Discover High-Performance Power Tools with Brushless Motors & IoT

Walk onto any modern job site, and you'll see it immediately: the tools are different. They're not just stronger; they're smarter and more connected than anything we had just a few years ago. This isn't a minor upgrade. It’s a complete overhaul driven by three game-changing technologies: brushless motors, IoT integration, and 3D-printed parts.

Together, this trio is pushing the boundaries of what high-performance power tools can do.

The Tech That's Reshaping the Toolbox

We're in the middle of a massive shift in the world of professional tools. The old-school, purely mechanical devices are giving way to intelligent, data-driven assets. This is more than just a little tweak here and there; it’s a ground-up rethinking of how tools are built, used, and kept running.

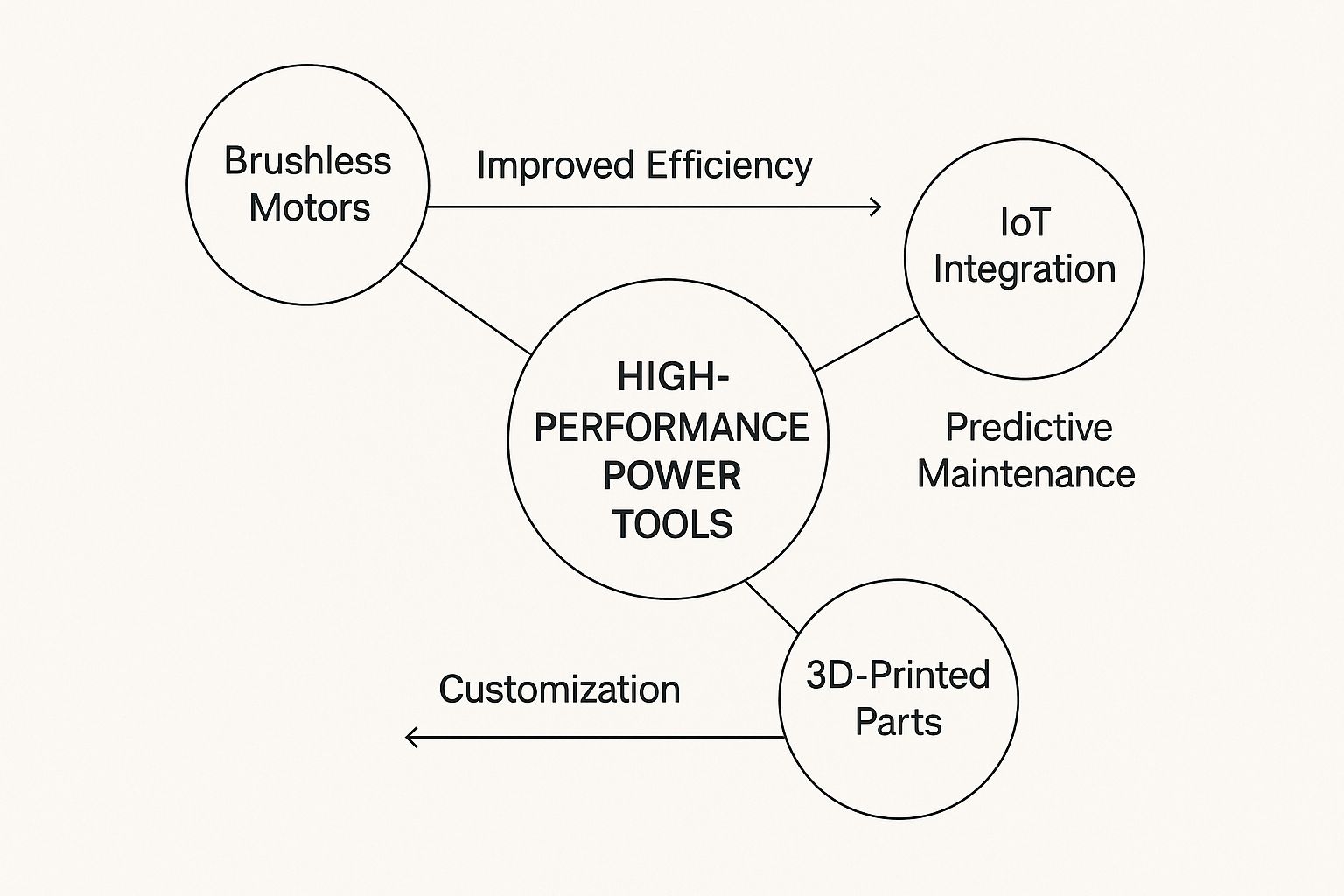

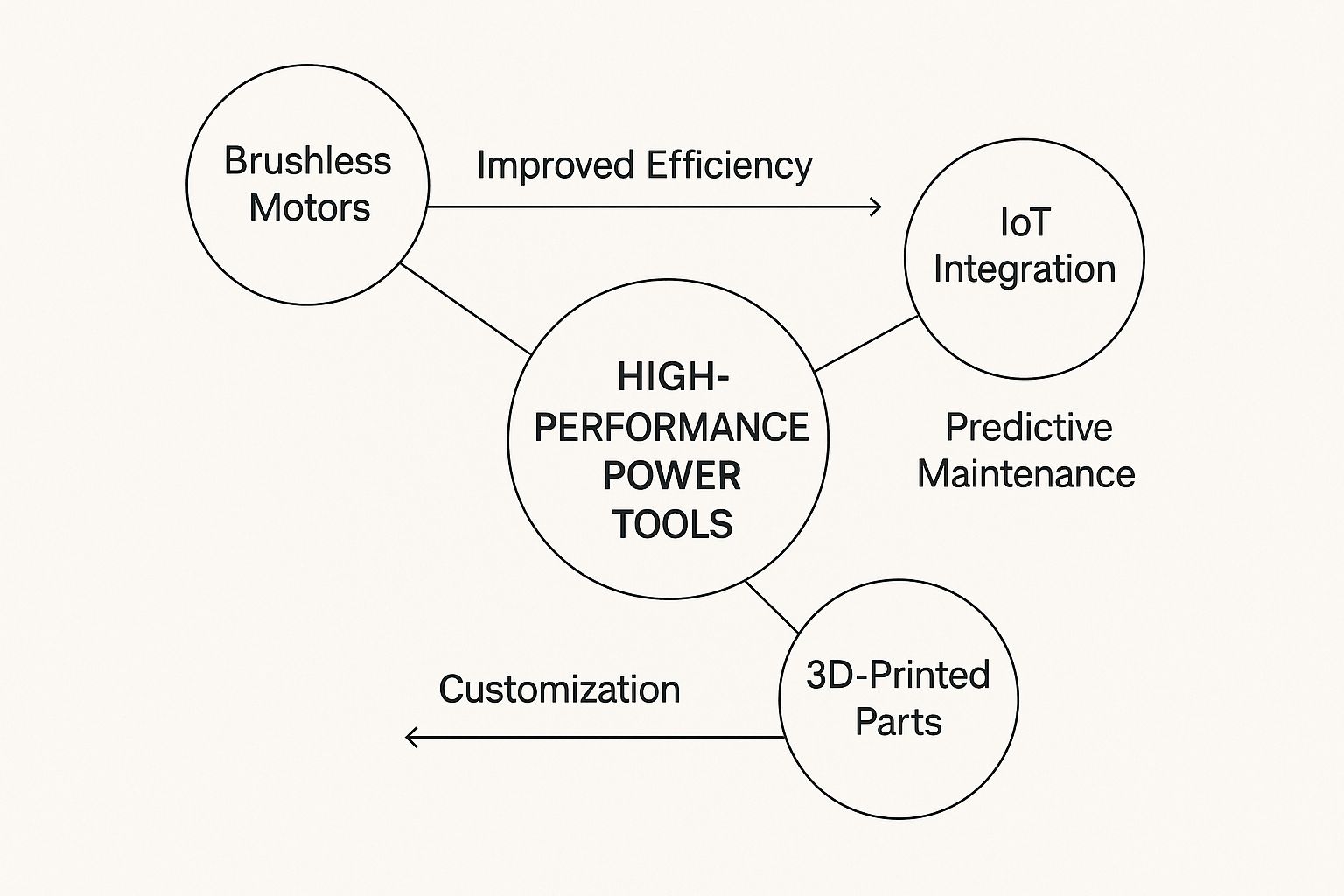

At the core of this movement, you’ll find three key pillars working together:

