What Is Better MS or GI in Bolts and Nuts? Find Out Now!

Deciding between Mild Steel (MS) and Galvanized Iron (GI) for bolts and nuts isn't about which one is "better" overall, but which one is right for the job at hand. The real answer comes down to one key factor: the environment.

If your project is outdoors, especially in a humid or coastal area where rust is a constant enemy, Galvanized Iron (GI) is unquestionably the way to go. But for indoor applications in a controlled, dry environment, Mild Steel (MS) is a perfectly suitable and more economical choice.

MS vs. GI: A Quick Comparison for Your Project

Getting a handle on the core differences between MS and GI is crucial for making the right call. This isn't just a simple material swap; you're weighing the initial price tag against long-term performance and safety. The magic behind GI bolts is the galvanization process—they're dipped in molten zinc, which forms a tough, protective coating.

This zinc layer is the game-changer. It acts as a sacrificial barrier, corroding first to protect the steel underneath. This gives GI fasteners a lifespan that can easily outlast untreated MS bolts by years, if not decades, when left exposed to the weather. Sure, MS bolts save you money upfront, but their tendency to rust can lead to structural failure, forcing expensive and time-consuming repairs later on.

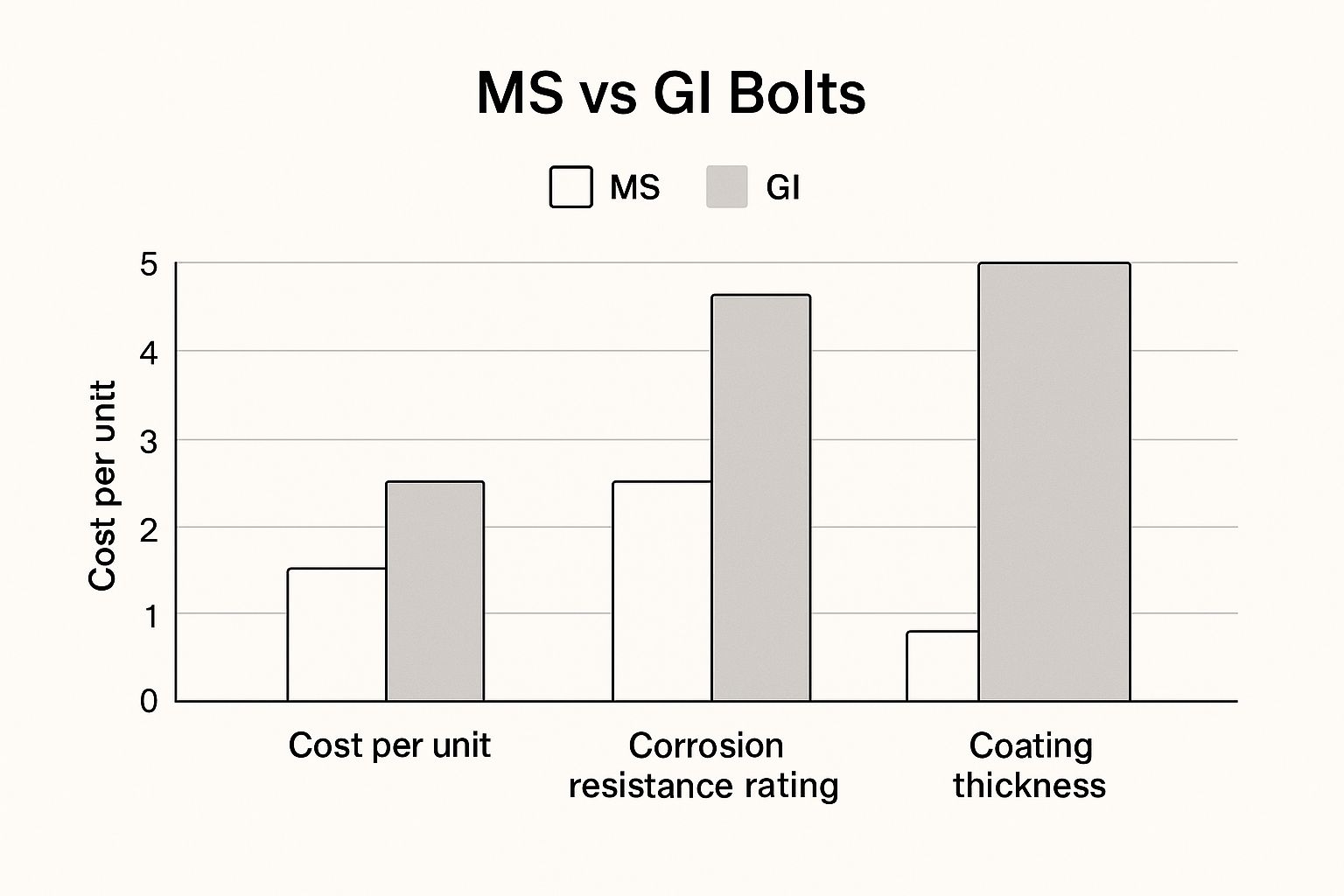

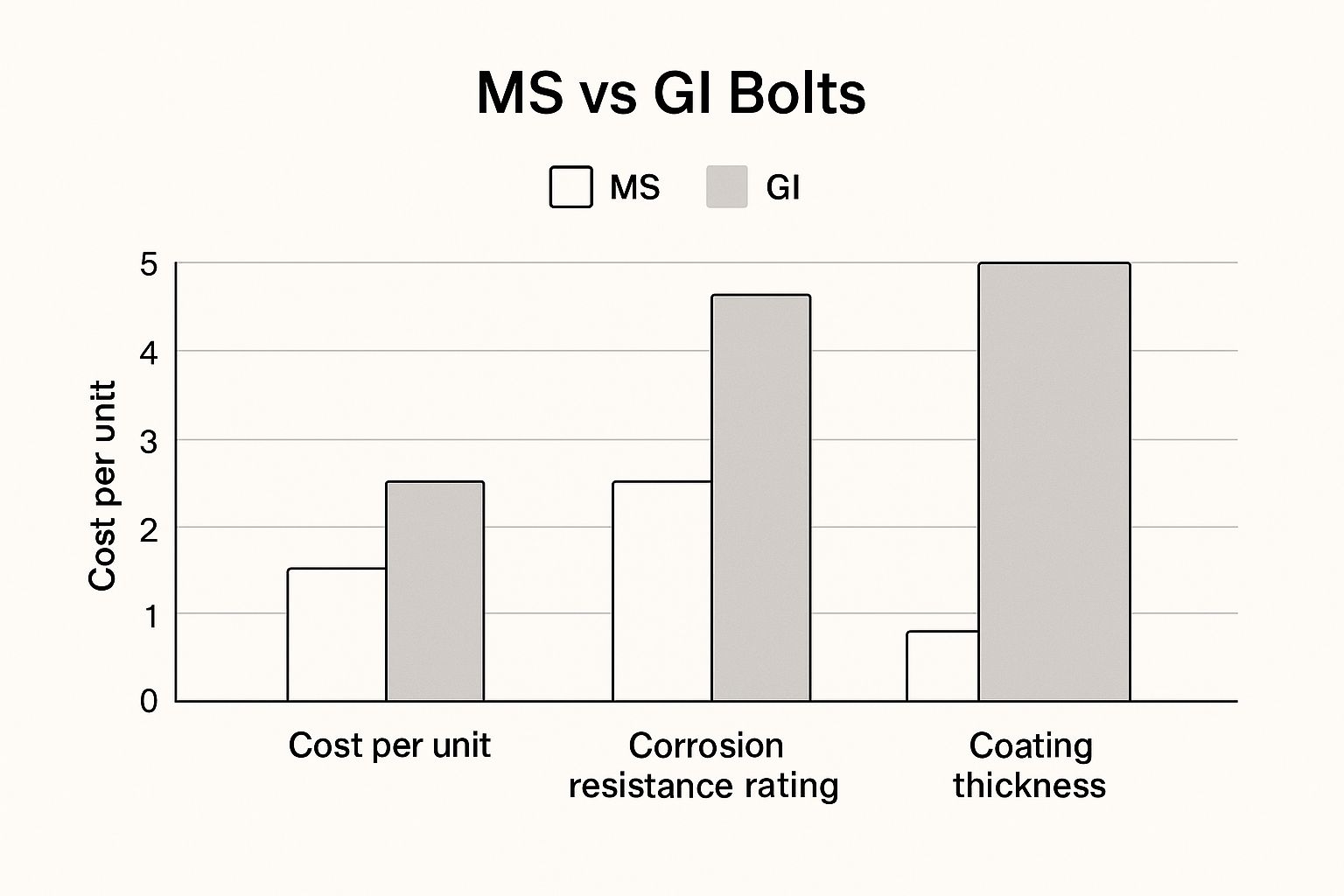

The chart below gives you a clear visual breakdown of how these two options stack up on cost, corrosion resistance, and coating.

