A Guide to Sourcing Restaurant Equipment

At its core, restaurant equipment is simply the collection of tools, appliances, and machinery that a commercial kitchen uses to prepare, cook, store, and clean up after food service. But that simple definition doesn't do it justice. Choosing the right equipment is one of the most fundamental decisions you'll make, dictating your kitchen's efficiency, safety, and ultimate ability to bring your menu to life. It's the operational heart of your entire establishment.

Building Your Kitchen From the Ground Up

Getting a new restaurant off the ground is a massive project, and the kitchen is the engine room that drives everything forward. Equipping a commercial kitchen isn't just a shopping spree; it's a strategic process where every single piece must earn its place. You're aligning your physical assets with your culinary vision.

Think of your menu as the script and your equipment as the cast. A high-volume café that churns out quick bites needs a very different set of "actors" than a fine-dining spot focused on elaborate, multi-course experiences. The café will lean heavily on high-speed ovens and industrial-grade coffee machines, whereas the fine-dining kitchen will invest in precision gear like sous-vide circulators and combi ovens.

The Four Core Kitchen Zones

The best way to get your head around the layout is to think of the kitchen as four interconnected zones, each with a clear purpose. A logical layout is your best defence against chaos and bottlenecks, ensuring a smooth workflow from the moment ingredients arrive to the final plate presentation.

Breaking it down helps simplify your purchasing decisions:

- Cooking Zone: This is where the heat is. It's home to your ranges, ovens, fryers, and grills.

- Refrigeration Zone: The cold storage hub, featuring everything from massive walk-in coolers and freezers to compact under-counter fridges.

- Preparation Zone: Where the magic begins. This area is kitted out with work tables, mixers, slicers, and prep sinks.

- Warewashing Zone: The clean-up station, housing commercial dishwashers, three-compartment sinks, and drying racks.

Creating a Cohesive Workflow

Real efficiency is born when these zones work together seamlessly. Your layout should follow the natural journey of the food, minimising how many steps your staff have to take. For instance, the prep area should sit logically between cold storage and the main cooking line. This kind of thoughtful design cuts down on wasted movement and boosts productivity, which directly impacts your service speed and bottom line.

A well-planned kitchen layout can increase a restaurant's efficiency by up to 25%. This isn't just about moving faster; it's about reducing staff fatigue and cutting the risk of cross-contamination, making for a safer and more pleasant work environment.

One crucial element you can't overlook when building from scratch is a powerful ventilation system. For an in-depth look at what's required, this guide on commercial kitchen ventilation systems is a fantastic resource. In the UAE, proper ventilation isn't just a regulatory hurdle—it's absolutely essential for maintaining air quality and ensuring your team's safety.

Ultimately, every decision you make about your restaurant equipment defines what your kitchen is capable of. If you treat this stage as a strategic planning phase instead of just a shopping trip, you’re laying the groundwork for an efficient, profitable, and successful operation for years to come.

A Closer Look at Essential Equipment Categories

Once you have a handle on the basic kitchen zones, it's time to dig into the specific hardware that brings each area to life. Every piece of equipment has a job to do, and choosing the right tools is about creating a synchronised system that works perfectly for your menu and service style. Think of it less as a shopping list and more as casting the key players for your operational team.

The choices can feel overwhelming. You’ll be weighing up everything from mighty combi ovens that can steam, bake, and roast all in one, to the trusty gas ranges that often form the heart of the cooking line. In the cold zone, you might be deciding between a huge walk-in cooler for bulk storage and a high-tech blast chiller for getting food through the danger zone quickly and safely. Every decision you make will directly influence your kitchen's workflow, energy bills, and the quality of the food on the plate.

The Foundation: Food Preparation

Long before the sizzle hits the pan, the prep zone is where the magic really begins. This is the engine room of your kitchen, where raw ingredients are transformed. When choosing equipment for this area, two words should be top of your mind: durability and hygiene.

