The UAE Contractor's Guide to upvc pipes & fittings

When you're choosing materials for modern plumbing and drainage, uPVC pipes and fittings are the go-to for a reason. They're tough, they last, and they just work. This material, which stands for Unplasticized Polyvinyl Chloride, is a very rigid and strong type of PVC. That makes it perfect for everything from high-pressure water supply lines to simple gravity-fed drainage systems, cementing its place as a true workhorse in today's construction world.

Why is uPVC a Go-To for UAE Construction Projects?

In a place like the UAE, where construction demands are incredibly high, the materials you choose can make or break a project. Time and again, engineers and contractors turn to uPVC for its sheer reliability and resilience, especially on the massive projects you see rising across Dubai and Abu Dhabi.

So, what does the 'u' actually mean? It signifies that no plasticizers have been added during manufacturing. The result is a pipe that’s exceptionally strong and inflexible. This structural integrity is exactly why uPVC is trusted for such a wide range of jobs, from handling the constant force in potable water networks to providing the backbone for vast underground drainage and sewer systems. Its popularity isn’t an accident; it's a strategic choice for long-term, hassle-free performance.

Why does uPVC make financial sense?

The shift towards uPVC isn't just about performance—it's also a smart financial decision that's helping to fuel the region's economy. The market numbers tell the story. In the UAE, the PVC pipes market, where uPVC pipes and fittings are a major player, was valued at a solid USD 280.0 million. And it’s not slowing down, with forecasts predicting it will climb to USD 384.0 million by 2033, growing at a steady 3.6% each year.

This growth is a direct reflection of the UAE's incredible infrastructure development and urban expansion. You can explore the data further by checking out the UAE PVC pipes market growth on imarcgroup.com. It's clear that these mega-projects rely on dependable piping for absolutely essential services like plumbing, irrigation, and wastewater management.

Why is finding the right supplier key?

A project is only as good as the materials you build it with, and sourcing top-quality uPVC is non-negotiable. This is where partnering with a trusted building materials distributor becomes critical. A good partner ensures every pipe and fitting you receive doesn't just meet but actually exceeds the strict UAE construction standards.

An experienced supplier in Dubai does more than just sell you products. They bring invaluable technical expertise to the table, helping you navigate the specs to select the right components for your specific needs. This kind of guidance is crucial for ensuring you comply with local municipality regulations, keeping your project on schedule and, just as importantly, on budget.

Why is uPVC a Smart Choice for the UAE Climate?

When you're building in the UAE, you're not just putting up a structure; you're fighting the environment. The relentless heat, the salty, humid air, and the corrosive soil can wreck standard building materials. This is precisely where uPVC pipes & fittings prove their worth, offering a robust solution that’s practically tailor-made for these tough conditions.

The biggest win for uPVC is its complete resistance to corrosion and chemical damage. Think about it: the desalinated water running through our taps and the aggressive salts in the ground along the coast are a death sentence for metal pipes. uPVC simply doesn't react to them. It won’t rust or degrade, which means you get a much longer, more reliable service life.

How does uPVC handle intense heat?

uPVC is specifically engineered to be tough and hold up under the constant sun. Its chemical makeup is naturally inert, so it doesn't suffer from the reactions that cause metals to corrode. On top of that, it's formulated to handle high levels of UV radiation, preventing it from going brittle and cracking under the Arabian sun.

For project managers and building owners, this translates to fewer repairs, minimal maintenance, and genuine peace of mind. Any reputable building materials distributor will stock uPVC that meets or exceeds UAE construction standards, ensuring it’s built for our climate.

What does this mean for a contractor's bottom line? A much lower total cost of ownership. When your piping system doesn't rust, corrode, or break down from sun exposure, you avoid the huge future costs and headaches of having to rip everything out and replace it.

Does uPVC keep drinking water pure?

Absolutely, uPVC is chemically inert and doesn’t leach anything into the water passing through it. This is a huge deal for preserving the taste, smell, and overall quality of potable water, which is a must-have for any residential or commercial project.

There’s another subtle but important benefit: the inside of a uPVC pipe is incredibly smooth. This isn't just for show; it actively works to prevent the build-up of scale and other nasty deposits that can plague other pipe materials.

