Predictive Maintenance for MEP: How IoT Sensors Reduce Downtime & Costs

Predictive maintenance in MEP isn't just a new buzzword; it's a fundamental shift in how we manage the lifelines of our buildings. By using IoT sensors to keep a constant watch on equipment health, we can finally get ahead of problems. This approach lets you see failures coming long before they cause a shutdown, moving you from costly, last-minute repairs to smart, data-informed decisions.

The True Cost of MEP Failures and the Predictive Fix

When an MEP system goes down, the repair bill is just the tip of the iceberg. It’s like hearing a faint rattle in your car's engine. If you ignore it, you’re not saving money; you're just setting yourself up for a catastrophic breakdown on the highway at the worst possible time.

The old way of doing things—waiting for something to break—is a high-stakes gamble. This reactive "firefighting" mode creates a domino effect of hidden costs that can quickly spiral out of control.

The Ripple Effect of Reactive Maintenance

Think about what happens when a critical HVAC unit quits in the middle of a summer heatwave or a major plumbing leak shuts down a hotel. The real pain isn't just in the parts and labor. The indirect costs are often far more damaging:

- Lost Productivity and Revenue: Operations grind to a halt, tenants are sent home, and business stops, leading to immediate financial losses.

- Tenant Dissatisfaction: Nobody wants to work in a sweltering office or stay in a hotel with no water. Unhappy tenants lead to complaints, broken leases, and long-term vacancies.

- Reputational Damage: Word gets around. A building known for frequent MEP issues is seen as unreliable, making it incredibly difficult to attract or keep high-value tenants.

- Overtime and Emergency Labour Costs: Calling in a technician at 2 a.m. on a holiday is always going to cost a premium, not to mention the rush charges for emergency parts.

To better understand these differences, let's compare the old way with the new.

Comparing Maintenance Strategies for MEP Systems

This table breaks down how traditional maintenance stacks up against the modern predictive model, highlighting the clear advantages in cost, efficiency, and reliability.

| Maintenance Strategy | Approach | Cost Impact | Downtime Risk |

|---|---|---|---|

| Reactive Maintenance | "If it ain't broke, don't fix it." | High emergency repair costs, overtime labor. | High, with unplanned, catastrophic failures. |

| Preventive Maintenance | Scheduled, time-based check-ups. | Moderate, but can include unnecessary work. | Lower, but misses issues between schedules. |

| Predictive Maintenance | Real-time, condition-based monitoring. | Lowest, with targeted, proactive repairs. | Minimal, as issues are caught early. |

The table makes it clear: moving from a reactive or even a scheduled approach to a truly predictive one is where the real value lies.

The core issue with traditional maintenance isn't a lack of effort; it's a lack of foresight. It forces skilled teams to react to emergencies rather than strategically preventing them.

Shifting From Firefighting to Future-Proofing

This is exactly where predictive maintenance changes the entire equation. By installing IoT sensors, you’re essentially giving your equipment a voice. These sensors are constantly listening for the earliest warning signs of trouble—a tiny increase in a motor's vibration, a slight temperature spike in an electrical panel, or a subtle change in water pressure.

This stream of data lets you hear that faint engine rattle long before it becomes a full-blown failure. Instead of a panicked, middle-of-the-night call, your team gets an automated alert to schedule a quick, low-cost fix during planned downtime. Your maintenance crew transforms from emergency responders into strategic asset managers. Our deeper look into preventive maintenance strategies offers more background on how to make this crucial operational leap.

This smarter approach is catching on fast. In the broader Middle East, the market for structural health monitoring—a field closely related to predictive maintenance—is expected to grow at a CAGR of 17.3% between 2025 and 2030. This boom is driven by mega-projects where MEP reliability is non-negotiable. Industry experts have found that a predictive model can slash equipment failures by 70–75% and cut overall maintenance spending by 25–30%. You can discover more insights about these market growth trends on encardio.com.

How IoT Sensors Become the Senses of Your Building

If you think of your building's MEP systems as its lifelines, then Internet of Things (IoT) sensors are its nervous system. They give your facility the ability to feel, see, and hear what's really going on inside its most critical equipment. This constant flow of information is the bedrock of predictive maintenance. It turns your building from a static structure into a responsive asset that can tell you something is wrong long before it becomes a crisis.

It’s a bit like a doctor monitoring a patient's vitals. They don't wait for the patient to clutch their chest in pain; they watch the EKG for subtle shifts that point to a future problem. IoT sensors do the same for your MEP systems, keeping a 24/7 watch on their operational "vital signs" and catching the first whispers of trouble.

