A Practical Guide to Water Proof Paint

Think of waterproof paint as the ultimate shield for your property against moisture. It’s not just a coat of paint; it’s a complete barrier designed to stop water in its tracks, preventing it from ever touching the surface underneath. Where a "water-resistant" coating might handle a light splash, a true waterproof system is built to protect everything from your basement walls to the building's foundation from constant water exposure.

Let's get into how to pick the right product and apply it correctly to truly safeguard your investment.

Why Waterproof Paint Is a Critical Defence

What's the difference between a light jacket and a serious, seam-sealed raincoat? One can handle a bit of drizzle, but the other will keep you dry in a full-on storm. That’s the difference between water-resistant and waterproof paint.

A genuine waterproof coating is the raincoat. It creates a seamless, non-porous membrane that physically blocks water from getting through, even when it’s under pressure—like groundwater pushing against a basement wall.

This isn't just a minor detail. Moisture is a destructive force, silently working to weaken your property's structure and drain its value. Letting it go unchecked is an invitation for a whole host of expensive headaches down the road.

Solving Common Moisture-Related Problems

When water finds its way into your walls, it doesn't just sit there. It causes a cascade of issues that a high-quality waterproof coating is specifically designed to prevent.

Here are the key problems it stops before they start:

- Peeling and Blistering: Moisture trapped behind a normal paint film will always try to escape. As it pushes outward, it causes the paint to bubble up, peel away, and flake off.

- Mould and Mildew Growth: Damp, dark spaces are a perfect home for mould and mildew. This leads to musty smells and can create unhealthy living conditions.

- Structural Damage: Over time, constant dampness can rot wood, crumble plaster, and even degrade concrete and masonry. This can lead to serious, and costly, structural failures.

- Efflorescence: Ever see that chalky, white powder on brick or concrete? That's efflorescence. It happens when water seeps into the masonry, dissolves the natural salts inside, and deposits them on the surface as it dries.

With construction booming in many parts of the world, the need for these protective solutions is only growing. The paints and coatings market in the Middle East and Africa, for example, was valued at around USD 18 billion in 2023. That number shows just how much builders and property owners rely on advanced coatings to protect their assets. Explore more details on the MEA coatings market growth.

Being proactive is always smarter—and cheaper—than making reactive repairs. Applying waterproof paint isn't a cosmetic choice; it's a fundamental investment in protecting your property from the damage water can cause.

By understanding what this paint does and the problems it solves, you're already in a better position to protect your home or commercial building. Now, let’s dive into the science behind these coatings and the practical steps for getting a perfect, long-lasting finish.

How Waterproof Coatings Actually Work

To really get how water proof paint does its job, picture it creating a seamless, rubber-like shield right over the surface. That’s the core idea. These aren't just paints with a bit of color; they're engineered systems designed to form a solid, continuous barrier that water molecules simply can't get through.

Regular decorative paints are porous, meaning they have tiny holes that let moisture seep in over time. Waterproof coatings are the complete opposite. They are loaded with special ingredients that, once applied, link together to form an impermeable film. This process effectively plugs the thousands of microscopic pores you'd find in concrete, brick, or plaster.

This barrier is your first and most critical line of defense against water damage. It stops moisture in its tracks before it can ever soak into the wall, preventing all the nasty stuff we talked about earlier, like mold and structural rot.

The Science of the Shield

So, what's the magic ingredient? It all comes down to the chemistry, specifically the polymers used as binders in the paint. Think of these as long chains of molecules that interlock as the paint dries, bonding tightly with each other and to the surface below. It’s like creating a microscopic net with openings so small that not even a single water molecule can squeeze past.

The heavy hitters you’ll find in high-performance waterproof paints include:

- Acrylics: These are fantastic for their flexibility and UV resistance. That makes them perfect for exterior walls that have to expand and contract with changing temperatures.

- Epoxies: When you need something incredibly tough, you turn to epoxy. It creates a hard, durable film with amazing adhesion and chemical resistance, which is why it's the go-to for basement floors and industrial spaces.

- Polyurethanes: Known for their sheer toughness and elasticity, polyurethanes form a robust barrier that holds up well against scuffs, scrapes, and movement.

