The Ultimate Pipe Size Chart and Reference Guide

If you've ever worked with pipes, you know the first rule: a pipe's name isn't its actual size. It's a classic rookie mistake to think a 2-inch Schedule 40 pipe actually measures 2 inches anywhere on a tape measure. It doesn’t. This guide is built to give you the charts and the know-how to get it right every single time.

Your Quick Guide to Pipe Dimensions

Getting your head around pipe sizing can feel like learning a new language. The whole industry has its own shorthand, and the biggest hurdle is understanding that what we call a pipe isn't what it measures. This is where you absolutely have to get familiar with terms like Nominal Pipe Size (NPS), Outside Diameter (OD), and Inside Diameter (ID).

Core Sizing Concepts

Let's break down the essential terms you'll see on every pipe chart.

- Nominal Pipe Size (NPS): Think of this as the pipe's nickname, not its real measurement. For pipes 12 inches and under, NPS is just a standard name that gives you a reference point. It’s loosely tied to the inside diameter, but it never matches it exactly. For instance, an NPS 4 pipe actually has an outside diameter of 4.5 inches.

- Outside Diameter (OD): This is the one constant, the true measurement across the exterior of the pipe. For any given NPS, the OD never changes, no matter how thick the pipe wall is. This is incredibly important because it guarantees that all your fittings, valves, and flanges will fit perfectly, regardless of the pipe's schedule.

- Inside Diameter (ID): Here’s where things change. The ID is the actual size of the hole—the bore—that fluid or gas flows through. It is directly determined by the wall thickness (the "schedule"). The thicker the wall, the smaller the inside diameter, which has a major impact on flow rate and pressure.

Nailing down these fundamentals is the crucial first step. Once you get this, you can look at any pipe dimension table and know exactly what you're dealing with, preventing expensive ordering mistakes and project delays. With this foundation, you're ready to dive into the detailed charts ahead.

Understanding Nominal Pipe Size and Schedules

Before you can make sense of any pipe size chart, you need to get familiar with two of the most important concepts in the world of piping: Nominal Pipe Size (NPS) and Pipe Schedule (SCH). These terms are the language of the industry. They work hand-in-hand to tell you a pipe's dimensions and how much pressure it can handle, but they can be a bit confusing at first glance. Once you get the hang of them, though, you'll be able to spec out any project with confidence.

