Smart Fasteners and 3D‑Printed Bolts: The Future of Hardware

For centuries, the humble bolt has been a cornerstone of construction and manufacturing, a simple yet effective tool for holding our world together. But what if these passive components could communicate, adapt, and even generate their own data? We are on the verge of a hardware revolution, moving from static metal to dynamic, intelligent systems. The convergence of IoT, advanced materials science, and additive manufacturing is transforming simple connectors into data-rich assets. This shift is not limited to industrial applications; even everyday environments are seeing an influx of intelligent hardware, such as smart appliances in modern renovation, transforming passive components into active partners.

This article explores eight groundbreaking advancements in smart fasteners and 3D-printed bolts: the future of hardware is here, and it is reshaping what's possible. From self-monitoring bolts that prevent catastrophic failures in high-rise towers to custom-printed fasteners for aerospace and medical implants, these innovations offer unprecedented levels of precision, efficiency, and safety. We will delve into specific examples, practical applications, and the unique benefits each technology brings to sectors ranging from construction and real estate development to specialised engineering fields. Prepare to see how these intelligent components are building a world that is stronger, lighter, and more responsive than ever imagined.

1. Smart Bolts with Integrated Load Sensors

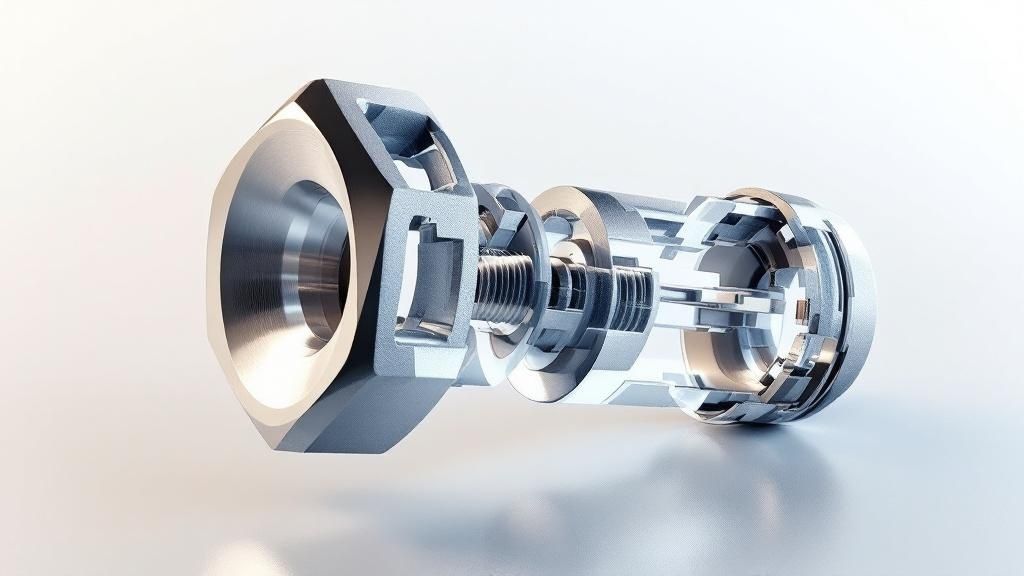

Smart bolts represent a revolutionary advancement in structural health monitoring, transforming traditional passive fasteners into active, data-gathering components. These are not ordinary bolts; they are engineered with embedded sensors such as strain gauges or piezoelectric load cells. This integration allows them to continuously measure and monitor crucial parameters like tension, torque, and clamp load in real-time.

By functioning as IoT-enabled devices, these fasteners can wirelessly transmit data to a central monitoring system. This constant stream of information provides engineers and maintenance teams with an unprecedented view of a structure's integrity. It enables them to detect potential issues like loosening due to vibration, material fatigue, or excessive stress long before they escalate into catastrophic failures. This proactive approach marks a significant shift from scheduled, often inefficient, maintenance checks to condition-based, predictive maintenance.

