What Is Better UPVC or CPVC Pipes? Find Out Quickly

When you're standing in the aisle trying to decide between UPVC and CPVC pipes, the right answer really boils down to one simple question: what’s the job? If you're running cold water lines for irrigation or setting up drainage, UPVC is the go-to, cost-effective workhorse. But the moment heat gets involved, like for hot water supply, CPVC is the only safe and reliable choice.

UPVC vs. CPVC: Choosing the Right Pipe

Picking the right pipe material is one of those decisions that can make or break a plumbing system. It directly affects how long the system lasts, how safe it is, and what it costs you in the long run. Both Unplasticized Polyvinyl Chloride (UPVC) and Chlorinated Polyvinyl Chloride (CPVC) are fantastic thermoplastic materials, but they’re built for completely different worlds. Getting them mixed up isn't a small mistake—it can lead to leaks, system failure, and some seriously expensive repairs.

This guide isn't about quick answers; it's about understanding why one pipe works where the other fails. The key difference is baked right into their chemistry. CPVC gets an extra dose of chlorine during manufacturing, a step that fundamentally changes its molecular structure and gives it the ability to handle heat. This is precisely why it’s a must for hot water lines, where standard UPVC would quickly soften, warp, and ultimately fail.

Core Distinctions and Applications

Before we get into the nitty-gritty of pressure ratings and chemical resistance, let's establish the main roles these two materials play. Knowing this basic difference makes all the technical details fall into place.

UPVC (Unplasticized Polyvinyl Chloride): Think of UPVC as the industry standard for anything that stays cool. Its rigidity and affordability make it perfect for cold water distribution, sewer lines, and drainage systems. It’s a dependable material as long as you keep it away from heat.

CPVC (Chlorinated Polyvinyl Chloride): This is the engineered solution for heat. CPVC is the go-to for both hot and cold water plumbing in homes and commercial buildings. Its superior chemical resistance also gives it an edge in certain industrial applications.

The single most important thing to remember is this: they might look alike, but their reaction to heat is night and day. Choosing UPVC for a hot water line isn’t a smart way to save a few bucks; it’s a guaranteed failure just waiting to happen.

To get a clearer picture, let's lay out the core distinctions side-by-side. This table offers a quick snapshot of where each material shines, helping you make a quick assessment before we dive deeper into the technical specs.

UPVC vs CPVC Key Differences at a Glance

| Attribute | UPVC (Unplasticized Polyvinyl Chloride) | CPVC (Chlorinated Polyvinyl Chloride) |

|---|---|---|

| Primary Use | Cold water, drainage, irrigation, vent lines | Hot and cold potable water, industrial liquids |

| Temperature Resistance | Up to 140°F (60°C) | Up to 200°F (93°C) |

| Material Cost | Lower initial cost | Higher initial cost |

| Chemical Composition | Standard polyvinyl chloride polymer | PVC polymer with added chlorine atoms |

| Best For | Cost-sensitive cold water and drainage projects | All residential and commercial water supply lines |

This side-by-side comparison makes it clear that while both are part of the same PVC family, their capabilities are worlds apart. The choice isn't about which is "better" overall, but which is specifically engineered for the temperature and pressure demands of your project.

Diving Into the Material Science

To get to the heart of the UPVC vs. CPVC debate, you have to look past the surface. They might look similar, but at a molecular level, they are built for entirely different jobs. The distinction isn't just a minor tweak; it's a specific chemical upgrade that gives CPVC its unique edge.

UPVC, which stands for Unplasticized Polyvinyl Chloride, is essentially PVC in its most rigid form. It’s made without plasticizers—the additives that make plastics flexible. This rigidity is its superpower, making it perfect for applications where temperature isn't a concern, like cold water lines, drainage, and irrigation. To get a better feel for this workhorse material, it helps to understand its basic building blocks, like the standard UPVC pressure pipe components.

The All-Important Chlorination Process

So, what separates the two? It all comes down to a process called free radical chlorination. CPVC (Chlorinated Polyvinyl Chloride) starts out as regular PVC resin before it undergoes this extra step. Chlorine atoms are introduced, which then bond to the PVC's carbon backbone, replacing some of the existing hydrogen atoms.