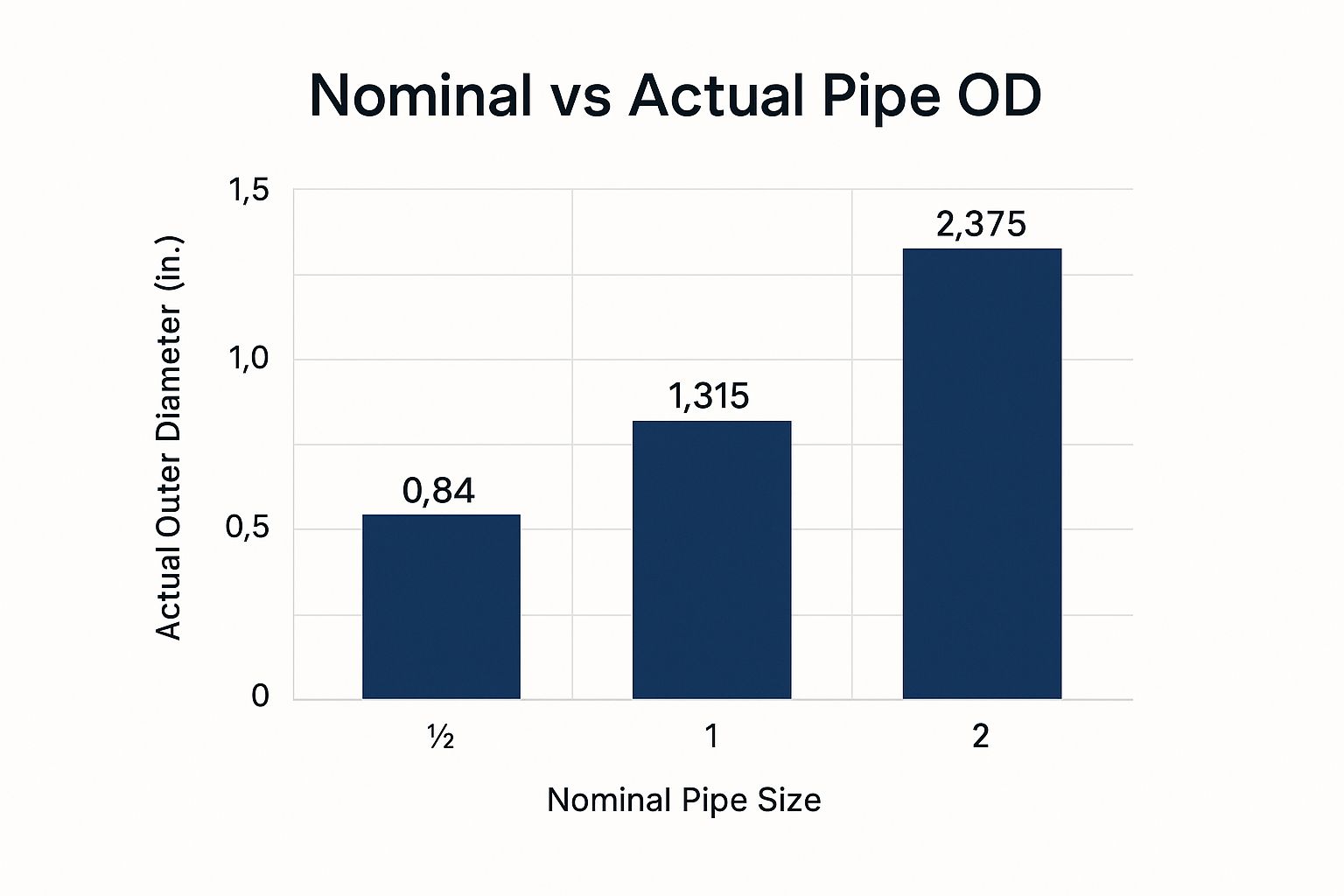

Let's start with NPS. This is the North American standard for pipe sizes, covering everything from high-pressure industrial lines to low-pressure plumbing. The most critical thing to remember is that NPS is just a name, a reference number. It's not the actual measurement of anything on the pipe, at least for sizes 12 inches and smaller. A classic example is an NPS 2 pipe; its actual outside diameter (OD) is 2.375 inches, not a neat 2 inches. This standardization is what ensures a pipe from one mill will fit perfectly with a fitting from another.

For any given NPS, the Outside Diameter (OD) is always the same. It's a constant. So, an NPS 4 pipe will always have an OD of 4.5 inches, no matter how thick its walls are. This is a huge deal because it means you can connect a Schedule 40 fitting to a much thicker Schedule 80 pipe, as long as they share the same NPS.

The Role of Pipe Schedule

So if NPS sets the outside diameter, what determines the wall thickness? That's where the Pipe Schedule (SCH) comes in. Think of the schedule number as an indicator of the pipe wall's thickness. The higher the schedule number, the thicker the wall. This has a direct effect on the pipe's strength and, just as importantly, its Inside Diameter (ID).

Since the OD is fixed for a given NPS, a pipe with a thicker wall (a higher schedule) is naturally going to have a smaller opening on the inside. This is a fundamental trade-off in system design because it impacts both the pressure rating and the flow capacity.

Key Takeaway: Here’s the main rule to burn into your memory: For any specific NPS, a higher schedule number means a thicker wall, a smaller inside diameter, and a stronger pipe.

Let's put this into a real-world context. Imagine you have two pipes, both with a Nominal Pipe Size of 2 inches:

- An NPS 2 Schedule 40 Pipe has a wall thickness of 0.154 inches and an inside diameter of 2.067 inches.

