Your Guide to Mapei Tile Glue for Dubai Projects

When you're a contractor or developer in the UAE, choosing a tile adhesive isn't just another item on a list. It's a decision that directly impacts the longevity of your work, your professional reputation, and your bottom line. Mapei tile glue is the premier choice for a simple reason: its formulas are built from the ground up to handle the extreme heat and humidity we face here. Standard adhesives just can't compete, often leading to failure, delamination, and costly rework.

Why Mapei Tile Glue Is a Top Choice in the UAE

Working on a project in Dubai, Abu Dhabi, or anywhere in the Emirates means battling the environment. The constant temperature swings, pervasive humidity, and relentless UV exposure are brutal on building materials. This is where Mapei tile glue truly proves its worth and why so many pros swear by it.

Experienced contractors count on Mapei because its adhesives deliver a bond that can withstand serious thermal shock—that daily cycle of expansion and contraction as surfaces go from scorching daytime heat to cooler nights. This resilience is absolutely critical, whether you're tiling a high-traffic hotel lobby or a massive exterior facade getting baked by the sun all day.

What makes Mapei tile glue ideal for the UAE climate?

Mapei adhesives are ideal for the UAE climate because they contain advanced polymers that prevent the bond from weakening or becoming brittle in extreme heat. This formulation ensures tiles remain securely in place for years, preventing costly failures and protecting the quality of your project.

Using the right product also ensures you're aligned with strict UAE construction standards. These aren't just suggestions; they're regulations designed to keep buildings safe and durable. Mapei's products are engineered to meet and often exceed these tough requirements. Getting them from a trusted building materials distributor like Yasu Trading guarantees you're working with the genuine article, fully certified and compliant with local codes.

How has Mapei performed on large-scale UAE projects?

Mapei's performance has been proven on some of the most recognisable projects in the region, including being the adhesive supplier for 55 national pavilions at Expo 2020 Dubai. In a market where a staggering 75-80% of all floor coverings are ceramic tiles, the need for a bulletproof adhesive is immense. With the UAE's tile adhesive market hitting a sales revenue of $51.52 million in 2024, it’s clear how much construction is happening. You can get more insight into these regional tile adhesive market trends and see how construction booms are shaping demand.

We've put together a quick summary to highlight why Mapei is such a reliable choice for projects here.

Mapei Tile Glue Benefits at a Glance

This table breaks down the key advantages of using Mapei adhesives for projects in the UAE, providing a quick reference for contractors and specifiers.

| Feature | Advantage for UAE Projects | Common Application |

|---|---|---|

| Heat & Humidity Resistance | Formulated with specialised polymers that prevent bond failure despite extreme temperature fluctuations and high moisture levels. | Exterior facades, swimming pools, wet areas (bathrooms, kitchens), and rooftop terraces. |

| Superior Bond Strength | Creates an incredibly strong, long-lasting bond that resists delamination, even under heavy foot traffic or thermal stress. | High-traffic commercial spaces, shopping malls, airports, and large-format tile installations. |

| Extended Open Time | Allows installers more time to adjust tiles, which is crucial in the fast-drying heat of the UAE climate. | Intricate mosaic work, large-format tiling, and projects with complex layouts. |

| Compliance & Certification | Meets or exceeds stringent UAE construction standards and international norms (e.g., ISO 13007), ensuring project compliance. | Government projects, high-rise buildings, and developments requiring strict quality control. |

Essentially, these features work together to provide peace of mind, ensuring that the final installation is as durable as it is beautiful.

By choosing a specialised adhesive from a reputable supplier in Dubai, contractors can effectively avoid the common pitfalls of adhesive-related failures. This proactive approach not only saves money on potential repairs but also helps deliver projects on time and within budget, enhancing client satisfaction and professional credibility.

How does using Mapei mitigate risks and ensure project success?

Opting for Mapei tile glue is a strategic move that directly mitigates the risk of tiling failures, which can derail project schedules and budgets. Investing in a superior adhesive system from the start is the best insurance against these headaches, protecting a contractor's reputation.

