Your Essential Guide to PVC Flooring Materials

At its heart, PVC flooring is really just a family of tough, man-made flooring options built from polyvinyl chloride. It’s become a go-to material in construction for a simple reason: it delivers a powerful mix of durability, water resistance, and incredible design freedom.

Think of it less as just a floor covering and more as an engineered surface, designed to perform under pressure.

What Exactly Are PVC Flooring Materials?

When you hear a fellow professional in the UAE mention PVC flooring, they're talking about what's widely known as vinyl flooring. But you need to get the old, single-pattern sheet vinyl of your grandmother's kitchen out of your head. Today's PVC flooring is a sophisticated, multi-layered product engineered for very specific demands.

Imagine building a floor from the ground up, layer by layer, to get the best possible outcome. That’s exactly what modern PVC flooring is—a composite material where each layer has a specific job to do. This layered construction is the secret to its performance and why it’s a fixture in projects all over the region.

Breaking Down The Core Layers

The real magic of PVC flooring is in its structure. While you'll find slight differences between products, almost all of them are built around these four key layers:

- Protective Wear Layer: This is the invisible shield on top. A clear coating that acts as the first line of defence against scratches, scuffs, and stains, it’s the single biggest factor in the floor's long-term durability.

- Printed Design Layer: Tucked right under the wear layer, this is where the visuals come to life. High-definition printing can realistically recreate the look and feel of natural materials like wood, stone, or even intricate ceramic tile patterns.

- The Core: This is the backbone of the plank or tile. It provides the stability and impact resistance, and it's what defines whether the product is flexible (like traditional LVT) or rigid (like SPC or WPC).

- Backing Layer: The very bottom layer provides foundational support and stability. It often plays a role in sound absorption and adds an extra bit of protection against moisture from the subfloor.

The key takeaway here is this multi-layered approach. It’s what allows manufacturers to create flooring that doesn't just look stunning but can also withstand the daily grind of high-traffic commercial spaces and busy family homes.

Getting to grips with this composition is vital for anyone specifying materials. It shifts the discussion from "how it looks" to "how it performs." That’s a critical distinction in the UAE, where all building materials must meet stringent local regulations. To get a better handle on these requirements, our guide on building materials quality standards in the UAE is a great resource. This knowledge helps ensure the products you choose aren't just aesthetically pleasing, but also fully compliant and built for the long haul.

How PVC Flooring Layers Create Performance

The real difference between a PVC floor that gives up after a few years and one that lasts for decades isn't the material itself—it's how the individual layers are engineered to work together. You have to look at pvc flooring materials as a complete system, not just a single surface. Each layer has a specific job, and when they function in harmony, they create something far more resilient than any single component could be on its own.

Think of it as a high-performance team. A star player is great, but a team where every member executes their role perfectly is what wins championships. For PVC flooring, this teamwork translates directly into durability, aesthetics, and the structural integrity you need on a busy project site.

The Protective Wear Layer

Right at the top, you have the transparent wear layer. This is the unsung hero, the floor's frontline defence. It’s a tough, clear coating that takes all the punishment—foot traffic, furniture scuffs, accidental spills—and protects the beautiful design underneath.

The thickness of this layer is one of the most critical specs you'll deal with. It directly dictates the floor's lifespan. A thicker wear layer means more robust protection, which is non-negotiable for high-traffic commercial spaces like retail outlets or building corridors. For any of us in the construction trade, getting the wear layer thickness right is fundamental to ensuring the client is happy for years to come.

The Design Layer and Structural Core

Just below that protective shield is the printed design layer. This is where the magic happens, giving the floor its character. High-resolution printing technology is used here to create incredibly realistic visuals of natural wood, stone, or even custom abstract patterns. The quality of this layer is what sells the floor, determining its visual depth and realism.

Holding it all together is the structural core. This is the backbone of the plank or tile, providing the essential stability, rigidity, and impact resistance. The core's makeup—whether it’s a flexible vinyl or a rigid composite like Stone Plastic Composite (SPC)—is what defines how the floor feels to walk on and how forgiving it is over different subfloor conditions.

The real value emerges when these layers work in concert. The wear layer protects the design layer’s beauty, while the core provides the stable foundation needed for both to perform optimally over years of use.