- Brushless Motors: Think of these as the high-efficiency engines of the tool world. By getting rid of the physical brushes that create friction and wear out, they use smart electronics to deliver more raw power, give you longer battery life, and make the tool itself last a whole lot longer. Less energy is wasted as heat, and more of it goes directly into the work.

- IoT Integration: This is where tools get a brain. By embedding sensors and wireless connectivity, a drill or a saw can now report back on its location, how it's being used, and even when it's about to fail. They stop being isolated pieces of equipment and become part of a managed fleet, which is a game-changer for preventing downtime.

- 3D-Printed Parts: Additive manufacturing gives us incredible flexibility. Need a custom grip for better ergonomics or a unique attachment for a specific job? You can print it. Even better, it means you can create replacement parts on-demand, slashing repair times and keeping expensive tools in service for years longer.

The infographic below really nails how these three technologies form the foundation of today's best power tools.

As you can see, each piece of the puzzle brings something unique to the table—efficiency, intelligence, and custom-fit design—that all add up to a tool that flat-out performs better.

Why the Market Is All-In

This isn't just a cool trend for tech nerds; it's driving serious money and shaking up industry standards. The demand for smarter, tougher tools is exploding, especially in busy sectors like construction and heavy industry.

Just look at the numbers. The power tools market in the Middle East and Africa (MEA) alone was valued at US$1.49 billion in 2023 and is expected to climb to US$1.88 billion by 2032. A big driver for that growth is the boom in major infrastructure projects where every minute of downtime costs a fortune. In a market this competitive, features like brushless motors and IoT tracking are no longer just nice-to-haves; they're what set the best tools apart. You can dig deeper into these numbers over at MarketDataForecast.com.

The real magic happens when these technologies work together. A brushless motor gives you a performance boost, IoT keeps an eye on its usage to warn you before it breaks, and a 3D-printed part can be made overnight to get it fixed fast. That's how you build a tough, super-efficient workflow.

Why Brushless Motors Are a Game Changer

If you've ever used an older power tool, you know that feeling of friction and heat. That’s a classic brushed motor at work. Now, think about the smooth, effortless glide of a modern high-performance tool. That's the brushless difference. This shift in motor design is one of the single biggest leaps forward for professional power tools in a generation.

