Expert Waterproofing Dubai | Protect Your Property Today

When we talk about building in Dubai, waterproofing isn't just another box to tick on a checklist. It's fundamental. Think of it as essential insurance against the region's uniquely demanding climate. We're applying a protective, impermeable barrier to stop water in its tracks, defending the structure against high humidity, punishing UV radiation, and those surprise deluges. This isn't just about preventing leaks; it's about guaranteeing a building's very longevity and structural health.

Why Waterproofing Is Your Building's First Line of Defence

Look at your building as a long-term investment. Just like any high-value asset, it needs robust protection from known threats. In Dubai, the biggest adversary isn't a single event like a storm, but a relentless combination of environmental forces constantly trying to break down building materials.

A structure without a solid waterproofing system is like heading into a sandstorm with no goggles—it’s not a matter of if things will go wrong, but when. Skipping this critical layer is a massive gamble. It leaves your property wide open to serious financial and structural damage, turning a manageable upfront cost into a potential nightmare of future repairs. This is exactly why waterproofing in Dubai is seen as a non-negotiable part of any project.

The Climate Challenge

Dubai's climate presents a very specific set of challenges that put buildings under constant stress. Let’s break down this "perfect storm" for water damage:

- Intense UV Radiation: The sun here is unforgiving. Over time, its powerful rays can degrade many waterproofing materials, making them brittle and causing them to crack. Those tiny cracks are all the invitation water needs.

- High Humidity: It’s not just the rain. Persistent moisture in the air can slowly work its way into porous materials like concrete. This fosters mould growth and can weaken the structure from the inside out.

- Sudden Downpours: While not a daily occurrence, when it rains in Dubai, it can rain hard. These sudden, heavy downpours can quickly overwhelm drainage systems, causing water to pool and relentlessly probe for any weakness in a building's shell.

Let's put this into perspective. We're not just dealing with minor nuisances; these are major environmental stressors that directly impact a building's lifespan and safety. The table below summarises how these climate factors translate into real-world building problems and how waterproofing acts as the solution.

Dubai's Climate Challenges and Waterproofing Responses

| Climate Challenge | Impact on Buildings | Role of Waterproofing |

|---|---|---|

| Intense UV Radiation | Causes material breakdown, brittleness, and cracking in protective layers. | Provides a UV-stable barrier that resists degradation and maintains flexibility. |

| High Ambient Humidity | Leads to water vapour ingress, internal condensation, mould, and concrete deterioration. | Creates an impermeable membrane that prevents moisture from penetrating the building envelope. |

| Sudden, Heavy Rainfall | Overwhelms drainage, causing water pooling, leaks, and structural water damage. | Ensures a seamless, sealed surface that contains and directs water to drainage systems, preventing infiltration. |

| High Salinity (Coastal Areas) | Accelerates corrosion of steel reinforcements (rebar) and degrades concrete. | Acts as a protective shield against chloride ion penetration, preserving the structural steel. |

As you can see, each element of the climate requires a specific, targeted defence, and a comprehensive waterproofing system is the only way to provide it. This reality is why the demand for high-performance solutions is skyrocketing. The Middle East and Africa waterproofing market is projected to jump from approximately USD 27.75 billion in 2025 to USD 38.44 billion by 2030, with the UAE's construction boom being a primary driver. You can dig deeper into these trends in this detailed industry report.

A building’s defence system is only as strong as its weakest point. In Dubai, water will always find that weakness, whether it’s a tiny crack in a roof membrane or an unprotected foundation. Effective waterproofing is about sealing those vulnerabilities before they become catastrophes.

Ultimately, a good waterproofing system does so much more than just keep the interior dry. It’s what protects structural steel from rusting away, prevents concrete from crumbling, and stops unhealthy mould from taking over your walls. It is the absolute first step in creating a safe, durable, and resilient building that can truly stand up to everything Dubai’s environment can throw at it for decades.

