Your Ultimate 2025 HVAC Maintenance Checklist for the UAE

In the United Arab Emirates, where extreme heat is a daily reality, a high-functioning HVAC system is not a luxury-it's the backbone of every commercial, residential, and industrial facility. For contractors and facility managers, system failure isn't just an inconvenience; it leads to operational disruptions, tenant dissatisfaction, and soaring energy costs. The key to ensuring reliability and efficiency lies in proactive, structured upkeep.

This comprehensive hvac maintenance checklist is designed specifically for the unique challenges of the UAE market. It moves beyond generic advice, providing a detailed, actionable framework organised by frequency, from daily checks to annual deep dives. Following this guide will not only extend the lifespan of your equipment but also optimise energy consumption and ensure a consistently comfortable environment, safeguarding your assets and operations. We will explore the critical tasks that form a robust preventive maintenance strategy, with practical tips and insights relevant to the local climate. This listicle breaks down everything you need to know, from filter inspections to refrigerant level checks, ensuring your systems perform flawlessly under pressure.

1. Filter Replacement and Inspection

Regular inspection and replacement of air filters is the most critical and impactful task in any comprehensive HVAC maintenance checklist. These filters are the system's first line of defence, capturing dust, pollen, sand, and other airborne particulates common in the UAE's environment. Neglecting them leads to clogged components, which forces the system to work harder, consume more energy, and ultimately fail sooner.

Proper filter management directly prevents system strain, maintains superior indoor air quality, and ensures optimal airflow. A clean filter allows air to pass through unrestricted, reducing the load on the blower motor and lowering energy bills. This simple task is fundamental to the efficiency and longevity of the entire HVAC system.

Why It's a Top Priority

For facility managers and contractors in the UAE, filter maintenance is non-negotiable. The high concentration of dust and sand means filters can become saturated much faster than in other climates. A clogged filter can quickly lead to a cascade of problems, including:

- Reduced Cooling Efficiency: Restricted airflow means the unit cannot cool the space effectively, leading to comfort complaints and increased run times.

- Frozen Evaporator Coils: Poor airflow can cause the evaporator coil's temperature to drop below freezing, forming ice that can severely damage the compressor.

- Poor Indoor Air Quality (IAQ): A dirty filter can no longer trap contaminants and may even become a breeding ground for mould and bacteria, circulating them throughout the building.

Expert Insight: In commercial settings like hotels or office buildings, a single clogged filter in a large Air Handling Unit (AHU) can impact the comfort of hundreds of occupants and significantly increase operational costs. Establishing a strict filter schedule is a low-cost, high-reward preventive measure.

