How to Maintain Power Tools in Dusty Climates and Extend Their Lifespan

To keep your power tools running and extend their life in dusty climates, you need to get three things right: consistent daily cleaning, correct lubrication, and protective, sealed storage. This straightforward, proactive approach is what stops abrasive desert sand from getting into motors and bearings—the number one reason for premature tool failure on construction sites across the UAE.

Why Are Dusty Climates So Hard on Power Tools?

The fine desert sand here in Dubai is an aggressive threat to your power tools because its microscopic, abrasive particles work their way into motor vents, bearings, and trigger mechanisms. Once inside, these particles act like sandpaper, grinding away at critical internal parts and causing tools to wear out far faster than they would in less punishing environments.

For any construction professional or facility manager in the UAE, this is a daily battle. The dust doesn't just wear down components; it also clogs cooling vents. When that happens, heat gets trapped inside the tool, causing the motor to overheat, lose power, and eventually burn out. A tool that's overheating is a tool on its last legs, and it always seems to fail at the worst possible time. For a deeper dive into the problem, understanding what makes an environment dusty can provide some useful context.

What is the Real-World Impact on UAE Worksites?

On a high-rise project, angle grinders and demolition hammers are constantly surrounded by concrete dust and airborne sand. If a strict maintenance routine isn't in place, that fine grit will inevitably mix with the tool's lubricants, turning the protective fluid into a destructive grinding paste. This contamination is a primary driver of gearbox failure and expensive downtime, directly hurting project timelines and budgets.

The effect of dust exposure builds up over time. It’s not one big incident but a slow, steady process of degradation that hurts tool efficiency, compromises safety, and ultimately eats into your profitability. Forgetting about dust is one of the most expensive mistakes a site manager can make.

Here, proactive maintenance is simply non-negotiable. It has to be a core part of meeting the high UAE construction standards. The numbers don't lie: in the UAE's dusty climates, where sites can see average annual dust levels top 300 mg/m³, something as simple as regular air filter cleaning on your power tools can extend their lifespan by up to 40%.

How Can You Build a Foundation for Tool Longevity?

Fighting back against the dust requires a solid strategy built on a few key practices. It starts with partnering with a reliable supplier in Dubai, like Yasu Trading Co. LLC, to make sure you have access to tools built for these conditions and the right consumables to maintain them. A good building materials distributor can also advise you on which tools offer superior seals and filtration systems right out of the box.

Technology is also on your side. Modern advancements can give you a real edge, which is why we put together a guide on [https://yasutrading.com/blog/high-performance-power-tools-brushless-motors-iot-integration-and-3-d-printed-parts] to highlight more durable options. With this foundation in place, let's get into the specific procedures that will protect your investment.

What is the Best Daily Cleaning Routine for Power Tools?

The best daily cleaning routine for your power tools on any UAE worksite is a quick but systematic one that removes the day's abrasive dust before it can cause internal damage. This simple end-of-day ritual is the most effective thing you can do to stop the slow grind that leads to overheating, power loss, and premature tool failure.

We're not talking about a full strip-down or deep clean here. It’s all about consistency. Just five minutes spent on each tool before it goes back in the box can easily add months, if not years, to its working life.

Why Should You Always Blow Out Dust First?

The single most important first step is to use low-pressure compressed air (under 90 PSI) to blow loose dust out of the tool. Blasting a tool with high pressure can actually force sharp particles deeper into sensitive motor bearings, switches, and electronic modules, doing more harm than good.

Concentrate the airflow on the areas where dust loves to hide:

- Motor Vents: Think of these as the lungs of your power tool. Once they're clogged, heat gets trapped, and that’s the number one killer of electric motors.

- Chuck and Collet Assemblies: Dust and grit here will cause bits to seize up or wobble, which ruins precision and is a major safety risk.

- Trigger and Switch Housings: It only takes a little fine grit to make a trigger stick or fail completely, creating a serious hazard on site.