Meeting Dubai's Waterproofing Standards and Codes

In Dubai, waterproofing isn't just a good idea—it's the law. To make sure every building can stand up to the local climate, authorities like the Dubai Municipality (DM) enforce a strict set of rules. These regulations aren't just red tape; they are the very blueprint for a building’s long-term survival.

Think of these codes as the absolute minimum standard for safety and quality. They're designed to protect your investment by demanding a certain level of performance from every waterproofing system installed. Getting this right from the start is the only way to build a durable, lasting structure.

These rules leave no stone unturned. They cover every vulnerable point of a building, from the vast, flat roofs of commercial towers to the subterranean basements of villas and the wet areas inside every apartment. The goal is simple: to prevent the costly headaches—leaks, concrete rot, and mould—that come from cutting corners.

Why Compliance Is Your Best Strategy

Following the official codes for waterproofing in Dubai is about so much more than just dodging fines or project hold-ups. It’s a proactive move that locks in quality and structural integrity from day one. When a contractor adheres to these standards, you know they're using approved materials and field-tested methods.

For property owners, this translates directly into peace of mind. You can rest easy knowing the protective shield wrapped around your building has been vetted and meets the tough demands of the UAE environment. This is your first and best defence against expensive future repairs.

“The Dubai Municipality building codes act as a safety net for property owners. They ensure that essential systems like waterproofing are implemented to a professional standard, safeguarding the building's structural health and market value for years to come.”

Ultimately, these standards pull the developer, contractor, and owner onto the same team, all working toward a single goal: a safe, resilient building. For a closer look at the specifics, our detailed guide to the Dubai building codes offers crucial context for any project.

Key Areas Covered by Dubai's Codes

The regulations are nothing if not thorough, zeroing in on the most critical zones where water could cause the most damage. While the full list is extensive, compliance generally revolves around a few key areas:

- Roofs and Terraces: All flat roofs need a tough, UV-resistant waterproofing membrane. Just as important is a proper slope for drainage to stop water from sitting around and causing trouble.

- Basements and Foundations: Anything built below ground level requires a full "tanking" system. This is essentially an impermeable bathtub that completely encases the structure to hold back groundwater pressure.

- Wet Areas: Bathrooms, kitchens, and laundries are obvious hotspots. Floors and walls must be waterproofed before any tiles go on, containing potential leaks and stopping moisture from creeping into other rooms or floors.

- Balconies and Podiums: These exposed platforms take a beating from rain and cleaning. They demand durable waterproofing with careful attention to details around railings and drains.

Making sure your project checks all these boxes isn't just about satisfying a regulator. It's a fundamental part of building science here in the UAE. It directly impacts how long your structure will last and how safe it will be. That’s why choosing a contractor who truly understands and rigorously applies these standards is essential for successful waterproofing in Dubai.

Of course. Here is the rewritten section, crafted to sound completely human-written and natural, following all your specific instructions.

Choosing the Right Waterproofing System

Picking the right waterproofing system for a project in Dubai isn’t a one-size-fits-all decision. It's a bit like choosing tyres for a car; what works for a high-performance sports car is completely wrong for a heavy-duty construction truck. In the same way, the system you’d use for a massive, flat commercial roof is worlds apart from what’s needed for a small, tiled balcony.

To make the right call, you have to look past the brand names and get to the heart of the technology. The real goal is to match the material's inherent strengths to the unique demands of the specific area you're protecting. This isn't just about stopping leaks today; it's about ensuring long-term performance and value for money, especially under Dubai's intense climate.

When it comes to waterproofing in Dubai, three main types of systems tend to dominate the market: liquid-applied membranes, sheet membranes, and cementitious coatings. Each has its own personality, with distinct pros, cons, and ideal applications.

H3: Decoding Liquid-Applied Membranes

Liquid-applied membranes are probably the most versatile tools in the waterproofing toolbox. Just like the name implies, they're applied as a liquid—with a roller, brush, or spray gun—and then cure to form a seamless, flexible, and fully bonded waterproof layer.

Think of it as literally painting a waterproof skin directly onto the surface. That seamless finish is their biggest selling point. There are no joints, no seams, and no overlaps that could eventually fail and let water in. This makes them a lifesaver for complex, fiddly areas.

