Preventive Maintenance in MEP: Top Strategies to Optimize Efficiency

In any modern facility, the intricate network of Mechanical, Electrical, and Plumbing (MEP) systems is the operational backbone. A failure in these systems can lead to catastrophic downtime, significant financial loss, and potential safety hazards. Reactive maintenance, fixing things only as they break, is no longer a viable or cost-effective strategy. The key to ensuring reliability, efficiency, and longevity lies in a robust approach to preventive maintenance in MEP systems. This involves moving beyond simple calendar-based checks to a sophisticated, strategic framework tailored to your facility's unique needs.

This guide explores seven distinct, yet complementary, strategies that facility managers can implement to transform their maintenance programmes, ensuring every component operates at peak performance. While our focus is on moving 'beyond the checklist' to truly proactive MEP management, a well-structured HVAC preventative maintenance checklist remains a foundational tool for ensuring system reliability. By understanding the approaches outlined here, you can select and combine the right strategies to build a resilient and cost-effective maintenance ecosystem.

1. Time-Based Maintenance (TBM)

Time-Based Maintenance (TBM) is a foundational strategy in MEP preventive maintenance where tasks are performed at fixed, predetermined intervals. This approach relies on calendar time (e.g., weekly, monthly, quarterly) or equipment runtime hours to schedule servicing, regardless of the asset's current operating condition. It is a proactive method designed to prevent failures before they occur by adhering strictly to manufacturer recommendations and established industry best practices.

For example, a large-scale development like Dubai's Burj Khalifa might implement quarterly filter changes and annual coil cleaning for its vast HVAC network. Similarly, major hotel chains in the UAE often schedule monthly chiller inspections and semi-annual oil changes on all mechanical equipment to ensure guest comfort and system reliability.

Implementing TBM Effectively

To maximise the benefits of TBM, a structured and consistent approach is essential. This method is particularly effective for critical assets where the cost of failure is high and for equipment with predictable wear patterns.

- Establish a Baseline: Start by aligning maintenance intervals with manufacturer guidelines. These provide a reliable foundation for your schedule.

- Utilise Technology: Employ a Computerised Maintenance Management System (CMMS) to automate scheduling, dispatch work orders, and track task completion. This ensures no scheduled maintenance is missed.

- Standardise Procedures: Create detailed checklists for each task. This guarantees that every technician performs the maintenance consistently and thoroughly, which is crucial for effective preventive maintenance in MEP.

- Schedule Strategically: Plan maintenance activities during off-peak hours or low-occupancy periods to minimise disruption to building operations and occupants.

2. Condition-Based Maintenance (CBM)

Condition-Based Maintenance (CBM) is a sophisticated strategy that shifts preventive maintenance from a fixed schedule to a dynamic, as-needed basis. This approach relies on real-time data from monitoring the actual operating condition of an asset to determine precisely when maintenance is required. By using performance indicators like vibration analysis, thermal imaging, oil analysis, and pressure readings, CBM identifies signs of decreasing performance or impending failure, allowing for interventions only when necessary.

For instance, Dubai Mall implements quarterly thermal imaging surveys on over 1,200 electrical panels to identify hot spots before they cause a critical failure. Similarly, major data centres across the UAE use continuous current signature analysis on their electrical distribution equipment, allowing them to predict bearing failures in cooling units weeks in advance and schedule repairs with zero downtime.

Implementing CBM Effectively

CBM is ideal for critical assets where unexpected failure carries significant financial or operational consequences. It optimises maintenance resources by avoiding unnecessary servicing of healthy equipment, representing a more advanced approach to preventive maintenance in MEP.

- Establish a Baseline: Begin by recording performance data when equipment is new or has just been serviced. This "healthy" baseline is the benchmark against which all future readings are compared.

- Set Alert Thresholds: Define specific measurement thresholds that trigger a response. For example, an "advisory" level might prompt a closer inspection, while a "critical" alert would trigger an immediate maintenance work order.

- Invest in Training and Tools: Equip your technical teams with the right diagnostic tools, such as vibration analysers or thermal cameras, and provide comprehensive training on how to use them and interpret the data correctly.

