UAE Building Materials: Your Ultimate Sourcing Guide

When you think of construction in the UAE, what comes to mind? Towering skyscrapers, futuristic designs, and a city that seems to rise from the desert overnight. The secret behind this incredible architectural ambition lies in the materials—a carefully selected trio of high-strength concrete, structural steel, and advanced glazing, all chosen to handle the region's intense climate.

These aren't just building blocks; they're the very foundation of every major project, from sprawling residential communities to the iconic structures that define the skyline.

The Blueprint for Building in the UAE

Look at any photo of Dubai's skyline or Abu Dhabi's mega-projects, and you're seeing a masterclass in modern construction. This isn't just about building; it's about setting a global benchmark for what's possible. All this rapid growth has forged a dynamic and incredibly demanding market for building supplies. For any developer, supplier, or project manager, getting a handle on this market isn't just helpful—it's absolutely critical for success.

This guide will pull back the curtain on the world of UAE building materials. We'll get into how the unique environment and bold architectural visions drive the selection process for every single nut, bolt, and panel used on a job site.

Navigating a Booming Market

The growth here isn't just something you feel in the air; it's backed by serious numbers. Thanks to huge government initiatives and private investment, the UAE construction market has been on a tear. Between 2020 and 2024, it expanded at a compound annual growth rate (CAGR) of 7.3%.

And it’s not slowing down. Forecasts predict the market will continue to climb at a CAGR of 4.8% from 2025 to 2029, hitting a potential value of around AED 242.33 billion (that's about USD 66 billion). This constant hum of activity puts enormous pressure on the supply chain and shines a spotlight on the need for materials that can truly take the heat.

The real challenge in the UAE isn't just building tall—it's building smart. Material selection is a careful balancing act between structural integrity, thermal performance, regulatory compliance, and aesthetic ambition.

Core Considerations for Material Selection

Getting a project off the ground and successfully completed in the Emirates means you have to deeply understand the key factors that steer material choices. These are the non-negotiables that inform every decision, from the foundation deep in the sand to the final facade panel catching the sun. You can get a closer look at what this involves by reading our guide on the essential building materials for construction projects in Dubai.

Here are the factors that drive every decision:

- Climate Resilience: Materials have to stand up to intense UV radiation, high humidity, and scorching summer heat without breaking down.

- Architectural Demands: The push for gravity-defying designs and complex shapes means we need materials with fantastic strength-to-weight ratios.

- Regulatory Compliance: Every single component must meet strict local codes, especially the UAE Fire and Life Safety Code.

- Logistical Complexity: Sourcing is a mix of local manufacturing and global imports, which demands sharp and efficient supply chain management.

In this guide, we'll take a journey through the materials that are literally building the nation, the tough standards they have to meet, and the market forces that shape their supply and demand.

The Pillars of UAE Construction: Concrete, Steel, and Glass

Walk through any major city in the UAE, and you're surrounded by the same three titans of construction: concrete, steel, and glass. I like to think of them as the foundational 'bones, skeleton, and skin' of modern Emirati architecture. Each one is a non-negotiable part of the equation, chosen specifically to solve the unique puzzle of building world-class structures in our demanding climate.

These materials aren't picked out of a catalogue at random. They are the workhorses that have proven themselves time and again. Without this powerful trio, the iconic skylines that define Dubai and Abu Dhabi would still be just ambitious drawings on a blueprint.

Concrete: The Bedrock of UAE Structures

Here in the UAE, concrete is more than just a material; it’s the absolute foundation of our nation's development. Its incredible compressive strength is the magic ingredient that allows us to build solid foundations in the region’s notoriously sandy and tricky soil. From the deepest skyscraper piles to the sprawling airport runways, concrete provides the unshakeable base everything else is built upon.

But it’s not just about strength. Its versatility is what truly makes it a star. You can pour it into almost any mould, giving architects the creative freedom to dream up the flowing, organic shapes that have become a signature of modern Gulf design. We're regularly using specialised mixes, like high-strength and self-compacting concrete, to make our supertalls not just possible, but efficient to build. It's the ultimate adaptable workhorse.

