A Complete Guide to Industrial Valves: Gate, Ball, and Globe Valves Explained

When you're running a major construction or industrial project here in the UAE, getting the details right is what separates success from costly failure. A huge part of that is understanding your industrial valves. It's not as simple as just picking one that fits the pipe.

We're going to break down the three workhorses you'll see everywhere: gate valves for basic on/off control, ball valves for when you need a fast shut-off, and globe valves when you need to fine-tune the flow. Picking the right one is fundamental to keeping your project safe and running like a well-oiled machine.

What is the Role of Industrial Valves in Modern Construction?

Industrial valves are the critical control points, or traffic cops, managing the flow of liquids and gases through a complex network of pipes. Their fundamental job is to start, stop, or regulate flow, making them the unsung heroes of any fluid system. Without them, you couldn't control the water supply in a skyscraper, manage fuel lines on an industrial site, or run a commercial HVAC system efficiently.

These components are foundational across nearly every heavy industry. For instance, in sectors like mining and gas material handling solutions, valves are what keep critical, and often hazardous, materials under control. For us in the UAE's fast-paced construction scene, choosing the correct valve isn't just about function; it's about meeting tough local standards and ensuring long-term durability in a demanding climate.

What is the Purpose of an Industrial Valve?

At its core, an industrial valve is there to control what's moving through a pipe—be it water, gas, or even a slurry. It does this by opening, closing, or partially blocking the flow path. This control is absolutely critical for the safety and efficiency of countless industrial and commercial processes.

For any project manager or engineer in the region, my best advice is to find a solid building materials distributor you can trust. A seasoned supplier in Dubai won't just sell you a part; they'll provide genuine expertise. They'll make sure every valve you spec not only works for the application but also complies with strict UAE construction standards. That kind of foresight saves you from headaches and expensive system failures down the road.

A valve is more than just a piece of hardware; it's a long-term investment in your system's integrity. The right valve minimizes pressure drop, prevents leaks, and contributes to the overall energy efficiency of the building or plant.

To help clarify the options, let's take a quick look at the main three valve types you'll encounter.

What is the Difference Between Gate, Ball, and Globe Valves?

Gate valves are for on/off isolation, ball valves offer quick shut-off, and globe valves provide precise flow control. The primary difference lies in their internal design and intended function, from simple stoppage to fine-tuned regulation.

| Valve Type | Primary Function | Best Use Case | Key Characteristic |

|---|---|---|---|

| Gate Valve | On/Off Isolation | When a straight, uninterrupted flow is needed | Minimal pressure drop when fully open |

| Ball Valve | Quick Shut-off | Emergency shut-off, frequent operation | A 90-degree turn provides instant on/off |

| Globe Valve | Throttling/Regulation | For precise flow control and adjustment | Excellent at regulating pressure and flow rate |

This table gives you a snapshot, but there's a lot more to it. In this guide, we'll dive deeper into the mechanics, ideal applications, and pros and cons of gate, ball, and globe valves. By the end, you'll have the practical knowledge to make confident, informed decisions for your next project.

Why Are Gate Valves a Top Choice in the UAE?

Gate valves are a top choice in the UAE because their simple, robust design offers reliable on/off control with minimal pressure drop, which is ideal for main supply lines. This makes them the workhorses for large-scale plumbing and industrial fluid transport systems where uninterrupted flow is critical.

When your system needs a straight, unimpeded flow path, a gate valve is almost always the answer.

This is precisely why any reputable supplier in Dubai will point you towards them for main supply lines or isolation points. These are spots where the valve will sit either fully open or fully closed for months, or even years, at a time. The design ensures that when open, the "gate" retracts completely out of the flow path. The result? Almost zero pressure drop, a massive advantage in large-scale plumbing and fluid transport systems.

How Does a Gate Valve Actually Work?