- An NPS 2 Schedule 80 Pipe has a significantly thicker wall at 0.218 inches, which shrinks its inside diameter down to 1.939 inches.

Both of these pipes share the exact same outside diameter (2.375 inches) and can use the same size fittings. The big difference? That Schedule 80 pipe is built like a tank and can handle much higher pressures, but at the cost of reduced flow due to its smaller bore. Getting this balance right is what good engineering is all about.

Steel Pipe Size Chart: NPS 1/8 to 12

When you're on a job site or in the planning phase, you'll find that steel pipes from Nominal Pipe Size (NPS) 1/8 to 12 are your bread and butter. These are the workhorses for everything from residential plumbing to heavy-duty industrial fluid lines. Getting the dimensions right is everything, so this chart is designed to be your go-to reference. It connects the dots between NPS, the actual Outside Diameter (OD), and how the wall thickness and Inside Diameter (ID) shift with different schedules.

One of the first things you learn in the field is that the number in the name (NPS) often doesn't match the measurement on your calipers, especially with smaller pipes. This is a classic "rookie mistake" that can cause major headaches with fittings.

As the visual shows, the actual OD is always a bit bigger than the nominal size it's called. Remembering this simple fact is absolutely fundamental to getting your connections right and avoiding costly mistakes.

Steel Pipe Dimensions for NPS 1/8 to NPS 12

Here's a straightforward table breaking down the most common dimensions for standard steel pipes. I've set it up so you can quickly find an NPS and see its specs for both Schedule 40 (your standard wall) and Schedule 80 (the heavy-duty stuff). All measurements are in millimeters (mm) to keep things consistent with international standards.

| NPS (inches) | OD (mm) | Schedule | Wall Thickness (mm) | ID (mm) |

|---|---|---|---|---|

| 1/2" | 21.3 | SCH 40 | 2.77 | 15.76 |

| SCH 80 | 3.73 | 13.84 | ||

| 3/4" | 26.7 | SCH 40 | 2.87 | 20.96 |

| SCH 80 | 3.91 | 18.88 | ||

| 1" | 33.4 | SCH 40 | 3.38 | 26.64 |

| SCH 80 | 4.55 | 24.30 | ||

| 1 1/4" | 42.2 | SCH 40 | 3.56 | 35.08 |

| SCH 80 | 4.85 | 32.50 | ||

| 1 1/2" | 48.3 | SCH 40 | 3.68 | 40.94 |

| SCH 80 | 5.08 | 38.14 | ||

| 2" | 60.3 | SCH 40 | 3.91 | 52.48 |

| SCH 80 | 5.54 | 49.22 |

It’s just good practice to always specify both the NPS and the Schedule—for example, "NPS 4 SCH 40." This simple step guarantees you're getting the exact OD, wall thickness, and pressure rating your system demands.

This need for precision is only growing. The pipe market in the Middle East and Africa, which includes the UAE, was valued at a massive USD 8.13 billion in 2023 and is projected to hit USD 11.56 billion by 2031. This explosive growth, fueled by infrastructure and industrial development, means the demand for a huge variety of reliable pipe sizes is at an all-time high.

Of course, steel isn't the only game in town anymore. Modern projects are increasingly turning to other materials. If you're curious about one of the most popular alternatives, take a look at our comprehensive guide on PPR pipes in the UAE.

Large Diameter Pipe Size Chart NPS 14 and Larger

Once you start dealing with large-scale projects—think city water mains, major industrial process piping, or oil and gas transmission lines—the way we talk about pipe sizes thankfully gets a lot simpler. For any pipe with a Nominal Pipe Size (NPS) of 14 inches and larger, the name finally tells the whole story: the NPS value is the same as the pipe's actual Outside Diameter (OD).

This is a huge relief after the confusing naming conventions for smaller pipes. It's a straight one-to-one relationship.

So, an NPS 14 pipe really does have an OD of 14 inches. An NPS 20 pipe? You guessed it, it measures 20 inches across. This direct correlation removes all the guesswork. But, the complexity doesn't disappear entirely; it just shifts over to how wall thickness is specified. Instead of just using standard schedule numbers like SCH 40, it's common for large pipes to have their wall thickness specified directly in inches or millimeters.