Why It's a Game-Changer

The primary benefit of smart bolts lies in their ability to provide certainty in clamped joints. For critical infrastructure, such as high-rise buildings in the UAE, large-scale industrial machinery, or transportation systems, ensuring that every bolt maintains its design tension is paramount for safety and operational efficiency.

- Aerospace: Airbus utilises smart bolts in its A350 XWB aircraft to monitor the structural health of critical airframe connections.

- Renewable Energy: Wind turbine manufacturers deploy them in tower flange connections, which are subject to immense and fluctuating loads.

- Infrastructure: Major bridge projects in Japan and Europe incorporate smart bolts for continuous seismic and structural monitoring.

- Oil & Gas: They are used on critical pipeline connections on offshore platforms to prevent dangerous leaks and structural compromises.

This infographic provides a quick reference for the typical performance specifications of these advanced fasteners.

These specifications highlight the technology's capability to deliver precise, long-term monitoring across significant distances, making it adaptable for large and complex structures.

Actionable Implementation Tips

To maximise the benefits of smart fasteners and 3D-printed bolts, especially in demanding environments, a strategic approach is essential.

- Prioritise Critical Joints: Focus deployment on safety-critical or high-stress locations rather than instrumenting every single fastener. This optimises cost and data relevance.

- Establish Baselines: Record initial tension and load readings immediately after proper installation to create a reliable baseline for future monitoring.

- Set Clear Alert Thresholds: Work with structural engineers to define specific alert parameters based on design calculations and safety factors.

- Plan Data Management: Before deployment, develop a robust protocol for managing, storing, and analysing the incoming data to ensure it translates into actionable insights.

2. Titanium 3D-Printed Aerospace Fasteners

Additive manufacturing is redefining the production of high-performance hardware, with titanium 3D-printed fasteners leading the charge. Using technologies like Direct Metal Laser Sintering (DMLS), these fasteners are built layer by layer from titanium powder. This process enables the creation of complex internal geometries and optimised shapes that are impossible to achieve with traditional subtractive machining, a key differentiator from standard MS or GI bolts.

This method allows for significant weight reduction through topology optimisation while maintaining or even enhancing strength. Engineers can design fasteners with integrated functionality, such as built-in locking mechanisms or custom heads, consolidating parts and simplifying assembly. This level of design freedom is crucial in sectors like aerospace and medical, where every gram and component counts. The ability to create bespoke, high-strength fasteners on-demand marks a pivotal evolution in hardware manufacturing.

Why It's a Game-Changer

The core advantage of 3D-printed titanium fasteners is their unparalleled strength-to-weight ratio and design flexibility. For industries where performance and weight are critical, this technology unlocks new possibilities for efficiency and innovation. It moves beyond standard off-the-shelf hardware to custom-engineered solutions for specific, high-stakes applications.

- Aerospace: Boeing uses 3D-printed titanium fasteners in its 787 Dreamliner, while SpaceX employs them in Falcon 9 rockets to save weight without compromising structural integrity.

- Automotive: Formula 1 teams produce bespoke lightweight fasteners for aerodynamic components, gaining a competitive edge through mass reduction.

- Medical: Custom titanium bone screws and implants are created to match a patient's specific anatomy, improving surgical outcomes.

- Defence: Military applications leverage this technology for rapid prototyping and production of specialised hardware for advanced equipment.

Actionable Implementation Tips

Adopting 3D-printed titanium fasteners requires a specialised approach to design and quality assurance to fully leverage their potential.

- Design for Additive: Optimise fastener designs specifically for 3D printing, incorporating internal lattices or topology-optimised shapes rather than replicating machined designs.

- Specify Post-Processing: Critical applications require post-processing steps. Use Hot Isostatic Pressing (HIP) to eliminate internal porosity and specify heat treatments to relieve residual stresses.

- Implement Rigorous QA: Use advanced inspection methods like CT scanning for internal defect detection to ensure parts meet stringent aerospace or medical standards.