- Integrate with a CMMS: Channel all condition data into your Computerised Maintenance Management System (CMMS). This creates a detailed asset history and allows for trend analysis to predict future maintenance needs more accurately.

3. Predictive Maintenance (PdM)

Predictive Maintenance (PdM) represents an advanced strategy in MEP systems, utilising data analytics, machine learning, and IoT sensors to forecast equipment failures before they happen. This forward-looking approach analyses real-time operational data, historical trends, and environmental factors to predict the remaining useful life of an asset. Unlike time-based schedules, PdM triggers maintenance only when data indicates a developing fault, optimising resource allocation and minimising downtime.

For instance, Singapore's Changi Airport implemented PdM on its chillers and Air Handling Units, using Schneider Electric's platform to predict compressor failures 45 days in advance with 92% accuracy. Similarly, Amazon Web Services data centres employ machine learning algorithms to analyse thousands of data points, predicting cooling system failures weeks before they can impact operations.

Implementing PdM Effectively

To successfully implement PdM, a robust data infrastructure and a strategic, phased approach are crucial. This method delivers maximum value for critical, high-cost assets where unplanned failure would cause significant disruption.

- Start with a Pilot: Begin with a small-scale pilot project on a few high-value assets to demonstrate return on investment and refine your processes before a full-scale rollout.

- Invest in Data Infrastructure: Ensure you have reliable sensors, secure connectivity, and a capable data storage and processing platform. Begin collecting data immediately to build a historical baseline for your models.

- Build a Cross-Functional Team: Involve maintenance, IT, and operations personnel to ensure seamless integration. Drawing parallels with the principles of preventive maintenance in MEP, the application of predictive safety analytics also leverages data to forecast potential issues, requiring similar inter-departmental collaboration.

- Partner with Experts: Collaborate with technology vendors like Siemens, GE Digital, or IBM who offer proven PdM platforms specifically for MEP applications. Explore how IoT sensors are transforming MEP maintenance to understand the technology's potential.

4. Risk-Based Maintenance (RBM)

Risk-Based Maintenance (RBM) is a strategic approach that prioritises maintenance resources based on the level of risk associated with equipment failure. It moves beyond fixed schedules by systematically evaluating both the probability of an asset failing and the severity of the consequences. This allows maintenance teams to focus their efforts where they matter most, protecting critical functions and high-value assets.

For instance, a data centre in the UAE would classify its cooling systems as the highest risk, as failure leads to server shutdowns and catastrophic data loss. These systems receive intensive, redundant maintenance, while lower-risk assets like office lighting receive minimal preventive attention. Similarly, petrochemical refineries apply RBM to electrical distribution, with life-safety circuits receiving more frequent thermographic surveys than administrative building circuits.

Implementing RBM Effectively

To implement RBM, you must quantify and categorise risk to make informed decisions. This method ensures that the most significant threats to safety, operations, and finance are addressed first, optimising the overall effectiveness of your preventive maintenance in MEP programme.

- Assemble a Cross-Functional Team: Involve operations, maintenance, safety, and engineering personnel in risk assessments to gain a holistic view of asset criticality.

- Establish a Risk Matrix: Develop a clear visual matrix to categorise assets. This involves defining specific criteria for both the likelihood of failure (e.g., age, condition, history) and the consequence of failure (e.g., safety, operational, financial).

- Link Risk to Action: Directly connect each risk category to a specific maintenance strategy. High-risk equipment might require predictive technologies and frequent inspections, while low-risk items may only need reactive maintenance.

- Continuously Re-evaluate: Risk profiles change over time. Reassess risks annually or whenever significant operational changes occur to ensure your maintenance strategy remains aligned with current priorities. For a deeper understanding of risk evaluation frameworks, consider exploring detailed guides on construction risk management.