Giving Your Equipment a Voice

These sensors aren't just spitting out random numbers. They're translating real-world physical conditions into data you can actually use. Each type of sensor acts like a specialized sense, honed in on a specific aspect of equipment health.

Let's break down the key players in this sensory network.

Vibration Sensors (The Sense of Touch): We attach these directly to rotating equipment—think motors, pumps, and fans. They constantly 'feel' for tiny changes in vibration. A healthy motor has a predictable, smooth hum. But as soon as a bearing starts to wear or a shaft gets misaligned, that vibration signature changes. A sensor can pick up on a minuscule tremor weeks or even months before the component fails, giving you more than enough time to schedule a simple fix.

Thermal Sensors (The Sense of Sight): Using infrared technology, these sensors essentially 'see' heat. They are a game-changer for electrical systems, where overheating is the classic red flag for a looming failure. A thermal sensor can spot a hotspot in an electrical panel—maybe from a loose wire or an overloaded circuit—long before it can spark a fire. This isn't just about saving equipment; it's a massive safety advantage.

Pressure Sensors (The Sense of Hearing): In your plumbing and HVAC systems, pressure is everything. These sensors 'listen' for anything out of the ordinary in water or refrigerant lines. A slow drop in pressure could signal a hidden leak you'd never find until it caused major water damage. On the flip side, a sudden pressure spike could mean a blockage is putting the whole system under dangerous strain.

And that's just scratching the surface. Other sensors track humidity, air quality, fluid flow, and even acoustic signatures, with each one adding another layer of awareness. To see how these smart devices fit into the bigger picture, check out this guide to IoT in property management.

Translating Data into Actionable Warnings

The real magic happens when this sensory network turns raw data into clear, early warnings. A single data point—say, a temperature reading of 45°C—doesn't mean much by itself. But when an AI-powered analytics platform sees that reading is 15% higher than the normal operating temperature for that specific asset at this specific time of day, it instantly flags it as an anomaly.

An IoT sensor network doesn't just provide data; it provides context. It learns what "normal" looks like for each piece of equipment and flags any deviation, effectively predicting failure by identifying the symptoms before the disease takes hold.

This intelligent analysis turns abstract numbers into concrete alerts. Your team no longer discovers a failed pump standing in a flooded basement. Instead, they get a notification on their dashboard: "Pump B-7 shows elevated vibration consistent with early-stage bearing wear. Recommend inspection within 7 days." This completely changes the dynamic. Maintenance stops being a chaotic reaction and becomes a calm, scheduled, and far more cost-effective action based on precise intelligence.