- Prioritise Material Science: Work closely with material scientists to select the right titanium alloy (e.g., Ti-6Al-4V) and printing parameters for the intended operational environment.

3. Self-Locking Nylon 3D-Printed Fasteners

Self-locking nylon fasteners represent a significant leap in customisable hardware, leveraging advanced 3D printing technologies like Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF). Instead of relying on separate components like lock washers or chemical thread-locking compounds, these fasteners integrate complex anti-loosening features directly into their geometric design. This is made possible by the unique properties of engineering-grade nylons (PA11/PA12), which offer a compelling combination of strength, flexibility, and chemical resistance.

These technologies enable the creation of bespoke bolts, clips, and connectors with integrated features such as ratchet mechanisms, living hinges, or specially profiled threads that deform slightly upon tightening to create a secure, vibration-resistant connection. This makes them a prime example of how smart fasteners and 3D-printed bolts: the future of hardware is moving towards function-integrated, single-part solutions, reducing assembly complexity and component count.

Why It's a Game-Changer

The primary advantage of 3D-printed nylon fasteners is the ability to produce highly customised, lightweight, and non-corrosive joining solutions on demand. This is particularly valuable for rapid prototyping, specialised assemblies, and applications where metal hardware would be impractical, excessively heavy, or too costly for low-volume production.

- Automotive: Manufacturers use them for assembling interior trim panels and dashboard components where vibration resistance is key.

- Electronics: They are employed in non-structural enclosure assemblies to avoid metal-on-metal contact and reduce weight.

- Medical: Prototypes for medical devices and prosthetics utilise them for creating patient-specific, ergonomic connections for testing.

- Aerospace: Consumer drone manufacturers rely on these fasteners for rapid design iteration and lightweight airframe assembly.

- Furniture: Custom furniture makers create unique, non-visible joinery solutions that would be impossible with traditional hardware.

Actionable Implementation Tips

To effectively integrate 3D-printed nylon fasteners into projects, especially those in the UAE's diverse climate, careful design and material handling are critical.

- Account for Flexibility: Design threads approximately 5-10% oversized to compensate for nylon's inherent flexibility and ensure a snug fit.

- Incorporate Design Aids: Add lead-in chamfers to the bolt tips and nut openings to make initial threading and assembly much smoother.

- Use Permanent Designs: For one-way, permanent assemblies, integrate ratchet or barb features that lock into place and resist removal.

- Control Material Storage: Store unused nylon powder in environments with controlled humidity, as moisture absorption can affect print quality and part performance.

4. RFID-Enabled Tracking Fasteners

RFID-enabled fasteners bridge the gap between physical hardware and digital asset management, embedding tiny radio-frequency identification (RFID) chips directly into the bolt head or nut. This simple addition transforms a standard component into a trackable asset with a unique digital identity. Each fastener can store critical information such as its manufacturing date, material specifications, installation torque values, and a complete maintenance history.

By scanning the fastener with an RFID reader, technicians can instantly access its "digital passport," verifying authenticity and confirming its lifecycle status. This technology revolutionises inventory management, quality assurance, and maintenance verification by automating data capture and eliminating manual record-keeping errors. It provides an indisputable audit trail for every critical connection, a vital capability in high-stakes industries where traceability is non-negotiable.

Why It's a Game-Changer

The core benefit of RFID-enabled fasteners is the creation of a reliable "single source of truth" for each component, ensuring complete traceability from manufacturing to decommissioning. This is essential for compliance, safety, and operational efficiency in complex assemblies and large-scale infrastructure projects.

- Aerospace: Manufacturers like SPS Technologies use them to track the pedigree of every fastener throughout an aircraft's lifecycle, ensuring compliance with stringent aviation standards.

- Automotive: Assembly lines integrate RFID fasteners for automated quality assurance, verifying that the correct bolt is used and torqued correctly at each station.

- Construction: Companies track fastener inventory across large job sites in Dubai and Abu Dhabi, preventing shortages and ensuring the right components are used in specific structural elements.