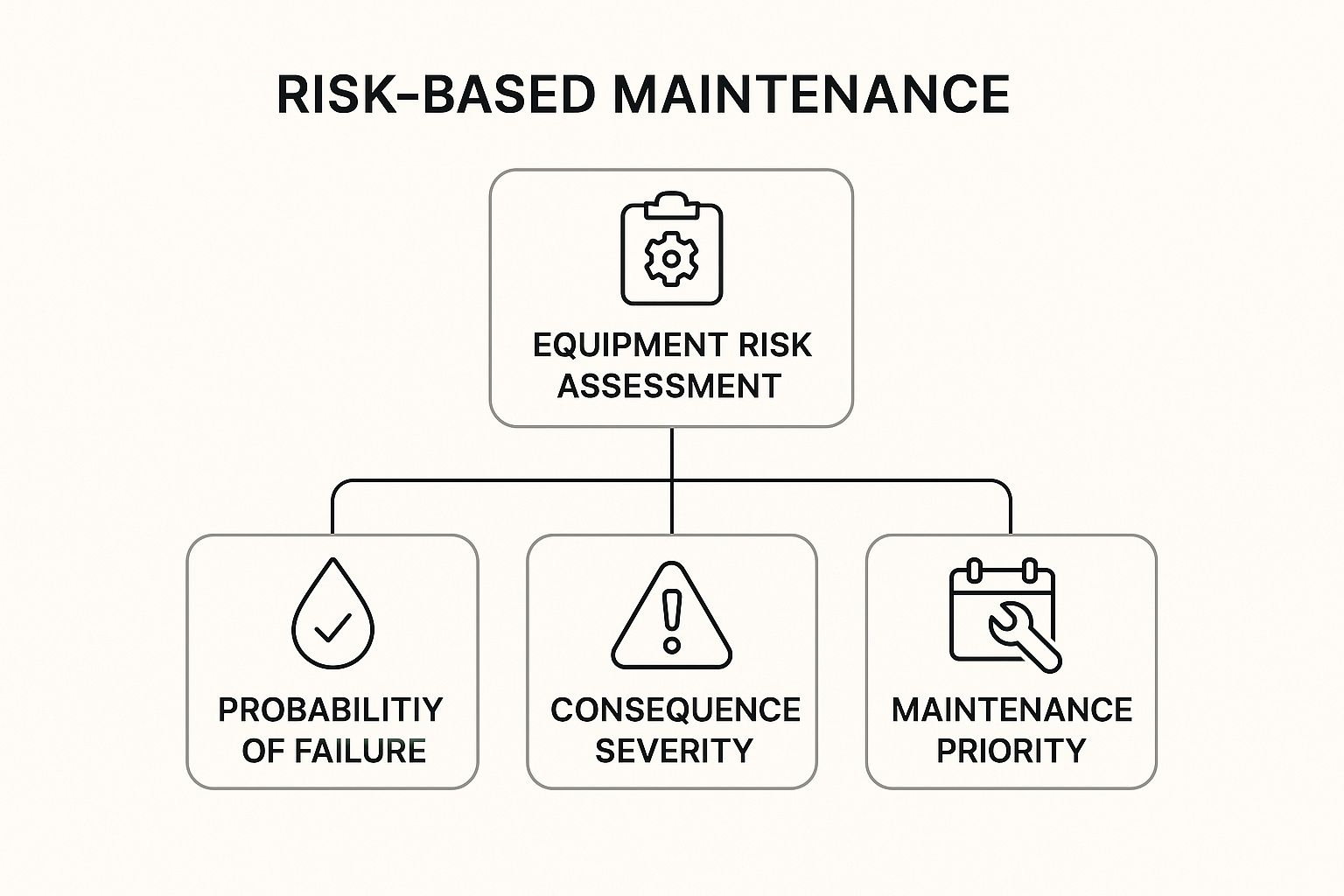

The hierarchy diagram below illustrates the core process of RBM, showing how risk assessment is broken down into its key components to determine maintenance priority.

This visualisation highlights that maintenance priority is not a standalone decision but the direct outcome of a structured analysis of both failure probability and consequence severity.

5. Reliability-Centred Maintenance (RCM)

Reliability-Centred Maintenance (RCM) is a highly systematic methodology used to determine the most effective maintenance strategy for each asset based on its specific function and failure consequences. Originating in the aviation industry, RCM analyses equipment at a component level to identify potential failure modes, their causes, and their effects on the overall system, thereby preserving function rather than just equipment.

