UAE Summer Work Ban: Essential Safety Gear for Working in the Heat

When the summer heat hits in the UAE, simply having safety gear isn't enough. We're talking about a specific toolkit designed to beat the heat: think ventilated helmets with attachable neck shades, lightweight, moisture-wicking hi-vis clothing, and even specialised cooling vests. Don't forget the ground up—heat-resistant (HRO) safety boots are non-negotiable. This equipment has moved from the 'nice-to-have' list to being an absolute must for keeping your team safe and your site compliant.

Understanding the UAE Midday Work Ban

The annual summer work ban in the UAE is much more than just a mandatory break. It's the cornerstone of a legally enforced safety protocol designed to prevent heat-related illness and is a vital part of any robust occupational health and safety management system. For anyone managing a construction site or facility, getting to grips with these rules is essential, as it directly shapes what you buy, how you schedule your day, and how you protect your people.

The rule is straightforward: all work performed outdoors or under direct sunlight must stop between 12:30 pm and 3:00 pm. This three-month period, running from June 15th to September 15th every year, is designed to get workers out of the sun during the most dangerously hot part of the day.

But the law doesn't just stop at telling people to put their tools down. It places clear, legally binding responsibilities on employers, forcing a more proactive approach to heat safety on every worksite.

To break it down, here’s a quick summary of what the midday work ban entails.

UAE Midday Work Ban at a Glance

Requirement Specification Legal Reference Work Stoppage Prohibits outdoor work under direct sunlight. Ministerial Resolution No. (44) of 2022 Timings Daily from 12:30 pm to 3:00 pm. Ministerial Resolution No. (44) of 2022 Duration Annually from June 15th to September 15th. Ministerial Resolution No. (44) of 2022 Rest Areas Employers must provide accessible, shaded rest areas. Ministerial Resolution No. (44) of 2022 Hydration Cool drinking water must be adequately supplied. Ministerial Resolution No. (44) of 2022 These regulations are about creating a complete safety system, not just a simple pause in the workday.

Employer Responsibilities Under the Ban

The legislation is all about active prevention, not just passive avoidance. It's about creating a safe environment for the hours workers are on the job, not just the hours they're off. Every employer has a few key duties they absolutely must fulfil:

- Provide Shaded Rest Areas: This is non-negotiable. Workers need a cool, protected space where they can genuinely recover from the heat.

- Supply Cool Drinking Water: You must have plenty of cool, clean water available at all times. Dehydration is one of the biggest risks out there.

- Mandate Appropriate PPE: The rules make it official—personal protective equipment designed specifically for hot weather is now a legal requirement.

This framework has completely changed the game for safety equipment suppliers and buyers. What might have been seen as a premium extra a decade ago is now standard issue, driving a huge demand for advanced, heat-mitigating gear.

High Compliance Drives Equipment Standards

The UAE’s Midday Break has been incredibly successful. Under Ministerial Resolution No. (44) of 2022, the rules are clear, and the enforcement is effective.

The Ministry of Human Resources and Emiratisation (MoHRE) consistently reports compliance rates reaching an incredible 99.9%. This widespread adoption, detailed in outlets like The National News, means the conversation has moved on from if companies will comply to how well they comply.

The focus is now squarely on the quality and suitability of the safety equipment being provided. Contractors are expected to equip their teams with gear that meets tough UAE construction standards—things like wide-brim helmet shades, high-tech cooling vests, and S3-rated safety boots that can handle surfaces hot enough to cook on.

What is the best head and face protection for summer heat?

The best head and face protection for a UAE summer is a complete system, not just a single piece of equipment. This system should start with a ventilated hard hat that meets EN 397 standards and include accessories like neck shades and UV-rated safety glasses to protect against relentless sun and radiation. Handing a worker a standard hard hat is like giving them a tiny umbrella in a monsoon—it’s a token gesture against the relentless sun and UV radiation on site.