Working with a reliable supplier in Dubai like Yasu Trading adds another layer of confidence. You get access to solid technical advice and a supply chain that just works, ensuring you have the right materials and the expert support you need to deliver a flawless, lasting finish that can stand up to anything the UAE environment throws at it.

How to Select the Right Mapei Adhesive for Your Project

Choosing the correct Mapei tile glue isn't just a minor detail; it’s the very foundation of a job that lasts. The real secret to a professional-looking, durable installation is correctly matching the adhesive to two things: the tile you're using and the surface (or substrate) you're sticking it to. Get this wrong, and you're looking at costly callbacks for cracked grout, hollow-sounding tiles, or even tiles completely detaching from the wall.

For example, those huge porcelain tiles you see in luxury Dubai villas need a high-performance, deformable adhesive, something rated C2. This isn't overkill; it's essential for handling the tiny movements and thermal expansion that come with a large tile. On the other hand, simple ceramic tiles for a kitchen backsplash might only need a basic C1 adhesive. The local environment plays a massive role, too.

What is the best Mapei glue for different tile types?

The best Mapei glue depends entirely on the tile's material, size, and porosity, as there is no single "best" product for all applications. For heavy, large-format porcelain slabs common in the UAE, a high-polymer, flexible adhesive like Mapei Keraflex Maxi S1 is ideal to prevent cracking.

A classic scenario we see all the time in the UAE is installing heavy, large-format porcelain slabs. For a job like that, you should be reaching for a product like Mapei Keraflex Maxi S1. Its high polymer content gives it incredible adhesion and flexibility—crucial for preventing cracks as a building settles or reacts to our intense temperature swings. If you're working with something more delicate, like glass mosaics or certain natural stones, a white adhesive is the smart play to avoid any colour bleeding through.

Choosing the right adhesive is about more than just holding a tile to the wall. It’s about creating a unified system where the substrate, adhesive, and tile work together to withstand environmental stresses, especially the intense heat and humidity common in the UAE.

How do you match Mapei adhesives to common UAE substrates?

To match an adhesive, you must consider the substrate's porosity and stability, such as concrete blockwork, cement screeds, or plasterboard. While a standard Mapei product works on cured concrete, less stable surfaces like plasterboard may require a ready-mixed adhesive, and external facades must use a high-performance, weather-resistant cementitious adhesive to meet strict UAE construction standards.