These polymers are the backbone of the paint, making sure the final coat is not just watertight but also durable enough to last for years. Getting a handle on these basic components is the first step in picking the right kind of water proofing material for your job.

Resisting Water Under Pressure

Here’s something most people don’t realize: not all moisture is the same. A coating on a bathroom wall might just need to fend off steam and a few splashes. But a coating on a basement wall? That’s a whole different ballgame. It's up against hydrostatic pressure.

Hydrostatic pressure is the force of groundwater literally pushing against your foundation. It's a constant, powerful force that can shove water through the tiniest imperfections in concrete. Your average can of paint doesn’t stand a chance.

A true water proof paint is engineered with a high solids content and powerful binders that create a membrane strong enough to resist this constant push. It doesn’t just repel surface water; it actively holds back water under pressure.

This is the key difference that separates a simple damp-proofing paint from a real-deal waterproofing solution for below-ground areas. The ability to fight back against hydrostatic pressure is what it's all about. For bigger jobs or areas under serious threat, the solution might go beyond just paint. It's smart to look into all the options, as there are comprehensive waterproofing and tanking systems built for maximum protection.

Choosing the right coating is all about matching its chemistry to the kind of water exposure it’s going to face. Now that you understand the mechanics behind it, you're in a much better position to pick a product that delivers exactly what your project needs.

Choosing the Right Water Proof Paint for Your Project

Picking the right water proof paint is probably the single most important decision you'll make for any waterproofing project. I like to think of it like choosing tires for a car—you wouldn't put slick city tires on an off-road beast headed for the desert, right? It's the same principle. Each coating is engineered for a very specific job, and matching the product to the problem is the only way to get a watertight seal that actually lasts.

Get this choice wrong, and you're not just wasting money; you're setting yourself up for failure. Slapping an interior-grade acrylic paint on an exterior foundation wall is a perfect example. Before you know it, you’ll be dealing with peeling, blistering, and eventually, the very water you were trying to keep out. This section is your field guide to navigating the different types of water proof paint so you can get it right the first time.

The Main Categories of Water Proof Paint

When you start looking at your options, you'll see they mostly fall into three main buckets. Each one has a unique chemical makeup that gives it specific superpowers and dictates where it’s going to perform best.

Acrylic-Based Coatings: These are some of the most common and user-friendly paints out there. Known for being incredibly flexible and holding up well against UV rays, acrylics are perfect for above-ground exterior walls that have to deal with sun, rain, and changing temperatures.

Epoxy Coatings: When you need a truly bomb-proof finish, epoxy is your answer. It cures into an insanely hard, non-porous barrier that laughs off abrasion, chemicals, and even significant water pressure. This makes it the go-to for tough environments like basement floors, industrial workshops, and concrete water tanks.

Bituminous Coatings: Often called asphalt coatings, this is the heavy-duty stuff for serious, below-ground waterproofing. Made from bitumen, these coatings create a thick, rubbery membrane that’s perfect for foundations, retaining walls, and any structure that’s in constant contact with damp soil.