A proper setup starts with a high-quality hard hat, but it certainly doesn't end there. You need to add accessories that shield the face and neck from every angle. Think of it as creating a personal, mobile canopy for each worker. This comprehensive approach is absolutely essential for complying with the UAE summer work ban and, more importantly, for keeping your team genuinely safe.

Why is a ventilated hard hat the starting point?

A ventilated hard hat meeting the EN 397 standard is the essential foundation because it allows hot air to escape and creates airflow. This simple feature helps cool the head, reduces sweat build-up, and lowers the risk of heat stress without compromising impact safety. Unlike old solid-shell models, these helmets have small, integrated vents.

This constant air exchange makes a huge difference. It cuts down on heat and sweat build-up, which directly improves comfort and lowers the risk of heat stress. Also, look for models made from lightweight materials like high-density polyethylene (HDPE) or ABS plastic. When a worker has to wear something all day, comfort is key to compliance.

A study on construction worker safety found that even a 1-2°C reduction in head temperature can improve alertness and reduce the likelihood of errors. Ventilated helmets are a simple engineering control that contributes directly to this outcome.

Meeting UAE construction standards isn't just about ticking boxes; it's about choosing equipment that's right for the job and the environment. A ventilated hard hat is the first and most critical piece of the puzzle.

How do you add full sun and UV coverage?

You add full coverage by using either full-brim hard hats or attachable neck shades. A standard hard hat leaves the neck and sides of the face completely exposed—areas incredibly vulnerable to severe sunburn and long-term UV damage.

Fortunately, there are two straightforward solutions that work perfectly with EN 397-compliant helmets:

- Full-Brim Hard Hats: These have a wide brim that goes all the way around the helmet, providing 360-degree shade for the face, ears, and neck. It's a fantastic all-in-one option.

- Attachable Neck Shades: These are lightweight fabric drapes, usually made from UV-resistant material, that clip onto the back of a standard hard hat. They are a versatile and cost-effective way to upgrade your existing helmet stock.

Both of these options dramatically reduce direct sun exposure, which is a major factor in heat stress. Sourcing these from a reliable supplier in Dubai ensures you’re getting products designed for our local conditions. For a bigger picture on what's needed on-site, our guide on essential construction site safety equipment is a great resource.

What is the right eye protection for intense glare?

The right eye protection for intense glare must meet EN 166 for impact resistance and EN 170 for ultraviolet filters. The intense glare on a construction site doesn't just cause eye strain; it can temporarily blind a worker, creating a huge accident risk.

When you're choosing eyewear, make sure it has these features:

- UV400 Rating: This is critical. It ensures the lenses block nearly 100% of harmful UVA and UVB rays.

- Anti-Fog Coating: Between the humidity and sweat, fogged-up lenses are a constant, dangerous nuisance. An anti-fog coating is a must-have.

- Anti-Scratch Coating: Worksites are tough on gear. A scratch-resistant coating keeps vision clear and extends the life of the glasses.

- Tinted Lenses: Look for grey or brown tints. They cut down on glare without distorting colours, which is important for identifying safety signs and wires.

Sourcing the right eyewear from a trusted building materials distributor is just as important as getting the right helmet. It’s the final piece that completes the head and face protection system, ensuring your crew is shielded from every heat-related hazard from the neck up.

How do you choose the right heat-resistant clothing?

Choosing the right clothing involves selecting advanced fabrics that actively manage sweat, like moisture-wicking materials and breathable hi-vis mesh. The days of relying on a simple cotton shirt to beat the heat are long gone. To truly protect your team, you need to think about advanced material technology, certified visibility, and, most importantly, breathability.

Think of it this way: traditional clothing acts like a passive barrier, soaking up sweat and trapping heat against the skin. Modern workwear, on the other hand, is an active system. It's engineered to work with the body’s natural cooling mechanisms, not against them. For any procurement manager, understanding this distinction is the first step to sourcing gear that genuinely keeps people safe during the UAE summer work ban.

What are moisture-wicking fabrics?