- Railway: Infrastructure managers use them for track bolt maintenance verification, creating a digital record of inspection and replacement schedules.

Actionable Implementation Tips

Integrating RFID fasteners effectively requires careful planning to ensure reliable data capture and system compatibility, especially within the demanding environments common in the UAE.

- Prioritise Tag Frequency: Choose the RFID frequency based on the application. Low Frequency (LF) tags often perform better in metal-rich environments, which is crucial for most fastener applications.

- Establish Data Standards: Before deployment, create a clear, standardised data protocol for what information is stored on each tag to ensure consistency across projects and suppliers.

- Optimise Reader Placement: Work with engineers to design reader and antenna placement that minimises signal interference from surrounding metal structures, ensuring reliable scan rates.

- Train Installation Teams: Provide thorough training for installers on proper scanning procedures and the importance of verification at each quality gate to maximise the system's effectiveness.

5. Shape Memory Alloy (SMA) Adaptive Fasteners

Shape Memory Alloy (SMA) fasteners represent a revolutionary leap in fastening technology, utilising materials like Nickel-Titanium (Nitinol) that change shape in response to temperature. These fasteners are pre-programmed with a "memory" shape. When heated above their transformation temperature, they revert to this shape, generating a powerful and uniform clamping force without the need for traditional torque application. This unique property enables the creation of self-tightening and damage-tolerant connections.

This mechanism fundamentally changes how joints are secured, particularly in hard-to-reach or sensitive applications. By applying controlled heat, the fastener activates and clamps down with immense, predictable force. This process removes the variability and potential for human error associated with mechanical tightening, offering a highly reliable solution for critical assemblies. These smart fasteners and 3D-printed bolts are truly defining the future of hardware.

Why It's a Game-Changer

The primary advantage of SMA fasteners is their ability to deliver a precise, torque-free clamping force in extreme environments where traditional methods fail. Their self-tightening capability ensures long-term joint integrity under vibration and thermal cycling, making them ideal for high-stakes applications. By incorporating unique hardware, construction and engineering projects can achieve unparalleled performance and safety.

- Aerospace: Boeing uses SMA fasteners in engine components and for space-qualified connections on satellites, where reliability is non-negotiable.

- Medical: Nitinol bone screws are used in implants as they can conform to bone remodelling over time, ensuring a secure fit.

- Energy: Jet engine manufacturers employ them for turbine blade attachments that must withstand intense temperatures and vibrations.

- Automotive: High-performance automotive exhaust systems utilise them to maintain tight seals despite constant thermal expansion and contraction.

Actionable Implementation Tips

To leverage the full potential of SMA adaptive fasteners, precise engineering and application control are crucial for success in specialised projects.

- Specify Transformation Temperature: Set the alloy's transformation temperature 20-30°C above the maximum expected installation or ambient temperature to prevent premature activation.

- Use Controlled Heating: Employ induction heating or another controlled method for localised and uniform activation without overheating surrounding components.

- Design for Shape Recovery: Ensure the joint geometry provides adequate clearance to accommodate the fastener's shape recovery movement during activation.

- Perform Thermal Cycling Tests: Validate the long-term performance and stability of the connection by subjecting prototypes to rigorous thermal cycling tests that mimic operational conditions.

6. Carbon Fiber Reinforced Polymer (CFRP) 3D-Printed Fasteners

Carbon Fiber Reinforced Polymer (CFRP) fasteners represent a significant leap in hardware, merging the exceptional lightweight properties of carbon fibre with the geometric freedom of additive manufacturing. Produced using advanced techniques like continuous fibre 3D printing, these components are not simply plastic bolts with chopped fibres mixed in; they strategically embed continuous carbon fibre strands along critical stress paths. This method creates fasteners with a strength-to-weight ratio that rivals aluminium.

The process allows for the creation of bespoke, high-performance hardware that is also electrically conductive, making it suitable for applications requiring electromagnetic interference (EMI) shielding or static dissipation. This customisation potential makes CFRP 3D-printed bolts a key part of the future of hardware, particularly where weight is a critical design constraint.