A gate valve works by using a flat gate that slides down, perpendicular to the flow, to block it completely. Turning the handwheel rotates a threaded stem, which lifts the gate straight up and out of the fluid's path, similar to a small guillotine inside the pipe. This simple mechanism makes it exceptionally durable and reliable for on/off applications.

It’s this built-in toughness that makes them a staple component sourced from any experienced building materials distributor in the region.

What Are the Core Components of a Gate Valve?

The core components of a gate valve include the Body (main structure), Bonnet (the cover), Trim (internal working parts like the Stem, Gate, and Seat), and the Handwheel for manual operation. Each part plays a critical role in ensuring a smooth, leak-proof seal.

- Body: This is the main pressure-containing structure. It houses all the internal parts and connects directly to the pipeline.

- Bonnet: Think of this as the "lid" for the valve body. It’s bolted or screwed on, creating a leak-proof seal and supporting the stem assembly.

- Trim: This is a catch-all term for the internal working parts that touch the fluid—namely the stem, the gate (or disc), and the seat rings.

- Stem: The critical link between the handwheel and the gate. It converts the twisting force you apply to the handwheel into the up-and-down motion needed to open or close the valve.

- Gate: The business end of the valve. This is the component that moves into the flow to stop it. It can be a solid wedge, a flexible wedge, or even a parallel slide, depending on the specific application.

- Handwheel: The manual operator. It’s what you grab and turn to control the valve's position.

Gate valves stand out for their ability to provide an unobstructed flow path. When fully open, the gate retracts completely, meaning the pressure drop across the valve is exceptionally low. This is a crucial performance factor in systems where maintaining pressure is essential for efficiency.

Where Are Gate Valves Most Effective?

Gate valves are most effective in applications requiring infrequent operation where the valve is either fully open or fully closed, such as main water shut-offs or system isolation points. They are absolutely not meant for throttling or trying to regulate flow, as a partially open gate will quickly erode and lead to failure.

A classic real-world scenario is the main water shut-off for a new commercial tower in Dubai. This valve might only be touched during the initial system commissioning, for major maintenance work a decade later, or in an emergency. The rest of the time, it sits fully open, allowing maximum water flow without adding any significant friction or pressure loss to the building's systems.

Their dominance here isn't just anecdotal. In the UAE's booming industrial landscape, gate valves command the largest market share precisely because of their suitability for on-off control in high-pressure, high-flow pipelines. The UAE industrial valves market, valued at USD 1.44 billion in 2023, is projected to hit USD 2.01 billion by 2029, with gate valves being a primary driver of this growth. You can explore the full research on the UAE industrial valves market to dig deeper into the data.

When Should You Use a Ball Valve?

You should use a ball valve when you need fast, reliable on/off control, as a simple 90-degree turn of the handle provides instant shut-off. This speed makes them the go-to solution for emergency shut-offs, frequent operation, and applications where a clear visual indicator of the valve's status is needed.

Forget the slow, multi-turn action of a gate valve. The design is brilliantly simple. A sphere with a hole drilled through it sits inside the valve body. When the handle is aligned with the pipe, the hole lines up, and you get nearly unobstructed flow. Turn the handle a quarter-turn, and the solid part of the ball blocks the pipe, creating a solid, dependable seal.

That quarter-turn action is the ball valve's signature feature. It’s not just fast; it’s also foolproof. You can tell the valve’s status at a glance: handle parallel with the pipe means open, perpendicular means closed. In a busy plant or a complex mechanical room, that kind of clear visual cue is invaluable for preventing mistakes.

Where Do Ball Valves Shine?

Ball valves shine in any spot that needs frequent, fast, and reliable on/off control, making them perfect for industrial process lines and building HVAC systems. Their tough design and tight seal are ideal for applications where you need to quickly isolate a section for maintenance without shutting down the entire system.