Stainless-steel tables are the non-negotiable workhorses here. You need sturdy, food-grade surfaces that are a breeze to sanitise and can take a beating day in, day out. Alongside these, industrial-grade mixers, food processors, and slicers are essential for automating repetitive jobs. They not only save a huge amount of staff time but also ensure every slice and dice is consistent.

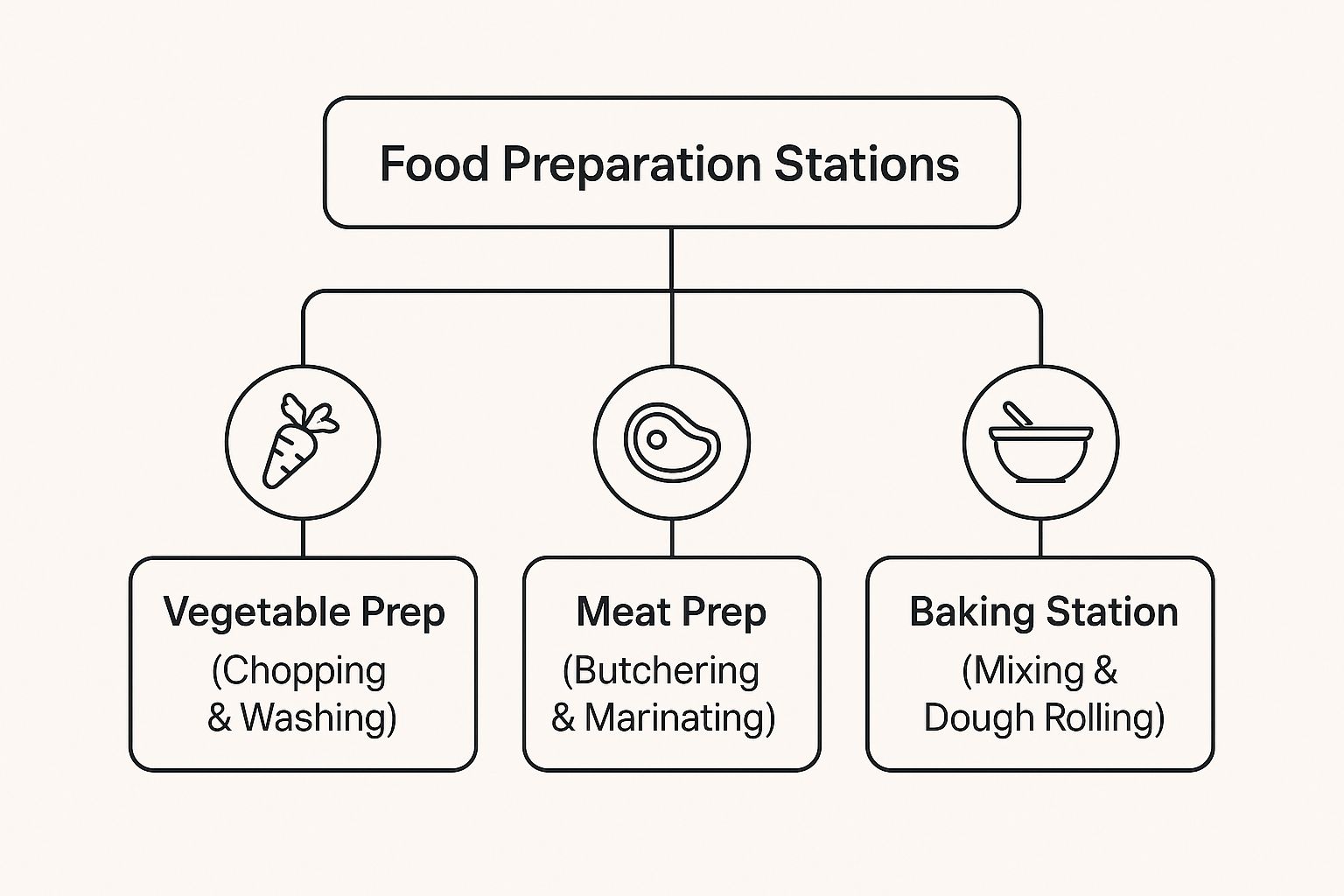

The image below shows how a well-thought-out prep station can be broken down into distinct, functional areas.