- Battery Terminals: For cordless tools, keeping these terminals clean is essential for a solid power connection and prevents annoying charging problems.

What is the Crucial Follow-Up Wipe-Down?

After blowing out loose debris, you must follow up with a thorough wipe-down using a clean, dry microfibre cloth. This step catches the fine film of dust that compressed air can leave behind on the tool's housing, grips, and cord.

Whatever you do, avoid using water or damp cloths. On a Dubai construction site, mixing fine dust with water creates a gritty, corrosive paste that will accelerate rust and wreak havoc on internal electronics. Keeping the entire process dry is a fundamental rule for maintaining your power tools in this climate.

In the harsh UAE environment, moisture is the enemy of tool longevity. A 'dry clean'—using only compressed air and a dry cloth—is a non-negotiable best practice. It aligns with high UAE construction standards and, most importantly, protects your investment.

The challenge of keeping equipment running in sandy, dusty conditions isn't limited to power tools. You can find surprisingly relevant tips for cleaning equipment in dusty, sandy environments by looking at how technicians service things like AC units. This just goes to show how universal the principle of removing abrasive particles really is.

How Does This Work in a Real-World Dubai Scenario?

Picture a crew wrapping up for the day on a high-rise project down by the Dubai Marina. Before packing away, each worker takes their angle grinders and drills to a dedicated cleaning station with a regulated air compressor and clean rags. One worker carefully blows concrete dust from the motor vents, while another ensures the battery contacts and chuck on a cordless drill are spotless.

This simple, five-minute habit prevents the vast majority of dust-related failures we see as a supplier in Dubai. It stops the gradual buildup that eventually leads to a tool dying mid-job, saving the company thousands of dirhams in repair bills and lost productivity. Any reputable building materials distributor will tell you the same thing: the best tools are the ones you look after.

How Do You Get Lubrication Right in High-Heat Conditions?

Proper lubrication separates a well-maintained tool from one destined for the scrap heap, especially in the relentless heat and dust of the UAE. High temperatures cause standard lubricants to melt away, losing their protective qualities and mixing with abrasive dust to form a destructive grinding paste inside your tool's most sensitive parts.

Think of lubrication less about reducing friction and more about creating a powerful barrier. In our climate, its main job is to constantly push out contaminants and shield delicate gears and bearings from being chewed up.

What is the Best Lubricant for Hot, Dusty Sites?

For the conditions we face in the UAE, you need a high-temperature, high-pressure grease like a lithium-based NLGI 2 grade formula. This type of grease is specifically designed to maintain its viscosity and stay put when a tool’s internal temperature skyrockets, so it won’t just leak out of the gearbox.

Forget about using all-purpose oils or cheap, lower-grade greases. They simply can't take the heat and will break down almost immediately, leaving your tool's internals completely exposed. When you're stocking up, make sure you're working with a knowledgeable supplier in Dubai who understands the demands of the region and can point you to greases engineered for these extremes.

What is the Most Overlooked Step in Lubrication?

The most overlooked step is cleaning out all the old, contaminated gunk before applying new lubricant. Skipping this step is a massive mistake because old grease is full of fine sand and metal shavings that will instantly ruin the fresh lubricant and defeat the entire purpose of the job.

Here’s the right way to tackle it:

- Disassemble Carefully: Pop open the tool’s gearbox housing, following the manufacturer’s guide. Take your time here.

- Scrape It Out: Use a small plastic scraper or even a wooden stick to meticulously dig out all the dark, gritty grease. Never use a metal screwdriver, as you’ll risk scratching the gears.

- Wipe It Down: Grab a clean, lint-free rag and wipe the gears and the inside of the housing until they are spotless.

This prep work is what allows the new grease to form a clean, powerful bond directly with the metal surfaces it’s meant to protect.

How Often Should You Re-Grease Power Tools?

For any tool getting daily use on a dusty site, plan on re-greasing the gearbox every 50 to 100 hours of operation. This might sound frequent, but it's the only way to purge the abrasive dust that will inevitably find its way past the seals. If you wait until you hear grinding noises, you've waited too long—the damage is already done.