This focus on durable, multi-layer construction is exactly why PVC is a cornerstone for so many large-scale projects here in the region. The Middle East and Africa's PVC market is overwhelmingly driven by construction, an industry that prizes its strength, low weight, and weather resistance. With major initiatives like the Dubai Tourism Strategy fuelling new projects, the demand for dependable materials that can offer maintenance-free performance for over 30 years is only growing. You can get a full market analysis from the experts at Mordor Intelligence.

Choosing Your Ideal PVC Flooring Format

Picking the right format for your PVC flooring is a lot like choosing the right tool for the job. You wouldn’t frame a wall with a screwdriver, and you wouldn't use a sledgehammer for delicate trim work. In the same way, the format of your pvc flooring materials—whether sheet, tile, or plank—needs to match the specific demands of your project’s performance, budget, and aesthetic goals.

Get this decision right from the start, and you'll sidestep costly fixes down the line and ensure the floor performs exactly as intended for years. Each format brings a unique set of benefits to the table, perfectly suited for different environments.

The Seamless Solution: Vinyl Sheet

Think of vinyl sheet flooring as a single, massive canvas for your floor. It arrives on-site in large rolls, ready to be cut precisely to the room's dimensions. The real magic happens when the seams are professionally heat-welded, creating a completely impermeable, water-tight surface from wall to wall.

This seamless quality is its biggest advantage. It makes sheet vinyl the go-to choice for any space where hygiene and moisture control are top priorities. We see it specified time and again for:

- Healthcare Facilities: Essential for hospitals, clinics, and labs where stopping bacterial growth in seams is a critical health and safety requirement.

- Educational Institutions: Perfect for high-traffic school corridors, science labs, and cafeterias where spills are inevitable.

- Cleanroom Environments: Any facility that demands uncompromising control over contamination.

The Workhorse: Vinyl Composite Tile (VCT)

Vinyl Composite Tile, or VCT as it’s known throughout the industry, is the undisputed workhorse of commercial flooring. These are typically square tiles made mostly of limestone and other fillers, blended with vinyl and colour pigments. Their reputation is built on sheer durability and an incredible ability to handle heavy rolling loads and relentless foot traffic.

While VCT doesn't offer the high-end visuals of its luxury counterparts, its performance-to-cost ratio is unbeatable. This makes it a foundational material for budget-conscious projects that still require high performance, such as supermarkets, schools, and back-of-house areas in commercial buildings.

The Design Leader: Luxury Vinyl Tile (LVT) and Plank (LVP)

At the premium end of the spectrum, you’ll find Luxury Vinyl Tile (LVT) and Luxury Vinyl Plank (LVP). These products are engineered for one primary purpose: to deliver the stunning, hyper-realistic appearance of natural materials like hardwood or stone, but with all the hard-wearing, low-maintenance benefits of vinyl.

Because they come as individual tiles or planks, the design possibilities are virtually endless. You can create intricate patterns like herringbone or chevron that simply aren't feasible with other resilient flooring. This makes LVT and LVP the perfect choice for client-facing spaces where aesthetics are just as important as performance—think high-end retail, corporate headquarters, and hospitality venues.

The demand for these materials in our region is exploding. In fact, PVC flooring installations across the Middle East and Africa shot past 600 million square metres in 2023, with the UAE a major driving force behind that growth. You can dig into more specifics on this regional trend in the latest Market Growth Reports.