As you can see, the initial savings with MS come at the cost of durability. The protective zinc on GI bolts is what gives them a decisive edge in any environment where corrosion is a concern.

For a more direct look, here’s a table that summarizes the key differences.

MS vs. GI Bolts At a Glance

| Attribute | Mild Steel (MS) | Galvanized Iron (GI) |

|---|---|---|

| Corrosion Resistance | Low; prone to rust in moist conditions | High; protected by a sacrificial zinc coating |

| Best Use Case | Indoor, dry environments; general fabrication | Outdoor, coastal, and high-humidity areas |

| Upfront Cost | Lower | Higher (due to the galvanization process) |

| Long-Term Cost | Can be higher due to replacement/maintenance | Lower in harsh environments due to longevity |

| Appearance | Dark gray, metallic | Dull gray, sometimes with a crystalline pattern |

| Primary Weakness | Susceptibility to rust and corrosion | The coating can be damaged by abrasion |

Ultimately, this table helps distill the choice down to its basics. Consider your project's specific needs, and the right fastener will become obvious.

Understanding the Core Materials

To really answer the question "what is better, MS or GI in bolts and nuts," we have to get down to the fundamentals. The choice isn't just about looks; it’s a decision between two completely different material makeups.

Mild Steel (MS) is a basic carbon steel with a pretty low carbon content—typically just 0.05% to 0.25%. This simple formula makes it impressively strong, easy to shape, and a breeze to weld. It’s no surprise it's a go-to, budget-friendly option for all sorts of projects.

But it has a critical flaw: rust. Expose an MS bolt to moisture and air, and oxidation is inevitable. Over time, that corrosion will eat away at the bolt, weakening its structural integrity and making it a poor choice for anything outdoors or in damp conditions unless you add a protective coating.

The Galvanized Iron Difference

This is where Galvanized Iron (GI) fasteners change the game. A GI bolt is essentially a standard steel bolt that has been given a serious upgrade through a process called hot-dip galvanization. The steel is literally dipped into a vat of molten zinc.

That zinc bath creates a tough, metallurgically bonded coating that seals the steel completely. The zinc layer acts as a shield, keeping corrosive elements like water and salt from ever touching the steel underneath. This is the single biggest factor that makes GI fasteners so much more durable in tough environments.

The zinc on a GI bolt isn't just a simple barrier; it's a sacrificial anode. If the coating gets scratched or damaged, the surrounding zinc will corrode first, sacrificing itself to protect the exposed steel. This "self-healing" property is a huge deal for long-term outdoor reliability.

This sacrificial protection is precisely why GI is the standard for outdoor construction, infrastructure projects, and anywhere else a fastener has to stand up to the elements. For a wider look at material options, our guide on essential building material hardware offers some great perspective. Grasping this core difference in how each material handles corrosion is the first step to picking the right fastener for your job.

Corrosion Resistance and Durability Under Pressure

The real measure of any fastener is how it holds up to the elements. This is where the difference between Mild Steel (MS) and Galvanized Iron (GI) becomes crystal clear. When someone asks what’s better, MS or GI, the answer almost always comes down to how they perform against corrosion.

Mild steel fasteners, being essentially untreated low-carbon steel, are incredibly vulnerable to rust. The moment they're exposed to moisture and oxygen, an electrochemical reaction kicks off, forming that all-too-familiar reddish-brown iron oxide. This isn't just a cosmetic problem; rust eats away at the steel, compromising its strength and setting the stage for failure.

Galvanized iron, on the other hand, comes prepared for battle. Its protective zinc coating provides a robust, multi-layered defense system that stops corrosion in its tracks.

The Science of GI Protection

That zinc coating on a GI bolt is much more than just a simple paint job. It offers cathodic protection, a clever electrochemical process where the zinc coating essentially sacrifices itself for the steel underneath.