- No Biofilm Growth: That slick surface gives bacteria nothing to cling to, stopping slimy biofilm from forming.

- Consistent Water Pressure: Without scale clogging up the pipes, the system’s flow rate and pressure stay strong for decades.

- Fewer Blockages: In drainage systems, this smoothness is key. Waste and debris flow right through, drastically cutting down the risk of clogs.

Is uPVC a good financial decision for big projects?

Without a doubt, uPVC is one of the most budget-friendly piping materials on the market from start to finish. Its light weight is a game-changer, making transportation to a job site cost far less in fuel and logistics compared to hauling heavy metal pipes.

That advantage carries right through to installation. You don’t need heavy lifting equipment or specialized welding gear. A smaller team can cut, fit, and join uPVC pipes quickly and easily, which means significant savings on labour. For any supplier in Dubai looking to give their contracting clients a competitive edge, these practical savings are a major selling point.

Navigating uPVC Pipe Standards and Specifications

Choosing the right uPVC pipes & fittings goes way beyond just picking a size from a catalogue. To get it right, especially for contractors here in the UAE, you need to speak the language of technical specifications. This means getting to grips with pressure ratings, size standards, and the local regulations that dictate every single installation.

Think of these standards as the official rulebook for your entire plumbing system. Get them right, and you’ve built a network that can handle the daily grind, from high-pressure water mains to simple drainage lines. Following these specs isn't optional—it's essential for meeting UAE construction standards and ensuring your work stands the test of time.

What are PN classes in uPVC pipes?

The term 'PN class' is a simple way to gauge a pipe's strength and pressure handling capability. The PN, or Pression Nominale, is a rating that tells you the maximum water pressure (in bars) a pipe can safely handle at 20°C.

So, a PN10 pipe is built to withstand 10 bars of pressure. It’s a beautifully simple system that cuts out the guesswork. You can directly match the pipe's capability to what the system needs. Any reputable supplier in Dubai should provide clear technical data sheets listing these ratings for their entire range.