- Ideal Applications: Roofs cluttered with pipes, vents, and HVAC units; balconies with unusual shapes; and podium decks.

- Key Advantage: Their incredible ability to form a continuous, monolithic barrier around awkward details where trying to cut and seal a sheet membrane would be a nightmare.

This combination of flexibility and easy application is fuelling some serious market growth. It’s no surprise that the global waterproof coatings market is expected to climb from USD 15,121.4 million in 2020 to over USD 17,797.8 million by 2025. Single-component coatings, in particular, are a popular choice for their durability on roofs, terraces, and balconies. You can discover more insights about this growing market and what's driving the trend.

H3: The Power of Sheet Membranes

Sheet membranes are the undisputed heavy-duty workhorses of the waterproofing world. These are prefabricated rolls of waterproof material, usually made from bitumen or modern polymers like PVC and TPO. On-site, they are simply rolled out and sealed together.

Imagine you're laying down a tough, factory-made protective blanket over the structure. Because they are manufactured in a controlled environment, their thickness is perfectly uniform, giving you a reliable and incredibly robust barrier against water. This makes them a fantastic option for large, simple surfaces where consistency is everything.

They really shine in below-ground applications, like basements and foundations, where they have the muscle to stand up to significant hydrostatic pressure from the surrounding groundwater.

H3: Understanding Cementitious Coatings

Cementitious coatings are essentially cement-based powders mixed with special additives and polymers. When mixed with water or a liquid agent, they create a rigid, hard-wearing waterproof barrier that’s often applied with a simple brush or trowel.

The best way to picture this system is as a permanent, waterproof plaster that bonds directly with the concrete or masonry. It doesn't just sit on top; it becomes an integral part of the structure itself, making it exceptionally durable and resistant to scrapes and abrasion. This is why it’s the go-to for areas facing constant moisture.

- Best For: Internal wet areas such as bathrooms, kitchens, and laundry rooms, applied right before tiling.

- Also Used For: Concrete water tanks, swimming pools, and retaining walls where toughness is paramount.

Comparing Waterproofing Systems for Dubai Applications

Making the final choice often comes down to weighing the pros and cons of each system against your project's specific needs. To make this easier, here’s a quick comparison of how these three systems stack up in the context of a Dubai project.

| System Type | Best For | Key Advantages | Considerations |

|---|---|---|---|

| Liquid-Applied Membranes | Complex roofs, balconies, podium decks, and detailed repair work. | Seamless and fully bonded, excellent flexibility, easy to apply on intricate shapes. | Requires a clean, dry substrate; application thickness must be carefully controlled. |

| Sheet Membranes | Large, flat roofs, foundations, basements, and tunnels. | Factory-controlled thickness, high puncture resistance, excellent for below-grade applications. | Seams are a potential weak point if not sealed perfectly; less flexible for complex details. |

| Cementitious Coatings | Wet areas (bathrooms, kitchens), water tanks, swimming pools, retaining walls. | Extremely durable and abrasion-resistant, becomes part of the structure, easy to apply. | Rigid and not flexible, so it may crack if the underlying structure moves. |

Each of these systems has a solid place in the construction industry. The key is knowing when and where to use them to get the best possible outcome for your building.