This chemical shuffle is a game-changer. The larger chlorine atoms create more robust intermolecular forces, seriously beefing up the polymer's structural integrity. It's like taking a standard material and reinforcing it with high-strength steel. This is precisely why CPVC can handle the high temperatures and pressures that would make UPVC soften, buckle, and fail.

Here's the bottom line: CPVC isn't just another plastic; it's a chemically fortified version of PVC. That fortification directly translates to superior heat resistance, making it the clear choice for any hot water application.

How This Affects Physical Properties

Adding chlorine doesn't just boost heat tolerance. It also fine-tunes several other physical properties that dictate where and how each pipe can be used.

- Structural Integrity: While both are considered rigid plastics, CPVC is actually a bit more flexible than UPVC at ambient temperatures. Its true strength, however, is its ability to stay rigid when the heat is on.

- Chemical Resistance: The extra chlorine gives CPVC a leg up against a wider range of corrosive chemicals, acids, and alkalis. This is a huge plus in demanding industrial environments.

- Fire Safety: CPVC has a higher Limiting Oxygen Index (LOI), meaning it needs more oxygen in the air to catch fire and burn. This makes it a safer option where fire resistance is a priority.

This molecular-level engineering is why we're seeing huge market growth, especially in places with tough building codes. For instance, the UAE's CPVC pipe market is projected to skyrocket from USD 582 million in 2025 to USD 1.16 billion by 2031. This boom is driven by CPVC’s reliability for both hot and cold water plumbing, along with its excellent corrosion resistance.

This trend shows how the industry is moving toward materials designed for specific, high-stakes jobs. If you're sourcing materials in the region, checking out a guide to finding quality UPVC pipes in Dubai can help you see the full range of options available. At the end of the day, choosing between UPVC and CPVC comes down to understanding this fundamental material science.

Comparing Heat and Pressure Tolerance

When you're trying to decide between UPVC and CPVC pipes, the conversation really begins and ends with heat. This one factor is the single biggest difference between them and almost always dictates which material is right for the job. It's not just a small technical detail; it’s the core of what makes them fundamentally different.

UPVC pipes are the go-to for many applications because they're strong, rigid, and reliable... at normal temperatures. They're perfect for cold water lines, drain-waste-vent (DWV) systems, and irrigation. But they have a hard stop: their operational limit is a firm 60°C (140°F). Push past that, and the material starts to lose its structural integrity.

If you connect a hot water line from a boiler or water heater to a UPVC pipe, it will soften and deform. It's only a matter of time before the pipe sags, the joints are compromised, and you're dealing with a system failure. In the real world, that means significant water damage and a hefty repair bill.

CPVC: The Engineered Solution for Heat

This is exactly where CPVC shines. The extra chlorination in its molecular structure isn't just for show; it's what gives CPVC the muscle to handle continuous operating temperatures up to 93°C (200°F). This massive thermal resistance makes it the only real choice for hot water plumbing in both homes and commercial buildings.

Think of it like this: using a UPVC pipe for a hot water line is like trying to contain high-pressure steam with a standard garden hose. It just wasn't built for that kind of stress and is guaranteed to fail. CPVC, on the other hand, is manufactured specifically to handle the heat, ensuring your system remains safe and reliable for years.

A classic rookie mistake is thinking "if the fitting connects, it must be okay." A UPVC fitting might seem to hold on a hot water line for a little while, but it's a ticking time bomb. Constant exposure to high temperatures will inevitably degrade the material, leading to a plumbing emergency.

The Link Between Temperature and Pressure

It’s critical to remember that heat and pressure ratings aren’t separate stats; they are deeply connected. As the water temperature inside a pipe goes up, the maximum pressure it can safely handle goes down. This concept, known as pressure derating, is a cornerstone of proper plumbing system design.

Both UPVC and CPVC pipes have their pressure ratings stamped on them, but those numbers are based on performance at room temperature (around 23°C). At that baseline, they're both impressively strong. But as things heat up, their ability to hold that pressure starts to fade.

- For UPVC, this drop-off is sharp. As it gets closer to its 60°C limit, its pressure rating plummets. A pipe rated for 450 PSI at room temperature might only handle 100 PSI as it nears its max temp.

- For CPVC, while derating still occurs, its higher heat tolerance gives it a huge advantage. Even at 82°C (180°F), a CPVC pipe maintains enough of its pressure capacity—often around 100 PSI—to easily handle a residential hot water system.

