Preventive Maintenance Tips to Save Costs & Boost Safety

Ever been on a job site that’s dead in the water because a key piece of machinery just gave up? That’s the all-too-common, and incredibly expensive, result of what we call reactive maintenance. Some call it a 'run-to-failure' strategy, which is a fancy way of saying you wait for something to break before you even think about fixing it.

The Hidden Costs of Reactive Maintenance

Picture this: you’re in the middle of a massive foundation pour, and your primary excavator suddenly grinds to a halt. The immediate issue might be a busted hydraulic pump, but that's just where the nightmare begins. A single breakdown like this sets off a disastrous chain reaction that can derail the entire project.

The first hit to your wallet is the emergency repair bill, which is always going to be steeper than planned work. In fact, unplanned maintenance can cost three to nine times more than scheduled service calls, thanks to rush fees for parts and last-minute labor. But that's just the tip of the iceberg.

The Ripple Effect of a Single Breakdown

For every hour that excavator sits idle, the project clock is ticking and your budget is bleeding. The real financial damage piles up fast:

- Idle Crews: Suddenly, you have an entire crew of operators and laborers getting paid to stand around. Productivity across the site tanks as every task that depended on that excavator is now on hold.

- Project Delays: The project timeline is shot. This can easily lead to missed deadlines, which often means paying out on penalty clauses baked into your contracts.

- Rental Costs: To get things moving again, you might have to scramble to rent a replacement machine at a premium, adding yet another unplanned expense to the growing list.

This scenario is a perfect example of why the "if it ain't broke, don't fix it" mentality is so dangerous in construction. It completely ignores the secondary financial shocks that cripple a project’s bottom line. Every unexpected breakdown throws your schedule and budget into chaos, eating away at profits and damaging your reputation for reliability. For a closer look at keeping these numbers in check, our guide on effective construction cost management offers some great insights.

Reactive maintenance turns project management into crisis management. You’re constantly fighting fires, which guarantees you’ll always be behind schedule and over budget.

Shifting From Reaction to Prevention

Many of these hidden costs are really just unmanaged operational risks. Getting a handle on risk management in operations can make a huge difference. At the end of the day, a reactive approach trades a little short-term convenience for a world of long-term financial pain.

This is where a solid preventive maintenance plan comes in. It’s about swapping that unpredictability for control. It’s not just about oiling gears; it's a strategic shield against the financial drain of equipment failures, keeping your projects on track and on budget.

Getting Ahead of Breakdowns: The Proactive Mindset

To escape the endless cycle of emergency repairs, you need to shift your thinking from reactive to proactive. It’s the difference between changing the oil in your work truck to prevent engine failure versus dealing with a seized engine on the side of the highway. The goal is simple: act before something breaks.

This proactive mindset is the very heart of preventive maintenance. It's a strategy built on a simple idea: perform small, routine tasks to keep equipment running smoothly and stop major breakdowns from ever happening. Instead of having a critical failure grind your entire project to a halt, you’re consistently taking steps to extend the life of your assets and keep everything reliable.

These proactive measures usually fall into one of two categories, each playing a unique role in a solid maintenance plan.

Time-Based Maintenance: Sticking to the Schedule

The most straightforward form of preventive maintenance is based on time. Here, tasks are performed at set intervals—weekly, monthly, annually—no matter how the equipment seems to be running. It’s all about the calendar.

Think of it like an annual physical for your machinery. You don't wait for symptoms to show up; you schedule the check-up to catch potential problems before they get serious. This approach brings a welcome level of predictability, making it far easier to plan your time and budget.

On a typical construction site, this might look like:

- Monthly: Inspecting and cleaning all HVAC unit filters.

- Quarterly: Running tests on fire alarms and emergency lighting systems.

- Annually: Servicing the backup generators to make sure they’ll fire up when you need them most.

This calendar-based system provides a strong foundation for any maintenance program, creating order out of what can often feel like equipment chaos.

Usage-Based Maintenance: Responding to Wear and Tear

While a schedule works for many things, some equipment wears out based on how much you use it, not just how much time has passed. This is where usage-based maintenance comes into play. Instead of the calendar, maintenance is triggered by specific operational milestones.