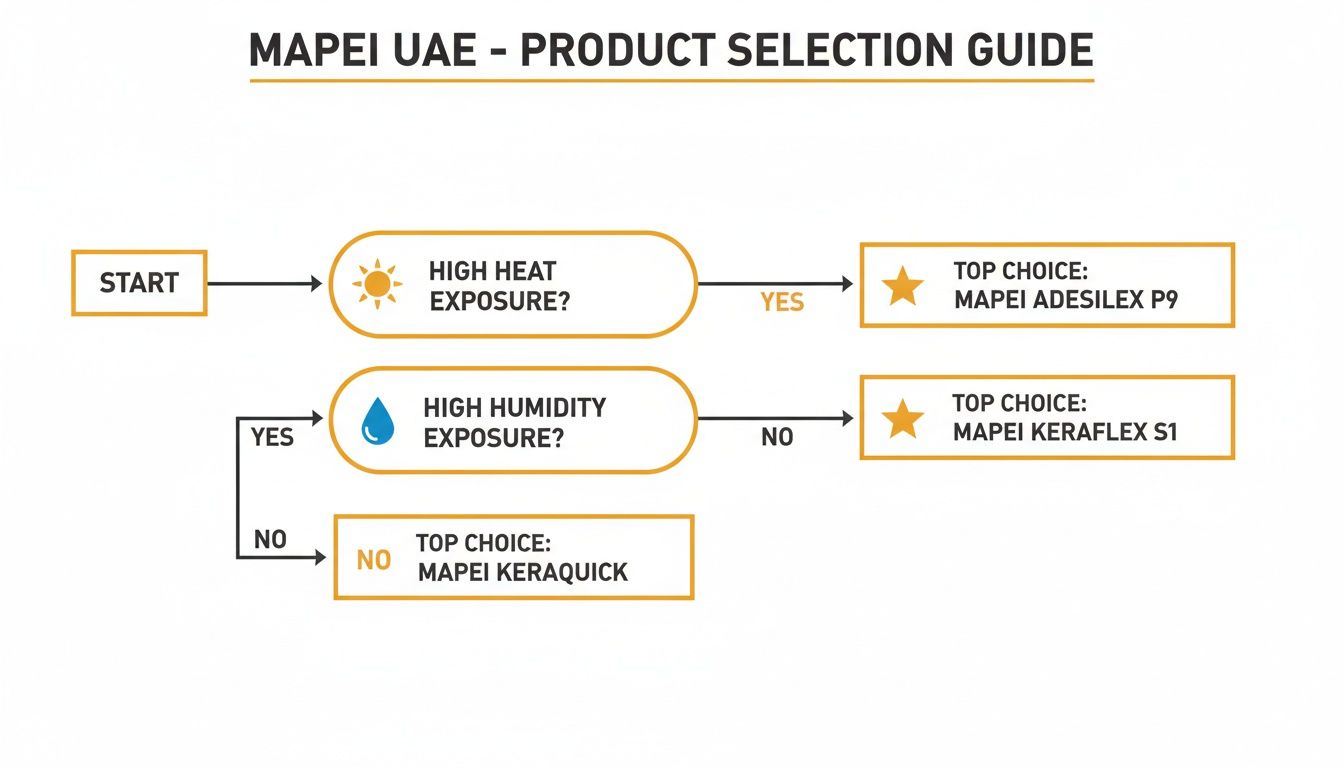

The surface you're tiling onto is every bit as important as the tile itself. In UAE construction, you're typically dealing with concrete blockwork, cement screeds, or plasterboard. Each one has its own personality—its own porosity and stability—that directly impacts your adhesive choice. This flowchart is a great starting point for thinking through the process based on our region's specific challenges.

As you can see, the tougher the environment—more heat, more humidity—the more you need to lean on a higher-specification Mapei adhesive to ensure the project stands the test of time.

Why are speciality adhesives needed for pools and wet areas?

Speciality adhesives are needed for pools and wet areas because these environments face constant water immersion, harsh chemicals, and significant temperature fluctuations. A standard adhesive would quickly break down under these conditions, leading to tile failure, leaks, and costly repairs.

Mapei has products specifically engineered for these punishing conditions. For a swimming pool, you need an adhesive that not only has incredible bond strength but is also built to resist chlorine and other pool chemicals. In projects like major commercial restaurant renovations, picking the right Mapei product for kitchens and bathrooms is critical for tiling that can handle constant moisture and aggressive cleaning.

Mapei Product Selector for Common UAE Applications

To make things a bit easier, here’s a quick reference guide that matches some popular Mapei products to the kinds of jobs we see every day across Dubai and the UAE.

| Mapei Product Line | Best For Tile Type | Ideal Substrate | Key Feature (e.g., Extended Open Time) |

|---|---|---|---|

| Adesilex P9 | Ceramic, Porcelain | Concrete, Screeds | Excellent bond strength for general use. |

| Keraflex Maxi S1 | Large-Format Porcelain, Stone | Concrete, Gypsum Board | High performance, deformable, no vertical slip. |

| Granirapid | Natural Stone, Agglomerates | Cement Screeds, Heated Floors | Rapid-setting for fast-track projects. |

| Kerabond T | Ceramic Tiles, Mosaics | Cementitious Renders, Blockwork | Thixotropic; ideal for vertical surfaces. |

When it comes down to it, the best move is to talk it through with your building materials distributor. A seasoned supplier in Dubai, like us at Yasu Trading, can give you technical advice based on the specifics of your project. This ensures you get the right Mapei tile glue for a flawless, long-lasting finish every time.