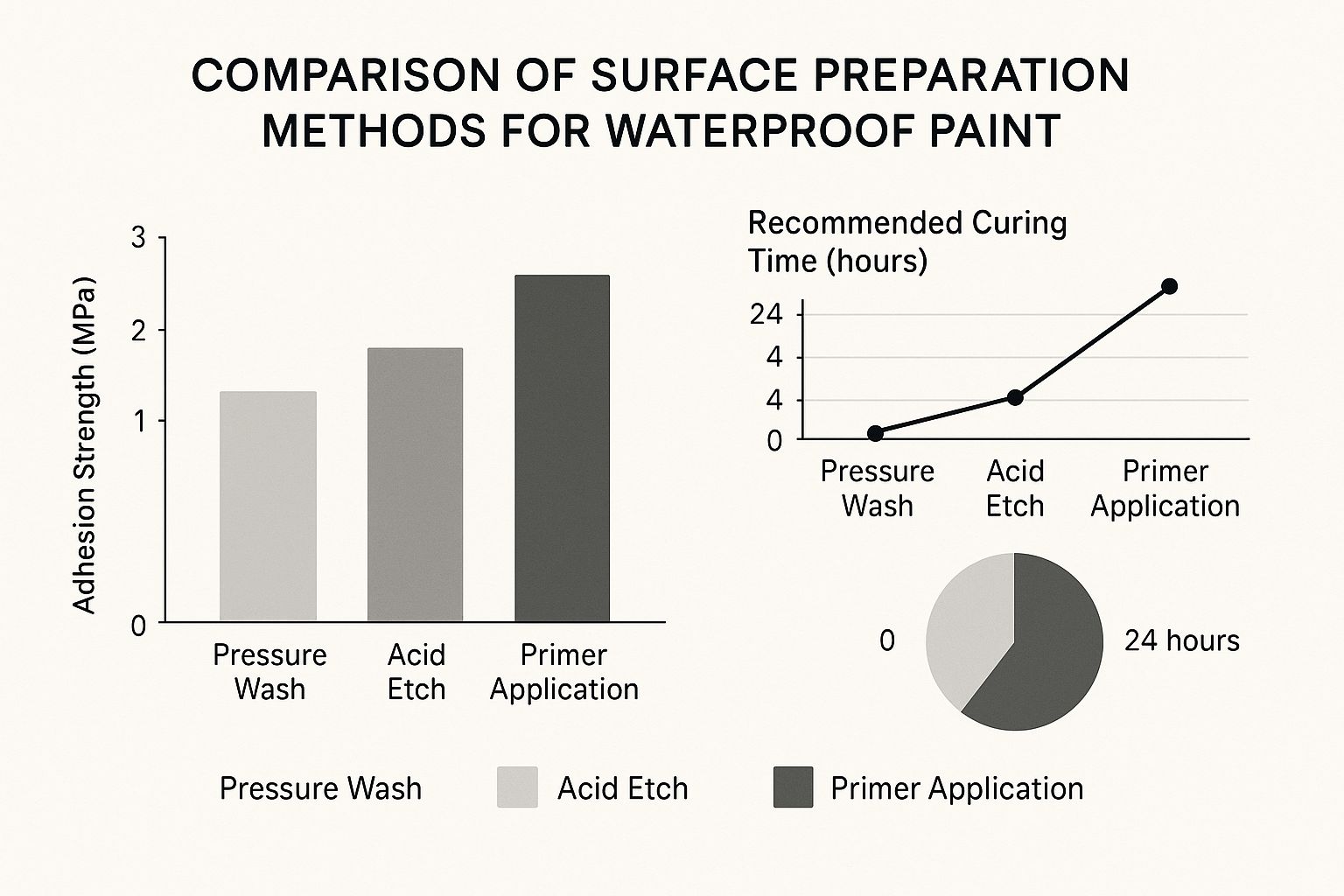

The image below gives you a clear picture of how different surface prep methods—a step you absolutely cannot skip—impact the final bond strength and the time it takes for the paint to cure properly.

As you can see, taking the time to apply a proper primer doesn't just give you the strongest possible bond; it also helps the coating cure more efficiently. It’s a clear reminder of why cutting corners on prep work is never a good idea.

Matching the Paint to the Surface

Okay, so you know the types. But that's only half the battle. You also need to know which paint works best with which surface. The material you're painting—whether it’s concrete, wood, or metal—has its own quirks that affect how well a coating will stick and perform over the long haul.

For porous surfaces like concrete and masonry, a penetrating epoxy primer followed by a tough epoxy topcoat is a fantastic combination. The primer sinks right into the pores of the concrete, creating an unbreakable anchor for the water proof paint on top. On the other hand, for something like exterior wood that expands and contracts with the weather, a flexible acrylic-based paint is a much smarter choice because it can move with the wood instead of cracking.

Here’s the golden rule: The success of your entire project hinges on getting a powerful, lasting bond between the paint and the surface underneath. Always think about the material's porosity, texture, and what kind of elements it will face before you buy a single can of paint.

And make no mistake, this is a big market. The Middle East and Africa water-resistant paint market was valued at around USD 0.09 billion in 2023. This market is broken down by paint types like acrylic and epoxy, and even by formulations like water-based or solvent-based. This variety allows for tailored solutions; for instance, water-based paints are often preferred for homes because of their low VOCs, while industrial jobs demand solvent-based epoxies for their superior chemical resistance. You can dig deeper into these regional water-resistant paint market trends if you're curious.