Keeping these prep functions separate isn't just about being organised; it's a critical step in preventing cross-contamination and creating a workflow that makes sense for your team.

The Main Event: The Cooking Line

The cooking line is the stage where your culinary vision becomes a reality. The equipment you select here must directly serve your menu. A high-end steakhouse will pour its budget into top-of-the-line grills and charbroilers, whereas an authentic Italian spot will prioritise powerful pasta cookers and specialty pizza ovens.

Here are a few of the usual suspects you'll find on any cooking line:

- Ranges: The classic choice, available in gas or electric, for all your sautéing, boiling, and simmering needs.

- Ovens: Convection ovens are fantastic for even baking, while combi ovens offer incredible versatility by combining steam and convection heat.

- Fryers: Absolutely essential for so many crowd-pleasers, from perfect chips to crispy fried chicken.

- Grills and Griddles: Your go-to for everything from morning eggs and pancakes to perfectly seared burgers and steaks.

The sheer importance of this category is clear when you look at the numbers. The Middle East restaurant equipment market is a huge piece of the wider foodservice industry, valued at around USD 4.4 billion. It's expected to grow at nearly 7.5% CAGR through 2030. Within that massive figure, cooking equipment like ovens and grills is the biggest player, accounting for about 45.78% of the market's revenue.

The Unsung Heroes: Refrigeration and Warewashing

Away from the heat and action of the cooking line, refrigeration and warewashing are the critical support systems that keep the whole operation running smoothly. Solid cold storage is non-negotiable for food safety and managing your inventory. Your setup could involve anything from large walk-in units to smaller under-counter fridges tucked into the prep line for quick access.

Good refrigeration isn't just about keeping things cold. It's about protecting your investment in inventory and safeguarding public health. One major freezer failure can cost you thousands of dirhams in spoiled food and attract the wrong kind of attention from regulators.

Likewise, the warewashing station is the backbone of your hygiene standards. It ensures you have a constant flow of clean dishes, glassware, and utensils, especially when you're in the middle of a frantic dinner rush. A small bar might get by with an under-counter glasswasher, but a high-volume restaurant needs a beast of a conveyor dishwasher that can churn through hundreds of racks an hour. Speed, efficiency, and sanitation are what count here.

To make sure you're not missing anything, it's always a good idea to work from a comprehensive checklist. This ultimate restaurant kitchen equipment list is a great starting point for building out a plan that truly fits your restaurant's needs.

To help you visualise this, here's a quick breakdown of essential equipment organised by its home in the kitchen.

Essential Equipment Checklist by Kitchen Zone

| Kitchen Zone | Essential Equipment Examples | Key Selection Factor |

|---|---|---|

| Preparation | Stainless-steel tables, food processors, mixers, slicers, sinks | Durability and Ease of Cleaning |

| Cooking Line | Ranges, ovens (convection/combi), grills, fryers, salamanders | Power Source (Gas/Electric) and Menu Suitability |

| Refrigeration | Walk-in coolers/freezers, reach-in fridges, under-counter units | Capacity, Energy Efficiency, and Temperature Control |

| Warewashing | 3-compartment sink, conveyor dishwasher, under-counter glasswasher | Volume Capacity and Cycle Speed |

| Storage | Dry storage shelving (wire or solid), dunnage racks | Material (e.g., stainless steel, polymer) and Weight Capacity |

| Service Area | Heat lamps, POS systems, beverage dispensers, ice machines | Reliability and Speed of Service |

This table serves as a simple guide to ensure you're placing the right tools in the right places for a kitchen that flows seamlessly.