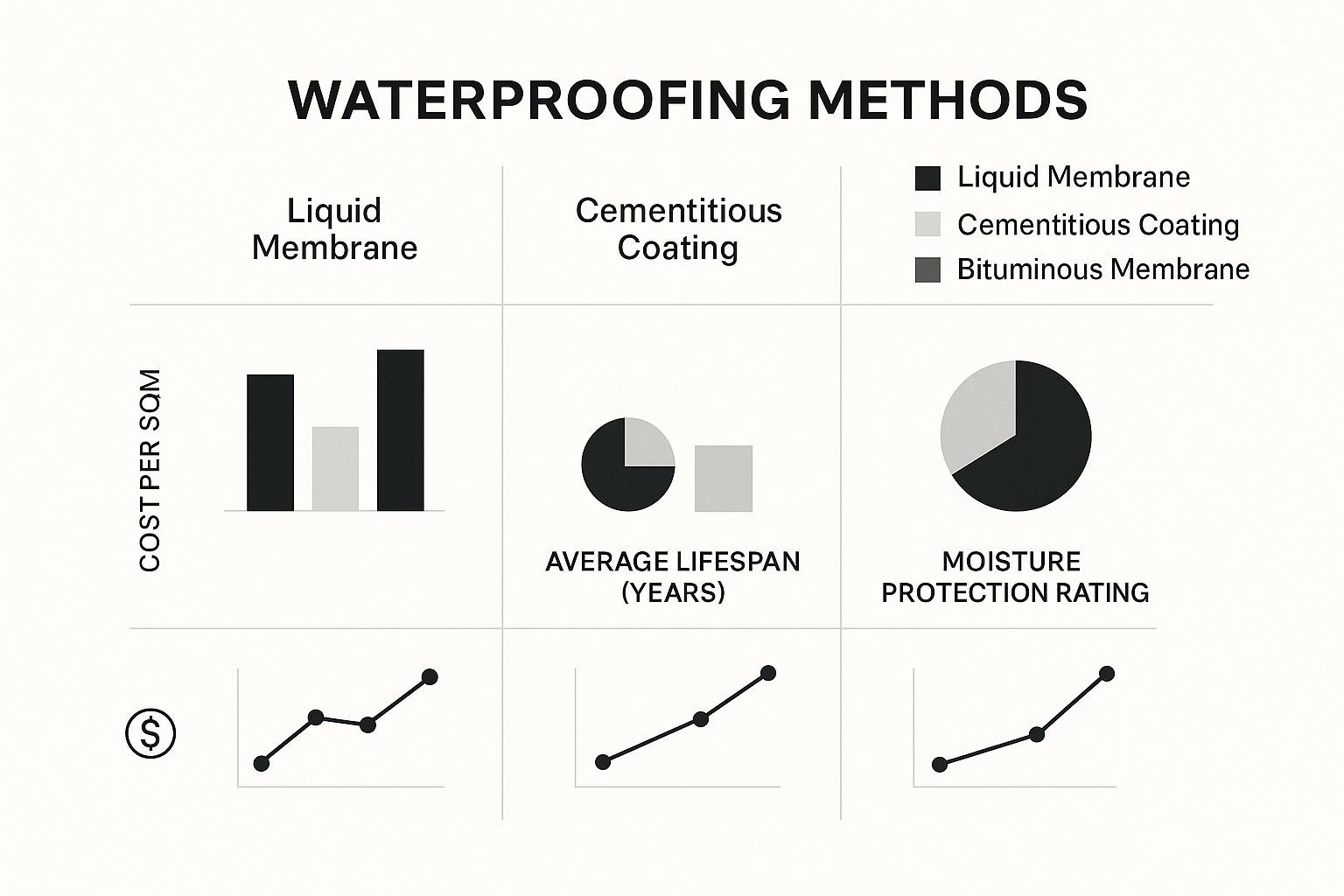

The data here is quite telling. While traditional bituminous membranes can be a cost-effective choice upfront, liquid-applied membranes often deliver a better balance of lifespan and robust moisture protection. Ultimately, your decision will hinge on balancing the project budget, the specific area needing protection, and how long you need the system to last. When applied correctly by skilled professionals, any of these options provides a reliable path to effective waterproofing in Dubai.

What a Professional Waterproofing Application Looks Like

As a property owner, you don’t need to become a waterproofing installer overnight. What you do need is a sharp eye for quality. Knowing what a first-class job looks like is your best defence, allowing you to hold your contractor to the high standards your project deserves.

A truly professional application is a meticulous, multi-stage process. There are no shortcuts.

Think of it like getting a car painted. You wouldn't just spray a new coat over dirt, rust, and old, flaking paint. You’d expect the body shop to strip it down, sand it smooth, and prime it perfectly. The same goes for waterproofing—the final protective layer is only as strong as the painstaking prep work that lies beneath.