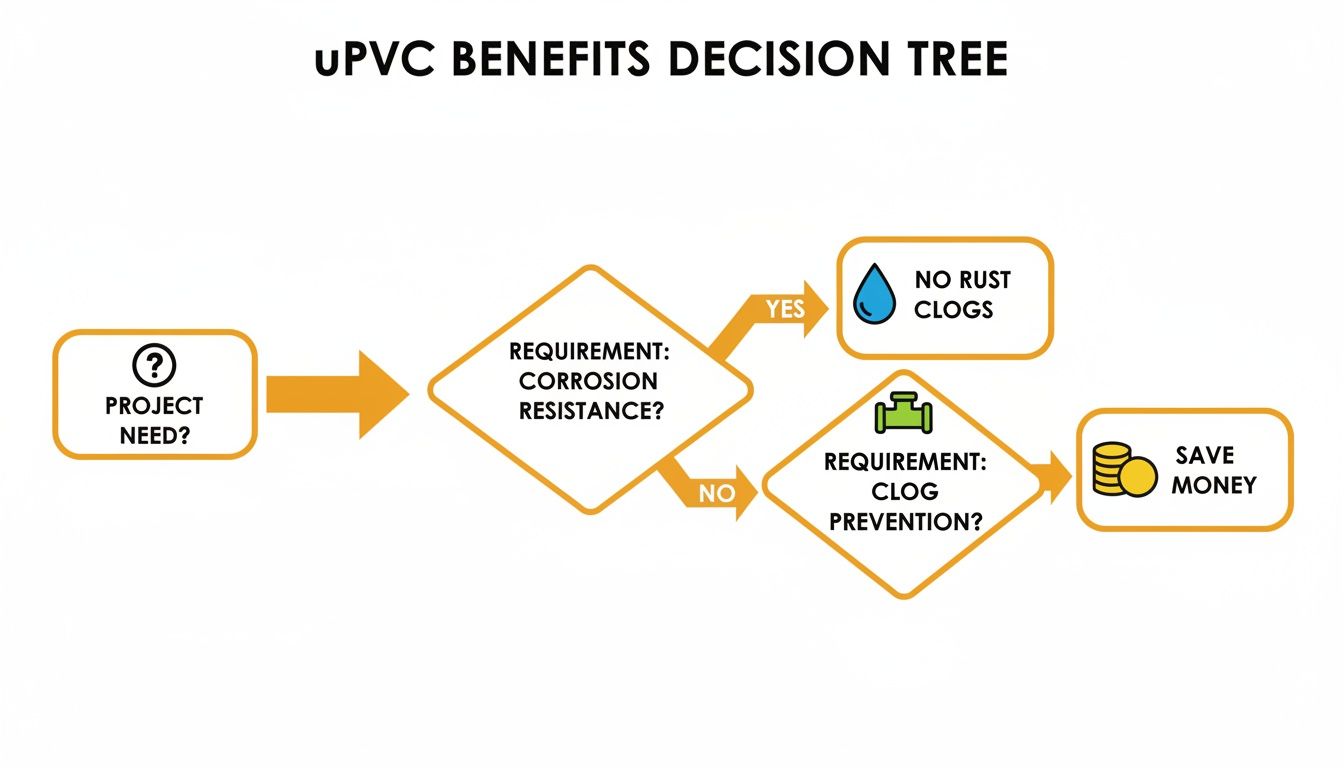

This visual helps break down why uPVC has become such a go-to choice for so many projects.

Whether you’re trying to head off rust, prevent clogs, or just keep costs down, the path often leads straight to uPVC.

How do I choose the right pressure class?

Picking the correct PN class is all about the specific job at hand. A low-pressure, gravity-fed drainage system has completely different demands compared to a high-pressure municipal water supply line.

A classic mistake is getting the pipe strength wrong. Go too low with the pressure rating, and you're setting yourself up for a catastrophic failure down the line. Go too high, and you're just wasting money on over-engineered pipe. Always, always check the project plans and local regulations first.

To give you a better idea, here's a quick guide to matching PN classes with common applications you’ll find across the UAE.

Matching uPVC Pipe Pressure Classes to Project Needs

| Pressure Class (PN) | Typical Application | Common Project Type |

|---|---|---|

| PN4 - PN6 | Gravity-fed drainage, non-pressure soil & waste | Residential villas, low-rise buildings |

| PN10 | Cold water distribution, irrigation main lines | Gated communities, landscaping projects, commercial towers |

| PN16 | High-pressure water mains, industrial process lines | Municipal infrastructure, large-scale industrial facilities |

This table is a starting point, but remember to always verify against the engineering specifications for your particular project.

The widespread use of uPVC pipes and fittings in this region isn't a coincidence; it's linked directly to major national goals. The UAE Water Security Strategy 2036, for example, is funnelling billions into upgrading plumbing networks to cope with a projected 40% increase in water demand. This push for resilient infrastructure has helped grow the MEA pipes and fittings market to a massive USD 7.98 billion, with the UAE at the forefront thanks to its huge construction pipeline.

How do I meet local municipality requirements?

Here in the UAE, compliance is everything, and authorities like DEWA and ADDC have strict standards. The smart move is to partner with a knowledgeable building materials distributor. They know the local landscape and can ensure every product you source is fully compliant, saving you from the headache of project delays and failed inspections. Having a good grasp of general metric pipe thread dimensions and standards is also incredibly useful, as it helps you see how all the different components fit together to create a compliant, functional system.

Getting to Grips with Common uPVC Fittings and Their Roles

A plumbing system isn't just a series of straight pipes. It’s a complex network that has to bend, branch off, and connect flawlessly. This is where uPVC pipes & fittings come into their own, acting as the crucial building blocks that bring a plumbing schematic to life. Each fitting has a specific role, and they all work in concert to build a reliable, leak-proof system.

Think of these fittings as the specialised pieces in a construction puzzle. You wouldn't force a piece where it doesn't belong, and similarly, you need the right fitting for every turn, junction, or endpoint in your pipework. Getting this right is fundamental to meeting UAE construction standards and guaranteeing the long-term integrity of the installation.