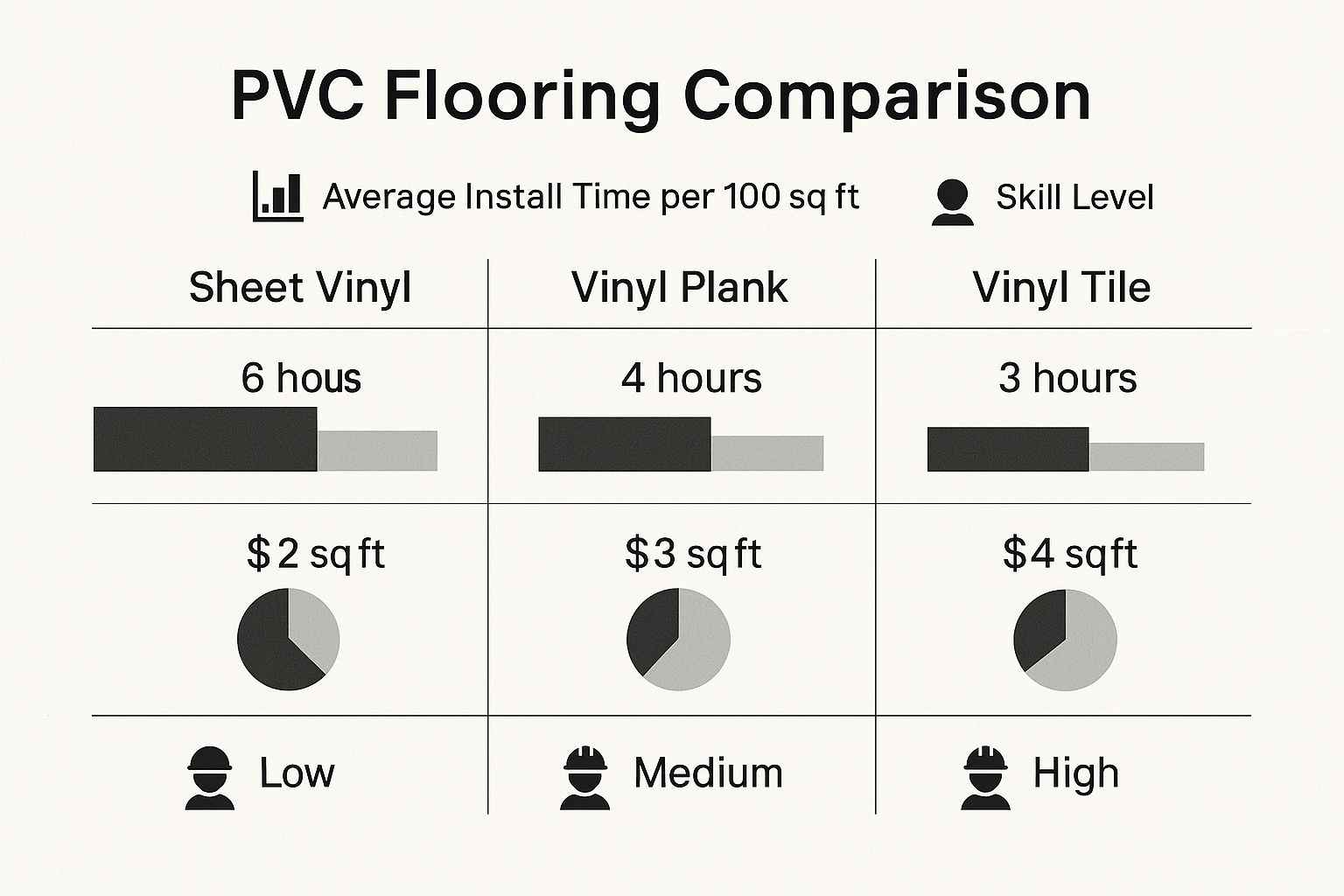

To help you decide, let’s break down how these three formats stack up against each other.

Comparison of PVC Flooring Types

The table below offers a straightforward comparison of the key factors you'll need to consider when specifying PVC flooring for your next project.

| Feature | PVC Sheet | Vinyl Composite Tile (VCT) | Luxury Vinyl Tile/Plank (LVT/LVP) |

|---|---|---|---|

| Primary Benefit | Seamless, hygienic surface | Extreme durability for the cost | Realistic aesthetics & design flexibility |

| Best For | Healthcare, labs, cleanrooms | High-traffic, budget-conscious areas | Retail, hospitality, corporate offices |

| Moisture Resistance | Excellent (if heat-welded) | Good (but has many seams) | Excellent |

| Initial Cost | Moderate | Low | High |

| Maintenance | Low | High (requires regular polishing) | Low |

| Design Options | Limited | Limited | Extensive |

Ultimately, the best choice hinges on balancing your project's budget, the expected foot traffic, and the final look you want to achieve.

The image below gives a great visual summary of how installation time, cost, and the required skill level differ across these formats.

As you can see, LVT strikes a good balance with moderate costs and installation needs, whereas sheet vinyl demands a higher level of skill to achieve that perfect, seamless professional finish.

The Real-World Advantages of PVC Flooring

When you're specifying materials for a project here in the UAE, theory is one thing, but real-world performance is everything. This is where PVC flooring materials really shine. They deliver practical, tangible advantages that directly solve the daily challenges we face in high-traffic commercial and residential spaces. It’s not just a surface; it’s a high-performance asset for the building.

