A Pro's Guide to Stainless Steel Pipes in the UAE

When you think of the essential materials in modern construction, stainless steel pipes should be right at the top of your list. They are the unsung heroes of countless projects, forming the circulatory system for everything from soaring skyscrapers to sprawling industrial facilities. Their reputation for durability, resistance to corrosion, and sheer longevity is well-earned.

But these aren't just simple metal tubes. They are highly engineered components, and choosing the right one can make or break a project's success.

A Practical Overview for UAE Professionals

If you're a construction or industrial professional in the UAE, this guide is for you. We're cutting through the dense technical jargon to give you practical, actionable advice for navigating the stainless steel pipe market in one of the world's most demanding environments.

Making the right choice in stainless steel pipes is a major decision that directly affects your project's safety, budget, and long-term viability. The UAE's climate is famously tough on building materials—the high humidity, salt-laden air in coastal areas, and punishing temperatures create a perfect storm for corrosion. A solid understanding of the basics is your best defence, ensuring you make smart, cost-effective decisions that stand the test of time.

Key Focus Areas in This Guide

- Material Grades: We’ll show you how to pick the right grade—like 316L for coastal projects—to win the battle against corrosion.

- Pipe Types: You'll learn the crucial differences between seamless and welded pipes, so you can perfectly match the product to your pressure requirements and budget.

- Industry Standards: We’ll demystify the critical ASTM and ASME standards that are non-negotiable for safety and compliance.

Think of this as your practical playbook for success. With the region's ambitious infrastructure projects, the demand for top-tier components is only growing. In fact, the Middle East and Africa stainless steel market was valued at USD 15.95 billion and is expected to climb to USD 22.41 billion by 2032, with construction and energy leading the charge. You can dig deeper into this trend over at Data Bridge Market Research.

Think of this guide as your on-site consultant. We’re not just listing specifications; we’re translating them into real-world advantages for your projects, whether it's an iconic tower or a vital industrial facility.

To get you started, we've put together a quick-reference table. It’s designed to simplify your initial selection by connecting common project needs directly to the most suitable stainless steel pipes. This helps you align your materials with your application right from the get-go.

Quick Selection Guide for Stainless Steel Pipes

| Selection Factor | Key Considerations for UAE Projects | Common Applications |

|---|---|---|

| Corrosion Resistance | High humidity and coastal salinity require superior rust prevention. Molybdenum content is a key advantage. | Water desalination plants, coastal construction, chemical processing facilities. |

| Pressure Rating | Applications involving high-pressure fluids or gases demand pipes without seams or weak points. | Oil and gas pipelines, high-pressure hydraulic systems, process piping. |

| Budget Constraints | Balancing initial cost with long-term maintenance and lifespan is essential for project profitability. | Structural components, general plumbing, architectural and decorative uses. |

Choosing the Right Stainless Steel Grade

Picking the right stainless steel grade can feel daunting, but it’s simpler than you might think. Just think of it like choosing fabric. For a casual shirt, cotton works perfectly fine. But if you’re hiking in a torrential downpour, you’ll need specialised, high-performance gear. The same logic applies to stainless steel pipes; the "grade" is just a way to classify the material based on its chemical makeup and physical properties.

That chemical recipe—mostly the amount of chromium and nickel—is what dictates everything from the pipe’s raw strength to how well it stands up to corrosion. For anyone working on projects in the UAE, getting this choice right is absolutely critical, especially with our harsh environmental conditions. The wrong grade can mean premature failure, eye-watering repair bills, and major project delays.

So, let's break down the three main families of stainless steel—Austenitic, Ferritic, and Duplex—to help you pinpoint exactly what you need for your next job.

The Austenitic Family: Workhorses of the Industry

When most people picture stainless steel, they’re thinking of an Austenitic grade. This family is the most popular kid on the block, making up over 70% of all stainless steel production globally. Why? Because they offer an incredible combination of excellent formability, easy weldability, and impressive corrosion resistance across a huge range of temperatures.

These grades are non-magnetic and packed with high levels of chromium and nickel, which gives them their famously robust character. The two stars of this family are undoubtedly Grade 304 and Grade 316.

- Grade 304: Often called "18/8" stainless for its 18% chromium and 8% nickel makeup, Grade 304 is the ultimate all-rounder. It provides great corrosion resistance for most everyday environments, making it ideal for structural applications, indoor plumbing, food processing equipment, and architectural touches in inland areas.