The payoff for being this disciplined is huge. Data from the Middle East Construction Equipment Report is eye-opening. Here in the UAE, wind-blown sand can speed up wear by a staggering 50% compared to milder climates. The report found that lubricating power tool gearboxes every 50 hours actually boosts their lifespan by 35%. Even more impressive, this simple habit prevents 62% of the premature failures tracked across 200 different Dubai construction sites. You can dig into the full research on the region's power tool market to see the numbers for yourself.

A scheduled lubrication plan isn't just maintenance; it's an insurance policy against downtime. A tube of the right grease costs a few dirhams, while a failed gearbox and a stalled project can cost thousands.

Can You Give a Real-World Example of a Lubrication Plan?

Picture a facility manager running a huge hotel renovation in Jumeirah. His crews are using demolition hammers and angle grinders non-stop, kicking up a storm of concrete dust. Instead of just reacting to breakdowns, he sets up a strict lubrication schedule.

Every Friday afternoon, without fail, the tools are pulled from service. A technician spends a few hours cleaning out each gearbox and repacking it with fresh, high-temp lithium grease. The result? Over a gruelling six-month project, they had zero gearbox-related failures. This proactive system didn't just save them thousands in repair bills; it kept the project running on time, which is everything in the hospitality business. It’s a perfect example of how high UAE construction standards are maintained through diligent practices, something every reliable building materials distributor in the region understands well.

How Can You Beat the Dust with Smart Storage and Transport?

When a tool isn't in your hands, its best defence against the relentless dust of the UAE is a solid physical barrier like a gasket-sealed tool case. Leaving tools out on-site overnight is one of the fastest ways to kill them, as fine dust mixes with evening humidity to create a gritty, corrosive paste that gets into everything.

Thinking about storage and transport isn't just a final step; it's a core part of any serious tool maintenance plan.

Every dirham you spend on a quality, gasket-sealed tool case is money you're saving on future repairs or replacements. Don't even bother with those standard canvas bags or open-top boxes—they're practically useless here. Fine sand and debris will settle right onto your equipment, undoing all the hard work you put into cleaning it.

Why Are Gasket-Sealed Cases Non-Negotiable?

Gasket-sealed cases are non-negotiable because they create a nearly airtight seal that physically blocks out fine desert dust and moisture. This prevents the slow, corrosive damage that happens when tools are left exposed. As a long-time building materials distributor, we can literally see the difference in repair requests between teams who use sealed cases and those who don't.

These protective cases aren't just a nice-to-have; they’re essential in our climate. Here's why:

- Dust Blockade: That rubber or foam gasket creates a tight seal that stops microscopic sand particles dead in their tracks.

- Humidity Shield: They protect against the damp air that loves to rust metal components and wreak havoc on sensitive electronics.

- Impact Armour: The tough outer shell and internal padding guard tools against the inevitable bumps and drops that happen during transport.

How Should You Set Up On-Site Storage "Clean Zones"?

Even with the best cases, where you store them on-site makes a huge difference. You must establish designated "clean zones" for your tools by keeping them well away from dust-heavy activities like concrete cutting, grinding, or sanding.

A simple, effective solution is using enclosed metal cabinets or even a dedicated storage container. Just make sure you place it upwind from the main work area. This small logistical step ensures that when you open a case, the tool inside isn't immediately coated in a fresh layer of abrasive grit. It’s a basic practice that supports high UAE construction standards by putting equipment care and readiness first.

Your storage location should be as clean as your tools. Storing a perfectly cleaned tool in a dusty, open-air shed is like washing your hands and then immediately drying them in the dirt—it completely defeats the purpose.

What is the Best Way to Transport Tools Between Sites?

The best way to transport tools is inside a vehicle, in the cab of a truck or a sealed van compartment, to protect them from airborne sand and road debris. The absolute worst thing you can do is toss them in the open bed of a truck, which is a surefire way to force dust deep into every vent, switch, and crevice.