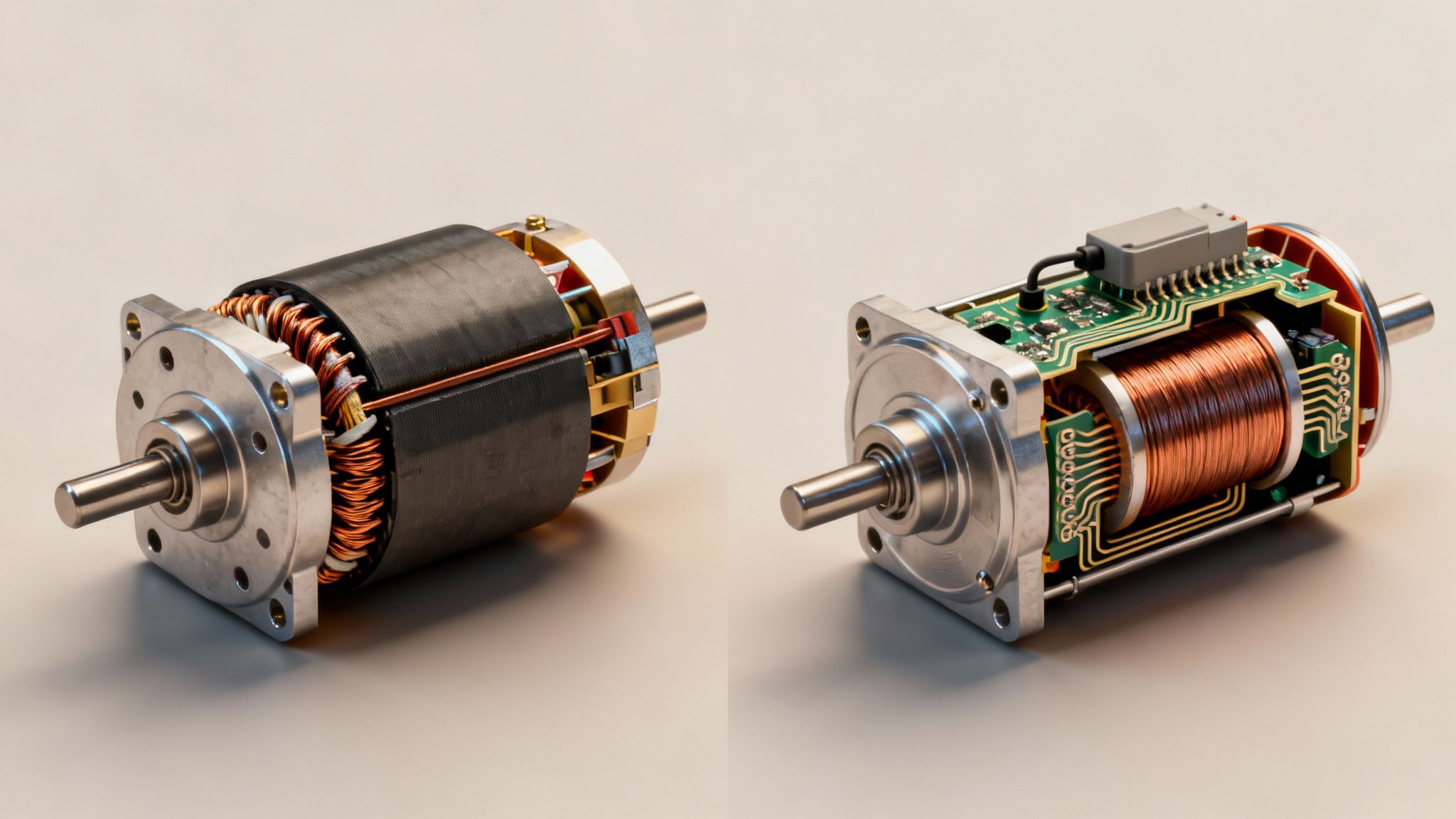

The old way was pretty simple: little carbon blocks, called brushes, physically rubbed against a spinning part of the motor to transfer electricity. The problem? That physical contact creates friction. Friction wastes energy as heat, makes a racket, and eventually wears those brushes down to nothing.

Brushless motors do away with that friction entirely. They use powerful magnets and smart electronics to get the motor spinning, with no physical brushes needed. This isn't just a small adjustment; it’s a complete rethink of how a motor should work, unlocking a whole new level of performance and durability.

The Power of Frictionless Operation

By getting rid of the brushes, these motors instantly solve the biggest headaches of the older designs. The onboard electronics act like a brain, constantly managing the power flow and giving the motor exactly what it needs for the job—no more, no less. It’s this intelligent power management that really sets them apart.

On the job site, you can feel the difference right away. The tool runs cooler, feels way smoother in your hand, and responds the second you pull the trigger. It's not just a nicer experience; it means you can work longer and harder with less fatigue.

The biggest win for most pros is the massive boost in battery life. Because they're so efficient, brushless motors can be up to 50% more efficient than their brushed counterparts. That means you get way more work done on a single charge, spending less time walking back to the charger. This is a huge consideration when weighing your options, as we detail in our guide to cordless vs corded tools for contractors.

