Understanding Thread Types: Tapered vs. Parallel Fittings in Plumbing

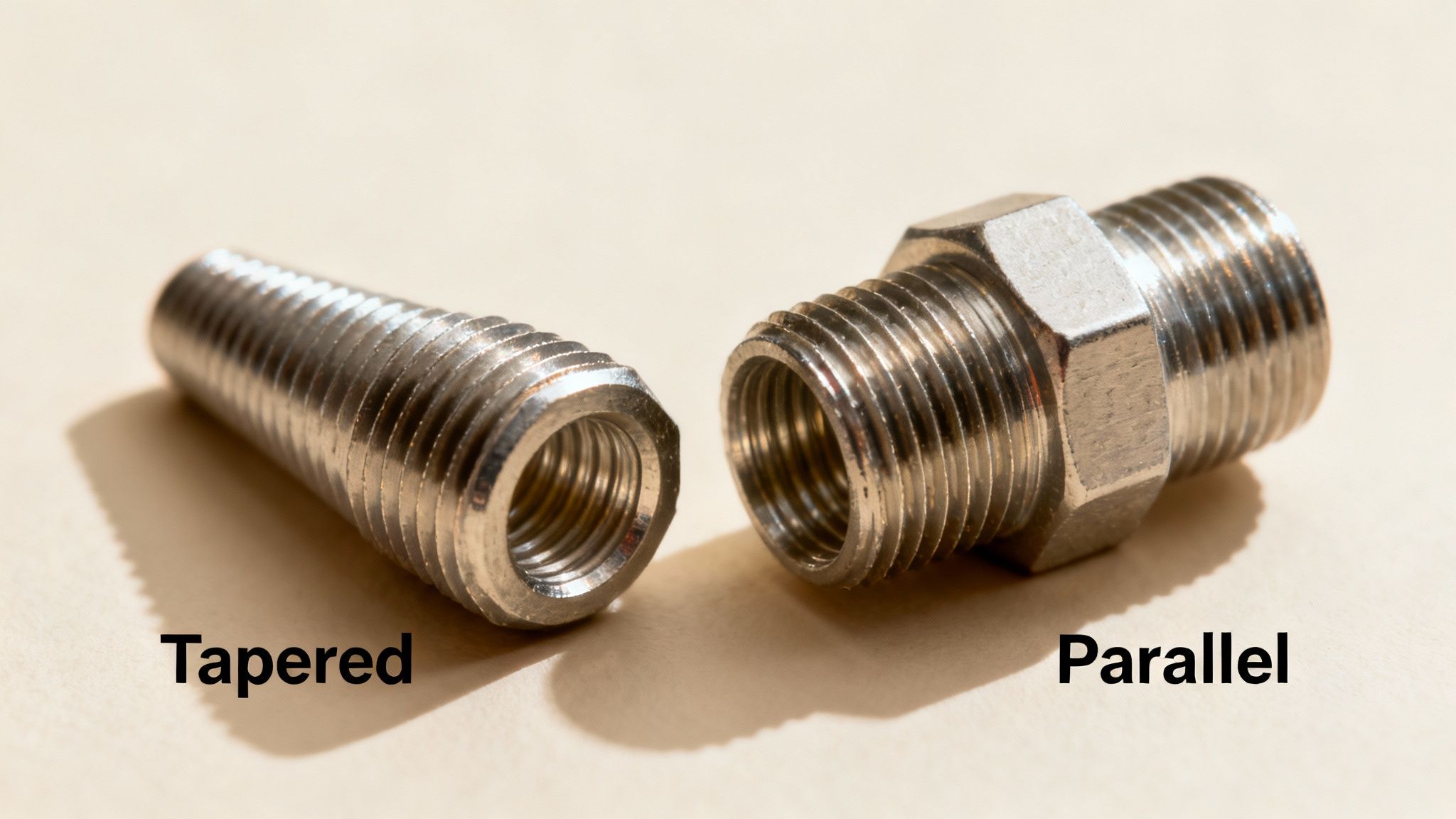

At the heart of it, the difference is straightforward. Tapered threads, like the common NPT and BSPT types, are designed to create a seal all on their own. As you tighten them, the threads wedge together, forming a strong metal-to-metal interference fit. On the other hand, parallel threads (like BSPP) need a little help; they rely on a separate gasket, washer, or O-ring to do the actual sealing.

This single design difference is what determines where they shine—tapered for high-pressure, permanent systems, and parallel for jobs that might need to be taken apart later.

Decoding the Language of Pipes

When you’re working with plumbing or mechanical systems, the threads on a fitting are doing much more than just holding pipes together. They're a core part of the system's integrity. Getting the thread type right is a fundamental decision that affects everything from performance and safety to long-term reliability.

