A Guide to Waterproof Roof Coating Systems

A waterproof roof coating is a liquid-applied membrane that bonds directly to your existing roof, creating a seamless, fully-adhered protective layer. Think of it less like paint and more like a custom-fit, industrial-strength raincoat for your entire building. It's designed to protect the roof you already have and significantly extend its service life.

Unpacking The Science Of A Seamless Raincoat

Picture a standard roof—whether it's made of metal sheets, felt, or shingles. It’s a patchwork of materials held together by seams, fasteners, and joints. Every single one of those connection points is a potential failure waiting to happen. Over time, the building shifts, materials expand and contract with the heat, and severe weather does its damage. Eventually, water finds a way in through those weak spots, leading to leaks and costly structural problems.

A waterproof roof coating completely changes the game by getting rid of the weak points altogether.

When a professional crew applies it, the liquid cures into a tough, flexible membrane that acts like a second skin. It stretches and moves with the building, adapting to temperature changes without cracking or pulling apart. No seams, no stitches, no gaps. Just one continuous shield that wraps the whole roof, making it virtually immune to the common failures that plague conventional systems. It’s a truly proactive defense, not just another temporary patch job.

More Than Just A Barrier

But these systems do a lot more than just keep water out. They're engineered to tackle the biggest threats a roof faces day in and day out.

- UV Radiation Defence: The sun is relentless. Its UV rays bake roofing materials, making them brittle and fragile over time. A reflective coating is like slapping on a powerful sunblock, bouncing that harmful radiation away and stopping premature aging in its tracks.

- Thermal Shock Resistance: A coating's ability to flex is critical, especially in climates where temperatures can swing wildly from day to night. It expands in the blistering heat and contracts in the cool evening, all without losing its integrity.

- Monolithic Protection: Because it’s a single, seamless layer, there are simply no entry points for water. Whether it’s driving rain or standing water after a downpour, the building stays dry.

Roofing pros will tell you that a staggering 90% of roof leaks happen in just 10% of the roof's area. Where? You guessed it—around vents, seams, and joints. A seamless coating system is engineered specifically to lock down these vulnerable spots for good.

The Foundation Of Modern Roofing

It's easy to mistake a roof coating for a thick layer of paint, but that’s not the whole story. While paint dries through simple water evaporation and leaves a thin film, a coating undergoes a chemical curing process. This creates a much thicker, more durable, and completely impermeable membrane.

That difference is what gives these systems their long-term value. They aren't a quick fix; they're a serious investment in protecting the asset. They're formulated to bond aggressively to all sorts of surfaces—from weathered metal to old single-ply membranes—and restore them to a condition that’s often better than new.

To really get a feel for the different technologies out there, checking out a complete https://yasutrading.com/blog/a-guide-to-water-proofing-material/ can put everything into context. This ability to restore and reinforce is exactly why coatings have become a cornerstone of modern roof maintenance and management.

Choosing the Right Type of Roof Coating

Picking the right waterproof roof coating isn't about finding a single "best" product. It's about matching the right chemistry to the specific challenges your building faces. Think of it like choosing tires for a vehicle—you wouldn't put racing slicks on an off-road truck, right? The same logic applies here. The perfect coating for a flat concrete roof in a rainy climate is likely the wrong choice for a sloped metal roof that gets a lot of foot traffic.

To make the right call, you need to understand the unique strengths of the main players in the coating world. Each formula—whether it's acrylic, silicone, or polyurethane—brings something different to the table, tailored for specific environments, roof designs, and performance goals. Let's break down their core characteristics so you can confidently specify a system that delivers real, lasting protection.

Acrylic Coatings: The Versatile Workhorse

Acrylic coatings are everywhere, and for good reason. These water-based formulas hit a sweet spot between performance, cost, and being environmentally friendly. Their biggest claim to fame is exceptional reflectivity and UV resistance, making them a go-to for "cool roof" applications that can seriously cut down on a building's cooling costs.

They stick well to most surfaces and hold up great in climates without wild temperature swings or constant moisture. But they do have an Achilles' heel: ponding water. If an acrylic coating stays submerged for too long, it can lose adhesion and start to break down. This makes them a tough sell for perfectly flat roofs where drainage is an issue.

- Best For: Sloped roofs where water drains away efficiently.

- Key Advantage: High solar reflectivity (albedo) and top-notch UV stability.