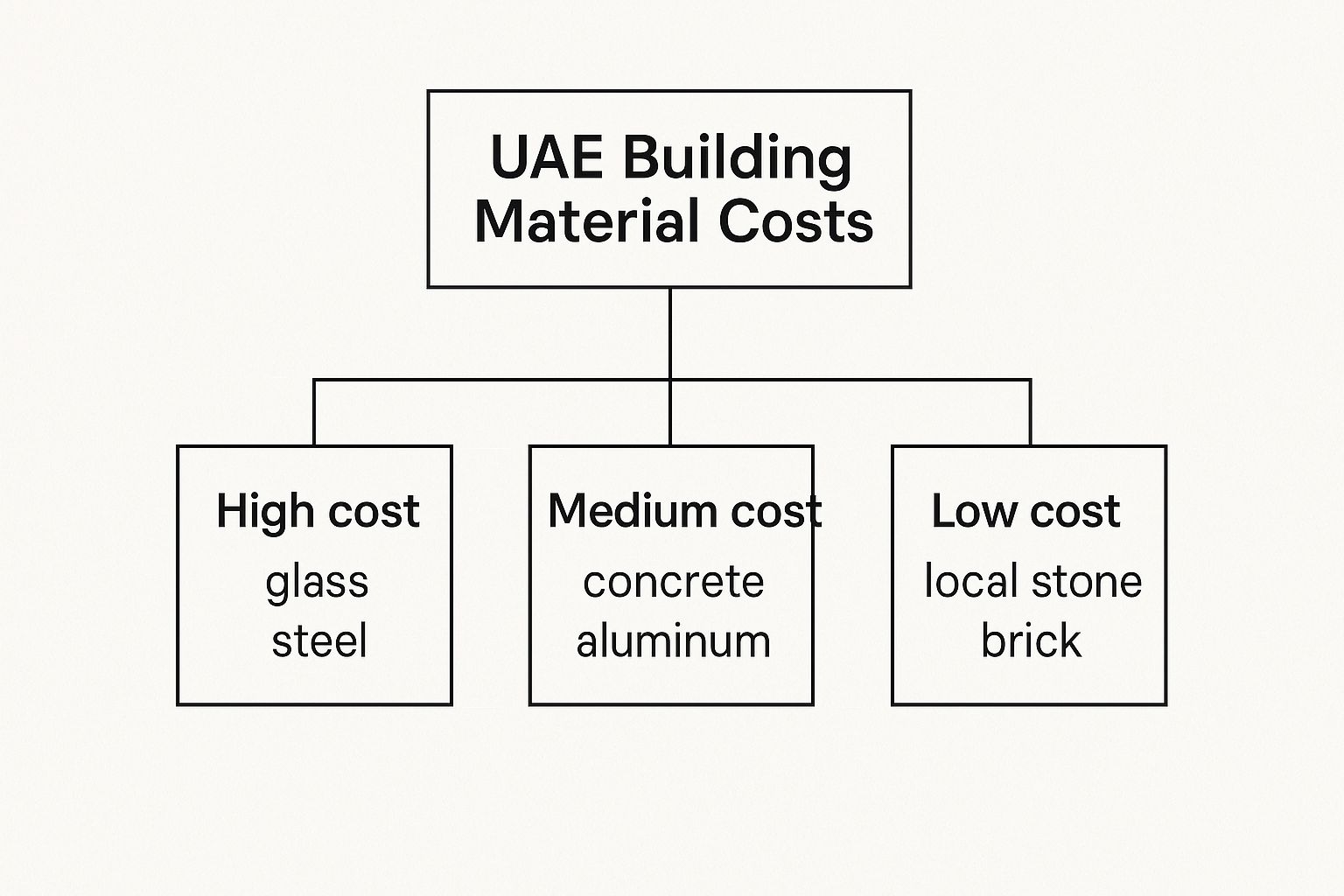

The image above gives you a good sense of where these materials sit in the budget hierarchy. While concrete is relatively mid-range in cost, the high-performance glass and structural steel needed for those landmark projects demand a much more significant investment.

Steel: The Framework for Ambition

If concrete forms the unshakeable foundation, steel provides the towering skeleton. The real power of structural steel lies in its tensile strength—its incredible ability to resist being pulled apart. This property makes it the only realistic choice for creating the massive, column-free interiors and jaw-dropping heights of our modern towers. It lets architects design those breathtaking atriums and expansive exhibition halls without visual clutter.