From the first inspection to the final flood test, every single step is critical. This knowledge isn't just trivia; it's your personal quality control tool, helping you spot the red flags and ensuring your investment is built to last.

The Foundation of Success Is Surface Preparation

I can't stress this enough: this is the single most important phase of any waterproofing job. A shocking number of failures we see in the field can be traced directly back to a poorly prepared surface. A professional crew knows this and will dedicate a huge chunk of their time right here, because a pristine substrate is non-negotiable for a permanent bond.

So, what does proper prep actually involve? It's a world away from a quick sweep with a broom. It's a systematic process to create the perfect canvas.

- Deep Cleaning: The surface has to be completely free of any contaminants—dust, grease, oil, old paint, you name it. This isn't a light dusting; it often means serious work with high-pressure washers or mechanical grinders.

- Structural Repairs: Every crack, hole, or void in the concrete needs to be properly filled and repaired using the right kind of mortars or sealants. Trying to waterproof over an unstable surface is just asking for trouble.

- Moisture Control: Concrete holds moisture. Before any membrane is applied, a pro will use a moisture meter to confirm the substrate is dry enough to meet the product manufacturer’s exact specs.

If these steps are rushed or skipped, the membrane simply won't stick properly. That leads to blisters, peeling, and, sooner or later, leaks.

Precision During Membrane Installation

Once the surface is absolutely perfect, the application of the waterproofing system itself can begin. Whether it’s a liquid membrane, a self-adhesive sheet, or a cement-based product, this stage is all about precision and a steady, experienced hand. The goal is a uniform, seamless shield with zero weak points.

This is where you really see the skill of the applicator. With liquid systems, they have to get the thickness just right across the entire area—too thin and it won't be durable, too thick and it might not cure correctly. For sheet membranes, every single seam and overlap must be perfectly welded or sealed. These are the classic failure points, and a pro knows not to mess them up.

This demand for skilled work is growing fast. The Middle East's waterproofing chemical market was valued at around USD 261.444 million and is expected to hit USD 315.782 million by 2025. The UAE alone accounts for about 12.60% of that market, showing a massive demand for both high-grade materials and expert application. You can explore more on the projected growth on Cognitive Market Research to see just how critical this sector is.

The Final Verdict Is Flood Testing

How do you know for sure that the job was done right? You test it. A reputable contractor will always finish with a post-application flood test. It’s the ultimate proof of their workmanship.

Flood testing is the non-negotiable quality assurance check. It involves deliberately ponding water on the newly waterproofed surface for a set period, typically 24 to 48 hours, to simulate heavy rainfall and proactively identify any potential leaks.

If the area below stays bone-dry after the test period, you’ve got a winner. But if even a hint of dampness appears, it flags a flaw that the contractor must find and fix before any protective layers or finishes like tiles are installed. Insisting on a flood test is your right, and it’s the best guarantee you have for a leak-free future.

Preventing Common Waterproofing Failures in Dubai

Even when you’ve invested in the best materials money can buy, a waterproofing system can still fail. And in Dubai, a failed system isn’t just a minor headache—it's a direct threat to a building's structural integrity and overall value. Getting to the root of why these failures happen is the only way to prevent them.

You might be surprised to learn that most issues don’t stem from a faulty product. Instead, they’re almost always caused by a breakdown in the process. This could be anything from a poor match between the material and the environment to critical mistakes made during the actual application. By understanding these common pitfalls, you can protect your investment and avoid costly repairs down the line.

The Problem of Thermal Shock and Material Choice

Dubai's climate is a masterclass in extremes. The massive temperature swing from the blistering daytime sun to cooler desert nights puts immense stress on building materials. This relentless cycle of expansion and contraction, known as thermal shock, is public enemy number one for waterproofing membranes.