More Power and a Longer Tool Life

It's not just about runtime, though. All that saved energy has to go somewhere, and in a brushless tool, it goes straight to power and torque. Since less energy is being wasted as heat, more of it is converted into raw rotational force.

This is why a brushless impact driver can sink huge fasteners into engineered lumber without breaking a sweat, and a brushless angle grinder can chew through rebar without getting bogged down.

It all comes down to the smarter design:

- No Friction: Energy isn't lost to physical contact, so it goes directly to the work.

- Cooler Operation: Less heat means less wear and tear on all the internal parts.

- Smart Electronics: The motor constantly adjusts its power draw to match the load, preventing burnout.

This smarter operation also means the tool itself lasts a whole lot longer. With no brushes to wear out and replace, there's one less major point of failure. You get less downtime for maintenance and a much better return on your investment over the life of the tool.

Think of a brushless motor as a "smart" motor. It’s in constant communication with the battery and the trigger, optimizing power delivery in real-time. This protects the motor from overload and the battery from damage, which is a huge reason these tools simply outperform and outlast the older models.

Brushed vs Brushless Motors: A Professional's Comparison

To really see why the industry has moved to brushless, it helps to put the two technologies side-by-side. The table below breaks down the key differences and shows why brushless has become the gold standard for any serious professional.

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Efficiency | Lower due to friction | Significantly higher |

| Power Output | Good | Excellent and responsive |

| Battery Life | Shorter | Up to 50% longer |

| Tool Lifespan | Limited by brush wear | Much longer lifespan |

| Maintenance | Requires brush replacement | Virtually maintenance-free |

| Size & Weight | Larger and heavier | More compact and lighter |

| Operation | Hotter and noisier | Cooler and quieter |

As you can see, the switch to brushless technology is a clear victory in every category that matters on the job. It's the engine driving the modern generation of power tools, allowing them to be smaller, lighter, and more powerful than we ever thought possible. This single innovation has completely reset the expectations for professional-grade equipment.

2. Connecting Your Tools with IoT Technology

Think of a standard power tool like an old-school flip phone. It does its one job reliably, and that’s about it. Now, an IoT-enabled tool is the smartphone equivalent. It still drills the hole or drives the screw perfectly, but it adds a layer of connectivity that opens up a whole new world of smart features. That’s the core idea behind IoT integration in professional-grade power tools.

In short, The Internet of Things (IoT) embeds tools with tiny sensors and wireless tech. This simple addition transforms them from isolated pieces of hardware into a fully connected, manageable fleet. Each tool can now gather and send back valuable data, giving you a level of visibility and control over your assets that was impossible before.

From Dumb Iron to Smart Assets

The real game-changer here is data. A traditional drill just drills. An IoT-enabled drill does the same job but also reports back on its location, how much battery is left, how long it's been running, and even its internal temperature. Suddenly, you have the information you need to work smarter, not just harder.

Picture a sprawling construction site with hundreds of tools moving around all day. Trying to find a specific impact driver can turn into a frustrating scavenger hunt, wasting precious time. With IoT asset tracking, a foreman can just pull up a map on a tablet and see its exact location in real-time.

This capability alone solves one of the biggest daily headaches on any job site. It helps cut down on theft, prevents tools from getting lost, and makes sure the right tool is in the right hands at the right time. All of this has a direct, positive impact on project timelines and your bottom line.

Predictive Maintenance: The End of Unexpected Downtime

One of the most powerful uses for IoT in power tools is predictive maintenance. Instead of waiting for a tool to die in the middle of a critical task—which always seems to happen at the worst moment—IoT sensors keep an eye on its health around the clock. To dig deeper into this strategy, you can explore how https://yasutrading.com/blog/predictive-maintenance-for-mep-how-iot-sensors-reduce-downtime-and-costs/ in our related article.

For example, these sensors can pick up on subtle signs that a problem is on the horizon:

- Excessive Vibration: This could be an early warning that a bearing is starting to fail.