The most obvious benefit is its incredible durability. Think about the relentless foot traffic in a busy Dubai mall or the constant clatter of rolling carts in a hospital corridor. PVC flooring, especially the options with a thick, commercial-grade wear layer, is built to handle that kind of abuse day in and day out without showing significant scratches or scuffs.

It's this sheer resilience that explains its rapid adoption across the Middle East. For twelve years straight, the market has seen a 25% jump in the production of PVC floor, wall, and ceiling coverings. That's a powerful vote of confidence from the industry. With projections showing the market will hit 277 million square metres by 2035, its place as a core building material is undeniable.

Solving Key Environmental and Practical Hurdles

Beyond toughness, water resistance is a game-changer, especially in the UAE's humid, coastal climate. PVC is inherently non-porous. Spills, moisture, and high humidity simply won't cause it to warp, swell, or break down like natural wood can. This makes it a perfect fit for kitchens and bathrooms, of course, but also for any ground-floor commercial space where moisture ingress is a real possibility.

That non-porous surface delivers another huge win: hygiene. With no grout lines or natural fibres to trap dirt and microbes, PVC flooring is incredibly easy to clean and sanitise. This is a non-negotiable feature for:

- Healthcare and F&B sectors where infection control is absolutely critical.

- Schools and nurseries that need tough surfaces that can be easily maintained.

- High-end residential projects where clients expect luxury without the high maintenance.

Unlocking Design Freedom and Acoustic Comfort

But all this functionality doesn't mean you have to sacrifice aesthetics. Not at all. Modern PVC flooring materials offer a stunning range of design possibilities. From luxury vinyl planks that convincingly mimic the grain of rare woods to tiles that replicate the look of polished concrete or marble, the creative options are vast. It’s a way for architects and designers to achieve their vision without blowing the budget or compromising on performance. You can see how this fits into the bigger picture by exploring trending construction materials in Dubai and their diverse applications.

One of the most overlooked benefits is acoustic performance. In busy commercial spaces—from open-plan offices to hotel lobbies—controlling noise is essential for creating a pleasant atmosphere. PVC flooring naturally helps dampen ambient sound and reduce the clatter of footfalls, contributing to a more comfortable and productive environment for everyone inside.

Where to Use PVC Flooring in UAE Projects

A building material is only as good as its real-world application. For pvc flooring materials, their true strength is how they solve specific, everyday challenges across the UAE's demanding construction landscape. It's one thing to talk about a material in theory; it's another to see it perform under pressure.

Its sheer adaptability makes it a go-to choice for a huge range of sectors, each with its own checklist of must-haves for durability, hygiene, and of course, style.

High-Traffic Commercial and Retail Spaces

Think about the sheer footfall in the commercial hearts of Dubai and Abu Dhabi. Shopping malls, busy corporate offices, and showrooms endure a constant assault from thousands of footsteps, rolling carts, and scuffing shoes every single day. This is exactly the kind of environment where PVC flooring proves its worth.

Luxury Vinyl Planks (LVP) and Tiles (LVT) are the champions in this arena. They bring some serious advantages to the table:

- Extreme Durability: Their tough wear layer is built to take a beating from relentless foot traffic and even heavy stock trolleys, keeping the floor looking sharp for years.

- Branding Opportunities: With a massive library of designs, you can create a look that perfectly matches a brand’s identity. Imagine replicating the feel of natural stone for a high-end boutique or laying down a custom pattern in a corporate headquarters.

Healthcare and Educational Facilities

In places like hospitals, clinics, and schools, hygiene isn't just a preference—it's paramount. This is where seamless sheet vinyl flooring becomes the industry standard, and for good reason. When the seams are properly heat-welded, the result is a completely impervious surface. Bacteria have nowhere to hide, and the floor is incredibly simple to sanitise.

This seamless, non-porous quality isn’t just a nice feature. It's a critical part of modern infection control protocols in healthcare and a practical lifesaver in busy school canteens and science labs.

Hospitality and Residential Developments

The UAE’s hospitality sector is famous for its glamour, but behind the scenes, practicality is king. LVT and LVP offer the rich, warm look of hardwood or the cool sophistication of marble for hotel rooms, lobbies, and restaurants, but without the maintenance nightmare. It's waterproof, resists stains, and is quiet underfoot, all of which elevate the guest experience.