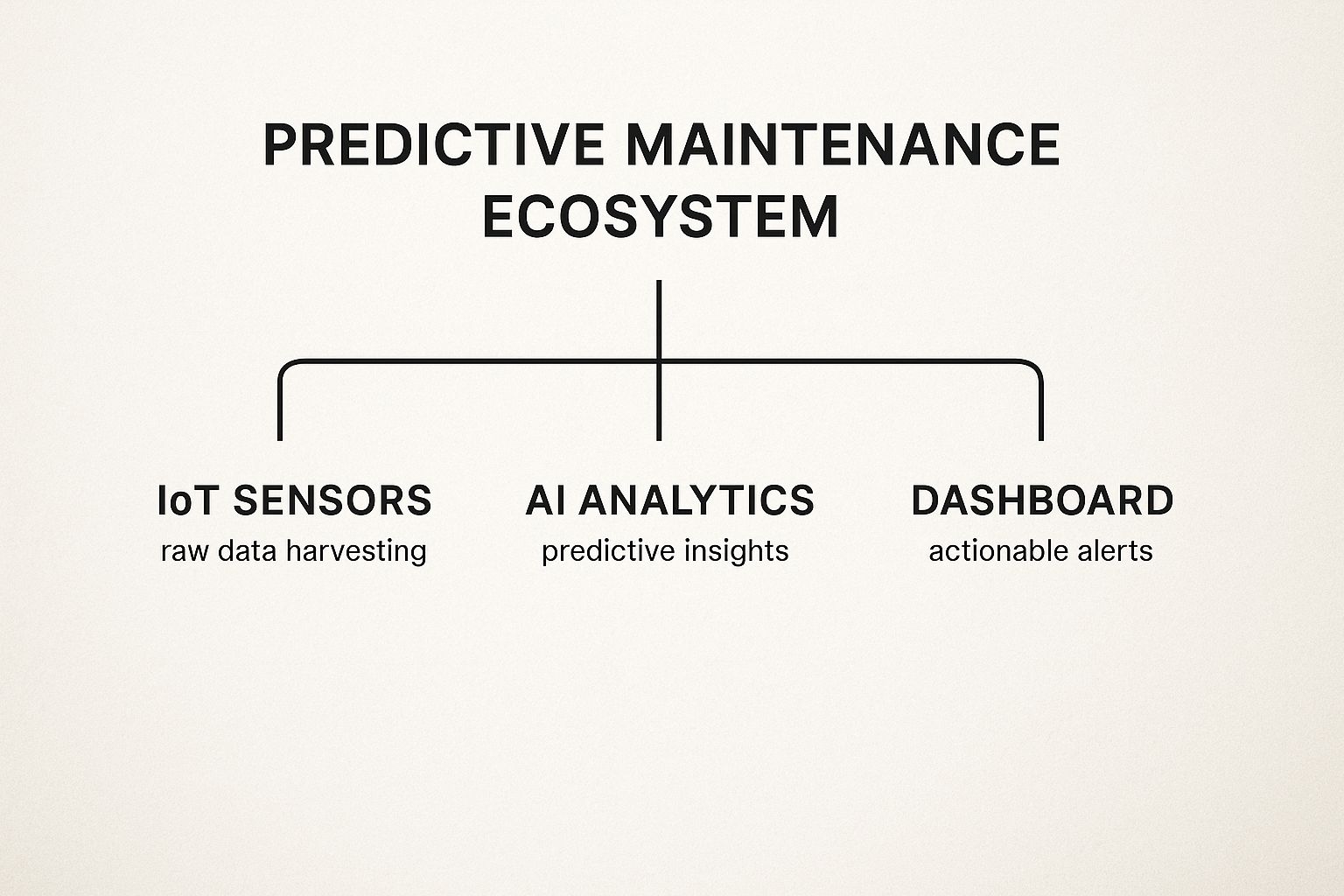

Understanding Your Predictive Maintenance Ecosystem

Getting predictive maintenance right for your MEP systems isn’t about just plugging in a few sensors and hoping for the best. It’s about building a connected ecosystem where every part works together seamlessly. The whole tech stack might seem complicated at first, but it helps to think of it like a sophisticated ‘farm-to-table’ operation, but for data.

Each component has a specific job, taking raw information harvested from your equipment and turning it into a final, actionable insight that lands right in front of your maintenance team. This process makes sure nothing gets lost in translation and every alert actually means something.

The infographic below lays out this ecosystem, breaking it down into its core layers—from gathering the raw data all the way to delivering those critical alerts.

You can see a clear flow here: IoT sensors provide the raw input, AI analytics cook up predictive insights, and the dashboard serves the final, ready-to-use intelligence.

The Farmers: IoT Sensors

At the very foundation of this entire setup are the IoT sensors. Picture them as diligent farmers out in the field, tirelessly collecting raw data straight from your MEP equipment. Whether it's a sensor measuring vibration, temperature, pressure, or electrical current, each one is gathering the essential ingredients needed for the analysis to come.

These little devices are your eyes and ears on the ground floor, picking up on tiny shifts in equipment behavior that are completely invisible to a human technician. Without this constant and reliable stream of high-quality data, the rest of the system would have nothing to work with. They are, without a doubt, the most critical first link in the chain.

The Transport Network: Cloud Platforms

Once the sensors have all that data, it needs to get where it's going safely and quickly. This is where the cloud platform steps in. Think of it as a highly efficient logistics network, moving huge amounts of information from the sensors (the 'farm') to a central processing hub.

But it’s doing more than just moving data from point A to point B. The cloud provides a secure, scalable, and accessible place to store and organize all the incoming data streams. It makes sure that the information pouring in from hundreds—or even thousands—of sensors across your facility is corralled safely, ready for the next step.

The real magic of predictive maintenance isn’t just in collecting data—it’s about turning that data into intelligence. The journey from a sensor reading to a real-world insight is what turns a simple number into a massive cost-saving action.

The Master Chef: AI Analytics

Here's where the raw ingredients get turned into something special. The AI and machine learning analytics engine is the master chef in this kitchen. It takes the flood of raw data delivered by the cloud and starts the complex work of cleaning it up, sorting it, and finding the hidden patterns.

The heart of predictive maintenance is all about mastering real-time data analytics, which is what transforms raw sensor readings into immediate, useful insights for your MEP systems. The AI uses sophisticated algorithms to spot anomalies and compare how a machine is running today against its entire performance history.