Making a Smart Equipment Investment

When you're outfitting a kitchen, the equipment list comes with some serious numbers. It's a massive capital outlay, and the temptation to slash costs by picking the cheapest option is huge. But I've seen it time and time again: focusing only on the initial price tag is one of the most expensive mistakes you can make.

The reality is that a cheaper machine can quickly turn into a financial black hole. It might bleed money through sky-high utility bills, break down during the Friday night rush, and cost a fortune in repairs. A smart investment isn't just about buying a tool; it's about acquiring an asset that works for you, not against you, for years to come.

The True Cost of Ownership

The secret to a wise purchase lies in what we call lifecycle cost. It’s a simple concept but incredibly powerful. It forces you to look at the total expense of a piece of equipment, from the day it’s delivered to the day you finally replace it.

Think of it like buying a car. You don't just consider the showroom price, do you? You factor in fuel consumption, insurance, servicing, and the cost of parts. Your kitchen equipment is no different.

Lifecycle cost isn't just some accounting term; it's your best strategic tool. Calculating the total cost of ownership lets you make decisions based on data, not just a price tag. It’s about choosing long-term value over a quick, short-term saving.

That seemingly affordable combi oven that guzzles electricity and needs a technician on speed dial? It will almost certainly end up costing you more than the premium, energy-efficient model that just works, day in and day out. This is the kind of forward-thinking that separates a good investment from a bad expense.

Prioritising Material Quality and Durability

In a high-pressure commercial kitchen, flimsy equipment doesn't last a week. The quality of construction isn't a "nice-to-have"—it's an absolute necessity. For any surface that touches food, the undisputed champion is food-grade stainless steel, typically grades like 304.

And it’s not just about looking clean and professional. There are rock-solid reasons why stainless steel is the industry standard:

- It's Non-Porous: The surface won’t absorb bacteria, flavours, or odours. This makes it incredibly hygienic and easy to keep sanitised, a non-negotiable for meeting UAE health codes.

- It Resists Corrosion: It shrugs off moisture, aggressive cleaning chemicals, and acidic ingredients without a hint of rust or decay.

- It's Tough: Stainless steel is built to take a beating—the constant heat, the impacts, and the general abuse of a busy service.

Investing in high-quality materials is really an investment in longevity. You’re buying peace of mind, reducing the chance of a premature failure, and ensuring your kitchen stays safe and efficient. This is crucial as the market grows; the region's commercial cooking equipment sector is projected to blow past USD 580 million between 2025 and 2030. You can get a better sense of where things are heading by reading up on the Middle East's commercial cooking equipment market trends.

Energy Efficiency and After-Sales Support

Your DEWA bill is one of those operational costs that never stops. Energy-efficient equipment is one of the single most effective ways to wrestle that cost under control. Always look for appliances with recognised energy-saving certifications; they are engineered to do the same job while using less power.

But the machine itself is only half the story. The support you get after the sale is just as critical. A warranty is a great start, but what happens when it runs out? Before you sign anything, ask your supplier some tough questions:

- Spare Parts: How fast can you get critical spare parts? A two-week wait for a component from Europe is two weeks of a dead machine and lost revenue.

- Technicians: Do you have trained technicians based locally who can get to me quickly?

- Service Plans: Can I get a preventative maintenance contract? These are lifesavers, helping you catch small problems before they become catastrophic failures.

When a supplier provides robust, local support, they stop being just a vendor. They become a partner in your operation. And in this business, a good partner is worth their weight in gold.

How to Source Your Equipment in the UAE

Finding the right restaurant equipment in the UAE’s dynamic market isn’t just about getting a good price—it's about building a solid procurement strategy. The suppliers you choose and how you buy from them will directly affect your kitchen's daily rhythm and long-term costs. Think of it as creating a supply chain you can truly count on.

This journey usually begins with a critical decision: do you work with local suppliers or go directly to international brands? Each option has its own set of pros and cons, and it’s well worth taking the time to weigh them up.