- Consideration: Steer clear of using them on flat roofs known for ponding water.

Silicone Coatings: The Ponding Water Specialist

When you’re dealing with a roof that just won't stay dry, silicone coatings are the undisputed champion. Unlike their water-based acrylic cousins, silicone is a moisture-cured material. This means it won't break down, soften, or wash away when it's underwater. It’s the definitive solution for flat or low-slope roofs where perfect drainage is more of a dream than a reality.

Silicone creates a seamless, flexible, and incredibly durable membrane that’s almost totally immune to ponding water. It also offers fantastic UV protection, shielding the underlying roof from the sun’s relentless abuse. Yes, it typically costs more than acrylic, but when you factor in the costly water damage it prevents, that initial investment often pays for itself.

Because silicone is an inorganic material, it provides no food source for mold or mildew to grow. This inherent resistance is a major benefit for roofs in humid climates or shaded areas, helping to maintain a clean, healthy, and effective waterproof roof coating system.

Polyurethane Coatings: The Heavy-Duty Protector

For sheer toughness, polyurethane coatings are in a class of their own. They stand out for their incredible strength, abrasion resistance, and durability. Often just called "urethanes," these coatings are built to handle serious physical stress. They're the perfect choice for roofs that see regular foot traffic from maintenance crews or have heavy equipment sitting on them.

Polyurethane systems usually involve two steps:

- Aromatic Urethanes: This is your base coat. It’s tough and sticks like crazy, but it’s not the most UV-stable.

- Aliphatic Urethanes: This is your top coat, applied over the aromatic base. It's highly UV-stable, holds its color, and provides a hard-as-nails finish that stands up to the weather.

This one-two punch creates a powerful waterproof barrier that can resist everything from hail impacts to chemical spills. It's definitely a premium option, but for high-traffic or high-value roofs, its incredible toughness is worth every penny.

Comparing Popular Waterproof Roof Coating Technologies

To help you visualize the differences, here’s a quick side-by-side comparison. Think of this as a cheat sheet for matching the right technology to your project's specific needs.

| Coating Type | Key Benefit | Ideal Use Case | UV Resistance | Ponding Water Resistance | Typical Lifespan |

|---|---|---|---|---|---|

| Acrylic | High reflectivity & cost-effective | Sloped roofs with good drainage | Excellent | Poor | 10-20 years |

| Silicone | Excellent waterproofing | Flat roofs prone to ponding water | Excellent | Excellent | 15-20+ years |

| Polyurethane | Extreme durability & traffic resistance | Roofs with heavy foot traffic | Excellent | Good to Excellent | 20-30+ years |

Choosing the right coating ultimately comes down to balancing your roof’s specific vulnerabilities against your budget and long-term performance goals. Each option offers a clear path to extending a roof's life—you just have to pick the right one.