A simple mix-up between tapered and parallel fittings can cause persistent leaks, damage expensive equipment, and lead to serious project delays. For any professional working in the UAE's demanding construction and industrial environments, getting this right isn't just a detail—it's essential.

Let's break down the key characteristics of each thread type so you can be confident you're making the right choice every time.

Key Distinctions at a Glance

Before we get into the nitty-gritty, this quick comparison should help frame the conversation. Think of it as the main trade-offs you're making when you choose one over the other.

| Feature | Tapered Threads (e.g., NPT, BSPT) | Parallel Threads (e.g., BSPP) |

|---|---|---|

| Sealing Method | Metal-to-metal interference (wedging action) | Compression of a gasket, washer, or O-ring |

| Primary Function | To create a pressure-tight seal directly | To provide strong mechanical clamping force |

| Ideal Pressure | High-pressure applications | Low to moderate-pressure systems |

| Reusability | Limited; threads can deform upon tightening | High; sealing element is replaceable |

Seeing these principles applied in practice is a cornerstone of large-scale construction. You can explore more on how these choices impact major projects through resources covering MEP Engineering in Dubai. Knowing these nuances is also critical when it comes to sourcing the right parts. For a look at what’s available locally, this overview of plumbing fittings in Dubai can help ensure you’re selecting components that meet regional standards. This knowledge helps guarantee every connection is secure, reliable, and perfectly suited for its job.

