PPR vs PVC vs CPVC: Which Pipe Is Best for UAE Construction?

When it comes to PPR vs. PVC vs. CPVC, there’s no single "best" pipe for every job in the UAE. The right choice really hinges on the specific application.

For hot and cold water systems inside buildings, PPR is often the top contender. Its heat-fused joints create a seamless, leak-proof system that’s hard to beat. If you're looking for a budget-friendly solution for drainage or cold water mains, PVC is still the go-to standard across the industry. Meanwhile, CPVC carves out its niche in high-temperature, high-pressure scenarios where you also need excellent chemical resistance.

Understanding the Core Differences in Piping Materials

Picking the right piping material is a critical decision for any construction project in the UAE. It’s a choice that directly affects the building's long-term safety, durability, and, of course, the bottom line.

Our region's extreme climate, high-salinity water, and strict building codes mean you can't just pick one pipe and hope for the best. PPR, PVC, and CPVC each bring a unique set of strengths to the table, and knowing which one to use where is key.

For engineers and contractors, getting this right means weighing a few crucial factors:

- Temperature Tolerance: How well does the pipe handle the UAE's ambient heat, not to mention the temperature of the water or fluid it's carrying?

- Installation Method: What kind of tools, skills, and time are needed? This has a major impact on labour costs.

- Chemical Resistance: Can the pipe stand up to corrosion from chemicals, saline soil, and treated water?

- Overall Cost: It’s not just the price per metre. You have to consider installation expenses and long-term maintenance.

Many professionals looking for a deeper dive into polypropylene random copolymer start by understanding the specific benefits of PPR pipes in the UAE, especially valued for their longevity in potable water systems.

To help simplify that initial decision, the table below gives a quick overview of where each pipe type shines in common UAE construction projects.

Quick Guide to Pipe Selection in the UAE

| Pipe Material | Primary Use Case in UAE | Key Advantage |

|---|---|---|

| PPR | Hot & Cold Potable Water (Villas, Towers) | Leak-proof heat-fused joints & non-toxic nature |

| PVC | Drainage, Wastewater & Cold Water Mains | Low cost & widespread availability |

| CPVC | High-Temp Industrial Lines & Hot Water Distribution | Superior heat/pressure resistance & chemical inertness |

This table serves as a starting point. Your final choice will always depend on the detailed engineering requirements and project specifications.

Comparing Performance in the UAE Climate

Choosing the right pipe for a project in the UAE isn’t just about picking a material off a spec sheet. It’s a serious decision that hinges on how that material will stand up to the region's relentless environment. We're talking about intense summer heat, high ambient temperatures year-round, and the unique chemical makeup of desalinated water. All of these factors play a huge role in whether a piping system will last five years or fifty.

Let's break down how PPR, PVC, and CPVC really perform when faced with these climate-specific challenges.

Temperature and Pressure Tolerance

The UAE climate puts enormous strain on piping, making temperature tolerance the first thing we need to look at. Standard PVC has a temperature limit of 60°C, which is perfectly fine for cold water supply, drainage, and waste systems where things stay cool. But it's a non-starter for hot water. High temperatures will cause it to soften and lose its shape.

This is exactly where CPVC and PPR come into their own. CPVC (Chlorinated Polyvinyl Chloride) was engineered specifically for heat, handling temperatures up to a very impressive 93°C. This makes it a go-to choice for both hot and cold water lines in everything from residential towers to commercial complexes.

PPR (Polypropylene Random Copolymer) is also a strong performer in the heat. It's rated for continuous use at 70°C and can handle short bursts up to 95°C. A key advantage of PPR is its low thermal conductivity—it's a natural insulator. This means it keeps hot water hotter for longer, which can lead to real energy savings down the line.