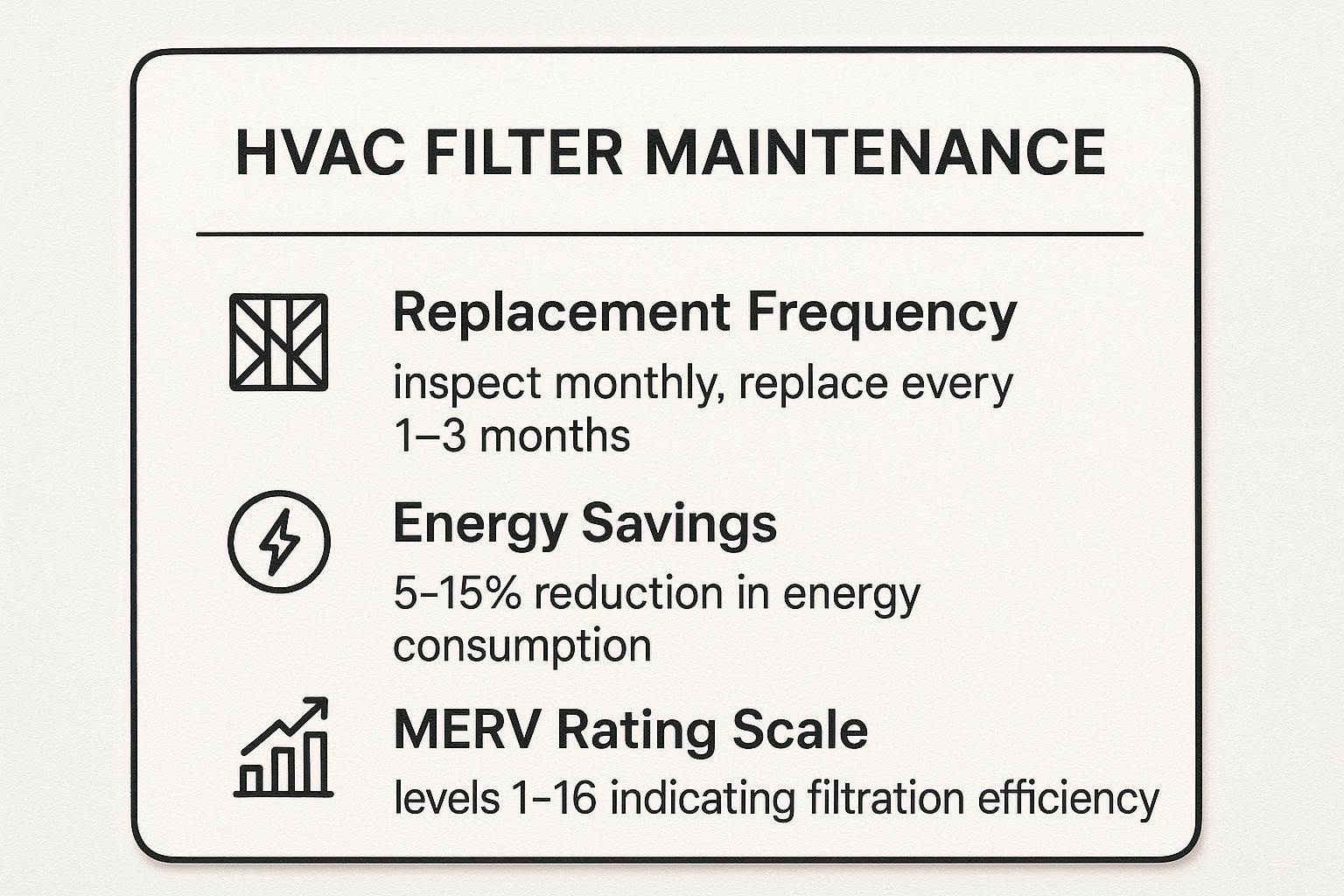

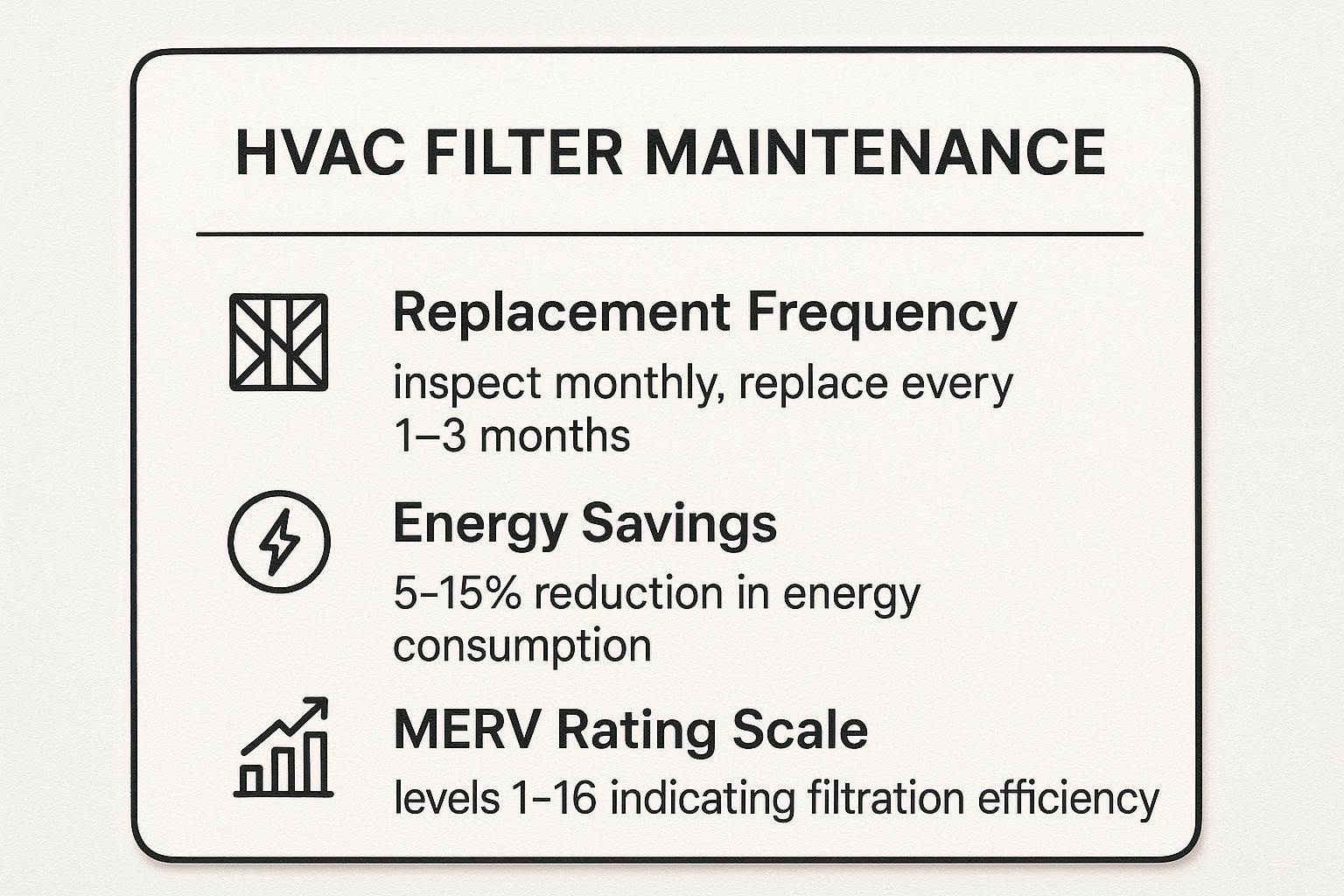

The following infographic summarises the core data points of effective filter maintenance.

As the data highlights, consistent filter changes can yield significant energy savings while improving air quality, making it a crucial component of your preventive maintenance strategy. A well-documented schedule is key to ensuring this task is never missed. You can create a robust plan by exploring a preventive maintenance schedule template on yasutrading.com to formalise your procedures.

2. Thermostat Calibration and Programming

An accurately calibrated and intelligently programmed thermostat is the brain of any modern HVAC system. This crucial component dictates when the system runs and for how long, directly impacting both occupant comfort and energy expenditure. Proper maintenance involves verifying temperature accuracy, optimising programmed schedules, and ensuring all settings are configured for maximum efficiency, especially in the demanding climate of the UAE.

Neglecting the thermostat can lead to significant energy waste and an uncomfortable indoor environment. An improperly calibrated unit might run excessively or fail to activate when needed, causing unnecessary strain on core HVAC components like the compressor and fans. For facility managers, ensuring thermostats are correctly set is a simple yet powerful step in a proactive HVAC maintenance checklist.

Why It's a Top Priority