This same blend of high-end aesthetics and real-world resilience makes it a huge hit in modern residential towers and villas. Homeowners get a stunning, durable floor that can easily handle the chaos of family life. Of course, with any material, it's vital to ensure everything is up to code. You can learn more by navigating the regulations for building materials in the UAE to make sure your project ticks all the right boxes. That knowledge is key to a smooth, successful build.

Making the Smart Choice in PVC Flooring

Choosing the right pvc flooring materials is about more than just matching a colour swatch. It’s a critical decision that ripples through your project’s entire lifecycle, affecting everything from durability to long-term maintenance costs. Getting it right from the start means taking a practical look at a few key factors to ensure the floor you specify today will still be performing a decade from now.

The first question you should always ask is: how many feet will be walking on this floor? The answer directly points you to the most important spec – the wear layer thickness. For a quiet residential bedroom, a standard wear layer will do the job just fine. But for a high-traffic retail space in a Dubai mall or a busy office corridor, a heavy-duty commercial-grade wear layer isn't just a good idea, it's essential for survival.

Aligning Installation with Subfloor Conditions

Next, you have to get honest about your subfloor. Is it a perfectly smooth, level concrete slab? If so, you’ve got the ideal canvas for a glue-down installation, which delivers unbeatable stability.

But in the real world, we often deal with less-than-perfect scenarios. If you’re renovating over old tiles or dealing with a slightly uneven surface, a modern click-lock system is your best friend. A rigid core product, in particular, can be far more forgiving and save you a small fortune in subfloor preparation.

This brings you to a key decision point on installation:

- Glue-Down Systems: These are the gold standard for stability, especially in large, open-plan areas that will see heavy rolling loads like office chairs or service carts. The catch? They demand a flawless subfloor.

- Click-Lock Systems: These are the champs of fast installation. They handle minor subfloor imperfections gracefully and make future repairs much simpler—if one plank gets gouged, you can often just replace that single piece.

Looking Beyond the Upfront Cost

A truly smart decision looks past the initial invoice and considers the total cost of ownership. Some pvc flooring materials might seem pricier at first, but they can save you a bundle down the line if they don't require constant waxing or polishing. That’s a real saving in both labour and material costs over the life of the building.

Always play the long game. The cheapest flooring option today can quickly become the most expensive headache over ten years if it demands constant attention or needs to be replaced prematurely.

Finally, we can’t ignore sustainability, especially as projects across the UAE chase higher green building standards. When you’re comparing products, look for those with a high percentage of recycled content. Check for certifications that guarantee low Volatile Organic Compound (VOC) emissions, too. This isn't just about ticking a box; it leads to healthier indoor air quality and shows your project is aligned with the region’s serious commitment to sustainable construction. Taking this kind of well-rounded approach is what separates a good flooring choice from a great one.

Clearing Up Common PVC Flooring Questions

Even after diving into the details, a few practical questions always pop up when it's time to specify pvc flooring materials. Let’s get you some clear answers to the common queries we hear from professionals on the ground.

Is PVC Flooring Genuinely Waterproof?

Yes, the surface of PVC flooring itself is 100% waterproof. This is what makes it a go-to choice for spaces that are constantly dealing with moisture, from commercial kitchens and bathrooms to busy cafes across the UAE.

But here’s the crucial part: the installation method determines how truly watertight the entire floor is. A heat-welded vinyl sheet creates a completely seamless, impermeable barrier. With click-lock planks, however, prolonged submersion could allow water to seep through the seams. It's all in the details.

What’s the Real-World Lifespan of PVC Flooring?

How long your PVC floor lasts really comes down to two things: the quality of its wear layer and how much foot traffic it has to handle every day. For a home, a good quality vinyl floor can easily look great for 15-25 years.

In a commercial setting, it's a different game. A product specified with a thicker, more durable wear layer can stand up to the relentless pressure of a busy retail store or office for 20 years or even longer.

Can You Install PVC Flooring Directly Over Old Tiles?

In many cases, absolutely. This is a huge time-saver in renovation projects. Rigid core PVC planks (LVP) are particularly well-suited for being laid directly over existing ceramic or porcelain tiles.

The golden rule is that the original floor must be flat, level, and firmly in place. Deep grout lines might need some prep work. A quick but thorough subfloor check is non-negotiable before you start.

For a comprehensive range of premium pvc flooring materials and other construction essentials designed for the demanding UAE market, look no further than Yasu Trading Co. LLC. Request a quote today and let our team help you source the ideal solutions for your next project.