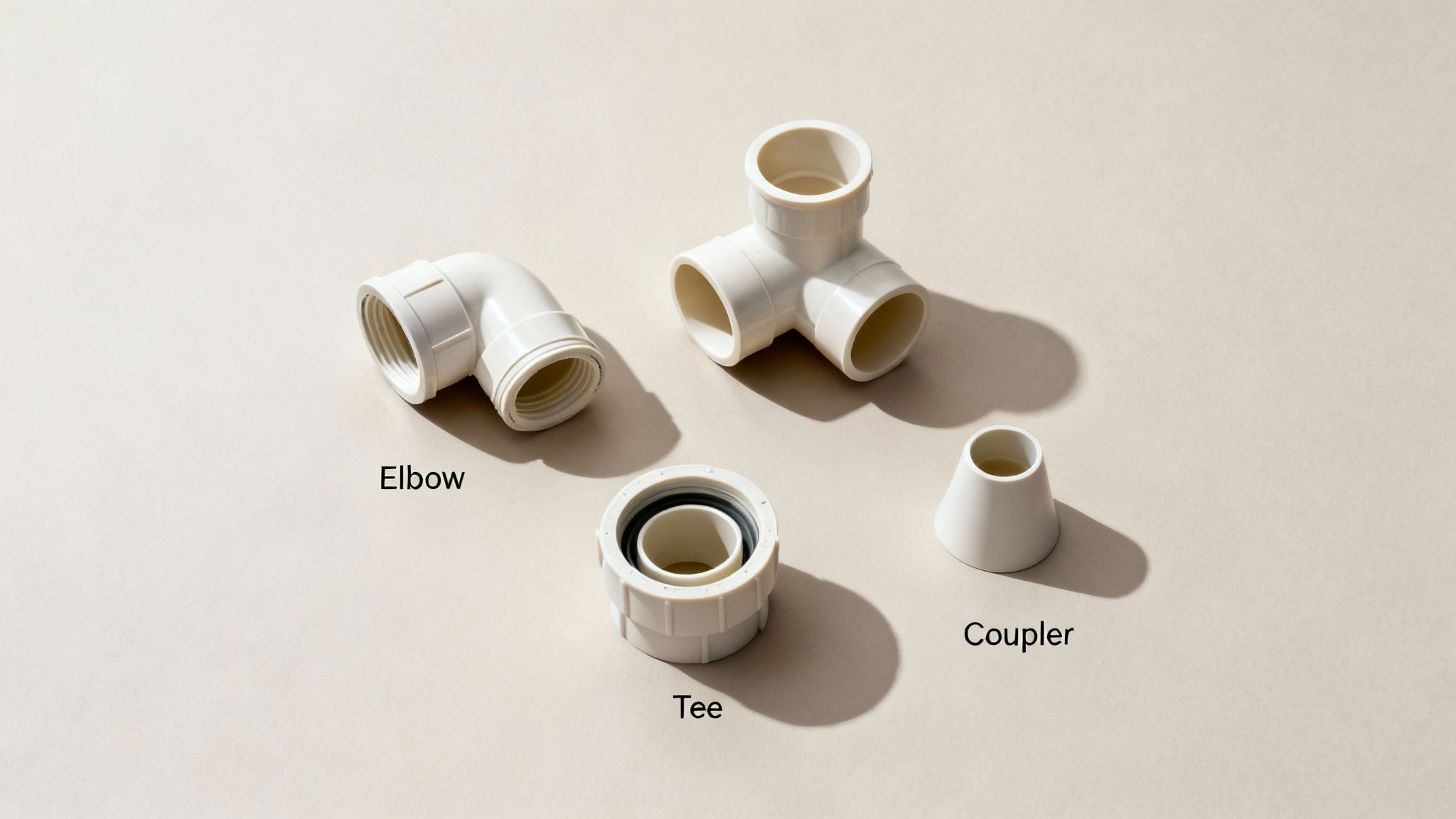

What is the purpose of a uPVC elbow?