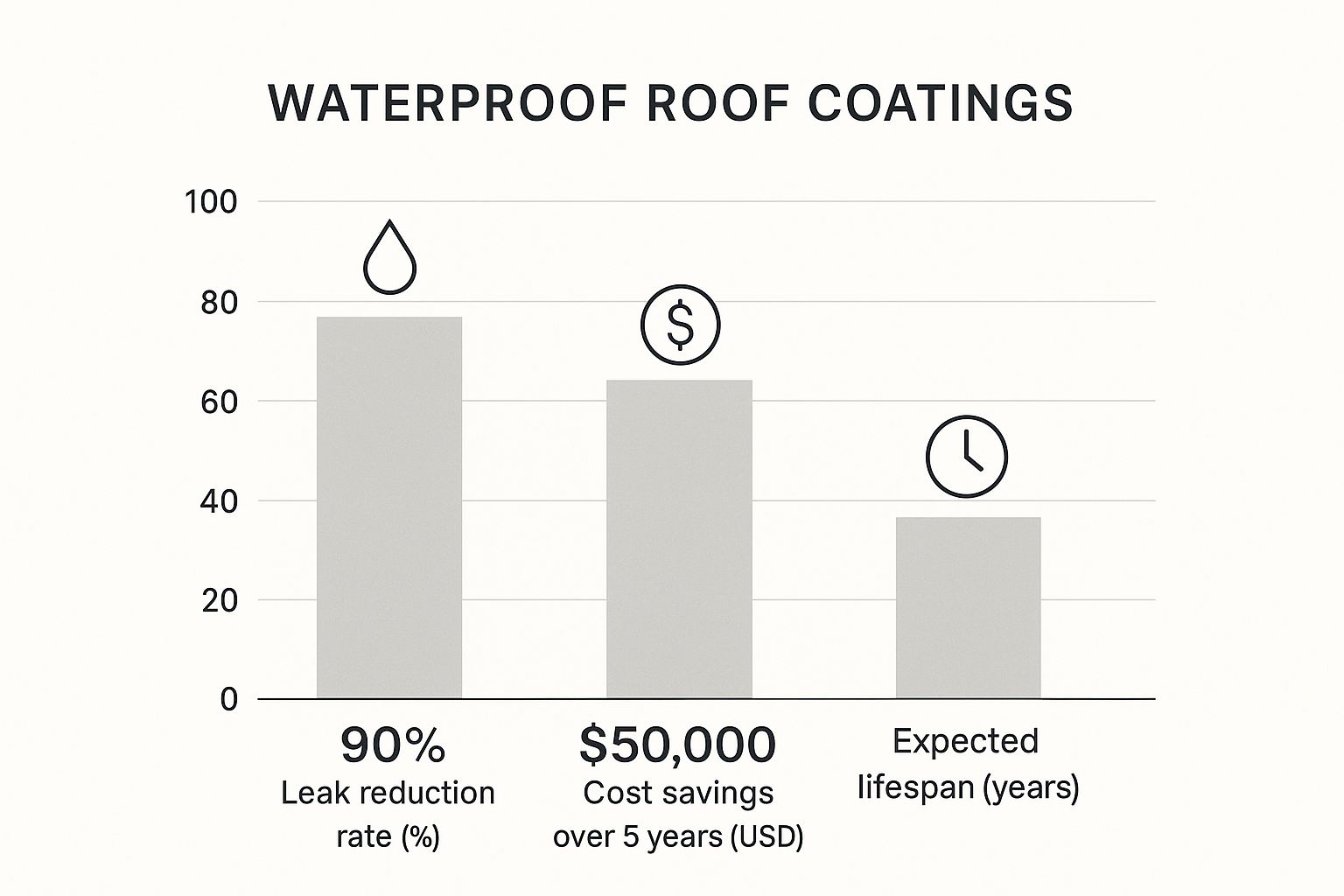

The infographic below drives this point home, showing the powerful return on investment these systems can offer.

As the data shows, putting your money into a quality coating system translates directly into a longer service life and significant long-term savings. It's not just about patching a leak; it's about making a smart investment in the building's future.

What You're Really Getting With Modern Coating Systems

Sure, the main job of a waterproof roof coating is to stop leaks. But if that's all you think they do, you're missing the bigger picture. Investing in a modern coating system is one of the smartest moves you can make to boost a building's performance, resilience, and even its bottom line. The benefits stack up, delivering a return that goes way beyond a simple patch job.

One of the biggest wins is a massive extension of your roof's service life. Think about it: instead of the headache and huge expense of a full tear-off, a coating breathes new life into the roof you already have. This can push back a capital-intensive replacement by 10, 15, or even 20 years. You’re not just fixing a problem; you're preserving a major asset.

The restoration process turns a tired, aging roof into a single, seamless membrane. It’s a durable shield that protects the structure not just from rain, but also from the constant stress of thermal expansion and contraction—a primary culprit behind material fatigue and failure over time.

Maximising Energy Efficiency with Cool Roofs

Here’s where things get really interesting, especially in sun-baked climates. The thermal properties of reflective coatings, often called "cool roofs," are a game-changer. They're engineered to bounce a huge percentage of solar radiation back into the sky instead of letting the building absorb it as heat.

It’s the same reason a white t-shirt feels cooler than a black one on a sunny day. A traditional dark roof can get incredibly hot, essentially cooking the building below and forcing the air conditioning to work overtime.

A reflective waterproof roof coating acts like a giant sun shield. By reflecting the sun's rays, it keeps the roof surface—and everything underneath it—significantly cooler. This simple change unlocks some serious energy savings.

- Reduced HVAC Load: Your cooling systems don't have to fight nearly as hard to keep indoor temperatures comfortable.

- Lower Energy Bills: Less HVAC usage means lower monthly electricity costs, which is a huge operational expense for any commercial building.

- Happier Occupants: A cooler building is simply more comfortable for tenants, employees, and customers.