A prime example is its application in mission-critical facilities like data centres or pharmaceutical cleanrooms in the UAE, where an HVAC failure can have catastrophic consequences. Instead of a blanket maintenance schedule, RCM would identify the most critical fan motor components and prioritise condition monitoring for them while deeming less critical parts as acceptable to run-to-failure. This optimises resource allocation and enhances overall system reliability.

Implementing RCM Effectively

To implement RCM, a deep, analytical approach is required. It is best suited for complex, critical systems where failure poses significant safety, environmental, or operational risks.

- Start with a Pilot Project: Select a single, high-value MEP system to apply the RCM methodology. This allows your team to learn the process on a manageable scale before a full rollout.

- Form a Multidisciplinary Team: Assemble a group that includes operations, maintenance, engineering, and safety personnel. This ensures all perspectives are considered during the failure modes and effects analysis (FMEA).

- Use Standardised Processes: Adopt established RCM standards like SAE JA1011 to guide your analysis. Using dedicated software and worksheets ensures a consistent and thorough evaluation.

- Focus on Functional Preservation: The core of RCM is maintaining system function, not just preventing every equipment failure. This is a crucial mindset shift for successful preventive maintenance in MEP and helps prioritise the most impactful tasks.

6. Preventive Replacement and Overhaul Programs

Preventive Replacement and Overhaul Programs are strategic initiatives where equipment or its critical components are replaced or fully refurbished at predetermined intervals. This approach is based on the component's expected useful life, rather than its current condition, to pre-empt failure. It targets assets with predictable wear-out patterns, like motors, bearings, belts, and contactors, shifting from reactive repairs to proactive, scheduled renewals.

For instance, major data centres in the UAE, such as those operated by Khazna, implement preventive replacement of server cooling fans on a fixed 3-year cycle. Similarly, many of the region's large-scale manufacturing plants schedule annual 'turnaround' shutdowns for comprehensive equipment overhauls, including motor rebuilds and system refurbishments, to ensure uninterrupted production.

Implementing Replacement and Overhaul Programs Effectively

This strategy is highly effective for critical equipment where the cost and operational impact of an unexpected failure far outweigh the cost of a planned replacement. A disciplined approach ensures maximum return on investment.

- Establish Lifecycles: Use manufacturer recommendations, historical failure data, and industry standards like ASHRAE guidelines to define accurate replacement intervals for key components.

- Leverage CMMS: Employ a Computerised Maintenance Management System to track component installation dates and automatically generate work orders as assets near their end-of-life, which is a core part of effective preventive maintenance in MEP.

- Group Components: Maximise efficiency by scheduling the replacement of multiple similar components during a single planned shutdown. This minimises downtime and labour costs.

- Plan Strategically: Schedule major overhauls during planned facility shutdowns or low-demand periods, such as the summer months for heating systems, to avoid disrupting core operations.

7. Integrated Computer-Aided Facility Management (CAFM/CMMS)

Integrated Computer-Aided Facility Management (CAFM) and Computerised Maintenance Management Systems (CMMS) represent a technology-enabled approach to organising, automating, and optimising all aspects of MEP maintenance. These platforms act as a central hub for equipment data, work order management, inventory control, and performance analytics, transforming maintenance from a reactive, paper-based operation into a proactive, data-driven programme.

For instance, MGM Resorts utilises a CMMS across its vast Las Vegas properties to manage over 500,000 work orders annually, providing real-time mobile access for thousands of technicians. Similarly, the UK's National Health Service standardised on a CMMS across its hospitals, successfully reducing reactive maintenance by 35% and improving regulatory compliance.

Implementing CAFM/CMMS Effectively

To harness the full power of a CAFM/CMMS, a strategic and phased implementation is crucial. This technology is foundational for any modern approach to preventive maintenance in MEP, enabling greater efficiency and insight.

- Define Clear Objectives: Before selecting software, outline specific goals such as reducing downtime by a certain percentage or improving first-time fix rates.

- Build a Comprehensive Asset Inventory: Start by cataloguing all MEP assets with standardised naming conventions. This data forms the backbone of the system.

- Prioritise and Phase Implementation: Begin by rolling out the system for the most critical equipment or high-frequency PMs before expanding to the entire facility.