A uPVC elbow simply changes the direction of a pipe run, allowing it to navigate around corners and obstacles. Elbows are the "knees" of your plumbing system, allowing pipes to navigate around corners, structural beams, and other site obstacles cleanly. You’ll find them most commonly in 90-degree and 45-degree angles, giving you the flexibility to create efficient layouts.

Using the right elbow is critical for maintaining good water flow and preventing unnecessary pressure loss. For a deeper dive into the various components available, this complete guide on plumbing fittings in Dubai is an excellent resource.

How do tees and couplers work?

Tees and couplers are essential for creating branches and extending pipe runs. If elbows handle the turns, then tees and couplers are all about connections and branches. For any contractor sourcing from a building materials distributor, understanding their distinct jobs is essential.

- Tee Fittings: Think of these as the intersections in your plumbing highway. A tee is a T-shaped fitting with three openings, used to create a new branch line that splits off from a main pipe. This is how you direct water from a single supply line to multiple fixtures.

- Couplers (or Sockets): These are the connectors. A coupler's sole job is to join two separate pipes together in a straight line, effectively extending the length of the run. When properly sealed with solvent cement, they create a bond that's as strong as the pipe itself.

In any plumbing network, every joint is a potential point of failure. Using high-quality uPVC fittings from a trusted supplier in Dubai ensures these connections are just as strong and durable as the pipes they join, preventing leaks for decades to come.

What other fittings are needed to complete a system?

Several other components play vital roles, handling transitions, terminations, and system control. Beyond the basics, several other components play vital roles in achieving a professional finish. These fittings are all about transitions, terminations, and giving you control over the system.

- Reducers: These fittings connect a pipe of a larger diameter to a smaller one, allowing you to step down the pipe size smoothly without creating flow turbulence.

- End Caps: Just like the name suggests, an end cap is used to seal the end of a pipe, permanently closing off that section of the line.

- Valves: Components like ball valves or gate valves are installed within the system to control or completely shut off the flow of water. They are absolutely essential for any future maintenance or repair work.

Together, these uPVC pipes & fittings provide a complete, integrated solution for any plumbing or drainage project you're tackling.

Mastering uPVC Pipe Installation on UAE Sites

You can have the best uPVC system in the world, but it's only as strong as its installation. On any fast-paced UAE construction site, getting this right isn't just about neatness; it's about building a plumbing or drainage network that will perform without leaks or failures for decades. Every single step, from the first cut to the final joint, demands precision.

It all starts with a clean, square cut. Whether you're using a fine-toothed handsaw or a proper plastic pipe cutter, the goal is a perfectly flat end. Next comes deburring—smoothing away any rough shavings from the inside and outside of the pipe. It sounds minor, but skipping this tiny step is a classic mistake that can snag debris and weaken the joint right from the start.

How do you properly join uPVC pipes?

The best method for a permanent, rock-solid connection is solvent cement welding. This chemical process fuses the pipe and fitting into a single, seamless piece of plastic, creating a joint as strong as the pipe itself. This is a fundamental skill for any professional installer.

To get that perfect weld, you start by cleaning the pipe end and the inside of the fitting with a primer. This not only removes grease and grime but also softens the uPVC surface just enough for the cement to bite. Then, apply a thin, even coat of solvent cement to both parts. Push the pipe into the fitting with a slight twist until it hits the back of the socket, and hold it firmly for a few seconds.

A common mistake we see is using too much or too little solvent cement. Slathering on too much can actually weaken the pipe wall, while being too stingy guarantees a poor bond and an eventual leak. The sign of a perfect joint is a small, even bead of cement visible all the way around the fitting.

What is the right way to support uPVC pipes?

Proper support is non-negotiable, especially with the high ambient temperatures in the UAE. Without it, pipes will sag over time, which messes up the slope and puts unnecessary stress on the joints. UAE construction standards are very clear on this.

For horizontal pipe runs, you need to install supports at regular intervals:

- For smaller diameter pipes (up to 50mm): Place supports roughly every 1.2 metres.

- For larger diameter pipes (over 50mm): You can extend this spacing, but don't go beyond 1.5 to 2.0 metres.