Another huge advantage is speed. Steel frames are prefabricated off-site with surgical precision, which dramatically shortens construction timelines—a game-changer in the fast-moving UAE market. Every single beam and column shows up on-site ready to be slotted into place, almost like a giant, meticulously planned Meccano set.

For anyone in the UAE construction sector, steel is the material that makes ambition possible. It delivers the strength-to-weight ratio you need to truly push architectural boundaries, creating buildings that are surprisingly lightweight for their size yet unbelievably strong.

It goes without saying that steel quality is under intense scrutiny. Every piece of structural steel used here must meet rigid local and international standards, ensuring it can handle not just the building's own weight, but also powerful wind loads and potential seismic shifts.

Glass: The Transparent Shield

Glass is the final piece of the puzzle, wrapping the building in a high-performance skin. In a part of the world blessed with so much sunshine, bringing natural light indoors is a top priority. The catch? That sunlight brings a massive amount of heat with it. Using standard glass would essentially turn our buildings into giant greenhouses, making cooling costs spiral out of control.

This is where advanced glazing technology steps in. The stunning glass facades you see across the UAE use sophisticated solar-control glass, which has been coated with microscopically thin layers of metal oxides. These coatings are engineered to be 'spectrally selective'—a fancy way of saying they let the good stuff (visible light) pass through while bouncing a huge chunk of the bad stuff (heat-carrying infrared radiation) back outside.

The benefits of using these highly technical uae building materials are massive:

- Energy Efficiency: By blocking so much solar heat, this glass dramatically reduces the workload on the HVAC systems, which are one of the biggest operational expenses for any building.

- Occupant Comfort: It floods interiors with beautiful, natural light without the associated glare and oppressive heat, creating a much healthier and more productive environment for everyone inside.

From double-glazed units filled with inert gases to incredibly complex curtain wall systems, glass in the UAE is far more than just a window. It’s a highly technical component that has to strike a perfect balance between the desire for transparency and the critical need for thermal performance.

Beyond the Structure: Essential Support Materials

The striking silhouette of a new tower is only where the story begins. While the big three—concrete, steel, and glass—give a building its bones, its long-term success really comes down to the supporting cast. These are the materials that work behind the scenes, controlling the climate inside, locking out moisture, and delivering the services we all take for granted.

Think of it this way: if the frame is the skeleton, these materials are the building's vital organs. They are the circulatory, respiratory, and nervous systems that transform a static shell into a high-performing, comfortable space. Without them, even the most beautiful structure would be completely unliveable in the UAE's challenging environment.

Superior Insulation and Cladding Systems

In a place where summer heat is relentless, good thermal insulation isn't just a nice-to-have; it's a fundamental requirement. It acts as a powerful shield, dramatically slowing down the flow of heat from the blistering outdoors into the air-conditioned interior. This single element has an outsized impact on a building’s running costs.

After all, a building’s HVAC system can be responsible for up to 70% of its total electricity consumption here in the UAE. By installing high-performance insulation like rigid foam boards or mineral wool, you're directly easing the load on that system, which translates into significantly lower energy bills for decades to come.

Cladding, the building's outer skin, is insulation's essential partner. It's not just there for looks. Modern systems like Aluminium Composite Panels (ACP) or ventilated rainscreen facades create additional thermal breaks and shield the core structure from direct sun, giving energy efficiency another major boost.

The selection of insulation and cladding is a critical economic decision disguised as a technical one. Investing in superior systems at the construction stage delivers compounding returns through decades of reduced energy expenditure and enhanced occupant comfort.

The Critical Role of Waterproofing

The UAE might be known for its arid climate, but the combination of intense humidity and the occasional torrential downpour is a serious threat. Once water or moisture finds a way in, it can cause devastating damage, from concrete spalling and rebar corrosion to mould growth that ruins indoor air quality.

This is why a solid waterproofing system is one of the most vital uae building materials you can specify. It’s the invisible shield protecting a building's foundations, basements, rooftops, and wet areas from assault. The go-to solutions in the region typically include:

- Bituminous Membranes: The tried-and-tested classic, these are applied as sheets or liquid coatings to form a tough, flexible waterproof barrier.

- Polyurethane Liquid Membranes: A fantastic seamless option that's highly elastic, making it perfect for complex roof shapes and other exposed areas.