- Grade 316: Think of this as Grade 304’s tougher, more resilient sibling. The key difference is the addition of molybdenum (usually 2-3%), which dramatically boosts its defence against chlorides. This makes it the non-negotiable choice for any project in the UAE's coastal zones, like Dubai and Abu Dhabi, where the salt-heavy air is a constant battle.

For any project exposed to saltwater spray, high humidity, or chemical exposure, using Grade 316 or its low-carbon variant, 316L, isn't just a smart idea—it’s essential for long-term survival. The slightly higher upfront cost is a small price to pay to avoid catastrophic corrosion failures down the line.

The Ferritic Family: Cost-Effective and Magnetic

Next up are the Ferritic grades. Unlike their Austenitic cousins, these steels are magnetic and contain less nickel, which generally makes them a more budget-friendly choice. While they don't have the same all-around corrosion resistance as the 300-series, they are particularly good at resisting stress corrosion cracking.

Their main selling points are moderate corrosion resistance and good ductility. This makes them a solid fit for applications where extreme toughness isn't the top priority.

You'll typically see Ferritic stainless steel pipes used in:

- Automotive exhaust systems

- Indoor decorative trim

- Industrial equipment where keeping costs down is a major factor

That said, their lower toughness and weldability compared to Austenitic grades mean you won't see them used much for high-pressure or critical structural roles here in the demanding UAE construction scene.

The Duplex Family: High Strength for Harsh Environments

Finally, we have the Duplex grades. Just as the name implies, these are a hybrid, engineered to give you the best of both worlds by combining the strengths of Austenitic and Ferritic steels. Their mixed microstructure results in incredible strength—often double that of standard Austenitic grades—along with phenomenal resistance to both chloride-induced pitting and stress corrosion cracking.

This powerful combination makes Duplex stainless steel pipes the ultimate solution for the most aggressive environments. This is the top-tier, specialised gear you bring when facing the worst possible conditions.

Here in the UAE, Duplex grades are absolutely vital for:

- Desalination plants

- Offshore oil and gas platforms

- Chemical processing facilities

- Wastewater treatment systems

Choosing Duplex is an investment in maximum performance and reliability where failure simply isn't an option. Its superior strength also means you can use thinner pipe walls, which can lead to significant weight and cost savings on massive projects, helping to balance out the higher material price. At the end of the day, matching the grade to the environment is the secret to building resilient, long-lasting infrastructure.

Seamless vs. Welded Pipes: A Critical Decision

When you're mapping out a project, one of the most fundamental choices you'll make is between seamless and welded stainless steel pipes. This decision has real-world consequences for your project's performance, safety, and bottom line.

Think of it this way: a seamless pipe is like a baseball bat carved from a single, solid block of wood. It's one continuous piece, with an uninterrupted grain and no joints or potential weak spots. A welded pipe, on the other hand, is like taking a flat sheet of that same wood, rolling it into a cylinder, and then fusing the edges together.

That single difference in manufacturing creates two very different products. One delivers ultimate strength for high-stakes jobs, while the other offers incredible versatility and cost-effectiveness for a wider range of needs. Knowing which one to pick for your specific project here in the UAE is the key to getting the job done right without overspending.

The Power of Seamless Pipes

Seamless pipes start their life as a solid, cylindrical hunk of steel known as a billet. This billet is heated until it's glowing hot and then pierced right through the centre with a mandrel. The result is a hollow tube with absolutely no seams or weld joints.

Because they have a perfectly uniform, homogenous structure, seamless pipes boast superior strength and can handle immense pressure.

There are simply no potential weak points along a weld line, which makes them unbelievably reliable under high pressure, high temperatures, and in corrosive environments. This structural integrity is why they are the undisputed champions for the most demanding applications.

In the UAE, you’ll see seamless stainless steel pipes specified for critical infrastructure:

- Oil and Gas: Transporting crude oil, natural gas, and other volatile substances where a leak could be catastrophic.

- Chemical Processing: Safely handling aggressive chemicals and high-pressure process fluids.

- Power Generation: Inside boilers and super-heaters that operate under extreme stress.

The region's focus on high-performance infrastructure has created a huge demand for this type of pipe. In fact, production of stainless steel seamless pipes in the Middle East has soared to 104,000 tons—an 84% jump year-over-year—driven largely by the stringent requirements of the oil and gas sector.