Always, always secure your tools inside a vehicle. If you have no choice but to use an open-bed truck, make sure every tool is in its gasket-sealed case and securely strapped down under a heavy-duty, tightly fastened tarp.

This simple precaution prevents countless hours of cleaning and can stop a catastrophic failure before it even has a chance to happen. Remember, when you partner with a reliable supplier in Dubai, you’re not just buying a piece of equipment; you're acquiring a valuable asset that deserves protection from the moment it leaves the store.

How Do You Build a Seasonal Maintenance Schedule for the UAE Climate?

A generic maintenance plan won't work in the UAE; you need a schedule that adapts to the brutal summer heat and cooler, humid winters. To truly understand how to maintain your power tools to extend their lifespan in dusty climates, you must create a proactive, seasonal schedule that shifts your maintenance focus from reacting to breakdowns to preventing them.

This ensures your tools are always ready to go, performing safely and efficiently, no matter what the calendar says. It's a fundamental part of upholding the high UAE construction standards that projects across the region are known for.

What Should You Focus On During the Hot and Dusty Season?

From May to October, your maintenance focus should be on combating heat and abrasion. The high ambient temperatures mean tool motors struggle to cool down, putting them at risk of overheating, while fine, airborne sand demands an aggressive cleaning and inspection routine.

During these months, your schedule needs to be relentless about a few key things:

- More Frequent Air Filter Checks: For tools like petrol cut-off saws and generators, you need to be checking and cleaning air filters at least twice a week. On a really dusty site, make it a daily habit. A clogged filter is a fast track to a seized engine.

- Daily Vent Blowouts: This should be non-negotiable. At the end of every single day, use low-pressure compressed air to blow out all motor vents. It’s the single most effective thing you can do to prevent the heat build-up that kills motors.

- Seal and Gasket Inspections: Intense heat is brutal on rubber. It causes seals to dry out, crack, and fail, letting dust right into sensitive gearboxes and motor housings. Give them a quick check weekly for any signs of trouble.

How Does the Maintenance Strategy Shift for the Cooler Season?

From November to April, your maintenance strategy should shift to address moisture and corrosion. While dust is still a reality, cooler temperatures and occasional humidity can cause condensation to form inside a tool’s housing, creating the perfect environment for rust to attack internal components.

For the cooler, damper months, your plan should adapt accordingly:

- Moisture Ingress Checks: After a humid spell or the rare rainy day, be extra vigilant about checking for moisture inside battery compartments and motor housings. If you have the option, always store tools in a dry, climate-controlled space.

- Corrosion Prevention: A simple wipe-down of all metal surfaces with a lightly oiled rag can make a world of difference. It creates a protective barrier against rust. Pay special attention to chucks, blades, and any unpainted metal parts.

- Electrical Component Inspection: Moisture and electronics are a bad mix. Regularly inspect switches, circuit boards, and battery terminals for any hint of corrosion or damage, and clean the contacts when you see it.

A seasonal approach isn't about creating more work; it's about doing the right work at the right time. By aligning your maintenance tasks with the climate’s demands, you protect your valuable tools and prevent that unexpected downtime that throws a project off schedule.