- Cementitious Coatings: Often applied to concrete water tanks and below-ground structures, these coatings bond with the concrete itself to create an impermeable layer.

Getting this right means matching the system to the job—a basement facing groundwater pressure needs a different solution than a flat roof baking in the sun. Skimping on waterproofing is a surefire way to sign up for expensive, disruptive repairs down the line.

The Web of MEP Components

Finally, no building actually works without its intricate network of Mechanical, Electrical, and Plumbing (MEP) systems. These are the arteries and veins carrying power, water, and conditioned air throughout the structure, making modern life possible.

The sheer range of MEP materials is huge and highly specialised, covering everything from massive chillers and air handlers right down to the last electrical socket and water tap. Sourcing quality MEP components is non-negotiable for both safety and performance. High-efficiency pumps and fans cut down on energy use, while certified fire-rated cabling and sprinkler systems are mandated by the strict UAE Fire and Life Safety Code. These are the unsung heroes, the essential uae building materials that ensure a project is not just built, but fully operational and safe for everyone inside.

Mastering the Supply Chain for UAE Building Materials

Getting the right materials to a UAE construction site, exactly when you need them, is a delicate dance. It’s a game of logistics, timing, and shrewd strategy that goes far beyond simply placing an order. You have to understand a material’s entire journey, from a factory somewhere in the world right to the foundation of your project.

Success here means mastering a system that cleverly blends the UAE’s own manufacturing power with a reliance on global imports.

Think of the supply chain for uae building materials as two parallel streams. One is local and incredibly responsive, carrying essentials like concrete, aggregates, and standard aluminium profiles. The other is a long-haul international channel, bringing in the showstoppers—specialised facade systems, luxurious Italian marble, or sophisticated MEP components. Juggling both effectively is the secret to keeping your project on time and on budget.

Local Sourcing Versus Global Imports

The UAE has built a formidable local manufacturing sector, especially for the bread-and-butter materials of construction. Factories across the Emirates churn out vast quantities of high-quality ready-mix concrete, steel rebar, and aluminium extrusions.

Leaning on these local suppliers gives you some serious advantages. You get shorter lead times, lower transport costs, and frankly, much easier conversations with your suppliers.

But for the signature elements that make UAE projects iconic—think custom-engineered glass panels or specific European stone—you have to look abroad. This is where a whole new set of challenges comes into play.

Navigating the global supply chain requires foresight. It’s not just about the cost of the material, but the cost of time. A delay at a foreign port or a snag in customs can have a ripple effect, stalling multiple trades on-site and inflating project costs.

Understanding the typical lead times is non-negotiable. A custom facade system, for instance, might take several months from the day you order it to its arrival on site. This has to be baked into your master schedule from day one to avoid paying crews to stand around.

The Role of Logistics Hubs and Common Bottlenecks

The UAE’s world-class logistics infrastructure, with powerhouses like Jebel Ali Port, is the backbone of the entire operation. This port is a massive gateway, processing incredible volumes of construction goods. While it's a model of efficiency, it can also become a bottleneck during peak construction seasons or when customs inspections ramp up.

This constant flow is fuelled by the country’s relentless ambition. The UAE commercial construction market, a primary driver for material demand, was valued at USD 42.5 billion in 2024. It’s projected to soar to USD 56.49 billion by 2030, thanks to ongoing mega-projects in Dubai and Abu Dhabi. You can read the full research about these market projections to get a deeper insight into this growth.

Procurement teams need to be acutely aware of potential delays and have a Plan B ready.

Common issues that can throw a wrench in the works include:

- Customs Clearance: Flawless paperwork is non-negotiable. Even a tiny error can lead to a massive hold-up.

- Port Congestion: When construction is booming, the sheer volume of imports can slow everything down.

- Inland Transportation: Getting materials from the port to your site is the final hurdle, requiring perfectly coordinated trucking and logistics.

Actionable Advice for Procurement Teams

To really get a handle on the supply of uae building materials, you have to be strategic. Waiting for problems to crop up simply isn't an option in this fast-paced environment.

Instead, get proactive. Diversify your supplier base so you aren't left in the lurch if one source hits a snag. Build strong relationships with seasoned freight forwarders who know UAE customs inside and out.