Moisture-wicking fabrics are specially designed materials that pull sweat away from your skin and push it to the outer surface of the garment. This allows sweat to evaporate quickly, which is absolutely critical for staying cool, as trapped moisture turns clothing into a damp, heavy insulator that can actually make you hotter.

The science behind it is pretty straightforward but incredibly effective. These textiles—often synthetic blends like polyester or specially treated cotton—use what's called capillary action to draw moisture through the fabric. This keeps a worker's skin drier, allows air to circulate, and helps the body cool itself down naturally. It also gets rid of that clammy, uncomfortable feeling that can lead to heat rash.

A dry worker is a cool worker. By actively managing sweat, moisture-wicking fabrics can lower the perceived temperature by several degrees, significantly reducing the risk of heat exhaustion and improving overall endurance on the job.

Why is high-visibility mesh essential?

High-visibility (hi-vis) mesh is essential because it combines critical visibility with maximum airflow, preventing heat build-up. A standard hi-vis vest made from solid polyester fabric can trap a huge amount of heat, but the open-weave, perforated design of mesh provides the perfect solution.

On a bustling construction site, being seen is just as important as staying cool. These vests are a critical piece of essential safety gear for working in the heat because they manage to combine safety with comfort. It’s vital to choose vests that comply with EN ISO 20471, the standard that certifies the fluorescent material and retroreflective tape for both day and night-time visibility. Sourcing these from a reputable supplier in Dubai will also ensure they meet local UAE construction standards.

What are cooling vests and how do they work?

Cooling vests are garments that use either water evaporation or phase-change technology to actively cool the body's core temperature. They offer the next level of personal cooling technology and are no longer a niche item but a practical tool for anyone doing high-exertion tasks in the sun.

There are two main types, each suited to different environments:

- Evaporative Cooling Vests: You simply soak these vests in cool water. As the water slowly evaporates throughout the day, it draws heat away from the body, creating a noticeable cooling effect that can last for hours. They work best in low-to-medium humidity, where evaporation happens efficiently.

- Phase-Change Cooling Vests: These use special inserts filled with a non-toxic liquid that freezes at a relatively high temperature (around 15°C). You freeze the packs, insert them into the vest's pockets, and they absorb body heat as they slowly melt. This makes them ideal for the high-humidity conditions common in the UAE, where evaporative cooling is less effective.

With temperatures continuing to rise, heat-adapted safety gear is no longer a luxury—it's a strategic necessity. The National Centre of Meteorology has confirmed the UAE is experiencing its hottest months on record, with on-site metal surfaces reaching over 50°C. It's for this reason that MoHRE policies now mandate controls like moisture-wicking garments, making them essential for mitigating the serious risks of working in the heat. You can find out more about how companies are adapting to these crucial heat safety measures.

What is the best hand and foot protection for hot surfaces?

The best protection comes from gear specifically certified for high contact temperatures, such as gloves meeting the EN 407 standard and S3-rated safety boots with an HRO-certified outsole. When you're dealing with surfaces on a UAE worksite that can easily top 60°C, standard leather gloves and basic safety boots just won't cut it. They simply aren't designed for that kind of thermal punishment. We're talking about hot metal scaffolding, sun-baked rebar, and scorching asphalt – all of which pose a severe burn risk.

Choosing the right gloves and boots is a massive part of complying with the UAE summer work ban safety rules. It's not just about ticking a box; it's about giving your crew the tools they need to work safely without the constant danger of contact injuries. For anyone in procurement, this means looking past the usual impact and puncture resistance specs and focusing on thermal insulation ratings. The smart move is to partner with a knowledgeable supplier in Dubai who understands our climate and can provide gear that meets strict UAE construction standards.

How do you select heat-resistant gloves?

You select heat-resistant gloves by looking for models certified to the EN 407 standard for thermal risk. This certification is your guarantee that the gloves have been properly tested and graded for their ability to protect against contact heat. Your typical work gloves offer next to no insulation against serious heat.