- Barrier Protection: First and foremost, the zinc creates a physical shield, blocking moisture and air from ever reaching the steel core.

- Sacrificial Action: Here’s the brilliant part. If that coating gets scratched or chipped, the zinc around the damage corrodes first. It willingly sacrifices itself to protect the exposed steel. This "self-healing" ability is a game-changer for maintaining integrity in the real world, where fasteners inevitably get scuffed up.

This one-two punch is precisely why GI fasteners are the go-to choice for almost any outdoor job, from putting up a fence to constructing massive bridges. Getting this choice right is crucial for a project's longevity, especially when dealing with damp or harsh conditions, like those requiring corrosion-resistant fasteners in plumbing.

Key Insight: Trying to save a little money by using MS bolts on an outdoor project is almost always a mistake. The long-term costs of replacement, labor, and potential structural failure from rust will quickly eclipse any initial savings.

Performance in the UAE Climate

In a demanding climate like the UAE, with its relentless humidity and salty coastal air, choosing the right fastener isn't just a recommendation—it's a necessity. It’s no surprise, then, that GI bolts and nuts are the overwhelming favorite for any application that sees the sun and sky.

Regional suppliers report that over 60% of outdoor structural bolts are galvanized. Why? Because a GI fastener can be expected to last 15-20 years or more, while an untreated MS bolt might fail in just 5-7 years under the same conditions.

This dramatic difference in lifespan is critical for everything from coastal infrastructure to communication towers. When moisture is a constant threat, like in plumbing systems, it's also worth looking into alternatives like stainless steel pipes and fittings for maximum protection. But when it comes to durability under environmental pressure, GI is the undisputed champion.

Cost: The Upfront Price vs. The Long-Term Value

When you're choosing between Mild Steel (MS) and Galvanized Iron (GI) bolts and nuts, it’s easy to get fixated on the price tag. But that's only half the story. The real financial picture emerges when you look at the total cost over the life of the fastener.

MS bolts are, without a doubt, cheaper upfront. You’ll typically find they cost 15-30% less than their galvanized equivalents. If you're working on a large-scale indoor project in a perfectly dry, controlled environment, that initial discount is hard to ignore and makes MS a sensible, budget-friendly pick.

But the game changes completely once you introduce any hint of moisture or outdoor exposure.

Why the Cheaper Bolt Can Cost You More

The true cost of a fastener goes far beyond its purchase price. It’s a sum of the part itself, the labor to install it, the maintenance it needs, and the potential price of failure. For MS bolts used outdoors or in humid conditions, this total cost can climb unexpectedly high.

Think about the long-term expenses that creep in:

- Replacement Costs: An MS bolt that rusts through will need to be replaced. A single GI bolt might outlast several MS replacements over the same period.

- Labor Expenses: The time and money spent paying someone to remove corroded fasteners and install new ones can quickly erase any initial savings.

- Downtime and Damage: What happens if a rusted bolt fails? In a commercial or industrial setting, this could mean expensive operational downtime, equipment damage, or even a safety hazard.

For projects in demanding environments like the UAE, paying more for GI fasteners isn't just an expense—it's an investment. It's insurance against future repairs, replacements, and headaches. The durability of GI bolts translates directly into savings down the road.

So, when it comes to the "MS or GI" cost debate, the right answer is always tied to the job at hand. For a simple indoor frame that will never see a drop of rain, MS saves you money right away. But for anything that has to stand up to the elements, the superior lifetime value of GI fasteners makes them the smarter, more economical choice in the long run.

Picking the Right Bolt for the Job: MS vs. GI in the Real World

Knowing when to use a Mild Steel (MS) bolt versus a Galvanized Iron (GI) one really comes down to the environment. Get this choice right, and you're not just ensuring your project holds together—you're saving yourself headaches and money down the road. Let’s break down where each of these fasteners truly belongs.

When to Stick with Mild Steel (MS) Bolts

Think of MS bolts as your indoor specialists. They're strong and, most importantly, cost-effective, making them the workhorse for projects that will stay dry and protected. When you don't have to worry about rust, there's no reason to spend more.

You'll find MS bolts are the perfect fit for:

- Assembling Indoor Furniture: Putting together a desk, bookshelf, or bed frame? MS bolts have all the strength you need without the added cost of a protective coating.