To put this into perspective, let's look at a direct comparison of their operational limits.

Operational Limits UPVC vs CPVC

This table breaks down the key performance differences you need to consider when designing a plumbing system.

| Performance Metric | UPVC Pipes | CPVC Pipes |

|---|---|---|

| Maximum Operating Temperature | 60°C (140°F) | 93°C (200°F) |

| Typical Pressure Rating (at 23°C) | High (e.g., 450 PSI for Sch 40) | High (e.g., 480 PSI for Sch 40) |

| Pressure Rating at 60°C (140°F) | Significantly reduced (approx. 22% of original) | Moderately reduced (approx. 50% of original) |

| Pressure Rating at 82°C (180°F) | Not recommended for use | Still robust (approx. 25% of original) |

The numbers make it clear: the choice is dictated by simple physics. For any application involving water heated above room temperature, CPVC is the only safe, durable, and correct material for the job. That slightly higher upfront cost is a small price to pay to avoid the much greater expense and headache of a system failure down the road.

How Do They Hold Up Over Time? A Look at Long-Term Durability

When you're plumbing a building, you’re making a decision that needs to last for decades. So, what’s the better long-term bet, UPVC or CPVC? Both are incredibly durable materials, easily capable of lasting over 50 years if they’re installed correctly and used for what they were designed for. They won't corrode, rust, or suffer from scale buildup, which gives them a huge leg up on old-school metal pipes.

But that’s where the similarities end. When you start throwing environmental challenges at them—like intense sunlight or harsh chemicals—their true differences come to light. Understanding these distinctions is key to predicting how each will perform over its long service life, especially in demanding climates like the UAE.

Resilience Against UV Radiation

Sunlight is the enemy of many plastics, and this is one of the biggest differentiators between UPVC and CPVC. Standard UPVC is fantastic for indoor plumbing or buried lines, but it really struggles with direct, long-term exposure to the sun's ultraviolet (UV) rays. Over time, that constant UV exposure can make the material brittle, weakening its impact resistance and setting the stage for cracks and leaks.

If you absolutely must use UPVC outdoors for something like an irrigation line or external drain, you have to protect it. A coat of light-colored, water-based latex paint is non-negotiable; it acts as a shield against those damaging rays.

CPVC, on the other hand, is built differently. Its chemical composition gives it a natural, inherent resistance to UV degradation. While you might see some surface discoloration after years of intense sun, its structural integrity remains largely intact. This makes CPVC a far more reliable and low-maintenance choice for any application where the pipe will be exposed to the elements, like external hot water lines.

Key Takeaway: For any plumbing that will see direct sunlight, CPVC is the smarter, more durable choice right out of the box. If you're using UPVC outdoors, painting it for UV protection isn't just a suggestion—it's essential for ensuring it lasts.

CPVC’s Edge in Chemical Resistance

While both UPVC and CPVC handle typical household chemicals just fine, CPVC’s modified molecular structure gives it a clear advantage in more chemically aggressive environments. This is a crucial factor in commercial and industrial settings where the pipes are carrying a lot more than just water.

CPVC stands up much better to a wider range of acids, alkalis, salts, and aliphatic hydrocarbons. This superior resilience makes it the go-to material for:

- Industrial processing plants handling corrosive liquids.

- Commercial plumbing systems where powerful cleaning agents are part of the daily routine.

- Water treatment facilities that rely on a variety of chemical processes.

UPVC is perfectly suitable for standard residential water and waste lines. But for any job where the pipes will be in regular contact with harsh chemicals, CPVC offers a critical layer of protection against chemical corrosion that could otherwise compromise the entire system.

The reliability of these materials is why the market continues to grow. In the UAE alone, the PVC pipes market hit a value of USD 280 million in 2024 and is expected to climb to USD 384 million by 2033. This growth is a testament to the proven durability and cost-effectiveness of these pipes in critical infrastructure. You can dive deeper into the regional market data over at imarcgroup.com.

Impact Strength and Physical Wear

When it comes to pure physical toughness at normal room temperatures, UPVC is slightly more rigid and boasts a higher tensile strength. This makes it an excellent choice for applications like buried sewer lines, where it needs to resist the constant pressure of the soil above without bending or deforming.