How Tapered Pipe Threads Create a Seal

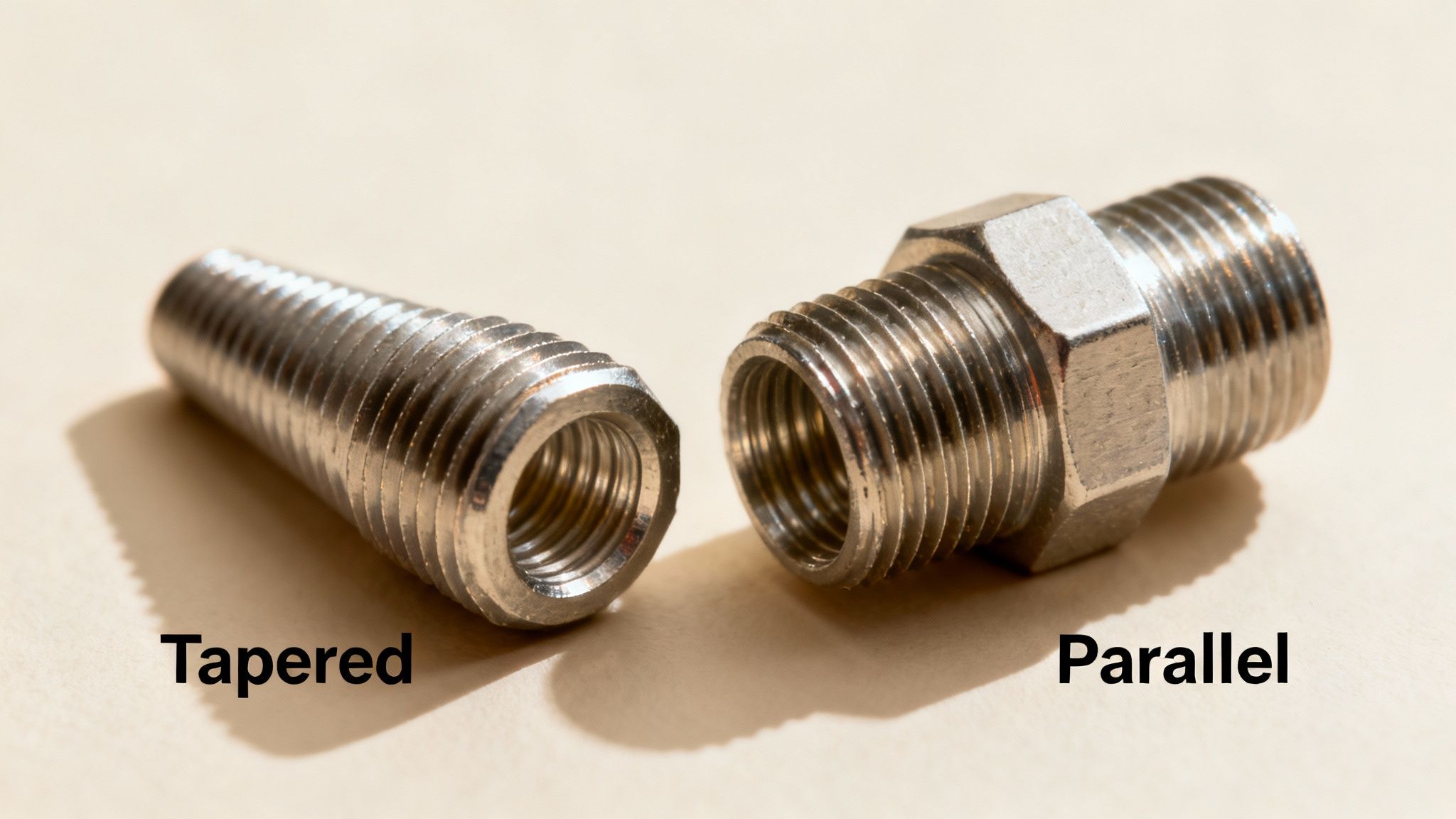

Tapered pipe threads are a classic piece of engineering, designed with one critical job in mind: creating an incredibly strong, pressure-tight seal through pure mechanical force. Unlike straight or parallel threads, the real genius of a tapered thread is its conical shape. The diameter of the thread actually gets smaller from the opening down to the tip.

When you tighten a male tapered fitting into a female one, this design creates a powerful wedging action. The threads are literally forced together, deforming just enough to crush any gap between them. This is what we call an interference fit, and it forms a solid metal-to-metal seal that can handle serious pressure without needing a separate gasket or O-ring.

The Mechanics of the Seal

The seal itself is created by the compression that happens on the flanks of the threads as you tighten the joint. Picture forcing a cone into a perfectly matched socket—the further you push it in, the tighter it gets. This is why tapered threads are the go-to choice for demanding plumbing systems you see across industrial and commercial sites in the UAE.

You'll encounter this design in the two most common standards: NPT (National Pipe Taper), which is the North American standard, and BSPT (British Standard Pipe Taper), which is the one we see most often here and across Europe. Both operate on this same fundamental wedging principle.

The real beauty of a tapered thread is that the seal actually gets stronger when it's put under internal pressure. The force from the gas or liquid inside the pipe pushes the male and female threads even tighter together, reinforcing the joint’s integrity.

The Essential Role of Thread Sealants

Now, while that interference fit does most of the heavy lifting, it's rarely a 100% perfect seal on its own. There are almost always microscopic gaps along the crests and roots of the threads, creating what's known as a spiral leak path. To guarantee a completely leak-proof connection, you absolutely need to use a thread sealant.

A good sealant does two critical things:

- Fills Voids: It gets into every tiny imperfection in the threads, completely blocking any potential escape route for liquids or gases.

- Lubricates: It acts as a lubricant during assembly, which is crucial for preventing galling. Galling is when the threads seize up from friction, which can damage them permanently and ruin the seal.

This one-two punch of a strong mechanical fit and a quality sealant is why tapered threads are non-negotiable for critical systems like gas lines, fire sprinklers, and hydraulic equipment. It's all about safety and performance when the stakes are high.

Here in the region, the booming Middle East and Africa pipe fittings market is built on the reliability of these pressure-tight connections, especially those that meet standards like ASME B1.20.1 for NPT threads. As you can see from the regional pipe fittings market trends on Grand View Research, this reliance highlights just how important proper thread selection and installation are for the massive infrastructure projects underway.

The Role of Parallel Pipe Threads in Systems

While tapered threads essentially jam themselves together to form a seal, parallel pipe threads are far more strategic. Think of them as a high-strength bolt rather than a wedge. Unlike their conical counterparts, these threads run straight, maintaining a constant diameter from start to finish. Their main job isn't sealing—it's to provide a powerful and reliable mechanical connection.