Local Suppliers vs International Brands

Partnering with a UAE-based supplier offers some immediate, practical advantages. They have boots on the ground and an invaluable understanding of the local scene, from navigating the climate's unique demands to meeting specific health regulations.

Most importantly, being local means they can respond quickly. When a crucial piece of equipment goes down, their proximity means faster service calls and easier access to spare parts. That can be the difference between a small hiccup and a complete shutdown of your service.

International brands, of course, might offer exclusive tech or a prestigious name that elevates your restaurant's profile. But that prestige can come with logistical headaches. Waiting for spare parts to arrive from overseas can mean days or even weeks of downtime, and their service teams might not be as available or familiar with the challenges of operating in this region.

For most restaurants, a local partner who guarantees swift service and parts availability is a massive strategic advantage. Downtime is the enemy of profitability, and a supplier who can get you back up and running in hours—not weeks—is priceless.

This is especially true when it comes to the bones of your kitchen. Sourcing quality materials is fundamental, which is why it pays to find the best stainless steel suppliers in the UAE for custom fabrication work.

New Versus Certified Used Equipment

Next up is the classic debate: invest in brand-new gear or explore the market for certified used equipment? This is really a question of balancing your budget against your comfort level with risk.

- New Equipment: The biggest selling point here is reliability. You get a full manufacturer's warranty, the latest in energy-efficient technology, and zero wear and tear. The upfront cost is higher, but what you’re really buying is peace of mind.

- Certified Used Equipment: This path can deliver major cost savings, freeing up precious capital to invest elsewhere in your business. The trick is to source from a reputable dealer who certifies their stock, provides a limited warranty, and can show you a clear service history.

A good rule of thumb? Go new for your workhorses—the main cooking range, the primary refrigerators. For less critical items like prep tables or shelving, certified used can be a very smart, budget-friendly move.

Negotiating Contracts and Planning Logistics

Once you've settled on a supplier, it's time to talk terms. A solid contract is about much more than the final price; it needs to clearly define the terms of your relationship to protect your investment for the long haul.

Key Contractual Elements to Review:

| Contract Section | What to Look For |

|---|---|

| Warranty Terms | Get specifics on what parts and labour are covered and for how long. Pay close attention to any exclusions. |

| Service Level Agreement (SLA) | This defines guaranteed response times for service calls. For critical equipment, push for a 4-8 hour response time. |

| Delivery & Installation | Clarify who handles logistics, site prep, and the professional commissioning of your new equipment. |

| Payment Schedule | Make sure the deposit, milestone payments, and final payment terms are clearly laid out and tied to successful installation. |

With the regional hospitality sector booming, locking in reliable suppliers is more important than ever. The Saudi Arabian foodservice equipment market alone is projected to grow at a CAGR of 8.5% between 2025 and 2030, with kitchen equipment accounting for over 46% of that. Building a strong supplier relationship now is a smart play for the future.

Getting the Installation Spot-On

You can buy the best piece of restaurant equipment in the world, but it’ll let you down if it’s installed poorly. Getting your hands on these high-value assets is only half the job. The real test is making sure they’re set up for peak performance from day one, which is where a flawless installation process comes in. A botched setup is a recipe for instant operational headaches, serious safety risks, and a long list of expensive service calls down the road.

Think of installation as the final, most critical step in your procurement journey. It’s the moment your investment is either proven right or completely undermined. Rushing this stage is a classic mistake. The errors made here can create a ripple effect, causing problems across your entire operation for years to come. A professional, step-by-step approach isn't just a good idea—it’s essential for protecting your gear and setting your kitchen up for success.

Pre-Installation Site Checks

Long before a single box arrives, a few critical checks need to happen on-site. This is all about making sure your kitchen is genuinely ready for its new hardware. It’s a simple step that helps you avoid that all-too-common scenario: the delivery team shows up, but the site isn't prepped, leading to frustrating delays and extra charges.

Your checklist should be laser-focused on verifying all the utility connections right where the equipment will stand.