CPVC, however, is a bit more flexible, which can be a real benefit. It’s slightly better at absorbing impacts without shattering, particularly in colder environments where UPVC can turn more brittle. Think about pipes running inside walls where they might get knocked around during future renovations or maintenance—CPVC's added ductility provides a nice buffer of security.

In the end, both materials offer phenomenal long-term durability. The secret is simply matching their unique strengths to the right job to ensure you get a reliable, leak-free system that will stand the test of time.

Analyzing the True Cost of Your Project

When you're standing in the aisle looking at UPVC and CPVC pipes, the price difference is the first thing that jumps out. UPVC is clearly the cheaper option, and for anyone trying to keep a project on budget, it's an easy choice to make. But when it comes to plumbing, the sticker price is just the beginning of the story.

To really understand the cost, you have to think about the total cost of ownership. The real financial hit isn’t what you pay for a meter of pipe; it’s what you might have to pay later to fix a bad decision. While installation for both is pretty similar—a simple solvent cement job—the long-term performance is where the costs really start to diverge.

Initial Material Costs

There's no getting around it: UPVC pipes are significantly cheaper upfront. This is their biggest advantage and why they’re the go-to material for cold water lines, drainage, and irrigation systems. In those scenarios, the lower cost is a smart, practical choice.

CPVC, on the other hand, costs more from the get-go. That extra expense comes from the additional chlorination step in its manufacturing—the very thing that gives it the muscle to handle heat and chemicals. This price difference is a critical factor, but you have to weigh it against what you're asking the pipe to do.

In the UAE, this cost-versus-performance balancing act is always in play. PVC pipes absolutely dominate the market, holding around 80.57% of the revenue share for plastic pipes and fittings in 2024, mostly because they are so affordable. Even though CPVC can be 20-30% more expensive, its incredible lifespan of over 50 years and ability to handle high temperatures make it non-negotiable for hot water systems. You can read more about the UAE pipe market dynamics over at Polaris Market Research.

The Hidden Costs of an Incorrect Choice

This is where a little foresight saves you a fortune. Choosing UPVC for a hot water line just to save a few dirhams upfront is a textbook example of a false economy. That pipe was never designed to handle anything above 60°C.

The most expensive pipe is the one you have to replace. Using UPVC in a hot water application guarantees failure, leading to leaks, extensive water damage to walls and floors, and the full cost of a complete system replacement. The final bill will be many times higher than the initial cost of using the correct CPVC pipe from the start.

This isn't a matter of "if" but "when." The long-term math has to include the price of repairs, fixing water-damaged property, and paying for the labor to re-pipe the entire system. To get a clear picture of your options, it's always a good idea to talk with experienced PVC pipe suppliers in Dubai who understand the local requirements and best practices.

A Framework for Cost-Effective Decision-Making

To make the right call financially, look at your project through this lens:

- Application Temperature: Is this system strictly for cold water? If the answer is yes, UPVC is your most cost-effective choice. If there's any hot water involved, the higher price of CPVC isn't just a good idea—it's a necessary investment.

- Likelihood of Failure: What happens if a pipe bursts? In a house, it's a huge, expensive mess. In an industrial plant handling chemicals, it could be a disaster for both safety and your bottom line.

- Total Lifespan Value: CPVC’s ruggedness in tough environments means it delivers value for decades without needing to be touched. That kind of longevity brings down the total cost of ownership, making that initial investment pay for itself many times over.

Ultimately, the right choice isn't about which pipe is cheaper, but which pipe is right. The higher price of CPVC isn't a luxury; it’s an essential investment in safety, durability, and long-term peace of mind for any job that involves heat.

Making the Final Decision for Your Application

After digging into the material science, durability, and cost of UPVC and CPVC, the question isn't really which one is better. It's about which one is right for the job at hand. Think of it like choosing the right tool from a toolbox; you wouldn't use a hammer to drive a screw. Picking the wrong pipe can lead to system failures and expensive headaches down the road, so let's translate the technical specs into practical, real-world decisions.

For any plumbing system that will only ever deal with cold water, UPVC is almost always the smart choice. It's rigid, fights off corrosion like a champ, and costs less. This makes it the go-to, economical option for residential cold water mains, drainage systems, and large-scale agricultural irrigation. As long as you keep it within its temperature limits, it will perform reliably for years.