- Internal Machine Guts: Inside the housing of machinery and equipment, components are shielded from the elements. MS fasteners are ideal for securing these internal frameworks.

- Garage and Workshop Projects: For that custom workbench or shelving system in your workshop, MS bolts are an excellent, budget-friendly choice, as long as the space stays relatively dry.

In these controlled settings, MS bolts give you the reliable performance you need without overspending.

Where Galvanized Iron (GI) Bolts Earn Their Keep

When your project steps outside, GI bolts are the only way to go. That zinc coating isn't just for show; it's a tough barrier against the moisture and humidity that would eat a plain steel bolt for breakfast.

Choosing a GI fastener is an investment in longevity. For any outdoor build, it’s the professional standard because you can’t afford for a connection to fail.

GI bolts are non-negotiable for demanding jobs like:

- Outdoor Construction: They are essential for putting up pergolas, carports, and steel building frames that will be battered by rain and sun.

- Roofing and Fencing: Attaching roofing panels or assembling a fence means constant exposure. GI fasteners are built to withstand those conditions year after year without corroding.

- Telecommunication Towers: These structures have to be rock-solid for decades. GI bolts deliver the corrosion resistance needed to ensure that level of long-term integrity.

- Farm Equipment: Agricultural machinery is constantly exposed to mud, moisture, and fertilizers. Galvanized fasteners are a must to keep the equipment from literally rusting apart.

For anything that lives outdoors or in a damp environment, the extra upfront cost of GI bolts is a small price to pay to avoid the much larger cost of rust-related failures later on.

How to Choose the Right Bolt for Your Needs

So, with all that information, how do you actually decide between MS and GI bolts? It really comes down to a few practical questions about your specific project. Let's walk through a simple framework to help you figure out which fastener is the right fit.

First, take a hard look at the environment. Where will these bolts be used? If they’ll face the elements—rain, high humidity, or salty coastal air—then Galvanized Iron is your go-to. Don’t even think about using anything else. For projects that are strictly indoors and stay dry, Mild Steel is a smart, budget-friendly choice that will do the job just fine.

Next, think about longevity and future access. Can you easily get to these fasteners later for maintenance or replacement, or are you sealing them behind a wall? For those hard-to-reach spots or critical structural joints where failure is not an option, the extra durability of GI gives you peace of mind and long-term reliability.

Final Recommendation: Think of the higher initial price of GI bolts as an investment. For any application exposed to moisture, that upfront cost buys you durability and safety, saving you from headaches down the road. But for protected, indoor projects where keeping costs low is the top priority, MS bolts are a perfectly reliable and economical solution.

Making the right choice is a crucial part of sourcing quality construction hardware in the UAE, where the climate can be unforgiving. By balancing the environmental exposure against your budget and long-term needs, you’re ensuring your project is built to last.

Frequently Asked Questions

Here are a few common questions that pop up when deciding between Mild Steel and Galvanized Iron fasteners.

Can I Just Paint MS Bolts for Outdoor Use?

You can, but it’s not a permanent solution. A good coat of paint on a Mild Steel bolt provides a temporary barrier, but it’s a fragile one. Scratches, chips, and general wear and tear will eventually break that seal.

Once the paint is compromised, moisture gets in, and rust is inevitable. For any application where you need genuine, long-lasting outdoor protection, GI bolts are always the safer bet.

Are GI Bolts Stronger Than MS Bolts?

Not really, at least not initially. The core strength of the bolt comes from the steel itself, and the galvanization process doesn't meaningfully change its tensile or shear strength.

The real difference isn't in raw power but in longevity and resistance to corrosion. A GI bolt will hold onto its original strength for much, much longer when exposed to the elements, while an MS bolt will weaken as it rusts.

How Do I Visually Tell Them Apart?

It's usually pretty easy to spot the difference. A Galvanized Iron bolt will have a somewhat dull, mottled grey finish. It might even feel slightly rough to the touch because of the protective zinc coating.

An untreated Mild Steel bolt, on the other hand, typically looks darker—often a dark grey or almost black—and might have a slight oily residue on it from the manufacturing process. The visual contrast is quite clear once you know what to look for.

For all your projects requiring durable and reliable fasteners, trust Yasu Trading Co. LLC to supply the highest quality building materials. Find the right bolts and nuts for any application by visiting us at https://yasutrading.com.