You'll want to find gloves made from materials like aramid fibres (think Kevlar) or even aluminised fabrics. These materials are fantastic at insulating against heat without being so thick and clumsy that a worker can't do their job. After all, a worker who can't grip their tools properly creates a whole new set of safety problems.

Choosing gloves is always a trade-off between protection and function. You're looking for that sweet spot: the highest possible thermal resistance that still lets your team handle tools and materials with precision.

For jobs that involve grabbing hot pipes or metal sheets, gloves with higher contact heat ratings are non-negotiable. They create a crucial barrier, preventing the kind of serious burns that can happen in just a couple of seconds.

What is the best footwear for hot ground?

The best footwear for hot ground is an S3-rated safety boot with an HRO-certified outsole. That HRO certification is everything – it means the sole is engineered to withstand contact with surfaces up to 300°C for one minute. This is essential for anyone walking on asphalt, concrete, or steel decking in the middle of a UAE summer.

A standard boot sole will soften, warp, or even melt in those conditions, which is a major slip and fall hazard. An HRO-certified sole, usually made from a specialised rubber compound, holds its shape and grip even on blistering hot surfaces.

When you're talking to your building materials distributor, don't stop at the HRO rating. A few other features are critical:

- Slip Resistance: Hot, dusty surfaces can be surprisingly slick. A top slip-resistance rating (SRC) is a must.

- Breathable Linings: A boot that traps sweat is just asking for blisters and heat rash. Look for models with moisture-wicking linings to help keep feet cooler and drier.

- Composite Toe Caps: Unlike steel, composite materials don't conduct heat. This small detail makes a huge difference to a worker's comfort over a long day.

Ultimately, investing in the right footwear is about more than just safety. It's a productivity tool that keeps your people stable, comfortable, and protected from the ground up.

Comparing Heat-Resistant PPE Features

Selecting the right hand and foot protection requires a close look at the specifications. The conditions in the UAE demand gear that goes beyond basic safety to provide specific thermal protection. This table breaks down what to look for when choosing gloves and boots for high-heat environments.

PPE Item Essential Feature Relevant Standard Why It Matters in the UAE Heat-Resistant Gloves Contact Heat Resistance EN 407:2020 This standard directly tests a glove's ability to insulate against contact heat, crucial for handling superheated materials like rebar or scaffolding. Heat-Resistant Gloves Material Composition Aramid (Kevlar), Aluminised Fabric These advanced materials provide a thermal barrier without sacrificing the dexterity needed to safely handle tools and equipment. Safety Boots Heat Resistant Outsole (HRO) EN ISO 20345:2011 An HRO rating ensures the sole won't melt or deform on surfaces up to 300°C, preventing slips and sole failure on hot asphalt or metal decking. Safety Boots Composite Toe Cap EN ISO 20345:2011 Unlike steel, composite toe caps don't conduct heat, keeping the foot cooler and reducing the risk of heat-related discomfort or burns. Choosing equipment that meets these standards is a critical step in building a robust safety plan. It ensures your team isn't just equipped, but correctly and effectively protected against the specific thermal hazards they face every day on site.

Keeping Your Crew Hydrated and Rested

Getting your team kitted out with the right PPE is a great start, but it's only half the battle. The real bedrock of heat safety on any UAE worksite is a smart, proactive plan for hydration and scheduled rest. Without it, even the best gear can't prevent heat stress. It’s like building a skyscraper on a foundation of sand – it just won’t hold up.

Let's walk through how to build and enforce a robust strategy that not only keeps your people safe but also keeps you fully compliant with the Ministry of Human Resources and Emiratisation (MoHRE). A well-planned schedule isn't just a nice-to-have; it's a critical safety control that systematically manages a worker's physical exertion and exposure to the heat. This means going way beyond just sticking a water cooler in a corner. It requires a site-wide system that makes hydration and rest non-negotiable.

The Legal Lowdown on Hydration

Under UAE law, employers have a legal duty to provide a constant supply of cool, clean drinking water. During the summer, this is an absolute must. The law is also specific about providing oral rehydration solutions (ORS) or salts to help workers replace the essential electrolytes they sweat out.