In the UAE's commercial and residential sectors, precise temperature control is essential for managing high operational costs. A thermostat that is off by even one or two degrees can lead to substantial energy overconsumption over time. Proper calibration and programming prevent this by aligning system operation with actual occupancy and thermal loads. Key issues arising from poor thermostat management include:

- Energy Waste: Inaccurate readings cause the HVAC system to run longer than necessary, directly increasing utility bills. For instance, setting a thermostat just a few degrees lower than needed can raise cooling costs significantly.

- Reduced Component Lifespan: Constant, unnecessary cycling caused by faulty programming or calibration places excessive wear on motors, compressors, and relays, leading to premature failures.

- Occupant Discomfort: Inaccurate temperature readings lead to inconsistent cooling, with spaces feeling either too warm or too cold, resulting in comfort complaints and manual overrides that disrupt efficiency.

Expert Insight: For large-scale facilities like hotels or multi-story office buildings, smart thermostats with remote sensors, such as those from Ecobee, can provide granular zone control. This prevents overcooling in unoccupied areas while ensuring precise comfort in occupied zones, a critical strategy for energy optimisation in the UAE.

Effective thermostat management hinges on regular checks and strategic programming. For instance, programming setback temperatures of 4-6°C (7-10°F) for periods of low or no occupancy, such as overnight in an office, can yield considerable savings without impacting comfort. Similarly, a simple annual calibration check against a reliable, separate thermometer ensures the system is responding to accurate environmental data. This small task is a cornerstone of any effective HVAC maintenance checklist.