Think about a building's HVAC chilled water system. You often need to isolate a single floor or zone for maintenance without shutting down cooling for the entire tower. Ball valves are the ideal choice here. A technician can walk up to an Air Handling Unit (AHU), give the valve a quick turn to shut off the water, do their work, and get the system back online with minimal fuss. Any experienced supplier in Dubai will tell you this is a classic application for them.

What is the Difference Between Full Port and Reduced Port Ball Valves?

A full port ball valve has a hole in the ball that is the same size as the pipe, offering no flow restriction. A reduced port ball valve has a smaller hole, which creates a slight restriction but makes the valve smaller, lighter, and more economical. The choice depends on whether maximum flow or cost-effectiveness is the priority for the application.

- Full Port (or Full Bore): In these valves, the hole in the ball is the same size as the inside of the pipe. This gives you a wide-open, straight-through path for the fluid, meaning there's practically zero pressure drop. If you need to maintain maximum flow, this is the one you want.

- Reduced Port (or Standard Bore): Here, the hole is a bit smaller than the pipe diameter, usually by one pipe size. This creates a slight restriction and a minor pressure drop. The trade-off? The valve is smaller, lighter, and costs less.

So, which one do you pick? It all comes down to the job. For a main water supply line where every bit of flow counts, go with full port. For less critical branch lines or drains, a reduced port valve is often a smart, economical choice that fully complies with UAE construction standards.

A key advantage of the ball valve is its longevity, especially when it's used a lot. Each time you turn it, the ball wipes against the seats. This self-cleaning action helps clear away any small particles that could otherwise build up and cause a leak down the line.

Why You Should Never Throttle with a Ball Valve

You should never throttle with a ball valve because leaving it partially open forces high-velocity fluid past the ball's edge, quickly eroding the soft seats that create the seal. This damage, known as "wire drawing," is permanent and will prevent the valve from ever providing a tight shut-off again, leading to leaks and premature failure.

If you need to regulate flow, a globe valve is the right tool. Using a ball valve for throttling is a common field mistake that always leads to premature failure and costly leaks. Remember this: ball valves are for stopping, not for steering.

When is a Globe Valve the Right Choice?

A globe valve is the right choice when you absolutely have to dial in the flow with precision. Their entire design is engineered for throttling, allowing for meticulous regulation of fluid flow and pressure, making them a cornerstone of complex systems like cooling lines, chemical dosing, and steam control.

This pinpoint accuracy comes from their unique internal mechanics. Inside the valve, the fluid can't just shoot straight through. It's forced to navigate a winding, S-shaped path, changing direction as it rises through an opening, or seat. A plug-shaped disc, controlled by the stem, moves up and down into this seat, allowing for incredibly fine adjustments to the flow.

This deliberately complex path is the secret to their throttling power, but it’s also a trade-off. By making the fluid work harder, globe valves naturally create more resistance. This means you’ll see a higher pressure drop across a globe valve compared to a fully open gate or ball valve. For any contractor or facility manager, weighing this need for control against the potential for pressure loss is a critical part of the job.

How Does a Globe Valve Control Flow?

A globe valve controls flow by forcing fluid through an S-shaped internal passageway and regulating it with a movable disc or plug. This design allows for extremely precise, fine adjustments to the flow rate as the disc is moved closer to or further from its seat, making it ideal for throttling applications.

You'll notice it takes multiple turns of the handwheel to move the disc from fully open to fully closed. This is by design. It's a world away from the quick quarter-turn of a ball valve and really highlights its purpose as a tool for fine-tuning, not just for emergency shut-offs.

Where is Precise Flow Control Everything?

Precise flow control is everything in systems where the amount of fluid is just as important as on/off capability, such as data centre cooling, chemical dosing, and steam systems. In these critical applications, globe valves are essential for regulating flow to maintain exact temperatures, concentrations, or pressures.

Think about these real-world scenarios:

- Data Centre Cooling: Keeping servers from frying requires an exact flow of chilled water. Globe valves are used to regulate that flow to each cooling unit, preventing catastrophic failure from too little flow and avoiding massive energy waste from too much.

