deficit in available skilled workers. This gap drives up costs and puts immense strain on timelines, pushing more firms toward automation and AI-powered project management to stay efficient.

Getting the legal side right is just as critical. Your contracts are what define who is responsible for delays and cost overruns. A well-written contract can shield you from a supplier's unforeseen problems, but a vague or poorly drafted one can leave you completely exposed. It’s always worth working with legal experts to make sure your agreements are rock-solid and fair.

Of course, staying on top of local building codes and regulations is non-negotiable. For a closer look at region-specific rules, you can explore our guide on navigating the regulations for building materials in the UAE.

In the end, successful procurement all comes down to foresight. By actively managing all these moving parts—from supplier relationships to contractual fine print—you can ensure a smooth, predictable flow of hardware building materials from the warehouse right to your work site.

Got Questions About Building Materials? We’ve Got Answers.

No matter how detailed your blueprint is, you’re bound to run into questions once you start handling the actual hardware. Getting these little details sorted out early can save you a world of headaches, wasted money, and last-minute panic.

We hear the same questions pop up time and again from pros and DIYers alike. So, let's clear the air and get you building with more confidence.

What's the Real Difference Between Galvanized and Stainless Steel?

This one trips a lot of people up because both are go-to choices for fighting off rust. But how they do it is completely different.

Think of galvanized steel as a regular steel core wearing a zinc jacket. That zinc coating takes the hit first, sacrificing itself to the elements to protect the steel underneath. It's a tough, effective barrier.

Stainless steel, on the other hand, has its protection built right in. It's an alloy, meaning chromium is mixed into the molten steel from the very start. This creates a passive, self-healing layer that prevents rust from ever taking hold. It's protected through and through, not just on the surface.

The Bottom Line: Galvanized steel is a fantastic, budget-friendly option for most outdoor projects. Just be aware that a deep scratch can break the zinc armor and let rust in. For ultimate, long-term durability—especially in salty coastal air or chemically harsh spots—stainless steel is the undisputed champion.

Can I Get Away With Mixing Different Metal Fasteners?

I wouldn't recommend it. Mixing metals, especially anywhere they might get wet, is asking for trouble. It creates a little chemical reaction called galvanic corrosion, where one metal basically eats the other one alive.

A classic example is putting steel screws into a copper flashing. In no time, you’ll find those screws have turned to dust. The rule of thumb is simple: match your fasteners to your materials. If you absolutely have to mix, use a plastic or rubber washer as a buffer to keep them from touching.

How Do I Pick the Right Anchor for Drywall?

This all comes down to one thing: how heavy is the item you're trying to hang?

- Light Stuff (under 5 kg): Your basic plastic expansion anchors will do the trick for small pictures or lightweight decor.

- Medium-Weight Things (5-15 kg): Step up to a threaded drywall anchor. These screw right into the wall and have much better grip for shelves or heavier frames.

- The Heavy Hitters (over 15 kg): For mirrors, cabinets, or anything you really don't want to fall, you need toggle bolts or molly bolts. These are the big guns—they pop open behind the drywall to spread the load over a much wider area, giving you a rock-solid hold.

Do yourself a favor and always check the weight rating on the package before you leave the store. It’s the easiest way to make sure whatever you hang stays hung.

From the nuts and bolts to the heavy-duty structural parts, Yasu Trading Co. LLC has the full range of quality hardware building materials your project demands. Find everything you need to get the job done right by visiting us at https://yasutrading.com.