Understanding Large Diameter Pipe Dimensions

While schedules do still exist for these sizes, you'll often find that engineers on a project will call out a very specific wall thickness. This is because they've run detailed calculations to handle the exact pressure and structural loads required, giving them much tighter control over the pipe's performance.

Important Note: Always double-check if a project's specifications call for a standard schedule or an exact wall thickness. With pipes this big, even a tiny difference in the wall can drastically change the project's cost, total weight, and the pipe's internal flow capacity.

The demand for these massive pipes is on the rise, particularly in regions with booming infrastructure development. To give you an idea of the scale, the Middle East and Africa Pipes and Fittings Market, which includes the UAE, was valued at approximately USD 7.98 billion in 2024. This growth is fueled almost entirely by huge infrastructure projects that depend on these large diameter pipes.

Below is a quick-reference chart for common large diameter pipes. You'll see how the OD is consistent with the NPS, and we've included a standard wall thickness to show how it affects the final Inside Diameter (ID).

| NPS (inches) | OD (mm) | Wall Thickness (mm) | ID (mm) |

|---|---|---|---|

| 14" | 355.6 | 9.53 (Std) | 336.54 |

| 16" | 406.4 | 9.53 (Std) | 387.34 |

| 18" | 457.2 | 9.53 (Std) | 438.14 |

| 20" | 508.0 | 9.53 (Std) | 488.94 |

| 24" | 609.6 | 9.53 (Std) | 590.54 |

HDPE Pipe Dimensions and SDR Standards

When you start working with High-Density Polyethylene (HDPE) pipes, you'll quickly realize they play by a different set of rules. Known for their incredible flexibility and near-perfect resistance to corrosion, HDPE pipes don't use the familiar Schedule (SCH) system. Instead, their dimensions are all about the Standard Dimension Ratio (SDR).

The SDR system is a refreshingly simple way to connect a pipe's outside diameter to its wall thickness. It's a clean ratio that gives you an immediate understanding of the pipe's pressure handling capabilities.

Understanding SDR in Pipe Sizing

So, how does it work? The SDR is calculated by dividing the pipe's average outside diameter by its minimum wall thickness. This simple formula leads to a core principle you can trust every time you look at an HDPE pipe chart.

Key Takeaway: A lower SDR number means a thicker pipe wall. As a result, a pipe with a lower SDR can handle much higher pressure and is far more robust.

For example, an SDR 11 pipe has a substantially thicker wall and a higher pressure rating than an SDR 17 pipe of the same nominal size. This isn't just a minor detail—it's a critical factor when you're designing systems for high-pressure water mains or sensitive gas distribution lines.

The demand for these durable pipes is on the rise, particularly in rapidly developing areas. In 2024, the HDPE pipe market in the Middle East and Africa hit a valuation of around USD 424.91 million, with the UAE's explosive urbanization being a major driver. You can read more about the regional market growth for HDPE pipes on cognitivemarketresearch.com.

The table below breaks down some common HDPE sizes, showing how the wall thickness changes based on the SDR rating. While HDPE has its own unique system, it's worth noting that other plastics like PVC often stick with the traditional NPS and Schedule system used for steel. For more on that, you can dive into our guide on PVC pipe suppliers in Dubai.

| Nominal Size (inches) | OD (mm) | SDR Rating | Wall Thickness (mm) |

|---|---|---|---|

| 2" | 63 | SDR 11 | 5.8 |

| SDR 17 | 3.8 | ||

| 4" | 110 | SDR 11 | 10.0 |

| SDR 17 | 6.6 | ||

| 6" | 160 | SDR 11 | 14.6 |

| SDR 17 | 9.5 |

PVC and CPVC Pipe Dimensions

When you walk onto almost any job site today, you're bound to see PVC and CPVC pipes. These plastic powerhouses have become absolute mainstays in plumbing and industrial work for good reason. They’re light, they don’t corrode, and they get the job done. The key difference between them really comes down to heat. Your standard PVC is perfect for cold water lines, but once the temperature climbs, you’ll need CPVC, its chlorinated cousin, which is built to handle the hot stuff.