The Versatility of Welded Pipes

Welded pipes are made differently. A flat steel plate or strip is rolled into a tubular shape, and the seam is then welded together longitudinally. Thanks to modern techniques like High-Frequency Induction (HFI) welding, these joints are incredibly strong and consistent, making welded pipes a reliable and very cost-effective choice.

Their biggest advantage is the lower production cost, especially when you need larger diameter pipes. And while they do have a weld seam, their pressure ratings and structural integrity are more than enough for the vast majority of jobs.

Welded pipes are the true workhorses for applications where extreme pressure isn't the number one concern. Their blend of affordability, availability in large sizes, and solid performance makes them the go-to choice for countless structural and fluid transport projects.

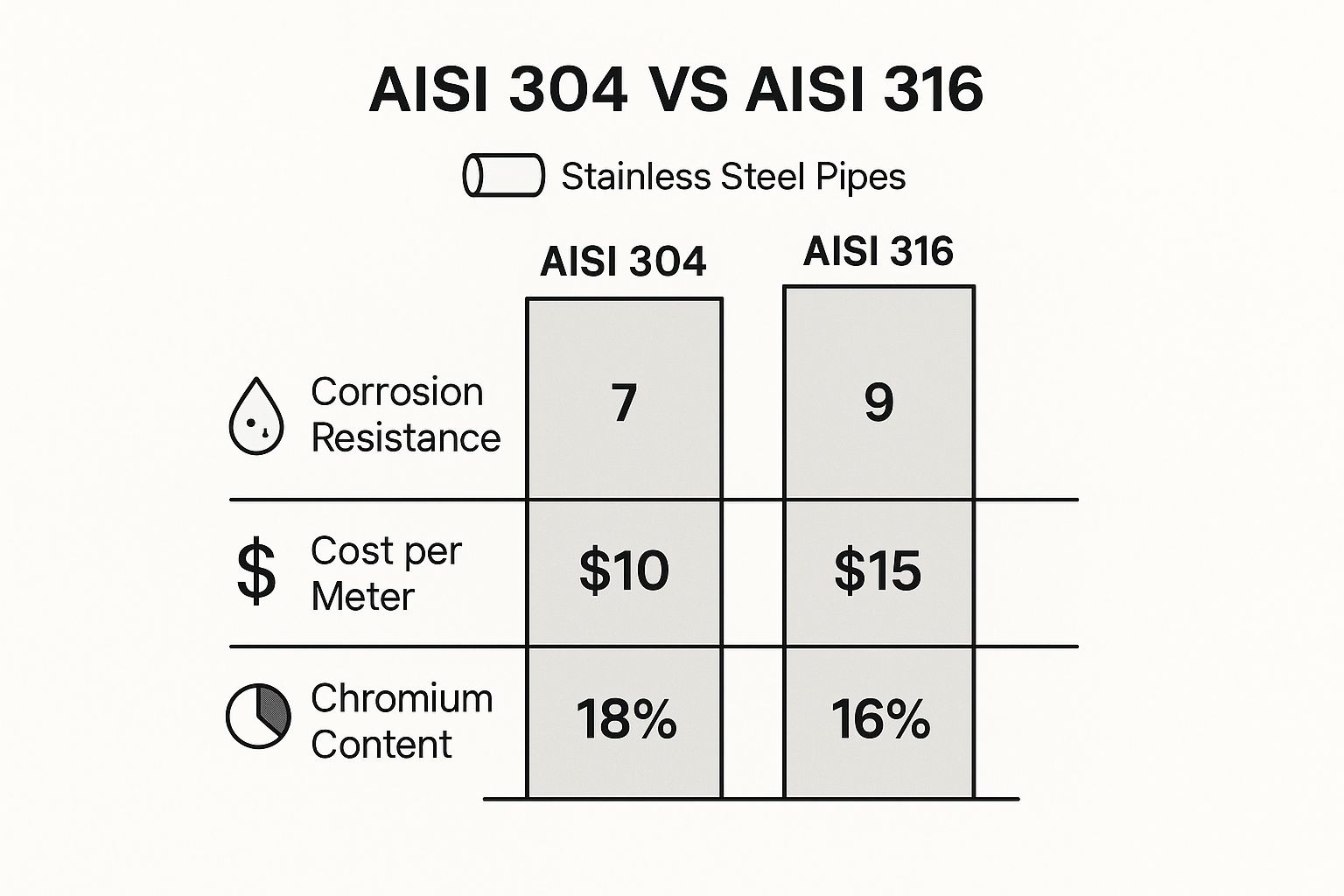

Choosing the right material grade is just as important as choosing the pipe type. This visual breaks down how two of the most popular grades, 304 and 316, stack up.