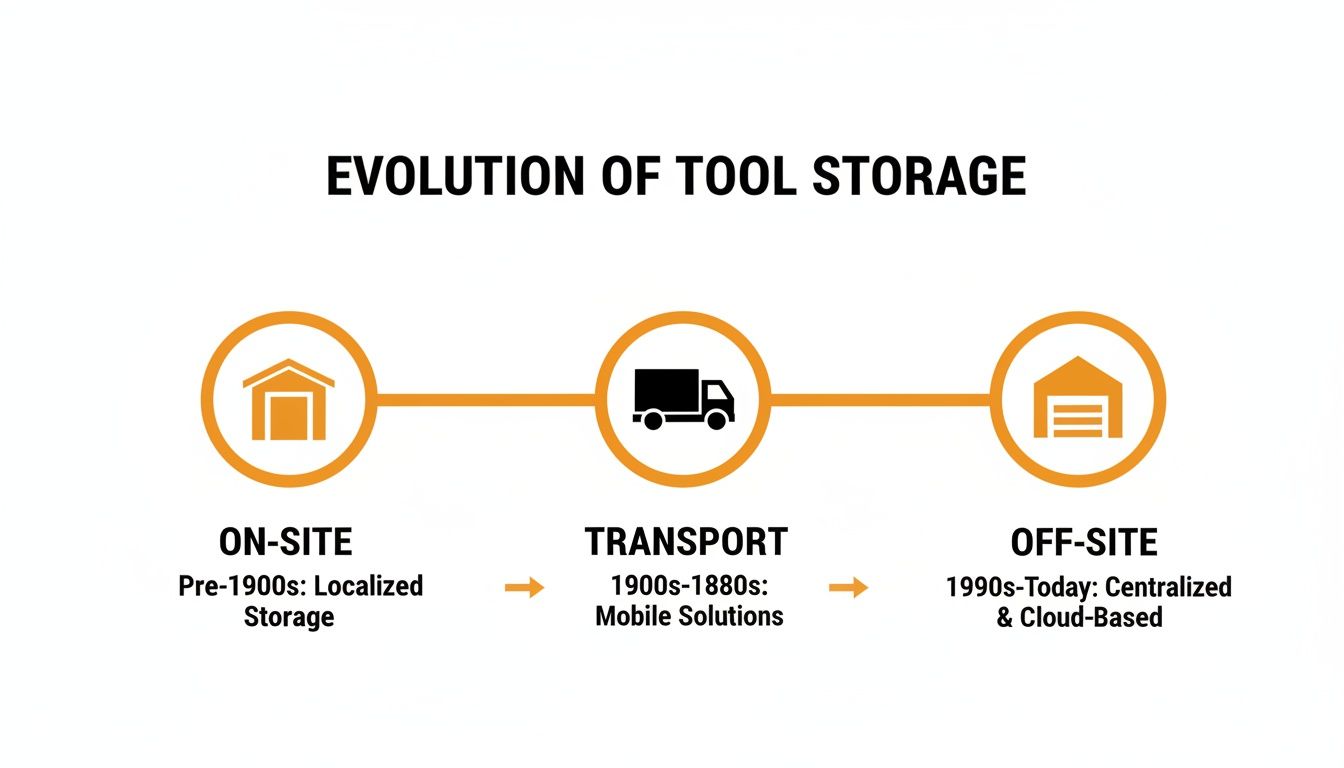

This timeline shows how protecting your tools is a journey, from on-site lockups to secure transport and proper off-site warehousing.

It’s a good reminder that tool protection is a continuous process, not a single action. A secure chain of custody is vital.

How Do You Build Your Year-Round Plan?

An effective schedule is a living document that combines seasonal demands with routine, year-round checks. As a leading supplier in Dubai, we’ve noticed that the most organised teams are the ones who use a clear, checklist-based system that everyone can follow.

If you’re looking for a solid foundation, our preventive maintenance schedule template offers a comprehensive framework that you can easily tailor to your specific inventory and project needs.

To help you get started, here's a look at how you might structure your plan.

What Does a UAE Seasonal Maintenance Plan Look Like?

This table breaks down how your focus should shift between the two distinct seasons in the UAE, ensuring you're always tackling the most immediate environmental threats to your equipment.

| Maintenance Task | Focus for Hot & Dusty Season (May-Oct) | Focus for Cooler Season (Nov-Apr) |

|---|---|---|

| Air Filter Cleaning | High Priority: Inspect and clean every 1-3 days, depending on site conditions. | Standard Priority: Inspect and clean weekly or as needed. |

| Lubrication | Critical: Check grease levels frequently as high heat can cause it to break down faster. | Important: Follow manufacturer guidelines, checking for moisture contamination. |

| Seals & Gaskets | Weekly Inspection: Check for cracks and brittleness caused by extreme heat. | Bi-weekly Inspection: Check for proper sealing to prevent moisture ingress. |

| Battery Terminals | Daily Cleaning: Wipe away dust to ensure a solid connection and prevent overheating. | Weekly Cleaning: Inspect for signs of corrosion from humidity. |

| Professional Servicing | End of Season: Schedule professional servicing to address wear from peak usage. | Start of Season: Schedule pre-season servicing to prepare for the heavy workload. |