- Gas Lines: Are the gas lines delivering the right pressure (psi)? Do the connector sizes match what the manufacturer requires?

- Water Supply: What are the water inlet temperatures and pressure like? Crucially, is the drainage system ready to handle the wastewater it’ll produce?

- Electrical Outlets: Does the voltage, amperage, and plug type perfectly match the equipment’s needs? A mismatch here isn’t just an inconvenience; it’s a major fire hazard.

It's a well-known fact in facilities management that up to 40% of equipment performance problems can be traced right back to an incorrect installation. That really drives home how a small oversight at the start can grow into a massive operational headache.

The Commissioning Process

Once the equipment is physically in place and hooked up, it’s time for professional commissioning. This is so much more than just flipping a switch to see if it powers on. Commissioning is a detailed process where certified technicians test, calibrate, and fine-tune every component to make sure the unit works exactly as the manufacturer designed it to.

During this stage, technicians will run through critical safety checks, calibrate thermostats for pinpoint temperature accuracy, and test every operational cycle. This is especially vital for things like ventilation. A poorly commissioned exhaust system won’t pull heat and grease out of the air effectively, leading to a dangerous and miserable working environment. Getting this right is a huge part of kitchen safety, something we cover in our guide on the importance of a proper kitchen exhaust hood.

Handover and Staff Training

The last piece of the puzzle is a proper handover from the technical team to your kitchen crew. This should never be a quick "sign here" moment. The goal is to give your team the confidence and knowledge to operate and look after the new equipment correctly from the very first service.

A solid handover always includes:

- A Full Demo: A complete walkthrough of all the machine’s functions, different modes, and controls.

- Daily Maintenance Rundown: Clear, simple instructions on how to clean the equipment daily, including which chemicals are safe and which to avoid.

- Basic Troubleshooting: A quick guide on how to handle common error codes or small glitches without having to immediately call for a technician.

- All the Paperwork: Handing over all user manuals, warranty cards, and the contact details for technical support.

When you treat installation as a critical project phase instead of an afterthought, you give every piece of equipment the best possible start. It ensures your new gear is ready to deliver the performance and reliability you invested in from day one.

Proactive Maintenance to Protect Your Investment

Your journey with top-tier restaurant equipment is far from over once the final piece is installed. Think of these machines as the heart of your kitchen—the engine that powers your entire operation. And just like any high-performance engine, they need regular, consistent care to keep running at their best.

Making the switch from a reactive, "fix-it-when-it-breaks" approach to a proactive maintenance programme is one of the smartest financial moves you can make. It’s the difference between controlling your kitchen's destiny and letting an unexpected breakdown dictate your day.

This forward-thinking strategy stops the chaos of a mid-service meltdown, which almost always results in lost revenue, frustrated customers, and eye-watering emergency repair bills. It’s about protecting your assets, pushing their lifespan further, and running a safer, more dependable kitchen.

Daily Care Versus Scheduled Servicing

Great maintenance is a two-part harmony, with distinct roles for your kitchen staff and your specialist technicians. One of the most common missteps is blurring these lines, which often leads to crucial tasks falling through the cracks.

Daily Upkeep (Your Crew): This is your first line of defence. Your team should be well-drilled in daily routines like wiping down every stainless steel surface, clearing out fryer grease traps, and cleaning dishwasher filters. These small, consistent actions are what stop a little grime from turning into a big, expensive problem.

Preventative Maintenance (The Experts): This is the deep-dive service performed by trained professionals on a set schedule. They’re the ones handling the technical stuff—calibrating oven thermostats, checking refrigerant levels in your chillers, inspecting gas lines for leaks, and lubricating moving parts. These jobs demand specialised tools and expertise.

The Power of a Maintenance Log

You can't manage what you don't measure. A simple maintenance log is an incredibly effective tool for keeping a finger on the pulse of every appliance in your kitchen. It doesn’t have to be fancy; a shared spreadsheet or even a classic logbook will do the trick.

For each machine, your log should capture:

- Equipment Details: The model, serial number, and the date it was installed.