It actually learns what "normal" looks like for each individual asset, which is how it can flag the slightest deviation that points to a potential failure down the road. The 'chef' doesn't just hand you data; it interprets it, forecasting when a part might fail and why.

The Menu: Your Dashboard and Alerts

Finally, all these brilliant insights need to be served to the people who can actually do something with them—your maintenance team. The user dashboard is the final 'menu', presenting complex findings as simple, clear, and actionable alerts.

So, instead of a spreadsheet filled with vibration readings, your team gets a notification that says: "Alert: HVAC Unit 3 shows a 15% increase in motor vibration. Bearing failure predicted within 30 days." The farm-to-table journey is complete.

This kind of proactive approach is really taking hold across the region. The Middle East and Africa (MEA) are quickly adopting predictive maintenance, pushed forward by digital transformation goals like Saudi Arabia’s Vision 2030. The predictive maintenance market in the rest of the Middle East is expected to grow at a CAGR of 34.1%, hitting USD 103.23 million by 2025. The total MEA market is projected to blow past USD 4.5 billion by 2030.

This complete ecosystem is what shifts maintenance teams from being reactive firefighters to proactive strategists—a central idea in modern facility management in Dubai. Once you understand how these pieces fit together, you can really see how predictive maintenance turns simple data points into your best tool for slashing downtime and costs.

Your Step-by-Step Implementation Roadmap

Moving to a predictive maintenance model isn't about ripping out everything and starting over. Think of it as a smart, strategic upgrade. By taking it one step at a time, you can prove the value, build momentum, and bring your team along for the ride without causing a massive disruption to your budget or operations.

This roadmap breaks the journey down into four manageable phases. The whole idea is to start small, score an early win, and then scale up intelligently. It’s the best way to minimize risk and get everyone from the technicians to the C-suite on board.

Phase 1: Identify Critical Assets

Before you even think about buying a sensor, you need to figure out where to start. The key is identifying where you'll get the biggest and fastest payoff. After all, not every piece of MEP equipment carries the same weight.

Start by mapping out your facility’s most essential systems. Ask yourself: which failures would cause the most pain, either operationally or financially?

- High-Impact Equipment: Zero in on the big-ticket items. Think central chillers, primary electrical switchgear, or the main water pumps. If these go down, everything stops.

- Chronic Problem Areas: You know the ones. That one air handler that's always on the fritz or the pump that needs constant attention. These are perfect candidates to show a quick improvement.

- Safety-Critical Systems: Don't forget the systems that protect people. Fire suppression pumps, emergency generators, and critical ventilation systems should be high on your list.

This simple audit gives you a clear, prioritized list. It ensures your first step into predictive maintenance delivers results you can actually see and measure.

Phase 2: Launch a Pilot Project

With your hit list of critical assets ready, it's tempting to go all-in. Resist that urge. Instead, kick things off with a small, focused pilot project. This is your proof of concept—a low-risk, high-reward test run.

Pick one or two pieces of equipment from your priority list. Maybe it's that troublesome HVAC unit or a critical pump. The goal here is simple: prove that this technology works in your building and delivers real benefits. A successful pilot gives you the hard data and the success story you need to justify a bigger investment.

A well-executed pilot project is your best sales tool for getting internal buy-in. It shifts the conversation from "what if" to "look what we did," making it a whole lot easier to get the budget and support for a full rollout.

This is also the stage where you'll pick a technology partner. You want someone who really understands MEP systems, not just software. Look for a provider who can guide you through the whole pilot, from choosing the right sensors to helping you make sense of the data.

Phase 3: Integrate and Train Your Team

Once your pilot has proven its value, it's time to weave the system into your team's daily routine. The last thing you want is another complicated tool they have to manage. This technology should make their jobs easier, not harder.

The key is connecting the new alert system to your existing Computerized Maintenance Management System (CMMS). When a sensor detects a problem, it should automatically create a work order in the system your team already uses. This simple step makes sure nothing falls through the cracks.

Training is just as crucial. Your maintenance crew needs to understand a few things:

- How to Interpret Alerts: They need to know what a vibration spike on a motor actually means.

- How to Respond Proactively: The goal is to shift their focus from putting out fires to preventing them in the first place.

- The 'Why' Behind the Tech: When your team sees how this helps them avoid catastrophic failures and weekend call-outs, they’ll become its biggest champions.