As you can see, Grade 316 offers much better corrosion resistance but comes at a higher price. It’s a classic example of balancing project-specific needs with the budget.

Comparing Seamless and Welded Stainless Steel Pipes

To make the choice clearer, let's put the two pipe types side-by-side. This table breaks down their key differences to help you match the right pipe to your project's demands.

| Attribute | Seamless Pipes | Welded Pipes |

|---|---|---|

| Manufacturing Process | Extruded and drawn from a solid billet | Rolled from a flat plate and welded |

| Pressure Rating | Excellent, due to uniform structure | Good, but limited by the weld seam |

| Corrosion Resistance | Superior, no weld seam to corrode | Generally good, but the weld can be a weak point |

| Cost | Higher, especially for larger diameters | More cost-effective, particularly in larger sizes |

| Wall Thickness | Highly uniform and consistent | Can have minor inconsistencies |

| Best For | High-pressure, high-temp, critical applications | General fluid transport, structural uses |

Ultimately, the best choice depends on your specific application and what you need to prioritise: absolute strength or cost-efficiency.

Making the Right Choice for Your Project

So, which one is it? The decision really boils down to a trade-off between pressure rating, budget, and the diameter you need.

If your project involves high-pressure fluids or gases, or it’s operating in an aggressive environment where failure is simply not an option, then the higher cost of a seamless pipe is a wise investment in safety and long-term reliability.

For structural applications, general plumbing, water transport, and architectural features, welded pipes hit that sweet spot of performance and affordability. They can also be made in much larger diameters more economically than seamless pipes, which is a huge advantage for large-scale infrastructure.

Of course, even the best pipes are only as strong as their connections. To ensure total system integrity, you need the right fittings. You can learn more about making those connections secure in our guide to pipe connectors in Dubai. By aligning your pipe selection with the real-world demands of your application, you guarantee a project that’s both safe and cost-effective.

Navigating Key Industry Standards and Certifications

In the high-stakes world of UAE construction, standards aren't just red tape—they're the bedrock of every safe, durable, and legally sound project. Sourcing stainless steel pipes without knowing the codes is like trying to navigate the Creek during peak hours without a map. You'll get lost, waste money, and end up with serious problems.

Getting these standards right from the start ensures every single pipe can handle the pressure, temperature, and corrosive environments it was specified for. Think of it as your best insurance policy against risk and a guarantee of long-term performance.

Decoding the Alphabet Soup of Standards

Let’s be honest, the world of material standards can look like a confusing mess of acronyms. But for any professional in the UAE, a couple of them are absolutely critical to know. These aren't just random letters; they're detailed frameworks built by generations of engineers to make sure materials behave exactly as they should.

Here are the ones that matter most on the ground:

ASTM (American Society for Testing and Materials): This is the big one. ASTM develops the technical rulebook for thousands of materials, including stainless steel pipes. When a pipe has an ASTM code, it's a seal of approval on its chemical makeup, its mechanical strength, and how it was made. For example, ASTM A312 is a specification you'll see everywhere. It covers pipes made for high-heat and corrosive jobs, making it a workhorse in our industry.

ASME (American Society of Mechanical Engineers): If ASTM writes the recipe for the material, ASME writes the instructions for how to build with it. It focuses on the design and construction of pressurised systems. ASME B31.3, for instance, is the essential code for process piping in oil and gas refineries, chemical plants, and pharmaceutical facilities. Complying with B31.3 ensures your entire system—pipes, fittings, joints, and all—is built to safely handle the job.

They work hand-in-hand. A project will often specify stainless steel pipes made to ASTM A312 standards, which are then installed following the engineering principles laid out in ASME B31.3.

Your Most Important Document: The Mill Test Certificate

So, how do you actually prove a pipe meets these strict requirements? The answer is the Mill Test Certificate (MTC). This document is the pipe's birth certificate, tracing its entire history from raw metal to the finished product in your hands.

The MTC is non-negotiable. It’s your definitive proof that the material you’ve received is exactly what you paid for and that it meets every required standard. Never, ever accept a shipment without one.