Why It's a Game-Changer

The primary advantage of CFRP fasteners is their ability to deliver metal-like strength at a fraction of the weight, a crucial factor in performance-driven industries. This technology, popularised by innovators like Markforged and Anisoprint, allows for rapid prototyping and production of custom fasteners without the need for expensive moulding or machining.

- Aerospace & Drones: Manufacturers use CFRP fasteners to reduce the overall weight of airframes, improving flight time and payload capacity.

- High-Performance Sports: In custom racing bicycles and motorsports, these fasteners secure components while minimising mass for a competitive edge.

- Robotics: They are used in robotic arms and actuation systems where low inertia and high strength are essential for rapid, precise movements.

- Military & Defence: Portable military equipment benefits from the weight reduction, enhancing soldier mobility and operational effectiveness.

Actionable Implementation Tips

To successfully integrate 3D-printed CFRP fasteners, careful design and process control are paramount. These tips ensure optimal performance and reliability.

- Orient Fibres Strategically: During the design phase, ensure continuous fibres are aligned parallel to the primary tensile and shear load directions to maximise strength.

- Increase Thread Engagement: Plan for a thread engagement length that is approximately 50% greater than what would be used for a standard metal bolt to distribute loads effectively.

- Consider Hybrid Designs: For applications requiring frequent assembly and disassembly, embed a metal threaded insert into the CFRP part to prevent thread wear.

- Optimise Print Settings: Use slower print speeds (around 20-40mm/s) for layers with continuous fibre to ensure proper bonding and prevent defects. Post-curing the printed part in an oven can further enhance its mechanical properties.

7. Piezoelectric Energy-Harvesting Fasteners

Piezoelectric energy-harvesting fasteners represent a groundbreaking convergence of fastening technology and power generation. These innovative components incorporate piezoelectric materials that possess the unique ability to convert mechanical stress, such as vibration and strain, into usable electrical energy. When installed in high-vibration environments, they effectively become miniature power plants, generating enough electricity to run embedded sensors, transmit wireless data, or power indicator LEDs.

This technology eliminates the need for batteries or external wiring, enabling the creation of truly autonomous, self-powered monitoring systems. By harvesting ambient energy from their operational environment, these fasteners provide a sustainable and maintenance-free solution for long-term structural health monitoring, transforming a simple bolt into an active part of an IoT ecosystem. This is a critical development in the field of smart fasteners and 3D-printed bolts: the future of hardware.

Why It's a Game-Changer

The core advantage of piezoelectric fasteners is their ability to create perpetual monitoring systems in inaccessible or remote locations. For complex machinery and infrastructure, this completely removes the logistical challenge and cost associated with battery replacement, making continuous data collection feasible where it was previously impractical.

- Infrastructure: They are used in bridge monitoring systems where self-powered strain gauges can report on structural integrity without manual intervention.

- Aerospace: Experimental use in aircraft allows for structural health monitoring on critical components without adding the weight or maintenance burden of batteries.

- Industrial Machinery: Deployed on heavy equipment in remote locations, they power condition-monitoring sensors to predict maintenance needs.

- Transportation: Used in railway track monitoring systems, these fasteners can detect integrity issues and wirelessly transmit alerts, powered solely by the vibrations from passing trains.

Actionable Implementation Tips

To effectively deploy these self-powered fasteners, particularly when selecting the right components for demanding projects, a detailed understanding is key. For more information on selecting advanced components, you can learn more about choosing building hardware in Dubai.

- Maximise Energy Capture: Strategically install fasteners at vibration antinodes, the points of maximum amplitude, to ensure the highest possible energy generation.

- Frequency Matching: Match the resonant frequency of the piezoelectric material with the dominant operational vibration frequencies of the machinery for optimal efficiency.

- Implement Energy Storage: Pair the fastener with a small supercapacitor to store harvested energy, ensuring consistent power for sensors during periods of low or no vibration.