Meeting Modern Sustainability Demands

This push for energy efficiency isn't just a trend; it's the future. The global cool roof coating market is expected to explode, reaching an estimated USD 9.51 billion by 2034. In places like the UAE, where summer temperatures regularly soar past 40°C, these coatings can drop roof surface temperatures by up to 30%. This has sparked major investment in high-performance coatings that deliver both waterproofing and thermal control, making them a cornerstone of sustainable building. You can learn more about the growing demand for these energy-saving solutions.

By restoring an existing roof instead of replacing it, a coating system diverts tonnes of old roofing material from landfills. This makes it a powerful choice for projects focused on sustainability and reducing environmental impact.

Beyond saving on energy, these systems help meet wider sustainability targets. They also make a building tougher, creating a monolithic barrier that stands up to severe weather, from torrential downpours to high winds, with no seams or weak points to fail. And let's not forget the aesthetics—a freshly coated roof looks clean, uniform, and professional, instantly boosting a property's curb appeal.

When you add it all up—extended lifespan, energy savings, improved resilience, and a better look—it’s clear that modern coating systems deliver impressive long-term value.

Your Step-by-Step Application Guide

Let’s be clear: even the best waterproof roof coating on the market will fail if you slap it on without care. The real magic happens during application, turning a can of liquid into a seamless, impenetrable shield. This isn't just a list of instructions; this is the field guide to getting it right, separating a ten-year fix from a one-year headache.

Think of it like painting a masterpiece. You wouldn’t start on a dirty, torn canvas, right? The same logic applies here. An overwhelming number of coating failures—some say as high as 80%—boil down to one thing: shoddy surface preparation.

This isn’t just about a quick sweep. It’s about creating the perfect foundation for the coating to grab onto and never let go. Nail this part, and the rest of the job becomes a whole lot easier.

Phase 1: Surface Preparation Is Everything

Before a single drop of coating touches the roof, that surface needs to be clean, solid, and bone-dry. This is the non-negotiable first step, and it involves a few critical jobs.

- A Deep Clean: Get everything off. We’re talking dirt, dust, grease, loose paint, and any organic growth like algae or moss. A good power wash, usually with 2,500-3,500 PSI, is your best friend here for blasting away years of grime.

- Meticulous Repairs: Walk every inch of that roof. You're looking for cracks to seal, blisters to fix, and any weak seams that need reinforcing with polyester fabric and a base coat. Every vent, pipe, and HVAC unit needs to be properly flashed and sealed tight.

- Priming for a Perfect Bond: Different roofs need different primers. A rusty metal roof needs a rust-inhibiting primer, no question. A porous concrete slab? It will likely need a specific sealer to stop it from drinking up the coating. Using the right primer is what creates that powerful chemical grip between the old surface and the new coating.

A rookie mistake is seeing prep work as just the warm-up. It's not. It's the main event. Every hour you spend cleaning, patching, and priming is a direct investment in how long that roof is going to last.

Phase 2: The Application Process

With a perfectly prepped surface, you’re ready to lay down the coating. The goal here is simple: hit the dry film thickness (DFT) the manufacturer specifies. Too thin, and you’ve got no real protection. Too thick, and it won't cure right, leading to a gummy mess.

The best tool for the job depends on the roof you're working on.

- Airless Sprayer: For big, wide-open roofs, nothing beats a sprayer. It's fast, efficient, and gives you the most uniform coverage.

- Roller: A heavy-nap roller is perfect for smaller jobs or for "back-rolling" after spraying to work the coating into the surface texture.

- Brush or Squeegee: You'll always need these for the tricky bits—cutting in around pipes, edges, and all those hard-to-reach corners.

No matter which tool you use, remember this: multiple thin coats are always better than one thick one. It builds a stronger, more consistent membrane every time.

Phase 3: Monitoring and Curing Conditions

The final boss of any coating job? The weather. A waterproof roof coating relies on a chemical reaction to cure, and that reaction is fussy about temperature and humidity. Get it wrong, and you're looking at blisters, poor adhesion, or a total do-over.

Always check the forecast and the product’s data sheet for these three things:

- Acceptable Temperature Range: Most coatings need the air and surface to be above a certain temperature (say, 10°C) and climbing.

- Humidity Levels: High humidity can kill your cure time, especially with water-based acrylics.