By putting a schedule like this in place, you’re no longer just putting out fires—you’re preventing them from starting. It’s a methodical approach any successful building materials distributor would recommend, and it's the key to keeping your tools, and your projects, running smoothly all year long.

What Are Some Common Questions About Tool Care in Dusty Climates?

Working in the UAE means dealing with conditions that are incredibly tough on tools. Over the years, I've heard a lot of the same questions come up from site managers and contractors trying to get the most out of their equipment. Let's get straight to the point and tackle some of the most common ones.

How Often Should I Replace Carbon Brushes on a Dusty Worksite?

On a dusty UAE construction site, you should check carbon brushes every 50-60 hours of operation because abrasive dust wears them down extremely quickly. While they might last hundreds of hours in a standard environment, you need to be much more vigilant here to prevent rapid failure.

The warning signs are hard to miss if you know what to look for. You'll see excessive sparking from the motor, notice a real drop in power when you're trying to work, or hear the motor running rough. We always tell our clients to keep spare brushes on hand for their most-used tools. It’s a small cost that prevents major downtime. And a pro tip: always, always replace them in pairs to keep the wear even and the motor happy.

Can I Use Any Air Compressor to Clean My Tools?

Yes, you can use a standard air compressor, but you must regulate the pressure to 90 PSI (6.2 bar) or lower. Using high-pressure air is a critical mistake because it can force fine grit deeper into the tool's bearings, seals, and motor windings, causing more damage than it prevents.

And please, think about safety. Use a focused nozzle to direct the air exactly where you want it—into the vents and crevices. More importantly, always wear proper PPE. At a minimum, that means safety glasses with side shields. Getting a high-velocity grain of sand in your eye is no joke and it’s a basic requirement to meet UAE construction standards for site safety.

What Is the Biggest Tool Storage Mistake in the UAE?

The single biggest mistake is leaving tools out overnight, either on an open site or in the back of an uncovered truck. The humidity that settles in overnight mixes with the dust already on the tool, creating a gritty, corrosive paste that seizes up metal parts and can fry electronics.

This simple oversight is probably the number one cause of avoidable tool failure we see. It completely negates all the cleaning and maintenance you did during the day. The only real solution is to store your gear in sealed, durable cases in a secure, dry place. Think of a quality case as part of the tool itself—it’s that important.

In this climate, protective storage isn't optional—it's a core component of your maintenance strategy. A sealed case is the final line of defence that preserves your tool's condition and readiness for the next workday.

Are Cordless Tools More Vulnerable to Dust Than Corded Ones?

Yes, in some ways, cordless tools are more vulnerable to dust because it can easily work its way into battery terminals, causing poor connections, overheating, or sudden power failure. The compact cooling vents on both the battery and the tool are also weak points that can become clogged more easily than on corded models.

The fix is a disciplined routine. Make it a habit to blow out the vents on the tool and the battery pack regularly. Before you put a battery on the charger, give the contacts a quick wipe with a clean, dry cloth. When buying new gear, it pays to ask your building materials distributor about models with an official IP (Ingress Protection) rating. These tools are specifically designed and tested to resist dust and moisture, making them a much smarter investment for the tough conditions you face every single day on a UAE worksite.

Your tools are a critical investment, and protecting them is essential for keeping your projects on schedule and on budget. At Yasu Trading Co. LLC, we provide the durable power tools, high-performance consumables, and expert advice you need to thrive in the UAE's demanding climate. Visit us online to explore our product range and request a quote today.