3. Electrical Connection Inspection and Tightening

A thorough inspection and tightening of all electrical connections is a fundamental safety and reliability measure within any HVAC maintenance checklist. Over time, vibrations, thermal expansion, and contraction can cause terminals, contactors, relays, and wiring to loosen. These loose connections increase electrical resistance, leading to overheating, voltage drops, and potential arcing, which can damage components or create a serious fire hazard.

Proactively addressing these connections prevents unexpected system failures and ensures the equipment operates safely and efficiently. By verifying that every connection is secure, technicians can guarantee the system receives stable, correct voltage, protecting sensitive electronic controls and extending the life of motors and compressors. This task is a cornerstone of preventative electrical maintenance.

Why It's a Top Priority

For contractors and facility managers, particularly in critical environments like hospitals or data centres, electrical integrity is paramount. A single loose connection can trip a breaker, shut down an entire cooling system, and lead to catastrophic operational disruptions. The consequences of neglecting this step include:

- Increased Fire Risk: Arcing from a loose wire is a leading cause of electrical fires in HVAC units, posing a significant threat to property and occupants.

- Component Failure: Inconsistent voltage from poor connections can burn out control boards, contactors, and expensive compressor motors, leading to costly and complex repairs.

- System Inefficiency: High resistance at a connection point forces the system to draw more current to perform the same amount of work, wasting energy and increasing operational costs.

Expert Insight: In a manufacturing facility, we once traced intermittent chiller shutdowns to a single loose terminal on a main power contactor. Implementing quarterly thermal imaging and torque checks completely eliminated this downtime, demonstrating how a simple check prevents major production losses.

Regular electrical inspections are a low-cost, high-impact activity that safeguards expensive assets and ensures operational continuity. Understanding the correct specifications for various components is crucial for proper execution. You can deepen your team's knowledge by reviewing a comprehensive guide to electrical fittings and materials on yasutrading.com to formalise best practices.

4. Condensate Drain Cleaning and Inspection

Consistent cleaning and inspection of the condensate drain line is a vital part of any HVAC maintenance checklist, particularly in the UAE's high-humidity environment. As air conditioners cool the air, they extract significant amounts of moisture, which is collected in a drain pan and channelled away through a condensate line. This process creates a dark, damp environment ideal for the growth of mould, algae, and bacteria, which can form blockages.

Neglecting the drain line leads to clogs that cause water to back up, potentially overflowing the drain pan. This can result in costly water damage to ceilings, walls, and furnishings, as well as create serious health risks from mould proliferation. Proactive drain maintenance is a simple preventive measure that avoids system shutdowns and expensive repairs.

Why It's a Top Priority

For contractors and facility managers, a blocked condensate drain is a common but entirely preventable emergency. The constant operation of AC units in the UAE means a continuous flow of condensation, accelerating the build-up of sludge and biological growth. A clogged drain can trigger several critical issues:

- Property Damage: Overflowing drain pans can saturate ceilings and walls, leading to structural damage and ruining inventory in commercial spaces like retail stores.

- System Shutdown: Many modern HVAC units are equipped with a float switch or overflow sensor that automatically shuts down the system if it detects a blockage, preventing further water damage but causing an immediate loss of cooling.

- Mould and Mildew Growth: The stagnant water and organic buildup in a clogged drain line create a perfect breeding ground for mould, which can then be circulated throughout the property, severely impacting indoor air quality.

Expert Insight: In a multi-storey office building, a single blocked condensate line on an upper floor can cause a chain reaction of water damage to the floors below. Implementing a quarterly drain cleaning schedule is essential to protect the asset and ensure tenant satisfaction.

Regularly clearing and treating the drain line is a low-effort task with a high return on investment, fundamental to a comprehensive HVAC maintenance checklist.

To ensure effective maintenance, consider using a wet/dry vacuum to clear stubborn blockages and treating the line with a diluted biocide or algaecide during the peak cooling season. Installing slow-release drain pan tablets can also help prevent organic growth between service visits, ensuring the system remains reliable and efficient.

5. Coil Cleaning and Inspection

Thorough cleaning and inspection of evaporator and condenser coils are fundamental to any effective HVAC maintenance checklist. These components are critical for the heat exchange process, with the evaporator coil absorbing heat from indoor air and the condenser coil releasing it outside. Over time, these coils accumulate dust, dirt, and in the UAE's humid climate, biological growth, which insulates them and severely hampers their ability to transfer heat.