And finally, whenever you can, use local manufacturing as your safety net. It provides a crucial buffer against the wild uncertainties of international shipping, ensuring the essential building blocks of your project are always within reach.

The Shift to Sustainable and Smart Materials

The future of construction here in the UAE is undeniably green and getting smarter by the day. We're moving past just thinking about structural integrity and looks. The industry is making a real pivot towards materials that are kinder to the planet and more intelligent in how they work.

This isn’t some passing trend. It's a fundamental change, pushed forward by government vision, economic sense, and incredible leaps in technology. It’s paving the way for a new generation of buildings that are more efficient, resilient, and environmentally responsible. For developers and contractors, getting to grips with these new materials isn't just a good idea—it's essential for staying competitive.

The Rise of Green Building Materials

The push for sustainability is changing the DNA of our foundational materials. You can see it in the growing demand for ‘green’ alternatives that slash the carbon footprint tied to traditional production. This is where innovation in core UAE building materials really gets exciting.

Take ‘green concrete’, for instance. It’s not one single product, but rather a whole category of concrete mixes that use recycled materials. Think crushed concrete from demolition sites or industrial by-products like fly ash. This approach is brilliant because it diverts tonnes of waste from landfills and reduces our reliance on quarrying fresh sand and gravel. In the same vein, low-carbon steel, made using electric arc furnaces powered by renewables, is gaining ground as a way to cut the massive emissions from old-school steel manufacturing.

The core idea behind sustainable materials is simple: build for the future without borrowing from it. By prioritising recycled content and lower-energy production, the industry is actively reducing its environmental impact one project at a time.

This entire movement gets a strong push from government-led initiatives. Programmes like Abu Dhabi's Estidama (which literally means 'sustainability') and Dubai's Al Sa'fat green building rating system provide a clear roadmap. They award points for using eco-friendly materials, which creates a powerful financial and regulatory reason for developers to choose green. You can learn more about how these rules influence what gets used on-site by checking out our guide on https://yasutrading.com/blog/navigating-the-regulations-for-building-materials-in-the-uae/.

Next-Generation Insulation and Design

In the UAE, energy use—especially for cooling—is a massive operational cost and a big environmental headache. This is where advanced insulation materials are making a huge difference, offering performance that blows traditional options out of the water. Materials like aerogel or vacuum-insulated panels give you incredible thermal resistance in a much thinner profile. This is a game-changer for architects, letting them design super-efficient buildings without eating into valuable interior space.

A major trend we're seeing is the adoption of concepts like Passive House principles for sustainable home design. It's all about creating an airtight building envelope with top-tier insulation to drastically cut down on energy needs from the get-go.

Here are a few sustainable categories really taking off:

- Recycled Plastics: Being cleverly transformed into durable decking, wall panels, and even insulation, giving plastic waste a valuable second life.

- Mass Timber: Engineered wood like cross-laminated timber (CLT) is popping up as a strong, low-carbon substitute for steel and concrete in certain structures.

- Hempcrete: This mix of hemp fibre, lime, and water creates a lightweight, breathable, and fantastic insulating material for walls and blocks.

The Dawn of Smart Materials

Beyond just being sustainable, the next frontier is intelligence. We're talking about smart materials, engineered with properties that let them react to their surroundings, offering incredible new levels of efficiency and strength.

Imagine concrete that can fix its own cracks. That’s the reality of self-healing concrete. It contains tiny capsules of healing agents that burst open when a crack forms, automatically sealing the damage and extending the life of the structure. It’s brilliant.

Then there's photovoltaic glass. This material looks just like regular architectural glass but has transparent solar cells embedded within it. It captures the sun's energy, essentially turning a building's entire facade into a power plant. These aren't just lab experiments anymore; they represent the real, practical future of building in the UAE—creating structures that are dynamic, responsive systems, not just static shells.

Decoding Costs and Regulatory Compliance

Getting a handle on the financial and legal side of things is just as vital as picking the right materials for any construction project here in the UAE. The final cost of UAE building materials isn't a simple line item on an invoice. It's a complex number, constantly pushed and pulled by global markets and local pressures. Knowing how these forces work is the secret to building a realistic budget and sidestepping nasty surprises down the line.