For example, when an alert comes in for an HVAC unit, pairing it with a clear action plan is a game-changer. Our detailed HVAC maintenance checklist is a great starting point for building these new, data-driven work orders.

Phase 4: Scale and Optimize

With a successful pilot under your belt and a trained team ready to go, you can confidently start scaling the solution. Using what you learned from the pilot, you can begin deploying sensors on the other critical assets you identified back in phase one.

But scaling isn't just about adding more hardware. It's about getting smarter. The more data your system collects, the better the AI algorithms get at predicting failures. You should constantly be reviewing performance, tweaking alert thresholds, and looking for new ways to boost efficiency. This is the phase where predictive maintenance stops being a "project" and becomes a core part of how you operate.

Calculating the Real-World ROI of Smarter Maintenance

Putting money into a predictive maintenance program for your MEP systems isn't just about getting new tech; it's a serious financial move. To build a solid business case, you have to look past the technical bells and whistles and get straight to the return on investment (ROI). A real ROI calculation means adding up both the easy-to-see cost cuts and the less obvious, but often more valuable, hidden gains.

Thinking about ROI as simply the cost of a sensor versus the cost of one avoided repair is selling the concept way short. It's really about a chain reaction of financial benefits that touches everything from your maintenance budget to your building's overall value.

Quantifying the Hard Savings

Let's start with the easy part: the "hard savings." These are the tangible cost reductions you can see directly on your balance sheet. They’re the numbers that make the initial investment make immediate sense.

You can find these savings in a few key places:

- Fewer Emergency Call-Outs: When an HVAC unit dies on a Friday night, you’re paying a premium for emergency labor—think overtime and weekend rates. Predictive maintenance turns these expensive surprises into planned repairs done during normal business hours, slashing labor costs.

- Smarter Spare Parts Inventory: Forget tying up capital in a storeroom packed with "just-in-case" parts. When you know a specific pump bearing has a high probability of failing in the next two months, you order just that part, right when you need it.

- Lower Energy Bills: Equipment that's struggling is an energy glutton. A motor fighting a failing component or a pump working against a clog burns more electricity to get the job done. Fixing these hidden inefficiencies can cut your utility bills, often by as much as 18%.

This forward-thinking approach is catching on fast. In Egypt, for example, the predictive maintenance market is expected to balloon at a 34.7% CAGR, hitting USD 27.90 million by 2025 as the country looks for smarter ways to manage its growing infrastructure. On a global scale, predictive maintenance is already proven to cut overall maintenance costs by 25–30%. You can dig deeper into these market trends and findings to see the bigger picture.

Uncovering the Hidden Value

While hard savings get the initial nod of approval, the "soft" benefits are where the real, long-term financial wins are found. This is about protecting revenue, boosting your property's value, and safeguarding your reputation.

The most profound financial wins from predictive maintenance don't always appear on a maintenance invoice. They show up in lease renewals, higher occupancy rates, and the extended lifespan of your most expensive MEP assets.

Think about these critical value drivers:

- Longer Equipment Life: Taking care of small problems before they escalate prevents the catastrophic failures that can send a six-figure chiller to the scrapyard. By reducing daily wear and tear, you can extend the life of your critical MEP assets by up to 30%, pushing massive replacement costs years down the road.

- Slashing Unplanned Downtime: In a commercial building, downtime isn't just an annoyance—it's lost cash. A retail store with no AC or an office building without power can't operate. Keeping these systems running protects your tenants' businesses and, by extension, your rental income.

- Better Tenant Retention: No one likes surprises, especially tenants. A building that just works—with consistent comfort and few disruptions—is one people want to stay in. Happy tenants renew leases, which saves you the hefty costs of marketing, vacancy periods, and tenant fit-outs.

When you add up both the hard savings and the hidden value, the argument for predictive maintenance becomes clear. It stops being a line item on the expense sheet and turns into a profit driver, transforming your MEP systems from a potential headache into a reliable, high-performing asset.

The Future of Self-Aware Buildings

Predictive maintenance for MEP systems is a huge leap forward, but it's really just the first step. The real-time alerts and early warnings we're seeing today are only scratching the surface. The next phase isn't just about predicting a problem—it's about the system prescribing and even automating the solution.

This is the shift from a merely connected building to a truly cognitive one. We're talking about structures that can diagnose issues, "heal" themselves, and optimize their own performance with little to no human input. When you adopt IoT sensors now, you're not just fixing today's maintenance headaches. You're getting your assets ready for the next wave of autonomous facility management.