It’s like changing the tires on a delivery truck after it hits a certain number of miles, not just because a year went by. The maintenance is directly tied to the machine's actual workload, which often makes it a much more efficient and accurate approach.

A usage-based strategy aligns your maintenance efforts with an asset's real wear and tear, stopping you from servicing equipment too early or, worse, too late.

For construction equipment, this could mean:

- Swapping out an excavator's bucket teeth after 1,000 hours of operation.

- Changing the hydraulic fluid in a dozer after every 500 lift cycles.

- Servicing a crane's engine after a specific number of lifting hours are logged.

This method does require you to track equipment usage, but the payoff is maintenance that’s perfectly timed and more cost-effective.

The Next Frontier: Predictive Maintenance

The next evolution on this proactive path is predictive maintenance (PdM). This approach uses technology to actually forecast when a failure is likely to happen. If preventive maintenance is a scheduled check-up, predictive is like a 24/7 health monitor that alerts you to trouble before you even notice a symptom.

PdM relies on sensors to collect real-time data on things like vibration, temperature, and fluid pressure. Sophisticated software then analyzes this data to spot tiny irregularities that signal a future breakdown. This allows your team to step in at the perfect moment—not too soon and never too late. To see how this applies in a specific field, this commercial HVAC preventative maintenance guide offers a deeper look.

As industrial equipment becomes more complex, especially in places like the UAE, companies are investing heavily in these advanced strategies. The Maintenance, Repair, and Operations (MRO) market in the Middle East and Africa is expected to grow from $62.4 billion in 2025 to $91.8 billion by 2031. This surge underscores just how vital sophisticated maintenance has become for maximizing the life and value of critical assets.

The Business Case for Proactive Maintenance

Moving from a reactive, "fix-it-when-it-breaks" mindset to a proactive one isn't just a procedural tweak. It's a fundamental business decision that hits your bottom line directly. Putting a solid preventive maintenance program in place isn't another expense on the ledger; it’s a powerful strategy for boosting profit and building stability.

The real value shines through when you look at the four pillars of its business case: dramatic cost savings, a safer job site, longer-lasting equipment, and far more predictable project timelines. Each of these works together to create a construction operation that’s more resilient, efficient, and profitable, turning maintenance from a necessary evil into a real competitive edge.

Let's break down the tangible returns you can expect from this strategic shift.

Drive Down Operational Costs

The first and most obvious win from preventive maintenance is how much money it saves. Running to put out fires with reactive maintenance might feel cheaper in the moment, but that's a dangerous illusion. Unplanned maintenance can easily cost three to nine times more than scheduled work when you factor in rush fees for parts, overtime for technicians, and the high cost of emergency shipping.

A proactive approach completely flips this script.

Think about something as common as the hydraulic system on a wheel loader. A routine, scheduled check involving fluid analysis and a filter change is a minor line item. But if you ignore that small task until the system fails catastrophically? You’re suddenly looking at a multi-thousand-dirham repair bill, not to mention the crippling cost of days of downtime. Small, preventive actions are always cheaper than big, emergency fixes.

This forward-thinking financial strategy is clearly gaining momentum in the region. A recent analysis shows the Middle East and Africa (MEA) predictive and preventive maintenance market is set to hit approximately $464.99 million in 2025. More telling is its projected compound annual growth rate of around 34% through 2033. This massive growth signals a major industry shift as construction and other sectors recognize the huge financial upside of catching failures before they happen. You can discover more insights about this growing market and its regional impact.

Enhance Construction Site Safety

It's a simple truth: a well-maintained machine is a safe machine. Equipment failure is a primary cause of accidents on construction sites, making a robust preventive maintenance plan one of your most effective safety tools. It’s a systematic way to spot and fix potential hazards before they can cause an injury—or worse.

Consider the brakes on a heavy dump truck. A scheduled inspection can catch worn pads or a leaking fluid line, a relatively minor repair that might take the truck out of service for a few hours. In a reactive world, that same problem might only be discovered when the brakes fail on a steep grade, putting the operator and everyone else on site in immediate danger.