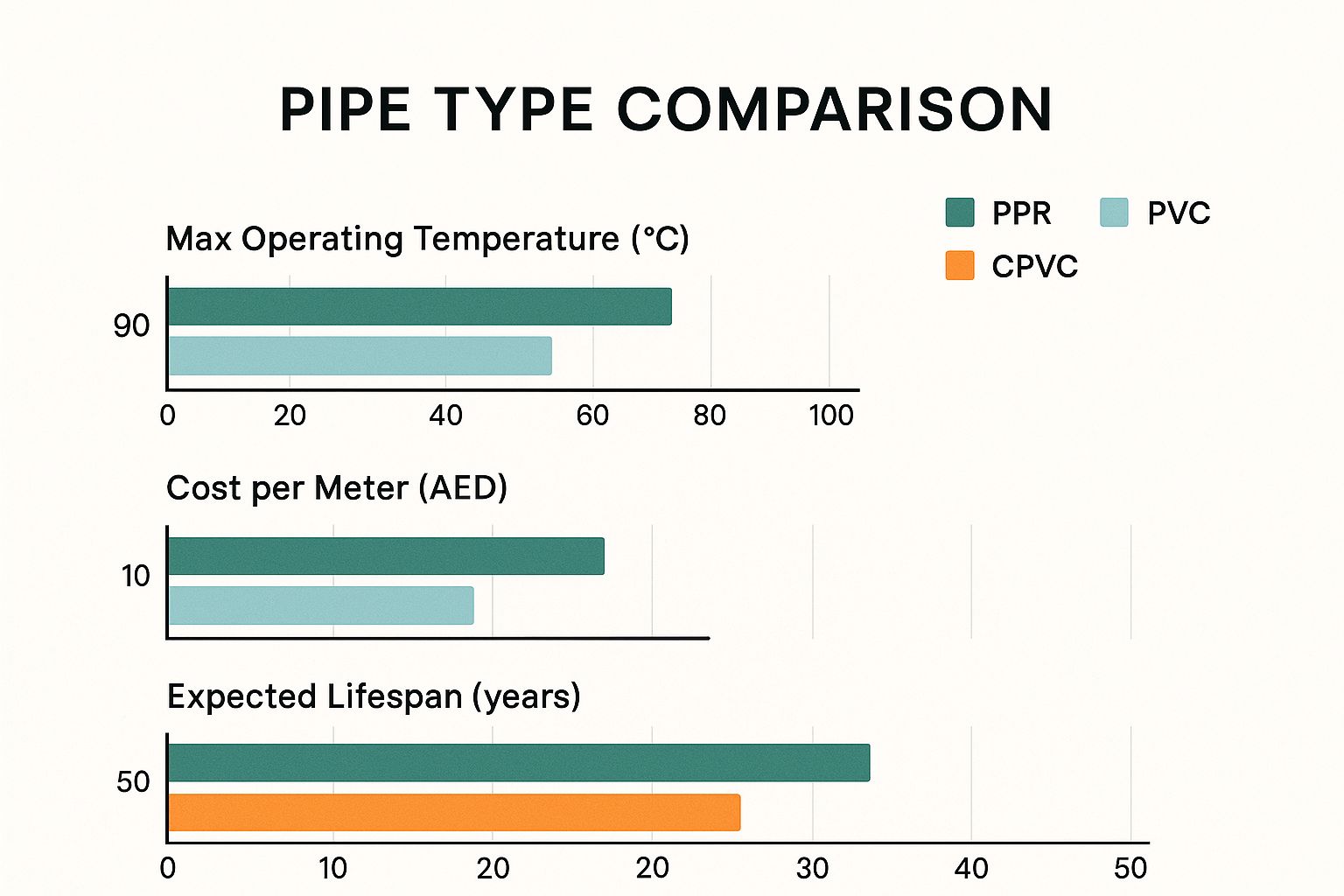

This infographic gives you a quick visual summary of how these materials stack up on performance and cost.

As you can see, CPVC leads on pure temperature rating, but PPR offers a fantastic blend of heat resistance and an exceptionally long lifespan. Both are clearly superior to standard PVC for any pressurised hot water system.

To provide a more granular look, here’s a table outlining the key technical specifications that are critical for performance in the UAE's demanding environment.