Comparison of Water Proof Paint Types

To make your decision a bit easier, it helps to see the main options laid out side-by-side. This table compares the key features, best use cases, and typical durability of the most common types of water proof paint to help you select the right one for your project.

| Paint Type | Primary Use Case | Durability Level | Key Advantage |

|---|---|---|---|

| Acrylic-Based | Exterior walls, balconies, terraces | High | Excellent flexibility and UV resistance |

| Epoxy Coating | Basement floors, workshops, water tanks | Very High | Extreme hardness and chemical resistance |

| Bituminous Coating | Foundations, retaining walls, below-ground | High | Superior waterproofing in constant moisture |

At the end of the day, picking the right water proof paint really boils down to three things: where the surface is located (inside, outside, or underground), what it's made of, and the specific moisture problem you're trying to solve. Nail these three points, and you can be confident you’re choosing a product that will deliver tough, long-lasting protection.

A Step-By-Step Application Guide for a Flawless Finish

Even the best water proof paint you can buy is only as good as the person applying it. Think of it like a chef with world-class ingredients—if the technique is sloppy, the final dish will be a disaster. The same goes for paint. A truly watertight finish doesn’t just come out of a can; it’s earned through a careful, methodical process.

Cutting corners is the number one reason these coatings fail. People get impatient. They rush the job and end up with peeling, blistering, and the exact leaks they were trying to stop in the first place. This guide is your playbook for getting it right the first time.

We’re going to spend a lot of time on what I consider the most important part of the entire project: preparing the surface. It’s not glamorous, but getting this right is easily 80% of your project's success.

Phase 1: The Non-Negotiable Preparation Work

Before you even think about opening a can of paint, the surface needs to be in perfect shape. Slapping a waterproof coating over a dirty, damp, or crumbling wall is like putting a band-aid on a broken leg. It’s a complete waste of time and money.

Your goal here is simple: create a clean, dry, and solid foundation that the paint can grab onto and never let go. This all comes down to three key steps: cleaning, repairing, and drying.

First, get rid of every bit of grime. We're talking dirt, dust, grease, oil, and any of that chalky dust from old, failing paint. For exterior walls or a basement floor, a pressure washer is your best friend. For indoor jobs, a stiff brush and a good degreasing cleaner will get the job done.

Next, you need to play detective. Go over every square inch of the surface and look for imperfections. Water is relentless and will find its way into the tiniest crack or hole, so you have to be just as relentless in finding and fixing them.

- For Hairline Cracks: A high-quality waterproof caulk or sealant is all you need.

- For Larger Gaps or Holes: Break out the heavy-duty stuff. Hydraulic cement or an epoxy-based filler will create a permanent patch.

- For Efflorescence: That fuzzy white powder is a sign of moisture. Scour it off with a wire brush and treat the area with a specialized acid-based cleaner.

Remember, the goal is to create a monolithic, unbroken surface. Every single crack, no matter how small, is a potential failure point that undermines the integrity of your waterproof barrier.

Finally—and I can't stress this enough—the surface has to be bone-dry. If you paint over a damp wall, you’re just trapping moisture behind the coating. That trapped water will eventually try to escape, pushing the paint right off the wall and creating massive bubbles and peeling. Use a moisture meter to be certain.

Phase 2: Priming for Unbeatable Adhesion

After all that prep work, it’s tempting to jump straight to the paint. Don't do it. Skipping primer is a classic rookie mistake, and it’s a costly one. A good primer isn’t just an extra step; it’s the crucial bridge connecting your wall to your waterproof topcoat.

Think of it like double-sided tape. One side is engineered to soak into and grip the raw concrete or masonry, while the other side creates the perfect surface for the topcoat to lock onto.

A quality primer will:

- Seal the Surface: It stops the topcoat from soaking in unevenly, giving you a smooth, consistent finish.

- Block Stains: It prevents old water stains or efflorescence from bleeding through and ruining your new paint job.

- Enhance Adhesion: This is its main job—creating a bond so strong that the paint becomes one with the wall.