By formalizing inspections and sticking to a repair schedule, you build a culture of diligence and safety. This commitment doesn't just protect your crew; it also shields you from the immense costs of accidents, legal battles, and project shutdowns ordered by safety inspectors.

Extend Equipment Lifespan

Your heavy machinery is one of your company's biggest capital investments. Preventive maintenance is the single best way to maximize the return on that investment. It’s no different than getting regular oil changes to make your car last longer—routine care protects your heavy equipment from the daily grind and premature failure.

Neglecting maintenance is like throwing away a portion of your equipment's value every single day. Proactive care ensures your assets serve you for their full intended operational life, and often beyond.

Simple, consistent actions deliver powerful, long-term results:

- Regular Lubrication: Reduces the friction on moving parts that literally grinds down expensive components over time.

- Fluid Analysis: Catches tiny contaminants in oil and hydraulic fluid that act as early warnings for internal problems, long before a catastrophic failure.

- Filter Changes: Protects engines and hydraulic systems from damaging particles, helping them run cleaner, cooler, and for much longer.

By sticking to a schedule for these basic tasks, you can add years to the working life of your most valuable assets and push the massive cost of replacement far into the future.

Achieve Greater Project Predictability

Finally, preventive maintenance delivers something every project manager dreams of: predictability. Reactive maintenance is fueled by chaos. It makes sticking to a schedule or a budget nearly impossible because you’re always just one breakdown away from a complete standstill. Planning becomes a total guessing game.

A proactive strategy puts you back in the driver's seat. You schedule maintenance during planned downtime—overnight, on a weekend, or between project phases. You control when your equipment is offline.

This simple change allows you to plan your resources, allocate your team effectively, and keep your project timeline firmly on track. That kind of reliability strengthens your reputation, helps you dodge late-delivery penalties, and ultimately makes your business more competitive and trustworthy in the eyes of your clients.

How to Build Your Preventive Maintenance Plan

Putting a preventive maintenance strategy into action is where the real value emerges. Building a plan from the ground up might feel like a huge task, especially on a hectic construction site, but a step-by-step approach makes it totally manageable. The goal is to create a clear, repeatable system that brings a sense of order to your fleet management.

This isn't about creating more paperwork. It’s about building a framework that stops tiny issues from spiraling into project-halting disasters. Let's walk through the essential steps to build a solid preventive maintenance plan that actually works in the real world.

Step 1: Inventory and Prioritize Your Equipment

You can’t maintain what you don’t track. The first order of business is to get a complete list of every single piece of equipment you own—from the massive excavators down to the small-but-mighty generators.

For each asset, you’ll want to log a few key details:

- The Basics: Machine type, brand, model, and serial number.

- Operational Info: What it does and where it currently lives on site.

- The History: Any repair or service records you have on hand.

Once you have your list, it's time to prioritize. Not all equipment carries the same weight. Just ask yourself one simple question: "If this machine went down tomorrow, how bad would the fallout be?"

Use that answer to sort your assets into tiers. Your Tier 1 machines are the mission-critical ones—the equipment that would cause the biggest delays and cost you the most money. These are where you’ll focus your initial efforts.

Step 2: Dig into Manufacturer Guides and Past Repair Data

Good news: you don't have to guess what maintenance to perform. Your best friend here is the original equipment manufacturer (OEM) manual. These guides are your cheat sheets, laying out the factory-recommended service schedules—what to do, and exactly when to do it.

Think of these manuals as the blueprint for keeping your gear in top shape. Following them not only helps machines run better but often keeps them compliant with warranty terms. They provide the "what" and the "when" for your entire plan.

Beyond the official guides, your own repair history is a goldmine. Sift through old work orders and breakdown reports to spot patterns. If you see that the same hydraulic pump fails every six months like clockwork, you’ve just found a perfect candidate for a proactive inspection. You can turn an unexpected headache into a simple, scheduled task.

Step 3: Create Simple, Clear Maintenance Checklists

Now that you know what to do and when, you need to define "how." This is where straightforward checklists become your most powerful tool. A good checklist takes the guesswork out of the equation and ensures every inspection is done the right way, every time, no matter who’s holding the clipboard.