- Overheating: If a tool is constantly running hot, it might mean the motor is being pushed too hard or is due for service.

- Unusual Power Draw: A sudden spike in how much energy it’s using could point to a worn-out internal part.

When the system flags one of these warnings, it can automatically send an alert to the fleet manager. This lets them pull the tool from service for a check-up before it fails completely, preventing expensive delays and extending the life of the equipment.

IoT integration transforms tool maintenance from a reactive, crisis-driven activity into a proactive, data-informed strategy. You're no longer guessing when a tool might fail; the tool itself tells you.

Optimizing Your Entire Tool Inventory

Beyond just tracking individual tools, the data collected through IoT gives you incredible insight into how your entire inventory is being used. A central dashboard can pull all this information together to answer key business questions.

Are some tools sitting on a shelf collecting dust while others are being run into the ground? This data allows managers to reallocate equipment more effectively across different job sites. Are crews constantly grabbing a smaller drill for a job that really needs a heavy-duty model? This insight can lead to better training or smarter purchasing decisions down the road.

This level of analysis helps companies get their inventory just right, ensuring they have exactly what they need without wasting money on equipment that isn't being used. It’s all about making strategic decisions based on hard evidence instead of just guesswork.

Customizing Your Tools with 3D Printing

For generations, the power tool industry worked on a pretty simple model: make one tool and hope it fits millions of different hands. But any pro on a job site knows that "one-size-fits-all" is usually code for "doesn't quite fit anyone perfectly." What if your angle grinder had a grip that felt like it was molded just for you, giving you better control? Or what if your impact driver could be fitted with a custom attachment for that one weird, specialized task you do all the time?

This is exactly where 3D printing is stepping in and completely changing the game.

The official term is "additive manufacturing," and it’s a pretty straightforward idea. You start with a digital file and build an object from the ground up, one tiny layer at a time. It’s the exact opposite of traditional manufacturing, where you’d start with a big block of metal or plastic and carve away everything you don't need. This simple switch—building up instead of cutting down—opens up a world of flexibility and speed that’s a perfect match for tool design.

Rapid Prototyping and Faster Innovation

Not too long ago, creating a prototype for a new drill housing was a huge pain. It was a long, expensive ordeal that involved making molds and tooling, a process that could easily drag on for weeks or even months. That slow, cautious pace didn't exactly encourage designers to take risks or try out bold new ideas.

Now, things are different. An engineer can sketch out a new component in CAD software in the morning and be holding a physical prototype in their hands by the next afternoon. This ability to rapidly iterate means manufacturers can test dozens of designs in the time it used to take to produce just one. They can tweak the ergonomics for better comfort, refine the airflow for cooling, and test the part's strength with actual models, not just simulations. The result? Better, smarter tools get into our hands much, much faster.

The impact on development is huge. A process that used to eat up months for tooling and testing can now be squeezed into a few days. That agility means the tools you buy next year will be more advanced and better suited for the job than ever before.

On-Demand Parts and Drastically Reduced Downtime

On any job, time is money. Every minute a tool is down, it’s costing you. In the past, if a simple plastic guard or a specialized switch broke, you were stuck. You'd have to wait weeks for a replacement part to ship—if you could even find one—or just bite the bullet and buy a whole new tool.

3D printing offers a far better solution: on-demand replacement parts.

Instead of filling warehouses with spare parts that might sit on a shelf for years, manufacturers can just keep a digital library of their components. When something breaks, a certified shop—or even a well-equipped user—can just print a new one. The advantages here are massive:

- Speed: A critical part can be printed and installed in a few hours, not a few weeks.

- Availability: The problem of obsolete or out-of-stock parts for older tools basically disappears.

- Cost: It’s almost always cheaper to print a single part than to manage shipping and storing a physical inventory.

This shifts tool repair from a logistical nightmare into a quick, local fix that gets your gear back in action with minimal delay.

The Rise of User-Specific Customization

This is where 3D printing really starts to get exciting for the person actually using the tool. We're moving away from mass production and into an era of true personalization. Pros can now download or create designs for parts that perfectly adapt a tool to their specific needs.