This certificate gives you the hard data you need to verify quality instantly:

- Chemical Composition: It details the exact percentage of elements like chromium and nickel, confirming you've received the correct grade (like 316L).

- Mechanical Properties: This section shows the results of physical tests—tensile strength, yield strength, and elongation—proving the pipe won't fail under stress.

- Standards Compliance: It clearly states which codes, like ASTM A312, the pipe conforms to.

Knowing how to read an MTC is a fundamental skill. It allows you to spot non-compliant materials on delivery, hold suppliers accountable, and maintain a bulletproof paper trail for your project. To see how this fits into the bigger picture, take a look at our deeper dive into building materials quality standards in the UAE.

Right, we’ve covered the technical side—the grades, types, and standards. But theory only gets you so far. Let's talk about where the rubber meets the road.

The real story of stainless steel pipes unfolds across the UAE's most ambitious industries. You can see their value in everything from the gleaming skyscrapers of Dubai to the critical, unseen infrastructure of its industrial heartlands. This isn't just a list of uses; it's a look at how these remarkable materials solve real-world problems.

Construction and Architectural Excellence

In the UAE's world-famous construction scene, stainless steel pipes pull double duty. They are the quiet workhorses and the visual showstoppers.

Functionally, you'll find them in the guts of a building—handling everything from internal plumbing and fire suppression systems to sturdy handrails and balustrades. Their strength and refusal to rust or wear down make them a go-to choice for systems you simply can't afford to fail.

But they also get their moment in the spotlight. Polished stainless steel is a signature element in the region's futuristic designs, used for everything from decorative columns to grand entrance canopies. The clean, modern aesthetic of a Grade 304 or 316 pipe can define a building's entire look, giving it a finish that’s both sleek and built to last. For anyone planning a project, understanding how different elements come together is crucial, which is why a guide to essential building materials for construction projects in Dubai can be so insightful.

The dual functionality of stainless steel is its superpower in modern architecture. It provides the hidden strength needed for safety and reliability while also delivering the polished, high-end finish that defines a landmark structure.

The Demanding World of Oil and Gas

The oil and gas sector is a world of extremes. We're talking immense pressure, blistering temperatures, and highly corrosive materials. In this environment, there is absolutely zero room for error, which is why high-performance seamless stainless steel pipes are non-negotiable.

Here, specialised grades are hand-picked to move everything from crude oil to sour gas. Duplex and super-duplex grades are often the standard, chosen for their incredible strength and ability to resist the stress corrosion cracking that plagues lesser metals exposed to chlorides and hydrogen sulphide. The integrity of these pipelines isn't just a technical detail—it's fundamental to safety and profitability.

This need is also a huge economic force. As the GCC diversifies its economy, massive investment is pouring into upgrading oil and gas infrastructure, which in turn fuels the demand for these durable materials. One recent USD 270 million investment in a new factory is a perfect example, showing a strategic push to boost local manufacturing to meet this exact need.

Water Treatment and Desalination

Turning seawater into fresh water is one of the UAE's great engineering triumphs, but it's a process that is incredibly tough on equipment. Desalination plants are a constant battle against saltwater corrosion, and it's a battle that Grade 316L and Duplex stainless steel pipes are built to win.

The high chloride content in seawater would chew through ordinary materials in no time. This is where a specific grade choice makes all the difference:

- Grade 316L: The added molybdenum in this grade is its secret weapon against pitting and crevice corrosion from chlorides. It's the baseline for most piping inside a desalination plant.

- Duplex Grades: For the most intense parts of the process, like high-pressure reverse osmosis, you need something even tougher. The superior strength and enhanced corrosion resistance of Duplex pipes make them essential here.

By selecting these materials, engineers ensure these vital facilities can run around the clock, supplying the nation with a sustainable source of fresh water. It’s a perfect case study in matching the right material to a mission-critical challenge.

Frequently Asked Questions About Stainless Steel Pipes

Even after you’ve got a handle on the grades, types, and standards, practical questions always pop up on the job site. This is where the real-world challenges live. So, let's tackle the common queries that professionals like you face when specifying, installing, and maintaining stainless steel pipes in the UAE's tough environment.

Getting straight answers to these questions can be the difference between a successful project and a costly mistake. Let’s dive into some of the most pressing concerns.