If a material doesn't have the flexibility to move with the building, it will eventually turn brittle and crack under the strain. A cheap, rigid coating might seem like a good deal initially, but it simply isn’t built to withstand this daily abuse. This is precisely why we see so much widespread cracking on roofs and exposed podiums, creating a highway for water to find its way in.

Choosing a waterproofing system is like picking an athlete for a specific sport. You wouldn't send a powerlifter to run a marathon. In the same way, a material that can't handle extreme thermal movement has no business being on a Dubai rooftop.

When Application Goes Wrong

Here’s a hard truth: a perfect material in the hands of an unskilled applicator is a guaranteed disaster. The most advanced membrane in the world is useless if the surface it’s applied to isn’t prepared flawlessly. And this, right here, is where so many projects fall apart.

Skipping or rushing surface preparation is probably the single biggest reason waterproofing systems fail. Any contaminants left behind—dust, oil, moisture, or loose debris—stop the membrane from forming a solid bond with the substrate. This negligence leads directly to two major problems:

- Blistering: When air or moisture gets trapped underneath the membrane, the intense heat causes it to expand, creating ugly bubbles or "blisters." These blisters are weak points that can be easily punctured, creating a direct path for leaks.

- Peeling and Delamination: If the membrane doesn't adhere properly from the start, it will inevitably start to peel away from the surface. This is especially common at edges and corners, leaving the entire system compromised.

Poor seam work on sheet membranes is another classic failure point. Every single overlap has to be perfectly welded or sealed according to the manufacturer’s exact instructions. Even a pinhole-sized gap is an open invitation for water ingress. Of course, picking the right materials in the first place is half the battle, which is why it pays to research the latest innovations. You can explore some of the more trending construction materials in Dubai to see how modern products are designed to meet these exact challenges.

Proactive Steps to Avoid Failure

The good news is that preventing these issues boils down to being diligent and asking the right questions from day one. Your goal is simple: ensure the system is not only specified correctly for the job but also installed with an obsessive focus on detail.

Here are the key areas to concentrate on:

- Verify Material Suitability: Don't just take someone's word for it. Confirm that the membrane has a high elongation value and is rated to handle the intense UV exposure and temperature swings we see in the UAE.

- Scrutinise the Contractor's Process: Ask any potential contractor to give you a step-by-step breakdown of their surface preparation plan. A true professional will have a detailed process they can explain clearly and confidently.

- Insist on Flood Testing: A mandatory flood test is your ultimate quality control check. It's the only real way to prove the system is 100% watertight before any final finishes are installed over it.

By taking a proactive approach, you’re no longer just hoping for the best—you’re actively ensuring a successful outcome. This knowledge is your best defence against the enormous cost and stress of dealing with leaks and structural damage from a failed waterproofing Dubai project.

Maintaining Your Waterproofing for Lasting Protection

Getting a high-quality waterproofing system installed is a brilliant start, but it’s definitely not a "set it and forget it" job. Think of it like servicing a premium car; a little proactive care ensures it performs perfectly for years and helps you avoid a catastrophic, expensive breakdown down the road.

This ongoing maintenance is your best strategy for protecting your investment. By spotting and fixing small issues early, you sidestep the massive reactive repair bills that a full system failure brings. A simple, consistent maintenance plan is all it takes to extend the life of your building's protective shield, keeping your asset secure against Dubai's tough climate.

Your Proactive Maintenance Checklist

A straightforward inspection schedule can make all the difference. The real goal here is to catch trouble before it turns into a disaster, especially right before the winter rainy season when your system will truly be put to the test. Regular checks are your best defence.

Here’s what to look for on your routine walk-throughs:

- Clear All Debris: Sand, leaves, and other debris blown in by the wind are the usual suspects for clogging up drains. When water has nowhere to go, it pools on the surface, putting immense, constant pressure on your waterproofing membrane.

- Inspect Drainage Outlets: Make sure every drain, scupper, and gutter is completely clear and working as it should. A single blockage can turn a light shower into a serious flood risk.

- Look for Visible Damage: Scan the surface for any signs of physical harm. Things like punctures from dropped tools, blistering in the membrane, or visible cracks are red flags that demand a professional repair.