PPR vs. PVC vs. CPVC Technical Specifications

| Attribute | PVC (Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) | PPR (Polypropylene Random Copolymer) |

|---|---|---|---|

| Max Service Temperature | 60°C (140°F) | 93°C (200°F) | 70°C (158°F) continuous; 95°C (203°F) short-term |

| Primary Use Cases | Cold water, drainage, sewage, irrigation | Hot & cold potable water, industrial liquids | Hot & cold potable water, HVAC systems |

| Chemical Resistance | Good resistance to acids, alkalis, salts | Excellent resistance to a broader range of chemicals, even at high temperatures | Exceptional resistance to chemicals found in potable water; very inert |

| UV Resistance | Poor; requires protection (e.g., painting) | Moderate; better than PVC but can still degrade without stabilisers | Good; often manufactured with UV stabilisers for outdoor use |

| Installation Method | Solvent cement (cold welding) | Solvent cement (specific to CPVC) | Heat fusion (hot welding) |

| Flexibility/Impact | Rigid, can become brittle with UV exposure | More rigid than PVC but also more brittle | Flexible and highly impact-resistant, even at low temperatures |

This data clearly illustrates the trade-offs. While PVC is a solid choice for non-pressurised, cold-water applications, the technical strengths of CPVC and PPR make them far more suitable for the complex plumbing needs of modern buildings in the region.

Chemical and Corrosion Resistance

The water in the UAE, often coming from desalination plants, can have higher levels of salinity and chlorine. While this is a death sentence for many metal pipes, it also puts plastics to the test. The good news is that PPR, PVC, and CPVC are all inherently resistant to rust and corrosion.

Still, their chemical resistance isn't identical. PVC holds up well against a wide array of acids and alkalis, which is one reason it's so dominant in wastewater and drainage applications.

CPVC’s extra chlorine atom gives it an edge, providing superior resistance to an even broader spectrum of chemicals, especially at high temperatures. This makes it a workhorse in industrial settings where corrosive liquids are common. In fact, the GCC CPVC pipes market was valued at USD 542 million in 2024 and is expected to hit USD 773 million by 2033, a testament to its suitability here. If you want to dive deeper, you can explore more about the differences between uPVC and CPVC pipes in our detailed guide.

PPR’s main advantage here is its exceptional purity. It is incredibly inert and won’t leach any substances into the water, ensuring quality and safety. This is precisely why it’s so often specified for drinking water lines in high-end villas, hotels, and hospitals.

Durability and Lifespan in the Sun

When we talk about durability, we can't just think about what's happening inside the pipe. The external environment, especially the punishing UAE sun, is a major factor. UV radiation will break down plastics over time, and this is a critical point of failure for any exposed pipework.

Of the three, standard PVC is the most vulnerable. Prolonged, direct sunlight will make it brittle, which eventually leads to cracks and fractures. If you absolutely have to use PVC outdoors, it must be protected, either with a coat of light-coloured, water-based paint or some form of physical shielding.

Both PPR and CPVC are formulated with better UV resistance, though neither is completely immune. Manufacturers often add UV stabilising agents to these materials to boost their longevity for outdoor use. PPR, especially in darker colours, generally holds up better against UV degradation, which helps it achieve its impressive 50+ year design lifespan, even in a climate like ours.

Analysing the True Cost of Installation

When you're pricing out a piping system for any project in the UAE, looking at the per-metre cost is only scratching the surface. The real picture emerges when you factor in fittings, any specialised tools needed, labour hours, and the potential for future maintenance. This total cost of ownership is where the financial distinctions between PPR, PVC, and CPVC really come into focus.

At first glance, PVC often wins on upfront material costs. This makes it a go-to choice for large-scale projects where the initial budget is tight. The installation method—using solvent cement—is quick, straightforward, and something most plumbers have been doing for years, which helps keep labour costs down and project timelines short.

The Financial Impact of Installation Methods

How you join the pipes together has a direct knock-on effect on your project's bottom line. PPR, for instance, uses a heat fusion process. This requires a special welding machine to melt the pipe and fitting together, creating a seamless, permanent joint. While you might have to invest in the equipment upfront, the result is an incredibly reliable, leak-proof bond.

This installation method virtually eliminates the risk of leaks over the system's lifespan. For high-rise towers or luxury villas, that translates into massive long-term savings by dodging expensive water damage repairs and maintenance call-outs.