When CPVC is Non-Negotiable

The moment heat gets involved, the conversation changes entirely. CPVC is the only safe and appropriate material for any line carrying hot water. Period. This covers every pipe connected to a water heater, boiler, or solar heating system in both homes and commercial buildings. Its ability to handle temperatures up to 93°C is what keeps your hot water system stable, secure, and leak-free for decades.

Beyond heat, CPVC's beefed-up chemical resistance makes it the default for many industrial settings. If you're running a system that transports corrosive chemicals, acids, or alkalis, CPVC offers a level of durability that UPVC simply can't touch. This makes it indispensable in chemical processing plants and facilities with aggressive water treatment needs.

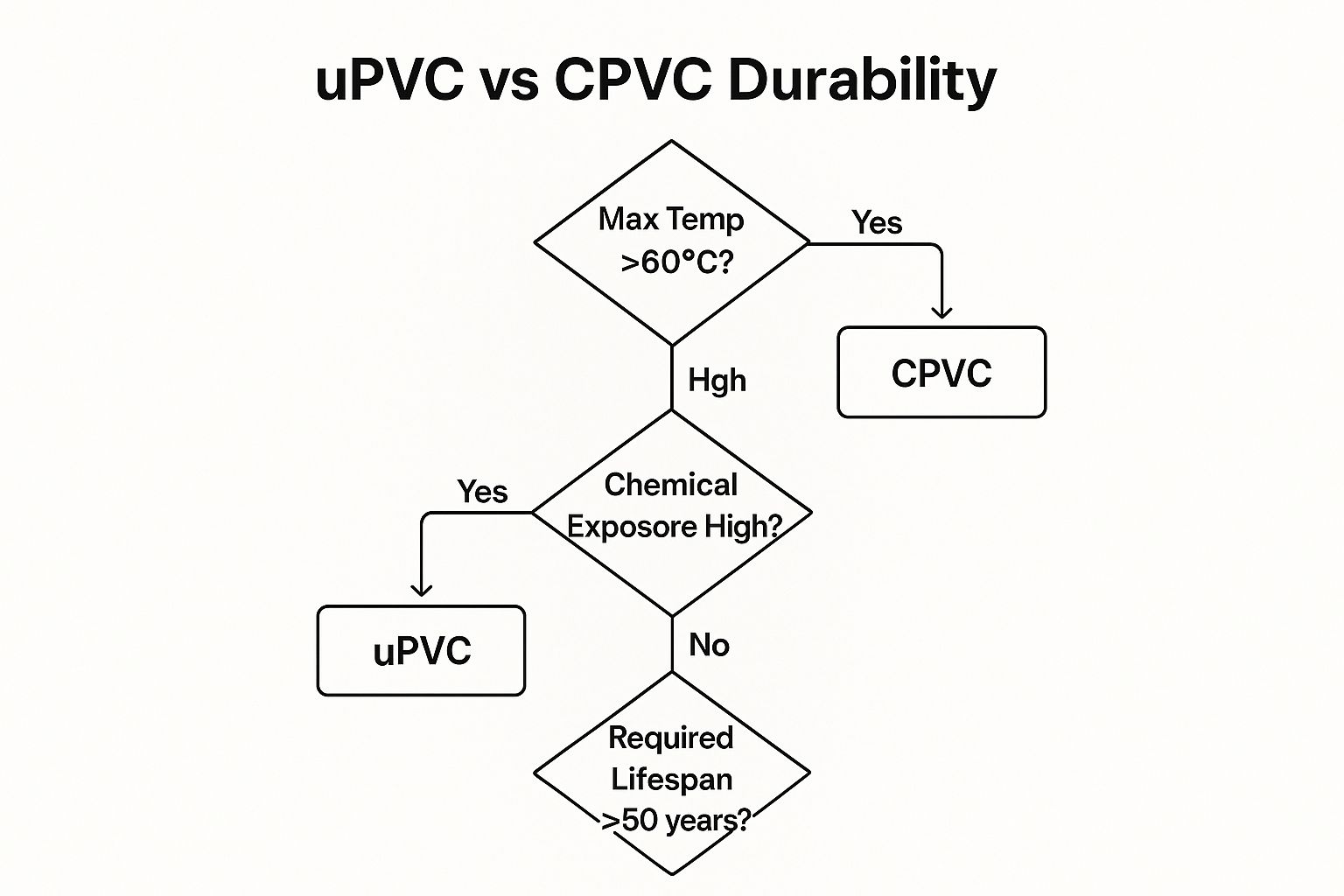

This decision tree gives you a quick visual guide for choosing between the two.