- Rain and Dew: The roof has to stay completely dry while you're working and while it's curing. No exceptions.

This level of detail is what separates the pros from the amateurs. And with the Middle East roofing materials market projected to hit USD 4.7 billion—and contractors making up 40% of that—skilled application is more critical than ever. It's what protects the region's massive investment in infrastructure. You can read the full report on the Middle East roofing market for a deeper dive.

If you’re looking to get even more familiar with protective coatings, our practical guide to waterproof paint has some great additional tips. Follow these steps, pay attention to the details, and you’ll deliver a roof that’s built to last.

Keeping Your Coated Roof in Top Shape for the Long Haul

Getting a high-quality waterproof coating on your roof is a smart move for protecting your building, but the job isn't truly finished when the last coat dries. Think of it like a new truck; you wouldn't just drive it for years without changing the oil or checking the tires. Its long-term performance hinges on regular check-ups.

A solid maintenance plan is what ensures you get the full 10 to 20 years of life you paid for. Ignoring simple upkeep is how small, easy fixes snowball into massive, expensive failures. By setting up a routine for inspections, cleaning, and minor repairs, you'll spot trouble early, keep that seamless membrane intact, and make sure it’s doing its job protecting your asset.

Your Routine Inspection Schedule

Consistent inspections are the absolute bedrock of a good roof maintenance program. Get in the habit of scheduling walk-throughs twice a year—spring and fall are perfect. This lets you see how the roof held up against the worst of the summer heat or winter storms and get it ready for what’s next. It’s a simple routine that nips minor damage in the bud before water finds a way in.

When you’re up there, you're looking for more than just obvious leaks. Your checklist needs to be thorough:

- Scan for Surface Damage: Get your eyes on the surface and look for punctures, blisters, or spots where the coating looks thin or is starting to peel. Pay extra attention to any high-traffic areas.

- Check Every Seam and Flashing: These are your critical points. Carefully inspect around every vent, pipe, HVAC unit, and drain. It’s no surprise that 90% of roof problems happen right at these penetrations.

- Clear Out Drains and Gutters: Make sure every drainage path is clear of leaves, dirt, and whatever else has collected up there. Clogged drains are the number one cause of ponding water, which puts a ton of stress on both the coating and the structure itself.

To make sure you're covering all your bases, this comprehensive roof maintenance guide is a fantastic resource to keep on hand.

Cleaning and Tackling Minor Repairs

Keeping the coating’s surface clean is a bigger deal than most people think, especially if you have a reflective "cool roof." A thick layer of grime can slash its ability to reflect sunlight, which means you’re losing out on those energy savings. For most roofs, a simple low-pressure wash with a mild detergent once or twice a year is all it takes to bring it back to peak performance.

If you spot minor damage, like a small slice or puncture, jump on it fast. A quick spot repair—just clean the area, apply a compatible sealant or patch, and feather it into the existing coating—prevents a much bigger headache later. It's a small job with a huge payoff in longevity. For issues that are a bit more complex, especially in unique climates, diving into resources on expert waterproofing like this one at https://yasutrading.com/blog/expert-waterproofing-dubai-protect-your-property-today/ can provide specialized guidance.

A proactive approach to maintenance isn’t an expense; it’s an investment. Every small repair you make extends the life of the entire system, pushing back the enormous cost of a full recoat or, worse, a complete roof replacement.

Knowing When It's Time to Recoat

Even the best-cared-for roof coating has a finite lifespan. Eventually, your inspections will start showing widespread thinning, a lot of surface cracking (crazing), or multiple spots of failure. At that point, spot repairs just won't cut it anymore. That's your signal that it's time for a strategic recoat.

A recoat isn't a full replacement. It’s a process of thoroughly cleaning the existing surface and applying a fresh system of coating right over top. This essentially hits the reset button, giving you another 10 to 15 years of protection. It’s a far more cost-effective way to restore your roof to its prime without the massive expense and disruption of a full tear-off, ensuring you get every bit of value out of your original investment.

Common Mistakes and How to Avoid Them

Let's be blunt: even the best waterproof roof coating on the market will fail if you don't get the application right. I've seen it happen time and again. A successful, watertight job is less about the fancy product in the bucket and more about sidestepping the common mistakes that lead to expensive callbacks.