For really tough surfaces like bare concrete or in areas facing hydrostatic pressure, you need to bring in a specialized epoxy or masonry primer. They provide a level of grip that standard primers just can't touch. For a deeper dive into preparing surfaces in the most demanding environments, it’s often useful to look at marine applications; a guide on how to paint a boat shows just how critical this step is.

Phase 3: Applying the Coating Like a Professional

With a perfectly prepped and primed surface, you’re finally ready for the main event. The key here is to build up the right thickness. One thin coat just won’t cut it.

Most high-performance water proof paint systems are designed for a minimum of two generous coats. The first coat lays the foundation, and the second coat fills in any tiny pinholes or thin spots, creating a completely seamless, impermeable shield. Always follow the manufacturer’s instructions for dry times between coats.

The tool you use makes a difference, too:

- Roller: Your go-to for big, flat areas like walls and floors. Use a roller with a thick nap to lay down a heavy, even coat.

- Brush: You'll need this for "cutting in"—getting those clean lines around edges, corners, and details where a roller can't go.

- Sprayer: On large commercial jobs, an airless sprayer is the fastest way to get a uniform finish, but it takes some practice to get right.

By following this disciplined process—clean, repair, dry, prime, and coat—you're not just painting. You're installing a high-performance system that will give you a flawless, long-lasting, and truly waterproof finish.

Key Areas That Need Water Proof Paint

Knowing where your property is most vulnerable to moisture is the first step. You don't need to slather water proof paint on every surface; it's about being strategic. Think of it as a targeted defense for the critical areas under constant attack from water and humidity.

Take a few minutes to do a quick 'moisture audit' of your home. By spotting these hotspots, you can apply the right protection exactly where it's needed most and stop small issues from turning into massive structural headaches.

Let’s break down the key zones, both inside and out, that are crying out for a truly waterproof coating.

Shielding Your Home's Interior

Some rooms in your home are in a never-ending battle with moisture. For these areas, a waterproof barrier isn't just a cosmetic touch-up—it's essential for keeping your living space healthy and sound.

Basements and Cellars

If there's one trouble spot, it's a below-ground space. Basements are constantly fighting against hydrostatic pressure from the groundwater outside, which literally tries to force its way through porous concrete walls. The result? That familiar dampness, musty smells, and the inevitable bloom of mold.

- The Challenge: Relentless groundwater pressure and a high risk of leaks.

- The Solution: You need a heavy-hitter here, like an epoxy or cementitious waterproof coating. These create a thick, seamless membrane that can stand up to significant negative-side water pressure.

Bathrooms and Kitchens

These are your home's humidity hotspots. Steam from showers, splashes from the sink, and daily condensation all team up to attack your walls. Over time, that moisture gets in, causing paint to peel, mold to grow behind tiles, and the drywall itself to degrade. For spaces like bathrooms, especially when you're looking at modern wet room design ideas, proper waterproofing is non-negotiable.

- The Challenge: High ambient humidity, steam, and direct water splashes.

- The Solution: A top-shelf acrylic waterproof paint with built-in mold and mildew inhibitors is a great choice. It gives you a tough, washable surface that moisture can't penetrate. To really bulletproof the system, start with a specialized base like waterproof gypsum board. You can learn more about how these two work together in our guide on waterproof gypsum board.

Fortifying Your Property's Exterior

The outside of your building is its first line of defense. It takes a beating from rain, soil moisture, and standing water, making targeted waterproofing an absolute must.

Think of your building's exterior like a ship's hull. Even a tiny, unnoticed leak can eventually lead to major damage. Applying waterproof paint to these vulnerable spots is crucial for long-term structural integrity.

Foundation Walls and Plinths

The very base of your building sits in direct contact with damp soil. Moisture has a nasty habit of wicking its way up from the ground into the masonry, a process called capillary action. This is what causes rising damp and that chalky white powder known as efflorescence.

- The Challenge: Constant contact with ground moisture.

- The Solution: For the foundation walls below ground, a bituminous or cementitious coating is your best bet. For the visible plinth area just above ground, a flexible acrylic waterproof paint will fend off rain while still allowing the structure to expand and contract with temperature changes.