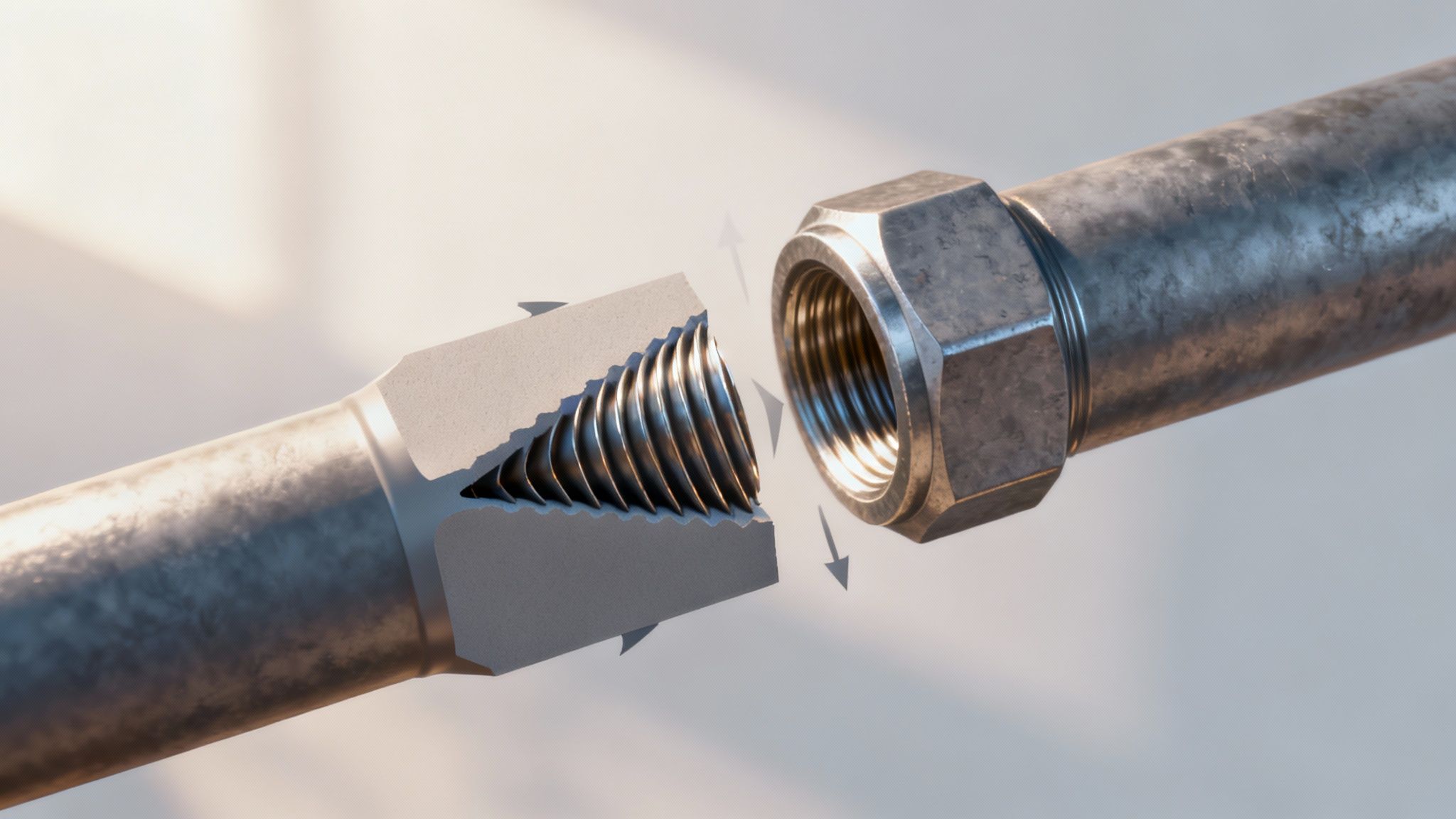

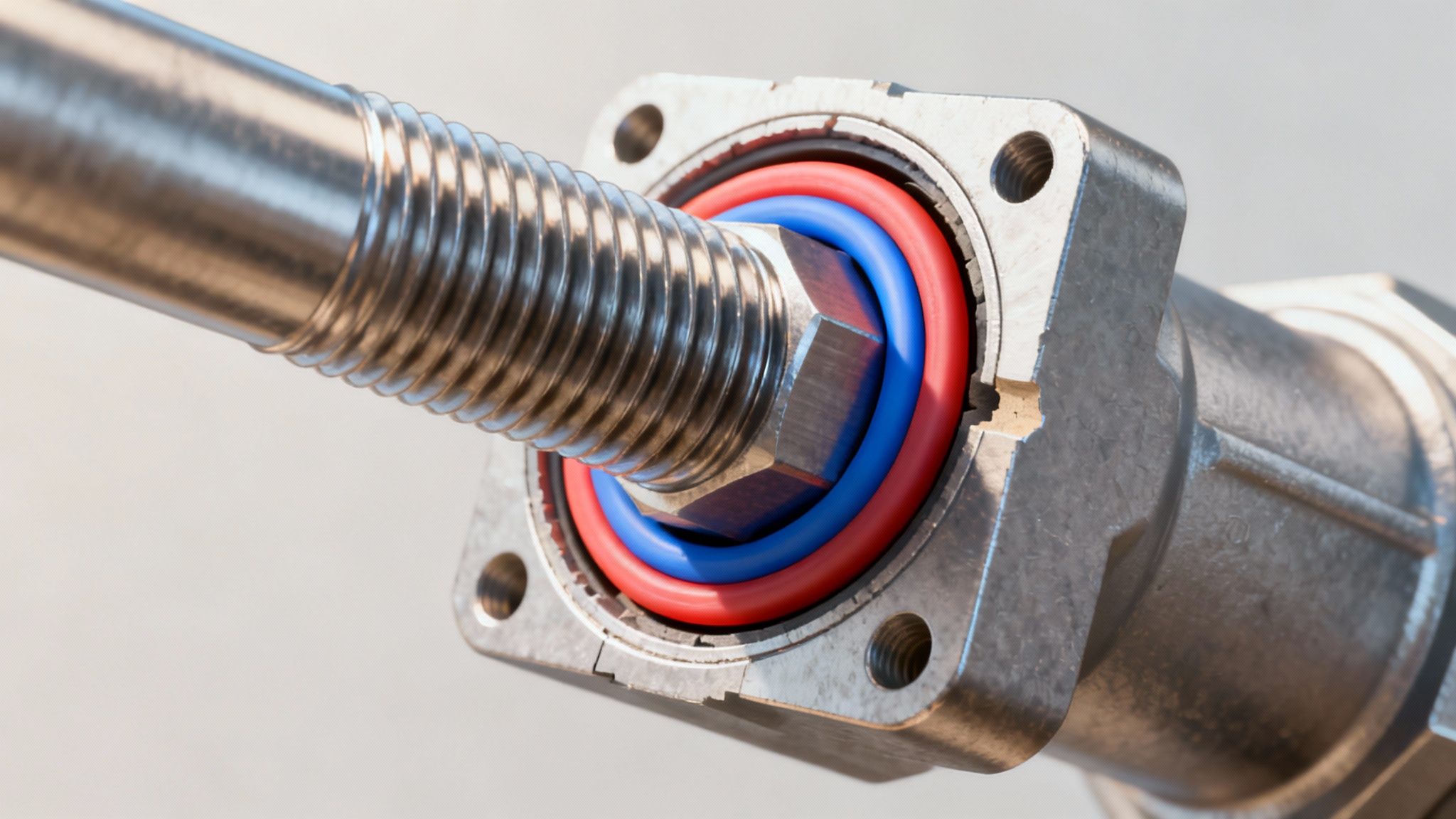

This design philosophy is the key to understanding where they shine. Because the threads themselves aren't creating the seal, another component has to step in to stop leaks. The pressure-tight barrier is only made when an external element, like a washer or O-ring, gets compressed between the male fitting and the face of the female port.

The Two-Part Sealing Mechanism

This two-part system is what gives parallel threads, such as the common BSPP (British Standard Pipe Parallel), their unique advantage. First, you establish a rock-solid mechanical connection by tightening the threads. Then, you create an entirely separate seal.

This seal is usually made by one of three things:

- Bonded Washer: A metal ring with a rubber seal vulcanised to its inside edge. When you tighten the fitting, this combination creates a fantastic, reliable seal.

- Gasket: A simple flat ring, typically made from fibre or rubber, that squashes down to fill any tiny gaps or imperfections on the mating surfaces.

- O-Ring: A tough rubber loop that sits neatly in a groove and gets compressed to form a dependable, tight seal.

Separating the job of clamping from the job of sealing is the whole point. Because you're not deforming the metal threads to make the seal, the risk of galling or stripping them is almost zero. This is what makes them so durable and, most importantly, reusable.

The core strength of a parallel thread fitting lies in its serviceability. Because the seal is created by a replaceable component, the fitting can be assembled and disassembled multiple times without compromising its integrity, making it ideal for systems requiring regular maintenance.

Ideal Applications in the UAE

This reusability makes parallel threads a go-to choice for modular systems or any equipment that needs regular check-ups. Across the UAE's industrial and commercial projects, you'll see them used anywhere components are frequently inspected, maintained, or swapped out. For a look at the different fittings available, this guide on pipe connectors in Dubai is a great resource that shows options perfect for these scenarios.

You'll often find parallel threads in situations like these:

- Hydraulic Power Packs: Connecting hoses, valves, and cylinders that will inevitably need servicing.

- HVAC Equipment: Used on pumps, filters, and other components subject to routine maintenance schedules.

- Accessible Plumbing Components: Perfect for connections to flexible hoses or fittings under a sink where you need the option for easy removal.

Ultimately, choosing a parallel thread is a practical decision. You're opting for long-term serviceability and ease of maintenance over the brute-force, one-and-done seal of a tapered thread. It’s an essential tool in any professional’s arsenal here in the UAE.