Neglecting coil hygiene forces the compressor and fans to work harder and longer to achieve the desired temperature, leading to increased energy consumption and premature component failure. For facilities in the UAE, where cooling systems run almost continuously, clean coils are directly linked to operational efficiency and cost control. Regular cleaning restores performance, reduces strain, and prevents costly breakdowns.

Why It's a Top Priority

For facility managers, particularly in high-demand environments, coil maintenance is crucial for sustaining performance and managing expenses. The combination of airborne dust, humidity, and salinity in coastal areas creates a challenging environment for HVAC systems. Dirty coils can rapidly degrade system efficiency, resulting in:

- Skyrocketing Energy Bills: Insulated coils reduce heat transfer, forcing the system to run longer cycles to cool the space, which directly translates to higher electricity costs.

- System Overheating and Compressor Failure: The condenser coil's inability to expel heat can cause the system to overheat, placing extreme stress on the compressor, the most expensive component to replace.

- Corrosion and Refrigerant Leaks: In coastal properties, salt deposits on condenser coils accelerate corrosion, leading to refrigerant leaks and irreversible damage if not addressed promptly.

Expert Insight: In a restaurant kitchen, grease-laden air can quickly coat evaporator coils, creating a sticky, insulating layer that also promotes bacterial growth. Implementing a quarterly deep-cleaning schedule, using specialised degreasing agents, is essential to maintain both cooling capacity and hygienic air circulation.

A consistent coil cleaning regimen is a core pillar of a robust HVAC maintenance checklist. By ensuring these critical components are free of contaminants, you safeguard the system's health, optimise energy usage, and ensure reliable cooling performance, even during the peak summer months in the UAE.

6. Refrigerant Level Check and Leak Detection

Proper refrigerant levels are the lifeblood of any air conditioning system, directly governing its ability to transfer heat and produce cool air. This critical check involves verifying refrigerant pressures and temperatures to ensure the system is correctly charged. Undercharging or overcharging can drastically reduce efficiency, cause severe component damage, and increase energy consumption, making it a vital part of any HVAC maintenance checklist.

Monitoring for leaks and maintaining the correct charge ensures the system operates at its designed capacity, especially crucial during the UAE's intense summer months. A system low on refrigerant will struggle to cool, leading to longer run times and premature wear on the compressor, the most expensive component of the unit. This proactive check prevents costly breakdowns and maintains operational reliability.

Why It's a Top Priority

For contractors and facility managers, refrigerant management is a matter of performance, cost, and environmental responsibility. An incorrect charge or an undetected leak can have immediate and long-term consequences that impact both budgets and occupant comfort. Key risks of neglecting this task include:

- Compressor Failure: Low refrigerant levels can cause the compressor to overheat and fail, resulting in expensive and complex repairs.

- Skyrocketing Energy Bills: An incorrectly charged system works significantly harder to achieve the desired temperature, leading to a direct increase in electricity consumption.

- Environmental Impact: Refrigerant leaks release potent greenhouse gases into the atmosphere, contributing to environmental damage and violating regulations.

Expert Insight: In critical environments like data centres or large supermarket chains, a refrigerant leak can be catastrophic. Data centres rely on precision cooling to protect sensitive servers, while supermarkets need consistent refrigeration to prevent food spoilage. Implementing continuous refrigerant monitoring systems in these settings is an essential risk mitigation strategy.

Technicians should be trained to use multiple methods for accuracy, such as electronic leak detectors, ultrasonic detectors, and traditional soap bubble tests. Documenting every refrigerant addition and repair is not just good practice; it is a regulatory requirement and essential for tracking system health over time. For a comprehensive approach, integrating these checks into a formal plan is key. You can find robust templates to help structure your procedures by exploring a preventive maintenance schedule template on yasutrading.com to formalise your maintenance activities.

7. Blower Motor and Belt Inspection

The blower motor and its associated belts and pulleys are the heart of the air distribution system, responsible for circulating conditioned air throughout a building. A thorough inspection of these components is a vital part of any HVAC maintenance checklist, ensuring consistent airflow and preventing catastrophic mechanical failures that can lead to costly downtime and repairs.

Proper maintenance of the blower assembly directly impacts system efficiency, occupant comfort, and operational costs. A worn belt or a struggling motor can significantly reduce airflow, forcing the entire HVAC unit to run longer and harder to meet temperature set points. This simple but crucial check preserves the mechanical integrity and performance of the air handling system.