Here's something that makes life a lot easier for everyone from engineers to the crew on the ground: both PVC and CPVC follow the exact same Nominal Pipe Size (NPS) and Schedule (SCH) system as their steel counterparts. This is a huge deal. It means you can use the same standard charts and your measurements are consistent, no matter which material you're spec'ing for the job. It just streamlines the entire process.

PVC and CPVC Pipe Dimension Chart

To give you a practical reference, the table below lays out the dimensions for the most common PVC and CPVC sizes you'll encounter, specifically for Schedule 40 and Schedule 80. Pay close attention to the relationship between the numbers. For any given NPS, the Outside Diameter (OD) never changes. What does change is the wall thickness. As you go up from Schedule 40 to Schedule 80, the wall gets thicker, which naturally makes the Inside Diameter (ID) smaller.

| NPS (inches) | OD (mm) | Schedule | Wall Thickness (mm) | ID (mm) |

|---|---|---|---|---|

| 1/2" | 21.34 | SCH 40 | 2.77 | 15.80 |

| SCH 80 | 3.73 | 13.88 | ||

| 1" | 33.40 | SCH 40 | 3.38 | 26.64 |

| SCH 80 | 4.55 | 24.30 | ||

| 2" | 60.33 | SCH 40 | 3.91 | 52.51 |

| SCH 80 | 5.54 | 49.25 | ||

| 4" | 114.30 | SCH 40 | 6.02 | 102.26 |

| SCH 80 | 8.56 | 97.18 |

This level of standardization is what keeps a project running smoothly, ensuring every part of the system fits together as it should. Of course, the pipe is only one part of the equation. Getting the connections right is critical, which is why picking the right fittings and valves is so important. If you want to dive deeper, our guide on pipe connectors in Dubai has you covered.

Practical Application: On a typical residential project here in the UAE, you’ll most often see NPS 1/2" or 3/4" Schedule 40 PVC used for the cold water supply lines. For the hot water lines, you'd switch to the same sizes but in Schedule 80 CPVC to safely manage the higher temperatures.

It's also important to remember that not all PVC is designed for pressure. For Drain, Waste, and Vent (DWV) systems, PVC is the go-to material, but these pipes are much thinner. They're built for gravity-fed flow, not for the pressure of a supply line. Always double-check that you're using pressure-rated schedule pipes for supply and DWV-rated pipes for drainage—it's essential for meeting building codes and ensuring a safe installation.

How to Read a Pipe Size Chart Correctly

At first glance, a pipe size chart can look like a confusing wall of numbers. But once you get the hang of what each column means, it's actually a straightforward tool. Mastering these charts is essential for making sure you get the exact pipe you need, saving you from expensive mistakes and frustrating project delays.

Let's walk through a common scenario to see how it works.

Imagine you're sourcing a standard steel pipe for a commercial plumbing job. The system needs to handle moderate pressure. Your first step is to find the Nominal Pipe Size (NPS), which is just the standard name everyone in the industry uses. For this job, we need an NPS 2 pipe.

Once you’ve located the NPS 2 row on the chart, you'll slide over to the Outside Diameter (OD) column. You'll notice that for an NPS 2 pipe, the OD is always 60.3 mm, no matter how thick the pipe wall is. This consistency is key—it guarantees that any standard 2-inch fitting will be a perfect match.

Selecting the Right Schedule

Next up is choosing the right Schedule (SCH). The schedule number tells you the wall thickness, which determines the pipe's strength and how much pressure it can take. For a standard-pressure job like this one, Schedule 40 is almost always the go-to choice.

Following the NPS 2 row over to the Schedule 40 specs, you’ll find the details you need:

- Wall Thickness: The chart will list this as 3.91 mm.