Tapered vs Parallel Fittings: A Head-to-Head Comparison

Picking between tapered and parallel fittings really comes down to understanding how they're built to work. While both are used to connect pipes, the way they create a seal is fundamentally different, which gives each one a clear advantage in certain plumbing situations. Let’s break down what professionals here in the UAE need to weigh up before making a choice.

A tapered thread seals with a combination of brute force and clever engineering. Its cone shape creates what we call an interference fit. As you tighten it, the male and female threads wedge together, forcing a powerful metal-to-metal seal. A parallel thread, on the other hand, works more like a simple clamp. Its job is to provide the mechanical strength, while a separate piece—like a gasket, washer, or O-ring—actually does the sealing work.

This basic difference in sealing method is what determines where each fitting shines and what can go wrong during installation.

Pressure Handling Capabilities

When you’re dealing with high-pressure systems, tapered threads are almost always the better bet. That wedging action creates a seal that's incredibly tough and can handle a huge amount of force. In many cases, the internal pressure of the system actually helps to reinforce the connection, pushing the threads even tighter together. This is why you see them used so often in gas lines, hydraulic systems, and fire protection pipework.

Parallel threads are generally a better fit for systems running at low to moderate pressures. Because the seal depends entirely on compressing a separate gasket or O-ring, the fitting's pressure rating is limited by that sealing component. They are perfectly fine for general plumbing and many HVAC systems, but they wouldn't be your first choice when containing extreme pressure is the top priority.

The decision often comes down to this: tapered threads are for permanent, high-integrity connections where leaks are not an option, whereas parallel threads offer practicality for systems that require accessibility and maintenance.

Reusability and Installation Risks

This is where the tables turn completely. For any system that needs to be taken apart from time to time, parallel fittings are the clear winner. The threads themselves don’t get deformed when you tighten them, so you can disassemble and reassemble the connection multiple times without losing its integrity. All you need to do is swap out the cheap gasket or O-ring, and you’ve got a perfect seal again.

Tapered fittings, however, really aren't meant to be reused. The very process of tightening them distorts the metal to form the seal. Every time you reassemble it, you risk distorting the threads even more, which dramatically increases the chance of a leak. There's also a real danger of over-tightening, which can crack the female fitting and lead to a catastrophic failure. This makes them ideal for "fit-and-forget" jobs.