- Check Sealants and Joints: Pay very close attention to the sealant around pipes, vents, and any other penetrations through the roof or walls. These areas are weak spots where sealants can dry out and pull away, creating a direct path for water.

Proactive maintenance is a game of prevention, not reaction. A few hours spent on inspection each year can save you tens of thousands of dirhams in water damage repairs, mould remediation, and structural fixes.

Knowing the Early Warning Signs

Beyond the obvious physical damage, you need a sharp eye for the subtle clues that your waterproofing is starting to wear out. Catching these early gives you a crucial window to act before a major leak springs. Be on the lookout for any changes, no matter how small they seem.

- Ponding Water: If you see water still standing on your roof 48 hours after it rains, that's a major red flag. It points directly to a drainage problem that needs to be sorted out immediately.

- Stains or Discolouration: Water stains on your interior ceilings or walls are late-stage signs that water has already gotten in. On the outside, look for dark patches on concrete, which show where moisture is being absorbed.

- Efflorescence: Ever see a white, powdery residue on concrete or masonry walls? That’s efflorescence. It's basically salt deposits left behind as water seeps through the material and evaporates, and it's a sure sign that water is passing through the structure.

Maintaining the integrity of your building envelope is directly tied to the materials used. Understanding the required level of quality is essential, and you can learn more about how these are regulated by exploring the official building materials quality standards in the UAE. By combining quality installation with diligent upkeep, you ensure your waterproofing in Dubai provides lasting, reliable protection for decades to come.

Your Top Waterproofing Questions, Answered

It's smart to have questions when you're investing in something as important as waterproofing. Getting clear, honest answers is the first step toward protecting your property and making a decision you won't regret. We've gathered some of the most common queries we hear about waterproofing in Dubai to give you some quick, practical insights.

How Often Should I Get My Building’s Waterproofing Inspected?

We strongly recommend having a professional take a look at least once a year. The best time for this is right before the winter rainy season kicks in. It’s also wise to call in an expert after any unusual weather event, like a particularly heavy downpour or a major sandstorm, just to be safe.

In between professional checks, you can do your own quick visual inspection every few months. Keep an eye out for the obvious red flags: piles of debris, standing water that isn't draining, or any visible cracks, peeling, or blisters on the membrane's surface. Catching these small issues early can save you from a world of trouble and expense down the road.

What’s the Biggest Waterproofing Mistake People Make in the UAE?

Hands down, the most common and costly mistake is chasing a low price tag at the expense of quality. Choosing an inexperienced contractor or a waterproofing system that simply wasn't designed for the UAE’s brutal climate is a recipe for disaster. It almost always fails prematurely.

Coming in at a close second is cutting corners on surface preparation. A shoddy job might look okay for a little while, but it will quickly break down under Dubai’s relentless sun and heat. This inevitably leads to leaks, costly structural damage, and a much bigger bill to fix everything properly.

Think of it this way: hiring a reputable, certified specialist for your waterproofing in Dubai isn't just an expense—it's the best insurance policy you can buy for your building. The money you think you're saving on a cheap job will disappear in a flash when you're paying to repair all the damage it caused.

Can I Just Do the Waterproofing Myself and Save Some Cash?

While it might be tempting to tackle a small crack with a tube of sealant from the hardware store, waterproofing critical areas like roofs, foundations, and basements is a job for the pros. It’s a technical discipline. A proper, lasting application requires a deep understanding of how different materials behave, meticulous prep work, and precise installation that aligns with Dubai Municipality codes.

A DIY attempt gone wrong can lead to widespread, hidden water damage that eats away at your building's structural integrity. It will also void any warranties on the materials you used and, ironically, end up costing you a whole lot more when you have to hire a professional team to tear out your work and do it all over again, the right way.

For any construction project in the UAE, you need a partner you can count on for quality materials. Yasu Trading Co. LLC offers a full suite of certified building materials, safety equipment, and all the essentials your project needs to meet the highest standards. Request your quote online today at yasutrading.com and build with confidence.