- Design for Low Power: Utilise ultra-low-power microcontrollers and sensors that can operate effectively on the small, intermittent bursts of energy generated by the fastener.

8. Degradable Biopolymer 3D-Printed Fasteners

Degradable biopolymer fasteners represent a significant step towards sustainable hardware solutions, leveraging 3D printing to create components from environmentally conscious materials. These fasteners are printed from biodegradable polymers like Polylactic Acid (PLA) or Polyhydroxyalkanoates (PHA). They are engineered for temporary applications where their controlled degradation eliminates waste and disposal concerns, offering an eco-friendly alternative to traditional single-use plastic or metal hardware.

These smart fasteners and 3D-printed bolts are not designed for permanence but for a specific, finite lifespan. Advanced material formulations allow manufacturers to programme the degradation timeline, ranging from a few weeks to several years, depending on the application's needs. This capability is invaluable for industries focused on reducing their environmental footprint, particularly in prototyping, packaging, and agriculture.

Why It's a Game-Changer

The core benefit of these fasteners is their ability to close the loop in a product's lifecycle, designing for disassembly and natural return to the environment. This is crucial for temporary structures and single-use products where hardware removal and disposal are often impractical and costly.

- Medical: Companies like Biomet use bioresorbable polymers for orthopedic screws that dissolve in the body over time, eliminating the need for a second surgery.

- Agriculture: They are used for plant supports and ties that decompose naturally at the end of a growing season, enriching the soil instead of polluting it.

- Packaging: Major consumer goods companies are exploring biopolymer fasteners for single-use product assemblies that can be composted along with the packaging.

- Prototyping: Development teams in consumer electronics use them for temporary assemblies, reducing plastic waste during the iterative design process.

This approach transforms fastening from a permanent decision to a temporary, planned lifecycle event, aligning with circular economy principles.

Actionable Implementation Tips

To effectively utilise degradable biopolymer fasteners, careful material handling and design considerations are paramount.

- Prioritise Moisture Control: Store biopolymer filaments in sealed bags with desiccant packs. If exposed to humidity, dry PLA at 40-50°C for 4-6 hours before printing to prevent material degradation.

- Compensate for Strength: Design fasteners with 20-30% larger cross-sections compared to their ABS or PETG counterparts to compensate for the inherently lower mechanical strength of most biopolymers.

- Optimise Infill for Structure: Use higher infill percentages, typically between 40-60%, to ensure the fasteners have sufficient structural adequacy for their intended temporary load.

- Test Degradation in Situ: Before full-scale deployment, test the degradation timeline of printed fasteners in the actual operating environment to confirm performance against lab-based estimates.

Smart Fasteners & 3D-Printed Bolts Comparison

| Fastener Type | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Smart Bolts with Integrated Load Sensors | High: Requires sensors, power source, and data management | Moderate to High: Batteries, wireless systems, cloud integration | Continuous structural health monitoring, early failure detection | Critical infrastructure, aerospace, heavy machinery | Early warnings, predictive maintenance, safety improvement |

| Titanium 3D-Printed Aerospace Fasteners | High: Advanced additive manufacturing and quality control | High: Specialized 3D printing and inspection equipment | Lightweight, strong, complex geometry fasteners with reduced waste | Aerospace, medical implants, custom high-performance parts | Weight reduction, design freedom, corrosion resistance |

| Self-Locking Nylon 3D-Printed Fasteners | Medium: 3D printing with mechanical design integration | Low to Moderate: Nylon printing tech and post-processing | Vibration-resistant, corrosion-proof fasteners with integrated locking | Automotive interiors, prototyping, consumer products | Corrosion and vibration resistance, low cost, insulation |

| RFID-Enabled Tracking Fasteners | Medium: Embedding RFID and software infrastructure | Moderate: RFID tags and scanning readers | Automated inventory, installation verification, lifecycle tracking | Assembly lines, aerospace, construction, maintenance | Inventory automation, counterfeit prevention, traceability |