From Prediction to Prescription

The goal is a closed-loop system where a building doesn't just flag an issue; it tells you exactly how to fix it. This is where the data foundation we're building with IoT will support even more advanced technologies.

These trends aren't science fiction—they're already starting to emerge:

- Digital Twins: Think about having a perfect virtual replica of your entire MEP system. Before a technician ever lays a hand on the physical equipment, they can run through a repair on the digital twin. This lets them test the fix, get it right the first time, and dramatically reduce risk.

- Generative AI: Let's say the system predicts a complex failure. Generative AI could instantly create detailed, step-by-step repair guides, complete with diagrams and a specific parts list. It gives your on-site team expert-level guidance for even the most unusual problems.

- Prescriptive Maintenance: This is the holy grail. The system doesn't just predict a fan motor in an HVAC unit is about to fail. It also automatically checks inventory, orders the correct replacement part, and schedules the work order in the CMMS.

The vision is clear: a future where buildings shift from needing constant human oversight to operating as self-sustaining ecosystems. This frees up facility managers to stop fighting fires and start focusing on high-level strategic planning and asset optimization.

Future-Proofing Your Assets Today

Putting a predictive maintenance for MEP strategy in place now using IoT sensors to reduce downtime and costs is more than an upgrade—it's how you future-proof your building. Every single data point you collect today is training the AI models that will run the autonomous systems of tomorrow.

By embracing this technology, you’re not just fine-tuning current operations. You're laying the foundation for a building that can self-diagnose, self-heal, and constantly adapt for peak performance, securing its value for decades to come.

Got Questions? We've Got Answers

Stepping into any new technology means asking the tough questions first. That's just smart business. Let's tackle the most common ones that facility managers and building owners have when they start looking into predictive maintenance for their MEP systems.

What’s the Real Cost of a Predictive Maintenance System?

There's no single price tag. The cost really depends on the size and complexity of your facility. Your initial outlay will cover the IoT sensors, the software platform that makes sense of the data, and the installation. But it's a mistake to view this purely as a cost. It’s an investment, and a smart one at that.

Think of it this way: the system pays for itself over time. You'll see fewer emergency repair bills, your energy consumption will drop, and your equipment will last longer. Many businesses start with a small pilot project, maybe focusing on a handful of their most critical assets. This lets you see a tangible return on a modest investment before you decide to roll it out across the entire building.

Can We Install This on Our Older MEP Equipment?

Yes, absolutely. In fact, this is where the technology truly shines. The vast majority of modern IoT sensors are designed to be retrofitted. They can be clamped onto older pumps, attached to motors, or placed on chillers and electrical panels without any invasive or disruptive work.

This means you can bring your existing infrastructure into the 21st century. You get all the benefits of smart, real-time monitoring on the reliable, legacy equipment you already own. It’s the perfect way to modernize what you have without a complete and costly overhaul.

Predictive maintenance isn't just for brand-new construction. Its real power is in upgrading the buildings you already operate, finding efficiencies and preventing failures in systems that have been running for years.

What Kind of Training Does My Maintenance Team Need?

A well-designed predictive maintenance platform should make your team's job easier, not harder. They don't need to become data scientists overnight. The training is straightforward and focuses on understanding the simple, actionable alerts the system provides. For instance, they'll learn what an "abnormal motor vibration" alert means and exactly what to do about it.

Typically, the platform provider will walk your team through everything they need to know, including:

- Using the Dashboard: How to quickly check on equipment health and look at performance history.

- Understanding Alerts: What different notifications mean and how to prioritize them.

- Switching to Proactive Work: How to use the system’s insights to plan maintenance instead of just reacting to breakdowns.

The transition is usually quite smooth. The tech gives technicians the information they need to be more effective and get ahead of problems.

How Secure Is Our Data from These IoT Sensors?

Security is non-negotiable, and any credible provider makes it their top priority. All the operational data gathered from your MEP systems is protected with serious security measures from the moment it leaves the sensor.

Here’s what you should expect as standard:

- End-to-End Encryption: Data is scrambled and unreadable from the sensor all the way to the cloud.

- Secure Cloud Hosting: The software platform is built on secure, protected servers.

- Strict Access Controls: You decide who gets to see your building's data.

These safeguards ensure your operational information stays private and secure, period.

Ready to turn your facility's maintenance from a recurring cost into a real strategic advantage? Yasu Trading Co. LLC supplies the top-tier MEP components, sensors, and hardware you need to build a rock-solid predictive maintenance program. Explore our extensive product range at yasutrading.com and start your journey toward zero unplanned downtime.