On the other hand, both PVC and CPVC rely on a solvent-welding process. It’s a faster technique that only requires basic, inexpensive hand tools. For projects where speed and upfront cost are the main concerns, this is a huge advantage. Think about laying extensive drainage or cold water networks—the sheer speed of PVC installation can give you a significant financial edge.

Labour, Fittings, and Long-Term Value

The pipe you choose also influences costs in other ways. PPR's heat fusion is a skilled job, so it might demand more training or a more experienced plumber. The trade-off? That rock-solid reliability often means fewer headaches with callbacks and repairs down the line.

PVC is everywhere in the UAE, which makes it a commodity. You’ll find competitive pricing on both the pipes and the huge variety of fittings available. The PVC pipe market in the region is booming for a reason—it was valued at around USD 280 million in 2024 and is expected to hit USD 384 million by 2033. This growth is fuelled by its cost-effectiveness in major construction and water management projects.

Ultimately, PVC makes a strong financial case for projects focused on controlling the initial budget, especially for non-pressurised systems like drainage. Finding that sweet spot between quality and cost is crucial, which is why partnering with experienced PVC pipe suppliers in Dubai who can advise on material selection is always a smart move. In contrast, for pressurised hot and cold water systems, PPR and CPVC often deliver better long-term value, where a higher initial spend is easily justified by superior performance and far fewer maintenance demands.

Matching Pipe Materials to Real-World UAE Projects

Knowing the specs on paper is one thing, but how a pipe performs on a real UAE construction site is what truly matters. Choosing between PPR, PVC, and CPVC isn’t about crowning a single winner; it’s about picking the right tool for the job at hand. The demands of a skyscraper are worlds apart from those of a luxury villa, and the material choices should reflect that.

A common pitfall is taking a one-size-fits-all approach. Specifying a single pipe type for an entire high-rise, for example, is a recipe for either overspending on materials or facing premature system failures. The smartest solutions often involve a hybrid system, playing to the strengths of each material where it counts the most.

This kind of practical decision-making is essential for balancing performance, budget, and compliance with local building codes. Let’s look at how these materials are best used in three common UAE construction scenarios.

The Hybrid Approach for High-Rise Towers

In the vertical cities of Dubai and Abu Dhabi, a hybrid piping system is almost always the most intelligent and economical strategy. The plumbing network in a skyscraper faces a huge range of demands, from the high-pressure pumps in the basement to the fixtures in a penthouse suite.

A best-practice specification often looks something like this:

- Hot & Cold Water Risers: For the main vertical lines pumping water up dozens of floors, CPVC is the go-to choice. Its high-pressure ratings and excellent temperature resistance are perfectly suited to handle the immense stress of these core supply lines.

- In-Apartment Distribution: Once the water enters an individual apartment, PPR takes over. Its heat-fused joints create a seamless, leak-proof network, which is an invaluable feature when you want to prevent water damage in finished residential spaces. It’s all about peace of mind.

- Wastewater & Drainage Stacks: When it comes to non-pressurised vertical drainage, PVC is the undisputed king. It’s affordable, readily available, and more than durable enough for waste lines, making it the most sensible and cost-effective pick.

This blended approach gives you the best of all worlds—performance where you need it and savings where you don’t.

Complete Systems for Luxury Villas and Residential Compounds

In the high-end residential market, the focus shifts to long-term reliability and pristine water quality. For luxury villas and exclusive compounds, specifying a complete PPR system for all potable water, both hot and cold, is becoming the standard.

The reasoning here is straightforward. The upfront investment in a fully heat-fused PPR system buys you an incredibly low risk of future leaks—a huge selling point for any premium property. Plus, its inert, non-toxic composition ensures water quality is never compromised, a top priority for homeowners.

While the initial cost for an all-PPR system is higher than alternatives, discerning developers and buyers view it as a long-term investment in quality and durability.

Industrial and Large-Scale Infrastructure Projects

For sprawling industrial projects, municipal water mains, or massive drainage networks, PVC is still the dominant force. It has a decades-long track record of reliability, stands up well to soil pressure when buried, and offers major economic advantages at scale. In the PPR vs. PVC vs. CPVC debate for these applications, PVC’s cost-efficiency and fast installation make it the clear winner for projects that cover huge areas.