Why It's a Top Priority

For facility managers and contractors, neglecting the blower assembly is a high-risk oversight. The continuous operation required in the UAE's climate puts immense strain on motors and belts. A sudden belt failure or motor seizure can halt cooling operations entirely, creating an emergency situation in a commercial or residential building.

- Preventing Unplanned Downtime: A snapped belt is one of the most common causes of HVAC service calls. Regular inspections can identify wear and tear before it leads to a complete failure.

- Maintaining Airflow Efficiency: Correct belt tension and pulley alignment are critical for optimal performance. Misalignment or improper tension can lead to slippage, reducing fan speed and airflow while increasing energy consumption.

- Extending Motor Lifespan: Checking motor amperage draw and ensuring proper lubrication (where applicable) helps identify performance issues before they cause the motor to burn out, avoiding an expensive replacement.

Expert Insight: In a large manufacturing facility, a failed blower motor on a primary Air Handling Unit (AHU) can disrupt production lines, leading to financial losses that far exceed the cost of routine maintenance. Implementing monthly belt inspections and annual motor performance checks is a fundamental aspect of a predictive maintenance strategy.

Key maintenance tasks include checking belt tension using a deflection gauge, verifying pulley alignment with laser tools, and listening for unusual noises like squealing or grinding. Ensuring spare belts are kept on-site for common units allows for immediate replacement, minimising system downtime. A well-maintained blower assembly is essential for a reliable and efficient HVAC system.

8. Ductwork Inspection and Sealing

Systematic inspection and sealing of ductwork is a crucial, though often overlooked, step in a complete HVAC maintenance checklist. Ducts are the arteries of your HVAC system, distributing conditioned air throughout the building. Leaks, holes, and poor connections in these channels can lead to significant energy waste, poor air quality, and imbalanced cooling, which are major concerns for properties in the UAE.

Sealing these leaks ensures that cooled air reaches its intended destination without escaping into unconditioned spaces like ceiling voids or wall cavities. This optimises system performance, reduces operational costs, and enhances occupant comfort. Properly sealed ductwork is fundamental to achieving the energy efficiency ratings modern buildings strive for.

Why It's a Top Priority

In the UAE's demanding climate, an HVAC system with leaky ducts must run longer and work harder to maintain set temperatures, leading to accelerated wear and tear. Leaks not only waste expensive cooled air but can also pull in hot, dusty, and un-filtered air from outside, degrading indoor air quality. For contractors and facility managers, addressing duct leakage is key to:

- Improving Energy Efficiency: Leaky ducts can account for 20-30% of energy loss in a typical building, making sealing a high-impact energy conservation measure.

- Ensuring Proper Air Distribution: Sealing ensures balanced airflow to all zones, eliminating hot and cold spots that generate occupant complaints.

- Preventing Contaminant Infiltration: Unsealed return ducts can pull in pollutants, dust, and insulation fibres from unconditioned areas, compromising indoor air quality.

Expert Insight: For commercial buildings, comprehensive duct sealing can deliver a rapid return on investment through immediate energy savings. Technologies like Aeroseal can identify and seal leaks from the inside, providing a verifiable and highly effective solution that is especially valuable for the complex duct systems found in large-scale facilities.

Effective ductwork management is a cornerstone of proactive building maintenance. Understanding these principles is essential for professionals in the field, and you can explore more advanced strategies for building upkeep by reviewing best practices in facility management in Dubai on yasutrading.com to elevate your operational standards.

8-Point HVAC Maintenance Checklist Comparison

| Maintenance Task | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Filter Replacement and Inspection | Low - requires regular scheduling and monitoring | Low cost filters, occasional bulk purchase | Improves air quality, reduces energy use (5-15%), extends equipment life | Residential, commercial, industrial with varied filtration needs | Significant air quality improvement; low cost; energy savings |

| Thermostat Calibration and Programming | Medium - involves calibration and programming, some complexity | Requires smart devices, WiFi, occasional professional support | Energy cost reduction (10-23%), precise temperature control | Smart homes, multi-zone buildings, energy-conscious users | Remote control, energy analytics, comfort optimization |

| Electrical Connection Inspection and Tightening | High - electrical expertise and safety protocols needed | Skilled technician, specialized tools (torque wrench, infrared camera) | Prevents electrical failures and fires, improves reliability | Hospitals, industrial, commercial critical systems | High safety impact; prevents costly failures; enhances reliability |