The Right Way to Prepare and Mix Mapei Tile Glue

Even the best Mapei tile adhesive will fail if it's not mixed and applied correctly. I've seen it happen. Getting that powerful, permanent bond isn't about luck; it's about following a methodical process that respects the material's chemistry. This process starts long before you even open the bag.

In the dusty construction environments we see all over the UAE, the first and most critical step is making sure your surface is perfectly clean, structurally sound, and free from any contaminants. From that solid foundation, precise mixing and application techniques will unlock the performance Mapei is known for.

How do you prepare a surface for tiling?

To prepare a surface for tiling, you must ensure it is clean, dry, stable, and completely free of any contaminants like dust or grease. Any residue left on the surface will compromise the adhesive's bond, leading to potential tile failure.

If you're working with new concrete or screed, you absolutely must allow it to cure fully. Tiling over "green" concrete traps moisture and creates a whole host of problems. A solid foundation is non-negotiable, and for a deep dive into this crucial first phase, check out a pro's guide to flawless floor preparation for tile. Putting in the effort here is what separates a professional job that lasts for decades from one that needs repairs in just a few years.

What is the correct water ratio for mixing Mapei glue?

The correct water ratio is always printed on the Mapei product bag and its Technical Data Sheet (TDS); deviating from this is a common and damaging mistake. Adding too much water weakens the adhesive's final cured strength by diluting the essential polymers.

Here's how we mix it on-site for perfect consistency:

- Water First: Pour about 80% of the recommended clean, cool water into a clean mixing bucket.

- Powder Second: Slowly add the Mapei tile glue powder to the water while you're mixing with a low-speed mechanical stirrer (around 500 RPM is ideal).

- Mix Well: Keep mixing until you have a smooth, lump-free paste. Don't forget to scrape the sides and bottom of the bucket to get all the dry powder incorporated.

- Let it Slake: Now, let the mixture rest or "slake" for 5-10 minutes. This pause is critical; it allows all the chemical additives to fully dissolve and activate.

- Final Mix: Give the adhesive one last, brief remix before you start applying it. And whatever you do, don't add more water at this stage.

Following the manufacturer's exact mixing instructions isn't just a recommendation; it's a core requirement for complying with UAE construction standards and ensuring the product performs as advertised. Any deviation can void warranties and compromise the entire installation.

How do you manage pot life in Dubai's heat?

To manage adhesive pot life in Dubai's heat, you should mix smaller batches more frequently and always keep materials out of direct sunlight. High temperatures significantly reduce the time you have to use the adhesive after mixing, so working in shade or during cooler parts of the day is crucial.

Never try to "re-hydrate" an adhesive that has started to set in the bucket by adding more water. Once that chemical curing process starts, it's irreversible. All you'll achieve is a weak, unreliable bond. It's this attention to detail that separates professional advice from generic guidance.

The incredible performance of Mapei products has cemented their place in the region. Mapei tile glue has captured a huge part of the UAE's adhesives market, contributing to the GCC construction adhesives sector's projected 5.5% CAGR from 2024-2030. Innovations like Kerabond Plus, with its extended open time perfect for 50°C+ heat, boosted its adoption by 18% among local contractors. For clients of a trusted supplier in Dubai like Yasu Trading, this means access to glues that can increase tile strength and slip resistance by a staggering 40% over traditional methods.

How to Troubleshoot Common Tiling Issues in the UAE Climate

Tiling in the UAE's demanding climate isn't just a job; it's a battle against the elements. The intense heat and relentless humidity create a unique set of challenges that can turn a flawless installation into a costly nightmare if you're not prepared. But with the right know-how and a high-performance **Mapei tile glue** in your bucket, these common problems are entirely avoidable.Think of this section as your on-site field guide. We'll walk through the most frequent issues contractors face, from adhesive flash-drying in the midday sun to heavy tiles slumping down a wall. You'll get practical, actionable solutions to ensure your work stands up to the highest professional standards, even on the toughest days.

What causes tile adhesive to dry too quickly?