Balconies and Flat Roof Terraces

These horizontal surfaces are magnets for trouble. They’re notorious for collecting rainwater, and if they aren’t sealed perfectly, that water will just sit there, slowly seeping into the structure below. This leads to leaks, crumbling concrete, and ugly water stains on your interior ceilings.

- The Challenge: Pooling water and brutal exposure to rain and sun.

- The Solution: A UV-stable, highly flexible polyurethane or acrylic-based membrane is perfect. Its elasticity is key—it can stretch to bridge small cracks and move with the building so it won't fail. This demand for high-performance coatings is a huge driver in construction, especially in booming regions. Back in 2015, the Middle East and Africa coatings market was already valued at around USD 8.6 billion, with countries like the UAE and Saudi Arabia leading the charge for advanced waterproofing in their massive new construction projects. Discover more insights about the Middle East coatings market on paint.org.

Common Questions About Water Proof Paint

Even after getting a handle on the basics of waterproof paint, a few specific questions always seem to pop up. Let's face it, getting clear answers is what separates a successful project from a costly mistake.

This is your quick-reference guide. We’ll cut through the confusion and tackle the most common queries I hear from clients—from decoding paint labels and painting over old coats to understanding how long the finish will last.

What Is the Difference Between Water Proof and Water Resistant Paint

This is, without a doubt, the most important distinction you need to grasp. The terms sound similar, but they describe products with completely different jobs. Mixing them up is a recipe for disaster, especially in basements or bathrooms.

Think of water-resistant paint as a light raincoat. It’s designed to shed the occasional splash or handle some surface condensation. It’s fine for a kitchen backsplash, but it will eventually fail under constant pressure.

True water proof paint, on the other hand, is like a diver's dry suit. It creates a solid, non-porous membrane that completely blocks water, even when it’s pushing against the surface from the outside. For basements, foundations, and retaining walls, anything less than a genuinely waterproof solution just won't cut it.

Can I Apply Water Proof Paint Over Existing Paint

The short answer is yes, but it comes with a huge "if." You can absolutely paint over an existing coat if you've done the prep work. The new paint needs a solid, clean, and stable surface to grab onto.

Simply rolling a fresh coat over a peeling, dirty wall is a complete waste of time and money. The existing paint has to be in good shape—no flaking, no peeling, and totally dry. Scrape off any loose bits, sand the edges smooth, and give the whole wall a thorough cleaning to get rid of any dust or grime.

Even then, I almost always recommend using a high-quality bonding primer first. This extra step acts like a double-sided adhesive, ensuring the new waterproof layer gets a death grip on the old surface. Skipping the prep is the number one reason these paint jobs fail.

How Long Does Water Proof Paint Typically Last

The real-world lifespan of a waterproof coating boils down to three things: the quality of the paint you chose, how well you prepped the surface, and what kind of abuse the environment throws at it. A top-of-the-line product on a poorly prepped wall is doomed from the start.

Here's a rough idea of what you can expect:

- High-Quality Epoxy Coating: Inside a basement, a properly applied epoxy system can easily last for 10 years or more. It’s tough as nails and built to handle pressure.

- Acrylic-Based Exterior Paint: On an outside wall getting blasted by sun and rain, a good acrylic waterproof paint will probably need a refresh every 5 to 7 years to stay effective.

Your best bet is to always check the manufacturer’s technical data sheet. That document will give you the most accurate timeline and spell out exactly what you need to do to get the maximum life out of the product.

Is Water Proof Paint Breathable

Generally, no. Most true water proof paint is designed to be a non-breathable barrier. Its whole purpose is to create a solid shield that stops water from moving through it—in either direction. This is perfect for keeping water out of your home.

But that same quality can be a problem if you have moisture already trapped inside the wall. Because the paint is a barrier, it will also stop that trapped moisture from escaping, which can lead to bigger issues down the road.

For some projects, especially on older buildings, a "breathable" water-repellent sealer might be a smarter choice. These let trapped water vapor out while still blocking liquid water from getting in. Understanding how different materials behave is key in modern building, a concept we explore more in our guide to eco-friendly construction. It all comes down to knowing where the moisture is coming from and what your specific wall needs.