What Is the Main Cause of Corrosion in the UAE and How Is It Prevented?

In the UAE, the biggest enemy of steel is the air itself. The relentless combination of coastal humidity and high salinity creates an aggressive, chloride-rich atmosphere that just loves to attack metal. This environment can eat away at the protective layer of stainless steel, leading to pitting and, eventually, failure.

Prevention starts with choosing the right material from day one. In a coastal city like Dubai or Sharjah, you can't afford to get this wrong.

- For Coastal Areas: Grade 316 or its low-carbon cousin, 316L, should be your starting point. These grades contain molybdenum, a key ingredient that dramatically boosts resistance to chloride corrosion. It’s a non-negotiable for projects near the sea.

- For Extremely Harsh Conditions: Sometimes, even 316L isn’t enough. For environments like desalination plants or certain chemical processing facilities, you need to bring in the heavy hitters. This is where Duplex stainless steel grades shine, offering superior strength and an even higher level of corrosion defence.

But your material choice is only half the battle. Proper installation is just as critical. Make sure your stainless steel pipes never touch carbon steel directly, and ensure all welds are clean and properly treated. This simple diligence helps prevent galvanic corrosion and other headaches down the line, safeguarding the pipe's lifespan.

How Does Temperature Affect Pipe Selection and Performance?

Temperature is a massive factor. It directly dictates which grade of stainless steel you need to use because different grades react to extreme heat and cold in completely different ways. A mismatch here can lead to a catastrophic loss of strength or corrosion resistance.

Austenitic grades, like the workhorses 304 and 316, are fantastic all-rounders. They perform beautifully in both high-temperature services and cryogenic applications, holding onto their toughness and strength. This versatility makes them a reliable pick for everything from process piping in industrial plants to LNG facilities.

It's crucial to remember that even the most robust grades have their limits. Push standard austenitic steels above 425°C, and they can become susceptible to carbide precipitation, which compromises their corrosion resistance. In those situations, stabilised grades like 321 (which contains titanium) are a much smarter choice.

On the flip side, Ferritic grades can be a bit sensitive. They tend to become brittle in very cold conditions and can lose a significant amount of strength when heated. This really limits their use to less demanding applications where temperatures stay moderate and stable. Always let your project's thermal conditions guide your selection.

Are There Sustainable Benefits to Using Stainless Steel Pipes?

Absolutely. When you choose stainless steel pipes, you're making a forward-thinking decision with some serious green credentials. The benefits go way beyond just performance on day one.

First off, there's its incredible durability. Stainless steel has a very long service life, which means fewer replacements are needed over the life of a building. That alone conserves a huge amount of resources and reduces the project's long-term environmental footprint.

Beyond that, stainless steel is a true champion of the circular economy.

- 100% Recyclable: It can be melted down and remade into new, high-quality products over and over again without losing any of its performance characteristics.

- High Recycled Content: On average, new stainless steel products already contain about 60% recycled material. This drastically cuts down on the need for virgin raw materials and the energy-intensive processes required to mine them.

By specifying stainless steel, you aren't just picking a durable material; you're actively supporting a system that minimises waste and champions resource efficiency. That makes it an environmentally responsible choice for any project.

What Is the Real Cost Difference Between Carbon and Stainless Steel?

It's the classic debate. Yes, the upfront cost of stainless steel is higher than carbon steel—there’s no getting around that initial sticker shock. But focusing only on the purchase price is a short-sighted view that completely misses the bigger picture: the total cost of ownership.

Think about it. Carbon steel demands constant attention to protect it, especially in a place like the UAE. It needs protective coatings, regular inspections, and frequent maintenance to keep rust at bay. Sooner or later, it will need to be replaced, which means more material, labour, and downtime costs.

The true economic advantage of stainless steel lies in what you don't have to spend on it. Its built-in corrosion resistance means no painting or coating, and it dramatically slashes your maintenance schedule and costs over decades of service.

When you add up all the costs for maintenance, repairs, and eventual replacement that come with carbon steel, that higher initial investment for stainless steel often proves to be the more economical choice in the long run. For critical applications, the reliability and reduced risk of downtime make stainless steel pipes a sound and financially prudent investment.

For all your construction and hardware needs, from high-quality stainless steel pipes to certified safety equipment, trust Yasu Trading Co. LLC to deliver excellence. We provide the essential materials that empower your projects to succeed. Request your quote today and build with confidence.