For example, a daily checklist for a wheel loader might include:

- Check engine oil and coolant levels.

- Inspect tires for proper inflation and visible damage.

- Test all lights, horns, and alarms.

- Look for leaks or cracks in hydraulic hoses.

A monthly checklist will be more involved—lubricating joints, checking batteries, inspecting brake systems. The goal is to keep these lists direct and easy to follow. For a deeper dive, you can explore some great examples in our guide to building a preventive maintenance schedule template.

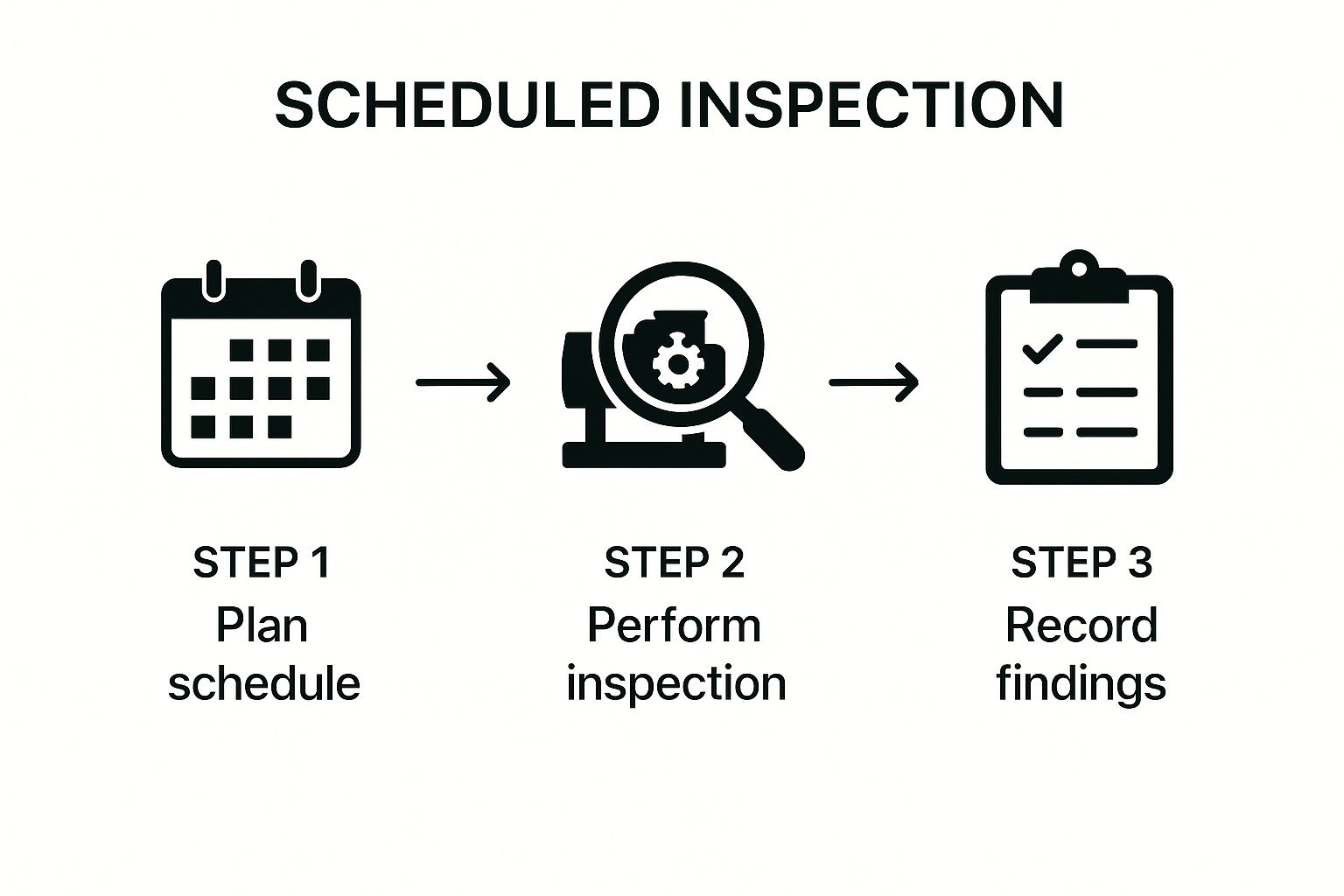

This workflow shows how a simple inspection cycle works, from planning to action and documentation.