- Service History: A running list of all scheduled maintenance checks.

- Repair Records: Notes on any repairs, including the problem, what parts were replaced, and the cost.

- Technician Notes: Any important observations or recommendations from your service provider.

This log builds a clear history, helping you spot repeat offenders and make smart calls on when it’s cheaper to replace a unit than to keep patching it up. For a more thorough look at this, our guide on the benefits of preventative maintenance for your equipment gets into even more detail.

A well-cared-for piece of commercial kitchen equipment can last up to 30% longer than one that's been ignored. That extra lifespan translates directly into serious long-term savings and a much better return on your investment.

Choosing a Reliable Service Partner

Think of a service contract with a trusted UAE provider as your insurance policy against downtime. When you’re looking for a partner, don't be afraid to ask the tough questions. What’s their guaranteed response time for an emergency call? This detail is non-negotiable.

A truly great service partner becomes an extension of your own team. They offer expert advice and work behind the scenes to ensure your kitchen never misses a beat, protecting the valuable restaurant equipment that keeps your business thriving.

A Few Common Questions, Answered

Diving into the world of commercial kitchen equipment can feel overwhelming, especially when you're dealing with the unique demands of the UAE. Let's tackle some of the most common questions we hear from hospitality and construction professionals across the region.

How Does the UAE Climate Affect My Equipment Choices?

This is a big one. The intense heat and humidity here are non-negotiable factors. Your top priority should be equipment built to withstand these conditions.

Look for refrigerators and freezers with heavy-duty compressors and superior insulation, specifically rated for high ambient temperatures. This prevents them from constantly running, saving you on DEWA bills and extending their lifespan. For all equipment, high-grade stainless steel is essential to fend off corrosion from the humid, salty air. It's also smart to choose units with sealed electronics to protect sensitive components from dust and moisture.

Should I Go for Brand New or Second-Hand Equipment?

This really comes down to balancing your budget against risk. For the heart of your kitchen—your ovens, ranges, and primary refrigeration—buying new is almost always the right call. It comes with a manufacturer’s warranty, the latest energy-efficient tech, and peace of mind.

On the other hand, you can find incredible value in certified used equipment for less critical items. Think stainless steel worktables, shelving units, or prep sinks. These items don't have complex moving parts, so a quality second-hand piece from a trusted dealer can save you a significant amount of cash. Just make sure to check its history and ask if they offer any kind of limited warranty.

A smart hybrid approach works wonders for most new kitchens. Invest your capital in new, mission-critical cooking and cooling units, but source your static items like tables and shelves from the certified pre-owned market.

How Can I Be Sure My Kitchen Meets Local Regulations?

Navigating local rules from bodies like Dubai Municipality or ADFCA can be tricky, but there’s a simple way to stay compliant: only work with reputable, established suppliers.

A good supplier lives and breathes these regulations. Before you even think about buying, ask them to provide the official certification documents for any piece of equipment. This paperwork is your golden ticket for passing health and safety inspections without any headaches. Don't leave this to chance—it's crucial for operating legally.

What's the Real Difference Between a Warranty and a Service Contract?

It’s easy to confuse these two, but they serve very different purposes.

A warranty is reactive. It's the manufacturer's promise to fix or replace a product if it fails due to a defect within a certain timeframe. You don't pay extra for it; it's included with a new purchase.

A service contract, however, is proactive. This is a separate, paid agreement for regular, scheduled maintenance. A technician will come out to inspect, clean, and calibrate your equipment to keep it running perfectly.

Think of it like this: a warranty fixes the problem after your oven breaks down mid-service. A service contract is designed to prevent it from ever breaking down in the first place, saving you from disastrous downtime and lost revenue.

For all your construction and hospitality fit-out needs, from durable hardware to specialised fittings, Yasu Trading Co. LLC provides the high-quality materials and expert guidance required to build and maintain exceptional facilities. Discover our full range of products at https://yasutrading.com.