Meeting Sustainability and Regulatory Standards

In the UAE, sustainability isn't just a buzzword; it's a fundamental part of the construction industry's DNA. With green building certifications like Estidama and LEED becoming standard, the environmental impact of every component is under the microscope. This makes the material choice in the PPR vs. PVC vs. CPVC debate more critical than ever.

Environmental Impact and Recyclability

When it comes to green credentials, PPR pipes often steal the spotlight. There’s a good reason why Polypropylene Random Copolymer has seen such a significant uptake across the UAE—it's remarkably eco-friendly.

PPR pipes are 100% recyclable, completely non-toxic, and built to last for 50 years or more. This long service life alone makes a huge contribution to sustainable building practices. For any project where sterile materials are a must, particularly under strict GCC health regulations, PPR is the go-to. If you want to dig deeper into its market adoption, this report on the UAE PVC and PPR pipes market offers some great insights.

Now, that's not to say PVC and CPVC are out of the race. While traditional PVC manufacturing raised some environmental red flags, modern production methods have come a long way in reducing its footprint. CPVC manufacturers are also pushing for better sustainability. Still, the inherent, clean recyclability and inert nature of PPR give it a clear edge.

For projects where water purity and green certifications are paramount, PPR’s non-toxic and fully recyclable properties make it the superior choice, aligning perfectly with the UAE’s sustainability vision.

Adherence to Local UAE Regulations

Navigating local building codes is a non-negotiable part of any project in the UAE. Authorities like Dubai Municipality (DM) and the Abu Dhabi Quality and Conformity Council (ADQCC) have exacting standards for water quality and safety.

The good news is that all three materials—PPR, PVC, and CPVC—can meet these standards, provided they come from a reputable supplier. The crucial step for any contractor is to verify that their chosen pipes have the necessary certifications. This isn't just about passing the initial inspection; it's about guaranteeing the long-term health and safety of the building’s occupants.

Got Questions About Pipes in the UAE? We’ve Got Answers.

When you're in the thick of a project, the whole PPR vs. PVC vs. CPVC debate boils down to a few practical questions. Engineers and project managers across the UAE are constantly asking which material truly fits the bill for their specific needs, especially given our unique climate and building codes.

Let's cut through the technical jargon and get straight to the answers you need for the job site.

Which Pipe Is Best For Hot Water Lines In a UAE Villa?

For hot water in a UAE villa, your best bets are either CPVC or PPR. Standard PVC just can't handle the heat, so it's not even in the running. CPVC has been a reliable go-to for years, known for its solid performance under high temperatures and pressure.

That said, PPR is often seen as the premium choice, and for good reason. Its joints are heat-fused, not glued. This process essentially melts the pipe and fitting into a single, seamless piece, creating a system that’s virtually leak-proof. In a luxury villa where water damage is a major concern, that’s a huge plus. The final decision often rests on the contractor’s familiarity with the installation—some prefer the traditional solvent-welding of CPVC, while others are all-in on the superior joint strength of PPR.

Can I Use PVC Pipes Outdoors in the UAE Sun?

Plain and simple, standard PVC isn’t built for direct, relentless exposure to the UAE sun. The intense UV radiation will eventually break down the material, leaving it brittle and susceptible to cracks.

If you absolutely must use PVC outdoors, you have a couple of options. You could source specialised UV-resistant PVC pipes, or you’ll need to protect standard PVC. This means either painting it with a light-coloured, water-based latex paint (dark colours absorb too much heat) or covering it with a proper, UV-rated shield. Honestly, for most applications that will be sitting in the sun, you’re better off choosing PPR or a UV-stabilised grade of CPVC for long-term peace of mind.

When it comes to drinking water, safety is non-negotiable. All three materials—PPR, PVC, and CPVC—are safe for potable water, provided they are certified by an organisation like NSF International. However, PPR often gets the nod for its inert nature. It doesn't leach chemicals, and its incredibly smooth interior surface resists the build-up of bacteria, ensuring water quality stays pure and meets the strict standards set by UAE municipalities.

For all your project needs, from high-performance piping to essential safety equipment, trust Yasu Trading Co. LLC to supply certified, high-quality materials. Request a quote today to ensure your project is built to last.