This structured process ensures that every maintenance task is properly planned, executed, and recorded, creating a reliable cycle of proactive care.

Step 4: Schedule Tasks and Assign Clear Responsibilities

A plan is just a piece of paper until you put it into motion. The next step is to build a master schedule that fits all your maintenance tasks into the natural flow of your project. You want to schedule this work during planned downtime—overnight, on weekends, or between project phases—to cause as little disruption as possible.

A well-organized schedule is the engine of your preventive maintenance plan. It transforms good intentions into consistent, disciplined action that protects your most valuable assets.

Just as important is assigning ownership. Every task needs a name next to it. Whether it's your in-house mechanic or an outside service team, everyone needs to know exactly what’s on their plate and when it’s due. This simple accountability is what keeps things from falling through the cracks.

Step 5: Track and Document Everything

The final—and arguably most important—step is to document everything. Every inspection, every oil change, every single repair needs to be logged.

This isn't just busywork. This documentation builds a complete service history for each machine. Over time, that history helps you spot trends, fine-tune your maintenance timing, and make much smarter decisions about whether to repair or replace equipment down the road. This final step closes the loop, turning your maintenance activities into a powerful source of business intelligence that saves you money in the long run.

The Right Tools for Modern Maintenance

Let's be honest, you can't run a modern maintenance program with a clipboard and a stack of paper logs anymore. As construction projects get bigger and more complex, technology is the only way to turn a good plan into a smooth, data-driven operation. The right tools take maintenance from a tedious manual chore to a streamlined digital process.

At the heart of this shift is the Computerized Maintenance Management System (CMMS). Think of it as the digital command center for your entire maintenance program. It's the single source of truth where every task, schedule, and report lives, all organized in one central hub that your team can access from anywhere.

For a busy construction firm juggling a diverse fleet across multiple job sites, this is a total game-changer. A CMMS automates routine task scheduling, pings technicians with reminders, and keeps a detailed service history for every single piece of equipment. It replaces guesswork with precision, making sure no critical task ever falls through the cracks.

The Power of a Centralized System

A good CMMS does more than just schedule work orders; it turns raw data into intelligence you can actually use. It gives managers a bird's-eye view of the entire maintenance operation, letting them track performance, monitor costs, and spot recurring problems before they snowball into something serious.

This centralized approach helps construction firms:

- Standardize Procedures: Ensure every inspection is done the same way, every time, using digital checklists.

- Improve Accountability: Assign specific tasks to technicians and see their completion status in real-time.

- Manage Inventory: Keep a close eye on spare parts so you don't have costly downtime waiting for a delivery.

- Generate Reports: Easily pull data on asset health, maintenance spending, and team productivity.

This level of organization is the backbone of any serious preventive maintenance effort. It provides the structure you need to manage a large and varied fleet of equipment, much like the diverse range of essential construction tools available in the UAE that all demand their own careful management and upkeep.

Going Beyond Schedules with Advanced Tech

While a CMMS organizes the "what" and "when" of maintenance, other technologies are completely changing the "why." Advanced tools are giving site managers an unprecedented look into the real-time health and performance of their machinery, making maintenance smarter, not just more frequent.

This move toward data-driven maintenance is powered by two key innovations: IoT sensors and telematics.

By integrating real-time data, modern maintenance shifts from following a calendar to responding to the actual condition of the equipment. This is the foundation of a truly proactive and cost-effective strategy.

IoT Sensors and Telematics in Action

The Internet of Things (IoT) is all about placing small sensors on equipment to continuously monitor its vital signs. These sensors track critical metrics like engine temperature, fluid pressure, and vibration levels. If a reading drifts outside the normal range, the system can automatically send an alert or even create a work order in the CMMS.