- Invest in Training: Ensure all users, from technicians to managers, are thoroughly trained. Develop internal "super-users" to support ongoing adoption and troubleshooting.

- Utilise Mobile Capabilities: Equip field technicians with mobile access to the CMMS to improve data accuracy, streamline work order updates, and increase overall system adoption. You can learn more about how to structure these tasks by exploring a preventive maintenance schedule template.

Preventive Maintenance Methods Comparison

| Maintenance Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Time-Based Maintenance (TBM) | Low - Simple fixed schedules; minimal technical expertise | Low - Basic scheduling software; minimal monitoring technology | Predictable costs; reduces unexpected failures but may over-maintain | Equipment with predictable wear; limited technical staff; warranty compliance | Easy to plan/budget; standardized; minimal expertise needed |

| Condition-Based Maintenance (CBM) | Medium - Requires sensors, data analysis, skilled technicians | Medium-High - Investment in monitoring equipment and data tools | Maintenance only when needed; extends equipment life; reduces costs | Critical equipment with variable usage; early problem detection | Cost savings; minimizes downtime; data-driven planning |

| Predictive Maintenance (PdM) | High - Advanced analytics, AI, and integration required | High - IoT sensors, data scientists, large-scale infrastructure | Maximum uptime; just-in-time maintenance; longer equipment life | Large-scale assets; critical systems requiring high reliability | Accurate failure forecasts; optimal maintenance timing |

| Risk-Based Maintenance (RBM) | Medium-High - Complex risk assessments; multidisciplinary input | Medium - Dedicated teams, ongoing risk reviews | Optimized resource use; improved safety and compliance | Facilities with critical safety/operational/assets; limited resources | Prioritizes highest-risk equipment; supports regulatory compliance |

| Reliability-Centered Maintenance (RCM) | High - Extensive failure mode analysis; requires expertise | High - Cross-functional teams; detailed documentation | Optimal maintenance strategies; improved reliability and cost-effectiveness | High-value, complex equipment; safety-critical systems | Scientifically rigorous; reduces unnecessary maintenance |

| Preventive Replacement & Overhaul | Medium - Scheduled replacements; coordination for shutdowns | Medium - Inventory management; planned downtime | Eliminates surprise failures; extends equipment life | Wear-prone components with predictable lifespans | Cost-effective batch replacements; reduces emergency repairs |

| Integrated CAFM/CMMS | Medium-High - Software setup, data migration, training | Medium-High - Licensing, IT support, user training | Automated scheduling; improved data management; better decision-making | Facilities of all sizes needing maintenance automation | Centralized info; improves technician productivity; audit trails |

Crafting Your Optimal MEP Maintenance Programme

Moving beyond a reactive, "fix-it-when-it-breaks" mentality is the single most impactful shift a facility management team can make. As we have explored, effective preventive maintenance in MEP is not about rigidly adhering to a single doctrine. Instead, it is a sophisticated blend of strategies, carefully calibrated to the unique demands of your building's mechanical, electrical, and plumbing systems. A truly optimised programme is a dynamic ecosystem, not a static checklist.

The most successful approaches often synthesise the methodologies we've discussed. You might use straightforward Time-Based Maintenance for non-critical assets like lighting fixtures, while deploying advanced Condition-Based Monitoring for essential chillers and pumps. Risk-Based Maintenance then becomes your strategic lens, guiding resource allocation to protect your most vital operations. Tying this all together is a robust CMMS, which transforms data into actionable intelligence and orchestrates the entire process, from scheduling to reporting.

Your journey towards an optimised maintenance programme starts now. Begin by auditing your existing MEP assets and identifying their criticality. The key is to transition from a cycle of constant firefighting to one of proactive control and strategic foresight. By thoughtfully implementing these preventive maintenance strategies, you ensure your MEP systems are not just functional, but are a reliable, efficient, and powerful foundation for your organisation’s success.

A successful maintenance strategy relies on high-quality components. For premium building hardware and construction essentials that ensure longevity and performance in the UAE, trust Yasu Trading Co. LLC. Equip your team with the superior parts needed to execute your preventive maintenance plan with confidence by visiting Yasu Trading Co. LLC.