- Inside Diameter (ID): This is your OD minus the wall thickness on both sides (OD - 2x Wall Thickness). For our pipe, that comes out to an ID of 52.48 mm. This is the actual opening for whatever is flowing through it.

Crucial Tip: One of the most common rookie mistakes is thinking the NPS number is the same as the outside diameter, especially for smaller pipes. It's not! Always check the OD column on the chart for the true external measurement. This single step will save you a world of headache when it comes to matching pipes with fittings and valves.

Now, what if your project had to handle higher pressures? In that case, you'd likely jump up to Schedule 80. Looking at the chart again, you'd see the wall thickness for an NPS 2, SCH 80 pipe increases to 5.54 mm. This shrinks the inside diameter down to 49.22 mm but gives the pipe a major boost in strength.

By following this simple process—start with NPS, confirm the OD, and then pick your Schedule—you can confidently read any pipe size chart and spec your materials like a pro.

Your Top Pipe Sizing Questions, Answered

Even with detailed charts in front of you, some questions always seem to come up on the job site. We get it. Here are some of the most common questions we hear from pros in the field, with straightforward answers to help you avoid confusion and keep things moving.

What's the Difference Between NPS and DN?

This is a classic source of mix-ups, especially when you're working on international projects or with European specs. It's simple, really: NPS (Nominal Pipe Size) is the North American standard, and DN (Diamètre Nominal) is the metric equivalent used pretty much everywhere else. Neither is a direct measurement; they're just reference names.

The trick is knowing the conversion. A good rule of thumb is DN = 25 x NPS (inch value).

- For instance: An NPS 2 pipe is a DN 50.

- And: An NPS 4 pipe translates to a DN 100.

Bottom line? Always, always stick to what's listed in the project's engineering documents. Mixing up NPS and DN is a surefire way to order the wrong materials, causing delays and expensive mistakes.

Does the Pipe Schedule Change the Outside Diameter?

Nope. This is probably one of the most critical things to understand about pipe sizing. For any given Nominal Pipe Size (NPS), the Outside Diameter (OD) is fixed. It never changes, no matter the schedule.

The schedule number—like SCH 40 or SCH 80—only tells you the thickness of the pipe's wall. A bigger schedule number means a thicker wall. This makes the pipe stronger and able to handle more pressure, but it also means the Inside Diameter (ID) gets smaller. This standardization is brilliant because it guarantees that a fitting for an NPS 3 pipe will work on any schedule of NPS 3 pipe, from SCH 10 to SCH 160.

How Do I Figure Out the Right Pipe Size?

Picking the right pipe size is more than just making sure it fits physically. It’s a balancing act that directly impacts how well your system works.

- Flow Rate: Start with how much fluid you need to move and how fast (e.g., gallons per minute).

- Fluid Velocity: You need to keep things moving just right. If the flow is too slow, solids can drop out and clog the line. Too fast, and you risk wearing down the pipe and losing too much pressure.

- Pressure Loss: Friction is a fact of life. Every foot of pipe and every bend causes a drop in pressure. A smaller inside diameter creates more friction and a bigger pressure drop.

- Pressure Rating: Finally, the pipe's schedule must be strong enough to contain the highest pressure your system will ever see.

Engineers use specialized calculators to juggle all these factors and pinpoint the most efficient and economical size for the job.

Can I Use Different Pipe Schedules in the Same System?

Absolutely, and it's quite common in well-designed systems. But you have to do it with intention. You might see a system start with a heavy-walled Schedule 80 pipe in a high-pressure zone, then switch to a more standard Schedule 40 pipe once the pressure drops. This is a smart way to manage costs without compromising safety.

The key is using the correct reducing fitting to handle the change in the internal diameter. The entire system must be designed so that no section is ever exposed to pressure beyond its certified rating.

For all your project needs, from high-pressure steel pipes to versatile PVC and certified fittings, Yasu Trading Co. LLC provides a complete range of building and construction materials to keep your projects moving forward. Explore our extensive inventory at https://yasutrading.com.