| Condensate Drain Cleaning and Inspection | Low to Medium - routine cleaning with some tools | Basic cleaning supplies, biocides, wet/dry vacuum | Prevents water damage, mold growth, system shutdowns | Humid climates, cooling systems, residential and commercial | Prevents water damage and mold; inexpensive; maintains air quality |

| Coil Cleaning and Inspection | Medium - requires chemicals and careful handling | Cleaning solutions, pressure washers, fin combs | Improves system efficiency (10-25%), reduces energy consumption | High-use systems, kitchens, coastal properties | Significant efficiency gains; protects equipment longevity |

| Refrigerant Level Check and Leak Detection | High - requires certification and specialized equipment | EPA-certified technicians, leak detectors, refrigerant handling tools | Prevents compressor failures, ensures compliance, optimizes performance | Supermarkets, data centers, critical cooling systems | Compliance assurance; early problem detection; system optimization |

| Blower Motor and Belt Inspection | Medium - routine mechanical checks and adjustments | Basic mechanical tools, possible professional repair | Maintains airflow, prevents failures, extends motor life | Manufacturing, commercial buildings, schools | Reduces downtime; energy-efficient; noise reduction |

| Ductwork Inspection and Sealing | Medium to High - some inaccessible areas, specialized testing | Duct testers, thermal cameras, sealing materials | Reduces energy waste (20-30%), improves comfort and air quality | Energy-efficient homes, commercial buildings, rebate programs | Large energy savings; improves comfort; dust prevention |

From Checklist to Competitive Advantage

Navigating the demands of the UAE's climate requires more than just a functional HVAC system; it demands an optimised, resilient, and meticulously maintained one. Moving beyond a simple to-do list, the comprehensive HVAC maintenance checklist detailed in this article serves as a strategic blueprint for operational excellence. It transforms routine tasks into powerful levers for efficiency, reliability, and significant cost savings.

We have explored the critical checkpoints, from daily visual inspections to intensive annual overhauls. Each step, whether it’s the precise calibration of a thermostat, the diligent cleaning of evaporator and condenser coils, or the crucial tightening of electrical connections, plays an integral role. Together, they form a holistic maintenance strategy that safeguards against the primary threats in our region: extreme heat, pervasive dust, and high humidity. For facility managers and contractors, mastering this schedule is not just about preventing breakdowns; it's about delivering consistent comfort, ensuring superior indoor air quality, and protecting substantial capital investments.

The Strategic Value of Proactive Maintenance

Adopting this structured approach yields tangible benefits that resonate across your operations and directly impact your bottom line. The key takeaways from this guide underscore a shift from a reactive repair model to a proactive, performance-driven one.

- Enhanced Energy Efficiency: Clean filters, unobstructed coils, and properly calibrated systems do not have to work as hard to achieve desired temperatures. This directly translates into lower DEWA bills and a reduced carbon footprint, a critical goal for sustainable building management in the UAE.

- Extended Equipment Lifespan: Regular maintenance mitigates the wear and tear caused by constant operation in a harsh environment. By addressing minor issues like loose belts or low refrigerant before they escalate, you can significantly extend the operational life of expensive HVAC units, deferring costly replacements.

- Improved Air Quality and Occupant Comfort: A well-maintained system is your first line of defence against airborne pollutants. Consistent cleaning of filters, condensate drains, and ductwork prevents the circulation of dust, mould, and allergens, creating a healthier and more comfortable environment for occupants, a non-negotiable factor in premium residential, commercial, and hospitality settings.

Ultimately, a robust HVAC maintenance checklist is your framework for turning a standard operational cost into a competitive advantage. It ensures your facilities are not just compliant, but are benchmarks of efficiency and reliability. By transforming this checklist from a document into a dynamic, ongoing programme, you establish a standard of excellence that protects assets, enhances occupant satisfaction, and solidifies your reputation in a demanding market. This is how maintenance evolves into a strategic asset.

To successfully implement a rigorous maintenance schedule, you need a reliable partner for certified, high-quality components. For all your supply needs, from electrical fittings to essential HVAC parts, trust Yasu Trading Co. LLC to provide the genuine materials required to keep your systems running at peak performance. Request a quotation today and ensure every repair and replacement upholds the integrity of your HVAC investments.