Think about what this means in the real world:

- Ergonomic Grips: A carpenter with big hands could print a thicker, custom-fit handle for their jigsaw to reduce fatigue on long projects.

- Specialized Attachments: An electrician could design and print a clever little bracket that mounts an LED light right onto their drill for working inside dark cabinets.

- Dust Collection Adapters: You could print the perfect adapter to connect your sander to that odd-sized shop vac hose, creating a perfect, leak-free seal.

This kind of customization was just a dream a decade ago. It gives us the power to modify our tools to solve unique problems, improve comfort, and ultimately work more efficiently. Of course, the real potential here lies in the design files themselves. To get the most out of this, it helps to have a good grasp of the digital blueprints, which is why understanding 3D printing file formats is so important.

This trend is even pushing into the core parts of the tools. As material science gets better, we're starting to see incredibly strong and durable printed components. You can read more about how this is changing hardware fundamentals in our guide on smart fasteners and 3D-printed bolts. It’s proof that 3D-printed parts are no longer just for simple accessories—they’re becoming critical, high-performance components.

How These Technologies Work Together

On their own, brushless motors, IoT connectivity, and 3D-printed parts each bring something special to the table for professional power tools. A brushless motor gives you raw, efficient power. IoT adds a layer of smarts and connectivity. 3D printing opens the door to hyper-specific, custom designs. But the real magic happens when you put them all together.

When these three technologies converge, they create a powerful loop where each one amplifies the others. Suddenly, a simple tool isn't just a tool anymore—it's an intelligent, self-monitoring piece of equipment that gets better over time. We're not just building a better drill; we're creating a system that learns, adapts, and evolves to handle the toughest jobs.

Creating a Self-Improving Feedback Loop

It all starts with the brushless motor. Because it’s electronically controlled, it’s the perfect partner for IoT sensors, which can track its performance with incredible detail. An IoT-equipped brushless drill doesn't just run longer; it constantly streams data about its own health and performance.

This data is the core of the whole system. Information on motor temperature, fluctuations in RPM, and battery discharge rates gets sent to a cloud platform in real time. This effectively creates a "digital twin" of the tool, giving managers and even manufacturers a clear window into how it's holding up under real-world stress.

This constant flow of information unlocks some seriously powerful capabilities:

- Predictive Alerts: If the data shows a motor is constantly getting too hot on a certain job, the system can flag it and warn the user before any permanent damage occurs.

- Performance Optimization: By analyzing how a tool is being used, the system can recommend the best speed or torque setting for a specific material, boosting both efficiency and the quality of the work.

- Firmware Updates: Manufacturers can push updates directly to the tool's electronics, fine-tuning motor performance based on data gathered from thousands of tools out in the field.

What you end up with is a dynamic relationship where the tool is no longer a static object but a platform that keeps improving.

Think about a crew using a fleet of IoT-enabled brushless grinders on a major pipeline project. The system notices that the tools used by one team are showing 15% more vibration than the others. This automatically triggers a maintenance alert for those specific grinders and also provides the data to create a quick training refresher on proper handling, preventing early tool failure and keeping everyone safer.

From Data Insights to Physical Innovation

The feedback loop doesn’t just stop at software tweaks. All that rich data from the IoT sensors provides invaluable clues that can directly shape the physical design of the tool itself. This is where 3D printing really shines. By sifting through performance data, engineers can pinpoint weaknesses or areas for improvement with surgical precision.

Let's say data from hundreds of tools reveals that a certain part of the housing consistently overheats. Engineers can take that insight and design a new, 3D-printed casing with a much more effective ventilation pattern or make it out of a material that handles heat better.

And because 3D printing makes prototyping so fast, they can test multiple new designs in a matter of days instead of months. This dramatically speeds up the whole innovation process. The end result is a tool that isn't just designed based on theory in a lab but is constantly being refined based on hard evidence from the job site.