If there's one mistake that causes more headaches than any other, it's inadequate surface preparation. Cutting corners here is the number one reason coatings fail, period. Think of it this way: the coating needs a perfectly clean, solid, and bone-dry surface to grab onto. Slapping it over dirt, damp spots, or flaking material is like trying to build a house on quicksand. It's not a matter of if it will fail, but when.

Choosing the Wrong Coating for the Job

Another all-too-common error is simply picking the wrong tool for the job. Not all coatings are built the same. A product that performs brilliantly on a steep-slope metal roof could be a complete disaster on a flat concrete deck that struggles with drainage. This is where you have to put your thinking cap on and match the coating to the roof's reality.

- Substrate Incompatibility: You can't just slap an acrylic coating over an old silicone roof and expect it to stick—it won't. You've got to check compatibility and use the right primer, or you'll get zero adhesion.

- Climate Mismatch: Using a standard acrylic on a flat roof in a rainy climate is just asking for problems. That's a job for silicone, which is built to handle ponding water without breaking a sweat.

A waterproof roof coating system is only as strong as its weakest link. A single missed crack, an improperly cleaned surface, or a coating applied too thin can compromise the integrity of the entire membrane, leading to premature failure.

Application and Environmental Errors

Once you've prepped the surface and selected the right product, you can still stumble during the application itself. Rushing the work or turning a blind eye to the weather forecast can completely sabotage the coating's ability to cure and perform as it should.

A classic rookie move is applying the coating too thinly. Manufacturers specify a dry film thickness (DFT) for a reason. That number isn't a suggestion; it's the absolute minimum needed to deliver real waterproof protection and stand up to years of sun exposure. Skimping on material is just throwing money away, as it drastically cuts down the system's lifespan.

Finally, ignoring weather conditions is a gamble that will eventually catch up with you. Trying to apply a coating when it's too cold, too humid, or with rain on the way is a recipe for disaster. The material won't cure correctly, leading to everything from blisters and peeling to a soft, tacky surface that never fully hardens. At that point, the entire job is a write-off.

Answering Your Top Questions

When you're talking about waterproof roof coatings, the same questions tend to pop up time and again. Whether you're specifying the material or getting ready for an installation, getting straight answers is key to a smooth project and happy clients.

Let's cut through the noise and tackle the big questions head-on. Understanding these details helps you see exactly where a coating system fits in compared to other roofing options, making sure you nail the right choice for the building and the budget.

What's the Real Cost of a Waterproof Roof Coating?

Trying to nail down a single price is tough because every roof is different. The final number really comes down to the type of coating you choose—acrylic, silicone, or polyurethane—the current shape of the roof, and just how big the job is. A roof that needs a ton of prep work and repairs is obviously going to have a higher price tag than one that's already in decent condition.

But here’s the most important thing to remember: restoring a roof with a coating is almost always a smarter financial move than a full tear-off. Building owners can often save up to 50% of the cost they would have spent on a total replacement. It's a serious investment in protecting the asset without breaking the bank.

How Long Will a Waterproof Roof Coating Actually Last?

When installed correctly by a professional, a good waterproof roof coating system should give you 10 to 20 years of solid performance. Of course, that lifespan depends on a few key things.

- Quality of the Material: You get what you pay for. Premium materials are engineered to last longer than their cheaper counterparts.

- Thickness of Application: Hitting the manufacturer's recommended dry film thickness (DFT) is absolutely crucial for long-term durability.

- The Weather It Faces: A roof baking in constant, harsh sun will age differently than one in a milder climate.

- Proper Maintenance: Just like anything else, a little upkeep goes a long way in getting the most out of the system.

The best part? With a solid maintenance plan, you can often apply a strategic recoat toward the end of its service life. This essentially hits the reset button, extending its protection for many more years.

Can You Really Put a Coating on Any Type of Roof?

Absolutely. One of the biggest advantages of these modern coatings is how versatile they are. They’re designed to go over just about any common commercial or industrial roofing material you can think of—metal, modified bitumen, concrete, and even single-ply membranes like TPO and EPDM.

The real secret to a bulletproof application isn’t just the coating. It's the prep work. A perfectly clean surface and the right primer are what create that unbreakable bond, guaranteeing the coating sticks and performs exactly like it's supposed to.

At Yasu Trading Co. LLC, we provide the premium building materials and expert guidance needed to ensure your projects succeed. Explore our extensive range of construction essentials by visiting us at https://yasutrading.com.