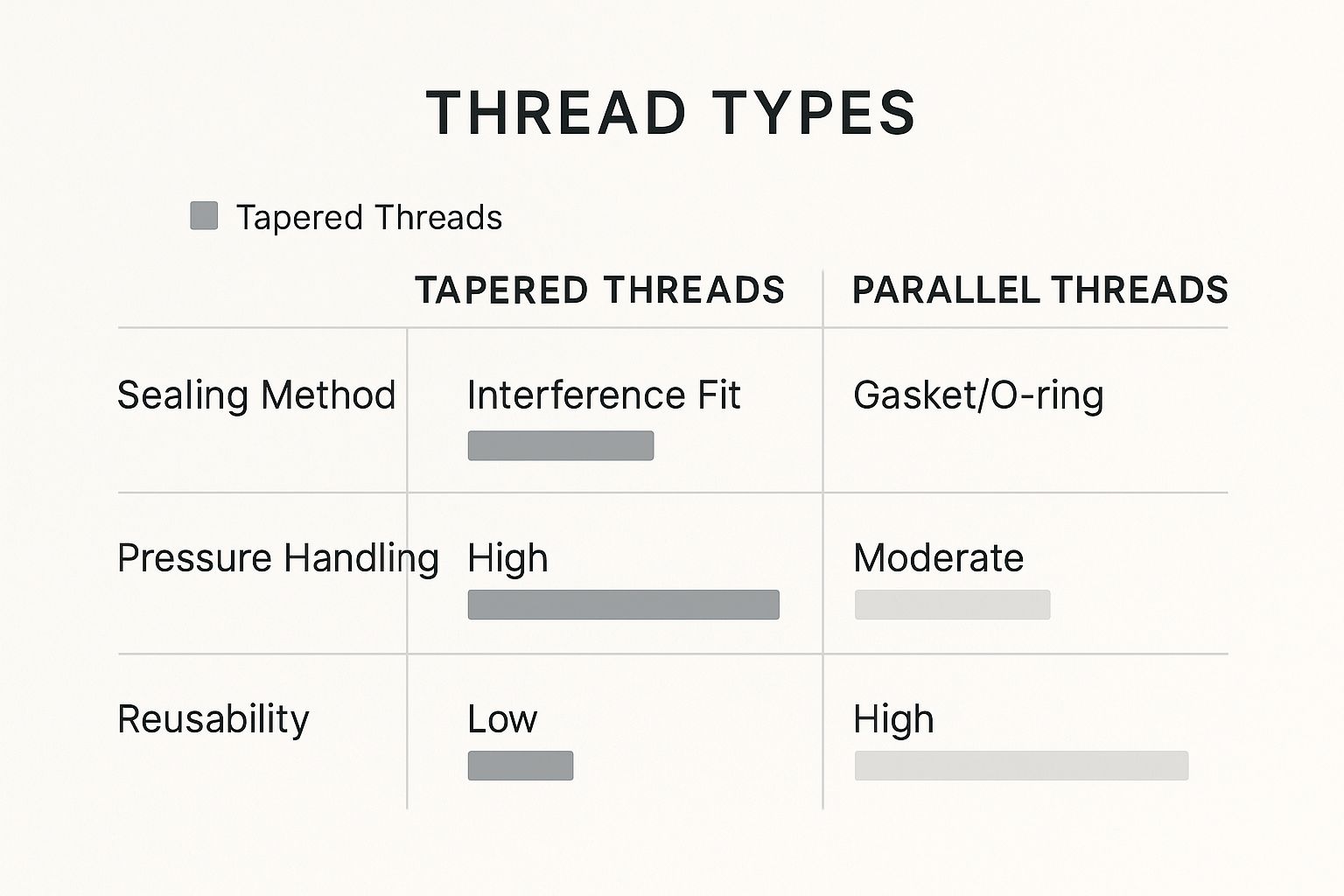

This infographic simplifies the primary trade-offs between tapered and parallel threads based on sealing, pressure, and reusability.

The visual breakdown makes it clear that the choice is not about which is better, but which is correct for the specific demands of the job.

With the pipes and fittings market in the MEA region valued at around USD 7.98 billion in 2024, these decisions are made by contractors every single day. Tapered fittings are typically specified for those permanent, pressure-tight jobs, while parallel fittings are chosen for their excellent serviceability. You can find more MEA pipes and fittings market trends on MarkNtel Advisors to see just how big this sector is. Getting these distinctions right is key to working effectively in this market.

Tapered vs Parallel Threads: A Feature Comparison

To make the choice even clearer, let's put these two thread types side-by-side. This table breaks down their core characteristics to help you quickly decide which one is right for your next project.

| Feature | Tapered Threads (e.g., NPT, BSPT) | Parallel Threads (e.g., BSPP) |

|---|---|---|

| Sealing Mechanism | Metal-to-metal interference fit; threads deform to create the seal. | Mechanical compression of a separate gasket, washer, or O-ring. |

| Primary Sealant | Thread sealant or PTFE tape is essential to fill gaps. | The gasket or O-ring provides the seal; no sealant on threads. |

| Pressure Rating | Excellent for high-pressure applications. | Best for low-to-moderate pressure systems. |

| Reusability | Not recommended; threads are damaged during initial tightening. | Highly reusable; just replace the sealing element. |

| Installation Risk | High risk of over-tightening, which can crack the female fitting. | Low risk of thread damage, but the gasket can be improperly seated. |

| Common Uses | Gas lines, fire sprinklers, hydraulic systems, permanent plumbing. | General plumbing, HVAC, systems requiring maintenance or service. |

| Vibration Resistance | Good, as the wedging action creates a tight, secure connection. | Can loosen under heavy vibration without a proper locking mechanism. |

Ultimately, both thread types have their place in modern plumbing. The key is to match the fitting's design philosophy with the demands of the specific application, ensuring a reliable and long-lasting installation every time.

Choosing the Right Thread for the Job

Knowing the technical differences between thread types is one thing, but translating that knowledge into a smart decision on a job site is what really counts. For contractors here in the UAE, picking the right fitting isn't just about performance—it’s about ensuring long-term reliability and meeting precise project specs. The choice between tapered and parallel threads boils down entirely to what the system needs to do.

When a connection needs to be permanent and absolutely leak-proof, tapered threads are the go-to standard. We're talking about critical infrastructure where failure simply isn't an option. Picture the high-pressure gas lines in a new commercial tower or the hydraulic connections on heavy industrial machinery—these applications depend on the solid, metal-to-metal seal that only a tapered design can deliver.

When to Specify Tapered Threads

Tapered threads really shine in applications where stability and pressure handling are non-negotiable. The wedging action of the threads creates an incredibly strong seal that holds up against serious force and vibration, making it the clear winner for fixed, permanent installations.

Think about these common scenarios:

- Permanent Gas and Fuel Lines: Here, the seal has to be 100% leak-proof and permanent.

- Fire Sprinkler Systems: These systems sit under high pressure for decades, so you need a true fit-and-forget solution.