These supports, usually clamps or hangers, need to be secure but still allow for the tiny amount of lengthwise movement that comes with temperature changes. A good building materials distributor will stock the right supports for your pipe sizes. Thinking ahead about proper support is one of the easiest ways to prevent future failures and ensure the system has a long, maintenance-free life.

How do you find the right uPVC pipe supplier in Dubai?

Choosing the right materials is only half the battle; you also need to partner with the right supplier in Dubai. For any procurement manager or contractor, this one decision can make or break timelines, budgets, and regulatory compliance.

The process itself should be simple enough: start with a detailed bill of quantities and then evaluate supplier quotes. But let's be honest, the real value of a supplier goes far beyond the price tag on an invoice. A great partner isn't just a vendor; they're a crucial part of your project's support system, making sure you get what you need, when you need it, without ever cutting corners on quality.

What makes a good supplier stand out?

A top-tier building materials distributor delivers on three key fronts: inventory, compliance, and reliability. They need a deep stock of uPVC pipes & fittings so you can get everything from one place. This one-stop-shop approach isn't just convenient; it streamlines your logistics and slashes administrative headaches.

More importantly, every single item they sell must be fully compliant with UAE construction standards. Your supplier should be able to hand over documentation proving their materials meet all local municipality regulations without you even having to ask. This is your best insurance against failed inspections and costly project delays.

Choosing a supplier is about building a partnership that supports your project from start to finish. Look for a distributor who provides strong manufacturer warranties, practical technical support, and reliable logistics, including direct-to-site delivery across Dubai and the Northern Emirates.

Finally, let’s talk logistics, because this part is non-negotiable. A truly exceptional supplier gets the pressure of a construction schedule. They need a rock-solid system for on-time, site-direct delivery. That kind of reliability is what keeps your teams working and your entire project moving forward without a hitch.

For more insights on finding the best partners, check out our guide to leading PVC pipe suppliers in Dubai for some valuable tips for your next project.

Your uPVC Pipe Questions, Answered

On the ground, contractors and site managers often have the same core questions about using uPVC pipes and fittings in the UAE. Let’s tackle them head-on.

What is the best pipe for hot water supply in the UAE?

For hot water, you need CPVC (Chlorinated Polyvinyl Chloride) pipes, not uPVC. While uPVC is the champion for cold water and drainage systems, it is not designed to handle high temperatures.

CPVC, on the other hand, is specifically engineered for that job. It’s the go-to standard for hot water plumbing in homes and commercial buildings across the region.

Are uPVC pipes safe for drinking water?

Yes, uPVC pipes are one of the safest materials for carrying potable (drinking) water. They are completely non-toxic, lead-free, and chemically inert, meaning they won't react with the water or leach chemicals.

This ensures that the water's taste, smell, and overall quality remain pure. Always double-check with your supplier in Dubai that the pipes you're buying are certified to meet local municipality and UAE construction standards.

The big takeaway here is that uPVC's stability is a huge win for public health. It delivers safe drinking water without the risk of rust, corrosion, or chemical contamination that plagued older metal pipes.

How long do uPVC pipes really last in the UAE climate?

You can expect uPVC pipes to last for 50 years or more, even under the relentless sun and harsh conditions here in the UAE.

The secret is in their formulation. They contain stabilisers that give them excellent resistance to UV radiation. Plus, the material itself is immune to corrosion from the often-saline soil and won't break down from chemicals. This adds up to incredible long-term durability with next to no maintenance.

Can I join uPVC pipes to other materials?

Yes, connecting uPVC to other pipe materials like copper or stainless steel is a routine task using the right transition fittings. Manufacturers produce special fittings like threaded adaptors or compression couplers specifically for this purpose. These create a tight, secure, and leak-proof seal between the different materials, making uPVC a great choice for repairs, extensions, or system upgrades.

For plumbing contractors wanting to grow their business, checking out a solid guide to SEO for plumbing companies can be a game-changer for finding new customers.

From the initial tender right through to project handover, Yasu Trading Co. LLC is the partner you need. We supply a full range of municipality-compliant uPVC pipes and fittings, backed by genuine technical expertise and reliable, direct-to-site delivery. See how we can help at https://yasutrading.com.