The whole point is to stop dehydration in its tracks, before it even has a chance to set in. Here’s how to make that happen on your site:

- Smart Placement: Put water stations everywhere your crews are. A worker should never be more than a minute's walk away from a drink. Think high-traffic areas and right next to active work zones.

- Keep it Cool: Nobody wants to drink warm water in 45°C heat. Use properly insulated coolers and make sure they’re topped up with fresh, cool water all day long.

- Make it Obvious: Use clear, multilingual signs to mark every hydration station. There should be zero confusion about where to find water.

Getting Work-Rest Cycles Right

A one-size-fits-all break schedule just doesn't work. You have to tailor rest periods to the job's intensity. A team pouring concrete in the sun is going to need more frequent and longer breaks than a crew doing lighter, indoor tasks.

One of the most effective ways to manage this is with a 'buddy system'. Pair up your workers and train them to keep an eye on each other for the early warning signs of heat stress—things like dizziness, confusion, or just looking completely drained. This creates a culture of shared responsibility and ensures no one tries to tough it out and push past their limits.

The rule of thumb is simple: as the temperature and humidity climb, your breaks need to become more frequent. It's far better to rest proactively before someone gets sick than to deal with a medical emergency after the fact.

The UAE's Midday Break is much more than just a time slot; it's a complete heat-safety framework. MoHRE requires employers to provide not just the break itself, but also cool drinking water, rehydration salts, properly shaded rest areas, and all the necessary PPE. The penalties for getting this wrong are steep—fines start at AED 5,000 per worker and can go up to AED 50,000 if multiple workers are found on-site during the restricted hours. This no-nonsense enforcement has resulted in a compliance rate of over 99%, making it one of the most successful labour protection measures anywhere in the world. You can read more about how the UAE implements its midday break for the 19th consecutive year.

Think of your shaded and ventilated rest areas as a critical piece of your safety infrastructure, not just an expense. These spaces need to be large enough for your teams to rest comfortably, away from the direct sun. Working with a reliable building materials distributor can help you find the right high-quality, durable shading materials to create effective rest zones. It’s all part of a smart, proactive approach that proves prioritising your team’s well-being is simply good business.

Your Checklist for Procuring Summer Safety Gear

Even the best heat-mitigation plan falls apart if the gear you provide can't handle the job. Getting the right summer safety equipment onto your site—and keeping it in top condition—requires a solid, structured approach. A simple checklist can break this down into manageable steps, ensuring your team is protected and your operations stay compliant with all UAE construction standards.

The process starts long before a hard hat ever reaches a worker. It begins with partnering with a reliable building materials distributor who can source PPE that’s certified, durable, and actually suited for our demanding local climate. From there, it’s all about rigorous inspection and maintenance routines to make sure that gear performs as it should, every single day of the summer.

How should you source compliant PPE?

You should partner with a trusted supplier in Dubai who genuinely understands the specific demands of the UAE summer work ban. A knowledgeable supplier won't just sell you gear; they'll provide certified equipment that meets critical EN and ISO standards, giving you peace of mind about both compliance and worker safety.

When you're sourcing your equipment, focus on these key actions:

- Verify Certifications: Always ask for the paperwork. You need to see documentation confirming that PPE meets required standards, like EN 397 for helmets or EN 407 for heat-resistant gloves.

- Request Material Specifications: Dig into the details. Ask for specifics on the fabric types for clothing and the outsoles for boots to ensure they are truly designed for heat mitigation, not just rebranded standard gear.

- Consolidate Your Orders: Working with a single, well-stocked distributor simplifies your logistics and can often lead to better pricing. To get a clearer picture of the benefits, check out our insights on managing safety gear for bulk orders in Dubai.