- High-Pressure Hydraulic Systems: In demanding industrial environments, these connections must handle extreme pressures without a hint of failure.

The core principle is simple: choose tapered threads for permanence. If a connection isn't meant to be regularly taken apart for servicing, the strength and reliability of that interference fit provides the best long-term security.

When Parallel Threads Are the Smart Choice

On the other hand, parallel threads are the practical pick for any system that needs routine maintenance, inspection, or component swaps. Their design separates the clamping force from the sealing action, which means you can assemble and disassemble them repeatedly without wrecking the threads. This makes them perfect for any accessible or modular system.

Here are a few prime examples:

- HVAC Equipment: Components like pumps, filters, and valves often need to be serviced or replaced.

- Water Pump Connections: Easy access for maintenance is key, and parallel fittings make that possible.

- Hydraulic Power Packs: These are modular units built for serviceability, making parallel threads a natural fit.

This decision-making process aligns with global best practices, which we see reflected right here in the region. As the MEA pipe market grows with major infrastructure investments, tapered fittings are typically specified for high-pressure oil and gas work, while parallel fittings are favoured for their ease of maintenance in commercial and residential projects. You can explore more about these trends in the MEA pipe market on Data Bridge Market Research to see how these choices play out on a larger scale.

Of course, making the right choice also means thinking about the fitting material itself. The durability and corrosion resistance of different metals can make a huge difference in the system's lifespan. For a deeper dive on this, check out our guide on stainless steel pipe fittings. At the end of the day, a solid understanding of tapered vs. parallel fittings in plumbing ensures every connection you make is not just secure, but perfectly suited for its specific job.

Answering Your Top Questions About Pipe Threads

Even when you know the difference between tapered and parallel threads, questions always pop up on the job site. Getting straight answers is key to avoiding expensive mistakes and making sure every connection is solid. Here, we tackle the most frequent queries we hear from plumbing pros about these fittings.

Choosing the right thread is a daily decision, and sorting out any confusion from the get-go is the best way to protect the integrity of your entire system.

Can You Mix Tapered and Parallel Threads?

This is probably the most critical question, and the answer is a hard no. You should never, ever mix thread standards. Trying to force a male NPT fitting into a female BSPP port, for instance, is just asking for trouble. Their designs are completely incompatible.

The problem is that the thread angles, pitches, and the very way they are designed to seal just don't match up. A mismatched connection won't form a proper mechanical bond, let alone a reliable seal. You'll end up with a weak joint that can't handle pressure and is almost guaranteed to leak, risking serious damage to the system and the property around it.

Pro Tip: Always double-check that the male and female fittings are the exact same thread standard before you even think about connecting them. This simple habit is one of the most effective ways to prevent leaks and build a plumbing system that lasts.

What's the Best Sealant to Use for Tapered Threads?

For tapered threads, using a sealant isn't just a good idea—it's absolutely mandatory if you want a leak-free joint. While the interference fit provides the mechanical strength, it's the sealant that fills the tiny gaps in the threads that can otherwise let liquid or gas spiral out. The best sealant really depends on what you're working with.

Here’s a quick breakdown:

- Standard Water Lines: A good-quality PTFE tape (often called Teflon tape) is usually all you need. It’s clean, simple to apply, and works perfectly for typical plumbing jobs.

- Gas or Chemical Lines: These systems are far more critical, so you must use a sealant specifically rated for the job. This could be a denser, chemical-resistant PTFE tape or a specialised anaerobic pipe sealant that hardens once the fitting is tight.

- High-Temperature Systems: For boilers or hot water systems, you'll need special sealants made to handle the heat. Standard ones will just break down and fail.

Always check the manufacturer's recommendations for both the fittings and the substance they'll be carrying. And, of course, make sure you're following local UAE plumbing codes to stay compliant and safe.

How Do I Stop Myself From Over-Tightening Tapered Fittings?

Over-tightening is easily the most common mistake we see with tapered threads, and the results can be catastrophic. The wedging action creates immense pressure that can crack the female fitting, causing the entire joint to fail. Remember, the seal comes from the taper of the threads, not from brute force.

The right way to do it is the "hand-tight plus turns" method. First, thread the fitting by hand until it’s snug. Then, grab your wrench and tighten it a specific number of extra turns—usually somewhere between one and two full rotations past hand-tight. The exact number depends on the size and material of the fitting, so always refer to the manufacturer's guidelines. This controlled technique creates a perfect seal without pushing the components past their limits.

For all your projects requiring precision-engineered fittings and reliable plumbing solutions, Yasu Trading Co. LLC offers a comprehensive selection of high-quality building materials tailored for the UAE market. Request a quote today and ensure your projects are built with the best.