Think of material costs like a moving target. A shift in the global steel market today can directly ripple through your project’s budget tomorrow. Factor in the choppy waters of international shipping costs and the classic economics of local supply and demand, and you've got a perfect storm for price changes. A sudden surge in popularity for a specific type of aluminium cladding, for instance, can send its price climbing across the Emirates in a flash.

Understanding Mandatory Local Standards

Money aside, regulatory compliance is the bedrock of building in the UAE. It's non-negotiable. Every single item, from massive structural beams down to the tiniest screw or wire, has to play by a strict set of rules. These aren't just helpful guidelines; they are legal requirements enforced by bodies like the Dubai Municipality and the Civil Defence.

Front and centre is the UAE Fire and Life Safety Code. This code is incredibly thorough, setting tough performance standards for materials, particularly for things like facade panels, insulation, and interior finishes. The goal is simple: minimise fire risk and keep people safe.

Trying to cut corners on compliance isn't a shortcut—it's a massive financial and legal gamble. Materials that don't meet the standards will be rejected on-site. This means expensive rip-outs, stalled progress, and the risk of serious legal trouble. That 'cheaper' uncertified option almost always becomes the most expensive mistake you can make.

Certification and Testing Protocols

So, how do you make sure the materials you’re buying are up to snuff? It all comes down to certification and testing. A trustworthy supplier won't just sell you a product; they'll provide the paperwork to back it up, proving it has passed tests at an accredited lab. This documentation is your guarantee that the material meets all the necessary standards for fire resistance, durability, and strength.

For a more detailed look at the specifics, you can learn more about the building materials quality standards in the UAE in our comprehensive guide.

Always, always ask to see these certificates before you sign off on a purchase. This simple step of due diligence protects your project, your investment, and—most importantly—the people who will one day live or work in the building. A compliant project isn't just a successful one; it's a statement of quality and responsibility.

A Few Common Questions We Hear

Getting to grips with the UAE's building materials market always throws up a few questions. Whether you're a project manager, contractor, or developer, you're not alone. Here are some straightforward answers to the queries we see time and time again.

What Are the Biggest Sourcing Headaches?

When it comes to sourcing UAE building materials, a few familiar hurdles pop up. The main challenges usually circle back to logistics, especially for specialised goods coming in from overseas. It's not uncommon to see unexpected delays at busy ports like Jebel Ali, which is why smart planning and a good freight forwarder are worth their weight in gold.

Price volatility is another big one. The global markets for commodities like steel can swing wildly, and those fluctuations hit project budgets directly. And finally, there's the constant need for vigilance. You have to ensure every single product—particularly imports—has the right certifications to satisfy bodies like Dubai Municipality. It's a critical task that you can't afford to get wrong.

How Do I Make Sure My Materials Are Fire-Safe?

This is the big one. There’s absolutely no room for error here for any project in the Emirates. To be certain you're compliant, you must confirm that all relevant materials have been tested and certified by a third-party lab that's been given the green light by the UAE Civil Defence. This is especially vital for things like cladding, insulation, and all your electrical cabling.

Before you even think about finalising a purchase, ask for the official Certificate of Compliance from your supplier and go through it with a fine-tooth comb. This piece of paper is your evidence that the material meets the tough standards of the UAE Fire and Life Safety Code. Don't let anything be installed without it.

Taking this one proactive step is your best line of defence. Getting it wrong can lead to work stoppages, expensive rework, and serious legal trouble. It’s a simple check that protects your entire project.

Is It Better to Source Locally or Import?

Honestly, the smartest approach is usually a blend of both. The right answer really hinges on what specific material you're after.

- Go Local For: The basics. Think concrete, standard aluminium extrusions, aggregates, and steel rebar. Local manufacturing is almost always the more sensible and economical choice, giving you shorter lead times and dodging hefty shipping costs.

- Import For: The specialised stuff. If you need advanced curtain wall systems, a particular type of European natural stone, or high-tech MEP components, importing is often your only real choice, even with the higher logistical costs.

A savvy procurement plan knows how to balance the two. It leans on the reliability and cost benefits of local suppliers while strategically importing the specialised components needed to bring the architectural vision to life. This mixed strategy gives you the best of both worlds on most jobs.

For all your construction needs, from foundational hardware to specialised MEP components, Yasu Trading Co. LLC is your trusted partner in the UAE. We provide certified, high-quality materials to keep your project on schedule and within budget. Request your quote today and build with confidence.