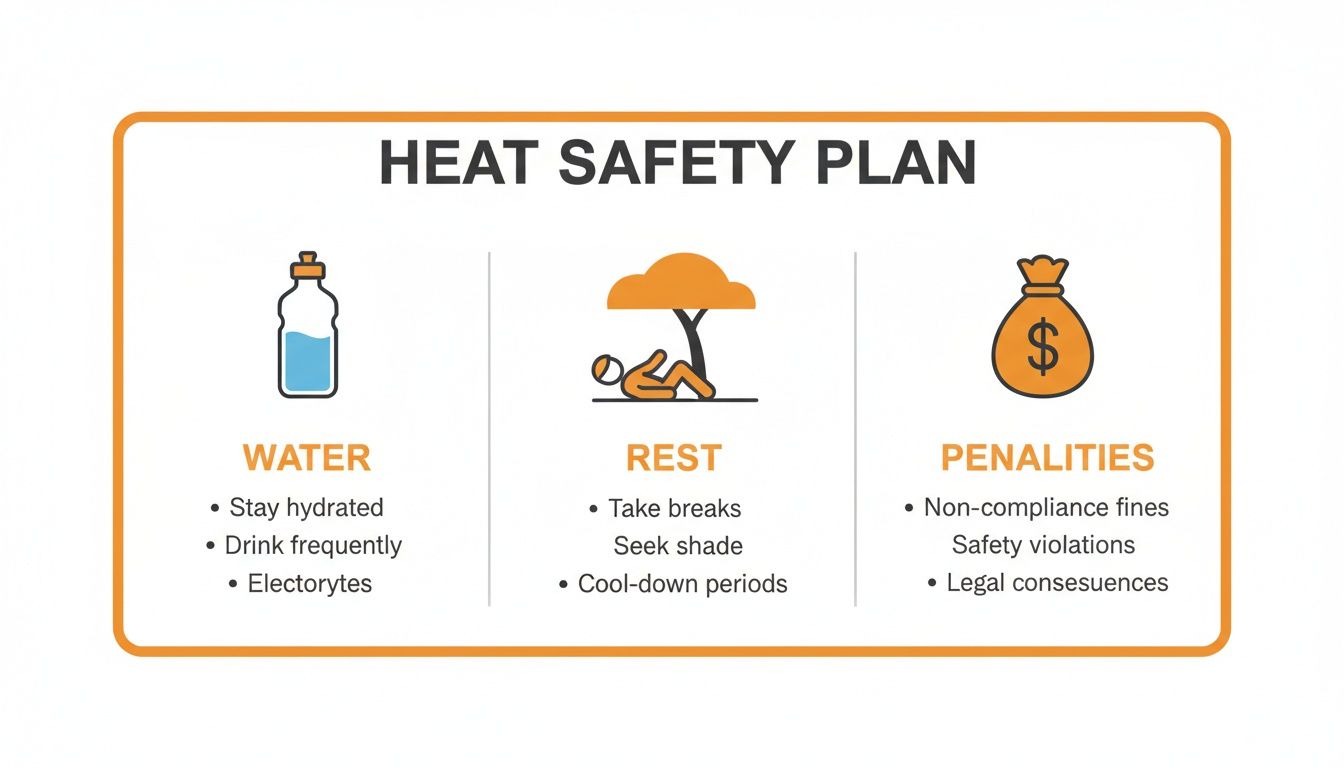

This graphic below neatly summarises the core pillars of any effective heat safety plan: water, rest, and the steep financial penalties for getting it wrong.

As you can see, worker welfare and regulatory compliance are two sides of the same coin—they form the foundation of successful summer worksite management.

What is on a daily and weekly inspection checklist?

A daily checklist includes worker self-checks for obvious damage like cracks in hard hats or scratches on safety glasses. A weekly checklist involves a supervisor conducting a more detailed inspection of all PPE for wear and tear, logging any issues, and testing the functionality of items like cooling vests.

Daily "Look-Over" Checks (By Worker):

- Hard Hats: Look for any cracks, dents, or a chalky appearance, which is a classic sign of UV degradation.

- Safety Glasses: Check for deep scratches that could obstruct vision. A small scratch is one thing; a major one is a hazard.

- Cooling Vests: Make sure there are no rips or leaks in the cooling packs.