| Shape Memory Alloy (SMA) Adaptive Fasteners | Very High: Specialized materials and precise activation control | High: SMA materials, training, and activation tools | Self-tightening, temperature-responsive clamping force | Aerospace, medical implants, cryogenic and high-temp uses | Tool-free installation, compensates relaxation, fatigue resistance |

| Carbon Fiber Reinforced Polymer (CFRP) 3D-Printed Fasteners | High: Composite 3D printing and fiber orientation design | Moderate to High: Carbon fiber materials and printers | High strength-to-weight ratio, EMI shielding, corrosion-proof | Drones, robotics, electronics, lightweight structural needs | Superior stiffness, corrosion resistance, EMI shielding |

| Piezoelectric Energy-Harvesting Fasteners | High: Integration of piezo materials and power management | Moderate: Piezo materials, circuits, vibration sources | Self-powered sensors, vibration energy harvesting | Remote monitoring, infrastructure health, wireless sensor systems | Battery-free power, continuous monitoring, eco-friendly |

| Degradable Biopolymer 3D-Printed Fasteners | Low to Medium: Standard 3D printing with biopolymer materials | Low: Biopolymer filaments and standard printers | Temporary fasteners with controlled degradation | Temporary assembly, medical implants, eco-sensitive products | Environmentally sustainable, biodegradable, safe for medical use |

Assembling the Future: From Passive Parts to Active Partners

The era of the purely mechanical, passive fastener is rapidly evolving. As we have explored, the intersection of material science, digital technology, and additive manufacturing is fundamentally reshaping our understanding of what a simple nut and bolt can achieve. The future of hardware is no longer about mere connection; it is about communication, customisation, and intelligent integration into the structures they hold together.

We have moved beyond the traditional and into the transformational. Smart bolts equipped with load sensors provide real-time structural health monitoring, turning passive components into active safety systems. Simultaneously, the advent of titanium and carbon fibre reinforced polymer (CFRP) 3D-printed fasteners offers unparalleled strength-to-weight ratios, unlocking new design possibilities in aerospace, automotive, and high-performance construction. These innovations represent a seismic shift from hardware as a commodity to hardware as a critical technological asset.

Key Takeaways for the Modern Builder

The journey through the world of smart fasteners and 3D-printed bolts: the future of hardware has highlighted several critical takeaways for professionals in the UAE's dynamic construction and maintenance sectors:

- From Reactive to Proactive: The most significant shift is towards proactive maintenance. Instead of waiting for a failure, technologies like RFID-enabled fasteners and piezoelectric energy-harvesting bolts allow for continuous monitoring and predictive analysis, preventing catastrophic failures and optimising service schedules.

- Customisation at Scale: Additive manufacturing eliminates the constraints of traditional fabrication. Whether it's a self-locking nylon bolt for a non-conductive application or a degradable biopolymer fastener for temporary medical or environmental use, 3D printing allows for on-demand, highly specific solutions tailored to unique project requirements.

- Enhanced Safety and Efficiency: Shape Memory Alloy (SMA) fasteners that self-tighten with heat and smart bolts that signal their own pre-load status directly translate to safer structures and more efficient, accurate installations. This reduces human error and enhances the long-term integrity of critical joints.

While hurdles such as initial cost, the need for new industry standards, and data management protocols remain, the direction is undeniable. The value proposition of enhanced safety, reduced lifecycle costs, and unprecedented design freedom is too compelling to ignore. For architects, engineers, and facility managers in the UAE, embracing this evolution is not merely an option; it is a strategic imperative. Adopting these advanced hardware solutions is a direct investment in constructing the safer, more resilient, and technologically advanced infrastructure of tomorrow.

Ready to integrate the next generation of hardware into your projects? Connect with Yasu Trading Co. LLC, a leading supplier in the UAE dedicated to providing innovative and reliable building materials and fastening solutions. Explore how their forward-thinking inventory can help you build smarter and more efficiently by visiting Yasu Trading Co. LLC today.