This synergy creates a powerful connection between the digital and physical worlds:

- The brushless motor delivers efficient, electronically controlled power.

- IoT sensors monitor that performance, gathering massive amounts of real-world data.

- That data is analyzed to find opportunities for improvement.

- 3D printing is then used to create optimized physical parts based on those data-driven insights.

By combining brushless motors, IoT, and 3D-printed components, we're creating a system where tools are always learning and improving. This leads to equipment that is more powerful, more reliable, and perfectly tuned for the real-world challenges of any job site.

What This Means for the Future of Work

The evolution of these high-performance power tools is more than just a tech story—it’s fundamentally changing what’s possible on the job site. The combination of brushless motors, IoT smarts, and 3D-printed parts isn't just an incremental upgrade; it's setting a whole new standard for performance, safety, and efficiency. For professionals, this is a change you can't afford to ignore.

This shift turns a simple drill or saw from a dumb piece of equipment into a smart, connected asset. Getting your head around these advancements is now critical for making smart buying decisions, the kind that actually deliver a solid return on your investment. It's how you'll tighten up your workflow, slash that frustrating downtime, and stay ahead of the competition.

And this trend is only going to pick up speed. I expect we'll see more Artificial Intelligence (AI) baked right into the tools themselves. Imagine a tool that senses the material you're working on and automatically dials in the perfect speed and torque. That level of automation will bring a whole new game of precision and productivity.

The next real frontier is sustainable, on-demand manufacturing. Picture this: a critical part on your main tool breaks. Instead of waiting days for a replacement, you just 3D-print a new one right there on-site, maybe even using recycled materials. Delays and waste could become a thing of the past.

For anyone in the trades, adapting isn't really optional anymore. Embracing the potential of high-performance power tools: brushless motors, IoT integration and 3D-printed parts is the ultimate power-up. It's what will keep you valuable and competitive in an industry where technology is now the driving force.

Frequently Asked Questions

Got questions about the tech that's changing the game for professional tools? We've got you covered. Here are some straightforward answers to what pros are asking about these new innovations.

Are Brushless Tools Really Worth the Extra Money?

For most pros, the answer is a definite yes. It's true that you'll pay more at the outset, but the long-term savings are where these tools really shine. Think of it this way: their incredible efficiency means you get more work done on a single battery charge, so you're not constantly swapping packs.

Plus, you can't ignore the durability. Since there are no brushes to wear out, they simply last longer and need way less maintenance. That means less time dealing with repairs and more time getting the job done, which saves you from the high cost of downtime.

How Does IoT Connectivity Actually Help on a Real Job Site?

Think of IoT as turning your tools into smart, connected members of your crew. The two biggest wins are asset tracking and predictive maintenance. On a sprawling job site, you can pull up an app and see exactly where every tool is, which is a massive help in preventing loss or theft.

Even better, IoT sensors are constantly monitoring the tool's condition. They can alert you that a motor is overheating or a component is close to failing before it actually breaks down. This lets you schedule maintenance on your own terms instead of having a critical tool die in the middle of a job.

When you connect your tools, you're fundamentally changing how you manage them. Instead of reacting to a lost drill or a fried motor, you can get ahead of those problems. It's all about keeping your projects running smoothly, on time, and on budget.

Isn't 3D Printing Just for Making Prototypes?

That’s how it started, but the technology has come a long way. Today, 3D printing is more than capable of producing tough, reliable parts that can handle the rigors of a job site. For high-performance power tools, this means things like custom-molded grips that fit your hand perfectly, unique attachments for very specific jobs, or even printing a replacement battery clip right when you need it.

As the materials get stronger and more advanced, we're seeing more and more core components being 3D printed. It's quickly moving from a nice-to-have feature for customization to a fundamental part of the manufacturing process, which will only make our tools more versatile in the future.

Ready to gear up with tools designed for the modern job site? Yasu Trading Co. LLC carries a complete lineup of premium power tools and construction supplies engineered for peak performance and reliability. Explore our catalogue and request a quote today.