Tile adhesive dries too quickly when high temperatures and low humidity cause moisture to evaporate from its surface, creating a "skin" that prevents a proper bond. This rapid drying, common in the UAE climate, leads to weak spots and potential tile delamination.

The trick is to outsmart the heat. Always work in smaller, more manageable sections—I'm talking no more than one square metre at a time. If you're working on a porous substrate like concrete or plaster, give it a light wipe with a damp sponge before you start. This simple step stops the surface from stealing moisture from your Mapei tile glue, buying you precious minutes to set your tiles perfectly.

Here's a pro-tip I swear by: periodically touch the adhesive with your fingertip. If it doesn't transfer to your skin, it has skinned over. Don't risk it. Scrape it off and apply a fresh layer before setting the tile.

How do you prevent tiles from slipping on walls?

To prevent tiles from slipping on walls, use a thixotropic (non-slip) adhesive like Mapei's Kerabond T or Keraflex Maxi S1. These are engineered to provide an immediate grip that holds heavy tiles in place, defying gravity while the adhesive cures.

There's nothing more frustrating than watching heavy, large-format tiles slowly slide down a vertical surface. This is almost always caused by one of two things: the adhesive mix is too thin, or you're using a product that just isn't built for the job. When you press a tile into the adhesive with a slight twisting motion, you create an immediate suction-like grip that holds it firm. And remember, using the right trowel size is non-negotiable for getting full coverage on the back of the tile.

What is efflorescence and how can you stop it?

Efflorescence is the chalky, white residue that appears on grout and tiles when water-soluble salts migrate to the surface and are left behind as moisture evaporates. To stop it, use a robust waterproofing system to block moisture intrusion and a high-density, polymer-modified grout to reduce water absorption.

It's especially common in coastal areas like Dubai, where salt is in the air and groundwater. A robust waterproofing system is your first line of defence, stopping moisture from getting into the tile assembly in the first place. You can get the full rundown in our guide on advanced sealants and waterproofing for the UAE climate. Beyond that, using a high-density, polymer-modified grout from Mapei's range dramatically reduces water absorption, which minimises the chance of salt migration.

For local pros, from real estate developers to renovation specialists, the right materials make all the difference. Mapei glues offer 100% exterior compatibility, a critical feature that slashes failure rates by 35% in sandy, humid conditions compared to basic mixes. Regional data shows the UAE drives 28% of GCC adhesive demand, and a reliable building materials distributor like Yasu Trading enables next-day delivery that can boost project efficiency by 25%. With a projected 70-100% rise in adhesive usage due to trends in exotic stones and weather extremes, Mapei’s extended-range products are essential for compliance and maintaining warranties.

Finding the Right Mapei Supplier in Dubai

Let’s be honest: your project’s success isn't just about using a great product. It's about having a rock-solid supply chain behind you. You can pick the perfect Mapei tile glue, but if you can't get it when you need it, or you get a bad batch, the whole project can grind to a halt.

That's where partnering with an authorised building materials distributor like Yasu Trading comes in. It’s about more than just buying a product; it’s about making sure everything from product authenticity to on-time delivery is handled professionally. This relationship is often the unsung hero that keeps a project on schedule and on budget.

Think of a dedicated supplier as an extension of your own team. They're the ones providing the critical support that helps you avoid costly delays and ensures your work meets the demanding UAE construction standards.

Why should you work with an authorised Mapei distributor?

You should work with an authorised distributor to guarantee you receive genuine Mapei products covered by full manufacturer warranties. This eliminates the risk of using counterfeit materials and provides a direct line to expert technical support for your project.

An official partner like Yasu Trading also gives you a direct line to expert technical support. Got a tricky substrate you're not sure about? Facing a challenging application? You get reliable answers straight from people who know the product inside and out. That kind of guidance is invaluable, especially on complex jobs where every detail matters.

The real value of a great supplier isn't just in the products they sell, but in the problems they help you avoid. From guaranteeing product integrity to smoothing out logistics, an authorised distributor is your project's best insurance policy.