As you can see, if the answer is "yes" to high temperatures or harsh chemicals, the path leads directly to CPVC.

Situational Recommendations

To put it even more simply, here are a few common scenarios and the clear-cut choice for each.

- Residential Hot and Cold Water Lines: Just go with CPVC for the whole system. It creates a unified, reliable network and completely removes the risk of someone accidentally installing UPVC on a hot water line.

- Drainage and Sewer Systems: UPVC is perfectly suited for this. The water isn't under high pressure or temperature, making it a highly durable and cost-effective solution.

- Outdoor Irrigation: For sprinkler systems and garden lines, UPVC is the standard due to its lower cost. Just remember to protect it from direct sun with a coat of light-colored, latex-based paint to prevent UV damage over time.

- Industrial Chemical Transport: This is CPVC territory, no exceptions. Its superior resistance to a wide range of chemicals is absolutely critical for safety and the long-term integrity of the system.

The final decision really boils down to one simple rule: respect the material's limits. UPVC is a fantastic, affordable pipe for cold applications. CPVC is the tougher, engineered solution required for any system that has to handle heat or aggressive chemicals.

Of course, choosing the right pipe is only half the battle; joining them correctly is just as vital. For a deeper dive on that topic, check out our guide on the different types of pipe connectors in Dubai to make sure your project is a success from start to finish.

Frequently Asked Questions

When you're trying to decide between UPVC and CPVC pipes, a few common questions always pop up. Getting straight answers to these can save you a lot of time, money, and future headaches. Let's tackle some of the most practical queries we hear from the field.

Can You Mix UPVC and CPVC Pipes and Fittings?

While you can technically connect a CPVC pipe to a UPVC one, you absolutely need a special transition fitting to do it right. You can't just use standard solvent cement to weld them together; their different chemical makeups mean the bond won't hold, creating a serious weak spot.

Frankly, mixing them is almost always a bad idea. We often see people try to save a few bucks by using cheaper UPVC fittings on a CPVC hot water line. This is a recipe for disaster. That UPVC part will inevitably fail under the heat, which completely defeats the purpose of using CPVC in the first place. For the sake of your plumbing system's integrity, stick to one material throughout.

Is CPVC Safe for Drinking Water?

Yes, absolutely. Both UPVC and CPVC are certified as safe for potable (drinking) water systems. Neither material will rust or corrode, and their slick interior surfaces are great at resisting biofilm buildup, which is a big plus for maintaining water quality.

Key takeaway: Always look for pipes and fittings that are certified to international standards like ASTM or NSF for potable water. This certification is your guarantee that the materials won't leach any harmful chemicals into your water supply, keeping it safe and clean for years to come.

Which Pipe Lasts Longer?

When used correctly, both UPVC and CPVC pipes are incredibly durable, with an expected service life of 50 years or more. The secret to that longevity is making sure you use the right pipe for the right job.

- UPVC: It's built to last for decades in cold water lines, drainage systems, or when buried underground. However, if you expose it to high temperatures or direct sunlight without any UV protection, it can become brittle and its lifespan will drop dramatically.

- CPVC: This material was specifically engineered to withstand tougher conditions. Its natural resistance to high heat and UV radiation makes it the clear winner for hot water lines and any plumbing that will be exposed to the elements.

Do I Need Special Tools for CPVC?

Nope, and that's one of its biggest perks. You can cut and install both UPVC and CPVC with simple, affordable hand tools like a ratchet cutter or even a basic handsaw. The joining process uses a solvent cement welding technique that is much faster and safer than the heat fusion needed for PPR pipes or the soldering required for copper. This straightforward installation keeps labor costs down and helps you stay on schedule.

For all your construction projects in the UAE, trust Yasu Trading Co. LLC to supply high-quality UPVC, CPVC, and a full range of building materials designed for performance and durability. Get a quote today and see how our premium products and expert service can support your success. Visit us at https://yasutrading.com.