Weekly "Deep-Dive" Inspections (By Supervisor):

- All PPE: Go through everything systematically. Look for signs of wear and tear, like frayed stitching on vests or worn-down boot treads.

- Functionality Test: Don’t just look at it—test it. For example, activate evaporative vests to make sure they still absorb and hold water effectively.

- Log Everything: Keep a detailed record of all inspections. Note any equipment that was flagged or replaced. This log is your proof of due diligence.

A proactive inspection routine does more than just catch failing equipment; it reinforces a site-wide culture of safety, showing every worker that their wellbeing is the top priority.

How do you maintain and store summer gear properly?

You maintain summer gear by cleaning it regularly according to manufacturer instructions and storing it in a cool, dry place away from direct sunlight. Proper maintenance and storage are essential for extending the life and effectiveness of your essential safety gear for working in the heat. Remember, intense heat and UV radiation can break down materials much faster than you’d think.

- Cleaning: Moisture-wicking clothing needs to be washed regularly to prevent bacteria buildup and keep it breathable. Hard hats and safety glasses should be wiped down daily.

- Storage: Store all PPE in a cool, dry place, and crucially, away from direct sunlight. Never, ever leave a hard hat on a vehicle dashboard where the intense heat can warp and weaken the plastic.

- Replacement Schedule: Have a clear schedule for replacement. Items like hard hats have an expiry date printed right on them, but they might need to be replaced even sooner if they show obvious signs of sun damage.

It's also worth noting that beyond traditional gear, innovative tools like augmented reality safety programs are emerging to help enhance training and hazard recognition, which is especially valuable in our challenging environment.

Got Questions? We've Got Answers

When it comes to the UAE's summer work ban, a lot of questions pop up for managers and safety officers on the ground. We get it. Let’s clear up some of the most common ones so you can keep your site safe, compliant, and running smoothly.

What are the official dates and times for the ban?

The official midday work ban runs every year from June 15th to September 15th. During this three-month stretch, all work performed outdoors and under direct sun must stop between 12:30 pm and 3:00 pm.

This isn't a guideline; it's a non-negotiable rule from the Ministry of Human Resources and Emiratisation (MoHRE), and it’s taken very seriously. Planning your project timelines around this break is simply part of doing business here in the summer.

Are there any exemptions to the rule?

Yes, there are specific exemptions for jobs that cannot be stopped for technical reasons. This could include critical infrastructure work like fixing a major water line, dealing with a power grid failure, or laying freshly mixed asphalt that has to be done in one continuous pour.

Getting an exemption isn't a free pass, though. If your team has to work through the break, you’re still on the hook for their safety. You must provide essentials like cool drinking water, rehydration salts and solutions, and access to cooling stations with fans or misters. The bottom line is always the well-being of your crew.

Where can I find safety gear that meets UAE standards?

You can find compliant safety gear by partnering with a specialised building materials distributor who knows the local landscape. A reliable supplier in Dubai won’t just sell you gear; they’ll have a deep understanding of what’s required, stocking PPE that meets both international standards (like EN or ISO) and specific UAE construction standards for heat resistance.

Think of a knowledgeable supplier as a procurement partner, not just a vendor. They can advise you on the right specs for everything from HRO-rated safety boots to properly ventilated hard hats, making sure the money you spend on safety actually keeps your people safe and your site compliant.

What happens if we don’t comply?

If you don’t comply, your company will be fined AED 5,000 per worker caught violating the midday work ban. If multiple workers are found on-site during the prohibited hours in a single instance, the total fine can go up to a maximum of AED 50,000. These steep penalties make it crystal clear: prioritising your team’s safety isn’t just the right thing to do, it's a financial necessity.

For all your municipality-compliant safety equipment and construction material needs, trust the experts at Yasu Trading Co. LLC. We provide a comprehensive range of certified PPE and offer site-direct delivery across the UAE to keep your projects safe, compliant, and on schedule. Explore our full catalogue at https://yasutrading.com.