How does a good supplier make procurement painless?

A good supplier in Dubai makes procurement painless by offering consolidated ordering and reliable, direct-to-site delivery across the UAE. This streamlines your logistics, reduces project delays, and allows you to focus on the construction work itself.

Yasu Trading maintains a robust inventory and an efficient delivery network to ensure you have what you need, right when you need it. Waiting on materials is one of the most common—and frustrating—causes of delays on a construction site. With a dependable partner, you can keep the workflow steady and your project moving forward. For more on this, check out our guide on choosing the right building materials suppliers.

How do you get your adhesive coverage calculations right?

To calculate adhesive coverage, start with the consumption rates on the Mapei Technical Data Sheet (TDS) and then adjust for real-world factors. Consider the trowel size, tile back pattern, and substrate condition to avoid over-ordering or shortages.

Nailing these calculations is the key to avoiding both wasteful over-ordering and work-stopping shortages. A good building materials distributor can even help you fine-tune these numbers.

Keep these key factors in mind when ordering your Mapei tile glue:

- Trowel Notch Size: Bigger tiles and uneven surfaces demand deeper notches, which naturally uses more adhesive.

- Substrate Porosity: A very absorbent surface might drink up more adhesive or require a primer first.

- Tile Type: Tiles with deep, uneven patterns on the back need a thicker bed of glue to achieve full contact and a solid bond.

By thinking through these variables, you can place a much more precise material order. This kind of careful planning, backed by a knowledgeable supplier, is what makes a tiling project in the UAE run smoothly, efficiently, and cost-effectively.

Got Questions About Mapei Tile Adhesives? We've Got Answers.

When you're on a job site in the UAE, you need clear, straightforward answers about the materials you're using. Here are some of the most common questions we get from contractors and engineers about Mapei tile glue, answered from our hands-on experience.

What is the go-to Mapei glue for porcelain tiles?

The go-to Mapei glue for porcelain tiles is a high-performance, deformable cementitious adhesive classified as C2S1, such as Mapei Keraflex Maxi S1. This type of adhesive is engineered for porcelain's low porosity and provides the flexibility needed to handle thermal expansion.

This type of Mapei tile glue has incredible adhesion, so it can handle the weight of even the heaviest tiles without any slippage. It's our top recommendation for both wall and floor applications.

Can you use Mapei glue over a waterproofing membrane?

Yes, you can use Mapei glue over a waterproofing membrane, but you must use a compatible polymer-modified adhesive designed for non-porous surfaces. Products from the Keraflex or Adesilex family are suitable for bonding tiles to membranes like Mapelastic.

Pro Tip: Always, and I mean always, check the Technical Data Sheet (TDS) for both the waterproofing product and the adhesive. Confirming compatibility is a critical step to meet UAE construction standards, especially for wet areas like bathrooms, kitchens, and swimming pools.

How long does Mapei tile adhesive take to dry?

Mapei tile adhesive is generally ready for light foot traffic and grouting after about 24 hours, though a full cure takes several days. Rapid-setting products like Granirapid can be ready in just 3-4 hours, but remember that the UAE heat can accelerate curing times.

Working with a reliable supplier in Dubai who understands local conditions is crucial. They can help you pick a product with the right open time to prevent it from skinning over too quickly.

Is Mapei adhesive good for outdoor use?

Yes, Mapei adhesive is excellent for outdoor use, with a range of products specifically designed to withstand the UAE's climate. For exterior applications, choose an adhesive that can handle thermal shock, UV exposure, and moisture, such as those with a "T" (thixotropic) and "E" (extended open time) classification.

Choosing the right exterior-grade adhesive from a trusted building materials distributor is fundamental. It’s the difference between a façade, balcony, or patio that looks great for years and one that fails under the constant stress of our sun and humidity.

For genuine Mapei products and expert technical support for your next project in the UAE, partner with Yasu Trading Co. LLC. We provide site-direct delivery and ensure you get the right materials to keep your project on schedule. Explore our full range of construction solutions.