It’s like having a doctor constantly monitoring your equipment's health. For instance, a gradual increase in vibration could signal a bearing is about to fail. That sensor gives you weeks of notice to schedule a repair during planned downtime instead of reacting to a catastrophic breakdown mid-project.

Telematics systems take this a step further by also tracking an asset's location and how it's being used. This technology is incredibly valuable for usage-based maintenance, as it automatically logs operational hours, mileage, or cycles. Instead of chasing down operators for manual logs, a telematics system can tell the CMMS a dump truck is due for an oil change the moment it hits its target hours.

Together, these technologies provide the data needed to move towards a predictive maintenance model. By understanding exactly how your equipment is performing and being used, you can fine-tune your maintenance schedule for maximum efficiency. This forward-looking approach ensures your team intervenes at the perfect moment—just before a problem occurs.

Got Questions? Let's Talk Preventive Maintenance

Even when the benefits seem obvious, making a real change in how you handle equipment maintenance always brings up a few practical questions. It's one thing to talk about a preventive maintenance plan, but it's another thing to actually get it off the ground.

Let's tackle some of the most common questions and concerns we hear from construction teams who are thinking about leaving the "run-it-til-it-breaks" model behind for good.

How Do I Start a Plan If My Budget Is Tight?

This is probably the biggest question we get, but it’s not the roadblock you might think. You don't need a huge cash injection to get started; you just need to be smart about it. The trick is to start small and zero in on your most critical assets. Think about the machines that would bring your job site to a screeching halt if they went down.

Start by picking your top three to five most essential pieces of equipment. Then, you can:

- Keep it simple. You don’t need fancy software right away. A basic spreadsheet is perfect for tracking maintenance schedules based on what the manufacturer recommends.

- Focus on the cheap fixes. The most powerful preventive tasks are often the simplest and least expensive. We're talking about regular fluid checks, clean filters, and quick daily walk-arounds. These small habits prevent the vast majority of catastrophic, budget-busting failures.

- Show your work. The goal here is to prove the concept. Once you can walk into a manager's office and show them how spending $50 on proactive care saved $5,000 on an emergency repair, you'll have a much easier time getting a bigger budget for the program.

Isn't Preventive Maintenance the Same as Predictive Maintenance?

It’s easy to mix these two up. They’re both proactive, but they come from two different schools of thought.

Here’s a simple way to look at it. Preventive maintenance is like going to the dentist every six months. You go based on a set schedule to prevent problems like cavities, whether you have a toothache or not. For your equipment, that means changing the oil every 250 operating hours, no matter what.

Predictive maintenance, on the other hand, is like wearing a heart rate monitor that alerts your doctor the second it spots an irregular rhythm. It’s based on the actual condition of the equipment.

Predictive maintenance uses real-time data from sensors to monitor an asset’s health. It tells you exactly when a part is about to fail, so you can step in at the perfect moment—not too early, and never too late. It's a more advanced, data-driven approach.

What's the Single Biggest Hurdle to Getting Started?

You might be surprised. It’s usually not about the money or the technology. The biggest challenge is almost always the culture. Getting a team to switch from the old "if it ain't broke, don't fix it" mindset to a disciplined, proactive one takes real commitment from top to bottom.

That "we've always done it this way" attitude can kill even the best-laid plans before they get a chance to work.

To get everyone on board, you have to:

- Explain the "Why." Make sure everyone, especially your crews in the field, understands the benefits. Talk about it in terms they care about, like a safer worksite or fewer frantic calls for middle-of-the-night repairs.

- Make It Painless. Use straightforward tools, like a simple CMMS, to make tracking and paperwork as easy as possible. If the new system is a hassle, people will find a way to avoid it.

- Get Leadership on Board. Management has to champion this. When the people in charge make proactive maintenance a priority, it sends a clear signal to everyone that this is the new standard.

Once your team buys into the proactive mindset, the rest of the logistical pieces of your preventive maintenance plan will fall into place much more smoothly.

At Yasu Trading Co. LLC, we provide the high-quality building materials, safety equipment, and reliable tools that keep your projects running smoothly. Explore our extensive product range and see how we can support your operational success at https://yasutrading.com.