- Chemical Dosing: In water treatment plants, you can't just dump chemicals in. A globe valve allows for the precise, measured injection of chemicals, ensuring public health standards are met without wasting expensive materials.

- Steam Systems: Whether it's for power generation or industrial heating, controlling steam is all about managing temperature and pressure. Globe valves are used to carefully regulate steam flow to turbines and heat exchangers.

The entire point of a globe valve is throttling. Its design intentionally creates a controlled obstruction, giving operators the power to dial in the exact flow rate an application needs. This makes it fundamentally different from gate and ball valves, which are designed for minimal obstruction when open.

You can't overstate how important this level of control is, especially in the UAE's most critical industries. Globe valves are essential in throttling applications, from chemical processing plants to power stations. The UAE's industrial valve market, valued at USD 1.4 billion and growing at a 6% CAGR through 2030, depends heavily on the precision of globe valves. You can discover more about the UAE industrial valve market trends to get a clearer picture of their role.

When you're talking to a supplier in Dubai, asking for a globe valve immediately signals that you're focused on performance and control, not just shut-off. A good building materials distributor will recognise this and understand that your choice is about optimising a system and meeting the stringent UAE construction standards for reliability. It’s this kind of careful selection that makes sure a critical system performs exactly as it was designed to.

How to Select the Right Industrial Valve for Your Project

Picking the right valve for a project in Dubai isn’t just about choosing between a gate, ball, or globe. Get this decision right, and you ensure system efficiency, safety, and a long service life. Get it wrong, and you’re looking at operational headaches, rising costs, and potential compliance issues. It's a critical decision where you have to balance the specific performance needs of your system against the tough local environment.

To make a smart choice, you need a solid framework. This means methodically evaluating what your system needs and matching those needs to what each valve can deliver. Let's walk through the essential criteria that should steer your selection, making sure every valve you spec is the right tool for the job.

What Is the First Step in Valve Selection?

The first step in valve selection is to define the system’s operating conditions, specifically pressure and temperature. Every valve has a maximum pressure and temperature rating it can safely handle, and exceeding these limits is a primary cause of catastrophic failure. Always choose valves with ratings that provide a comfortable safety margin above your system's maximum expected conditions.

Here in the UAE, temperature is a double-edged sword. You have to consider the temperature of the fluid inside the pipe, of course, but you also have to account for the extreme ambient heat. This external heat can seriously impact valve materials and the performance of actuators over time.

How Does Fluid Type Affect Valve Material Choice?

Fluid type directly dictates the required materials for the valve body and its internal parts to prevent corrosion and ensure a long service life. A valve suitable for water might quickly fail if used with saltwater or corrosive chemicals, making material compatibility a critical factor for preventing leaks and premature failure.

With so many coastal projects and desalination plants in the UAE, saltwater corrosion is a huge factor. This is why you'll often see materials like stainless steel (grades 316 and higher), bronze, and other specialised alloys specified. Partnering with a skilled building materials distributor ensures you’re getting materials tough enough for the region. This is especially true when sourcing a whole system of specialised components, including the right plumbing fittings in Dubai.

What Are the Main Valve Actuation Options?

The main valve actuation options are manual (handwheel or lever), electric (motor-driven for precision and automation), and pneumatic (air-powered for fast, powerful, and safe operation in hazardous areas). The choice depends on the required operating speed, power, accessibility, and need for automation within the system.

- Manual Actuation: The simplest method, using a handwheel or a lever. It's perfect for valves that don't need to be operated often and are easy for staff to get to.

- Electric Actuation: An electric actuator uses a motor to do the work. This gives you very precise control, is ideal for remote operation, and integrates smoothly into larger automated control systems (like a BMS).

- Pneumatic Actuation: These actuators rely on compressed air to provide fast, powerful force. They are incredibly reliable and are considered intrinsically safe for hazardous areas where an electric spark could be disastrous.

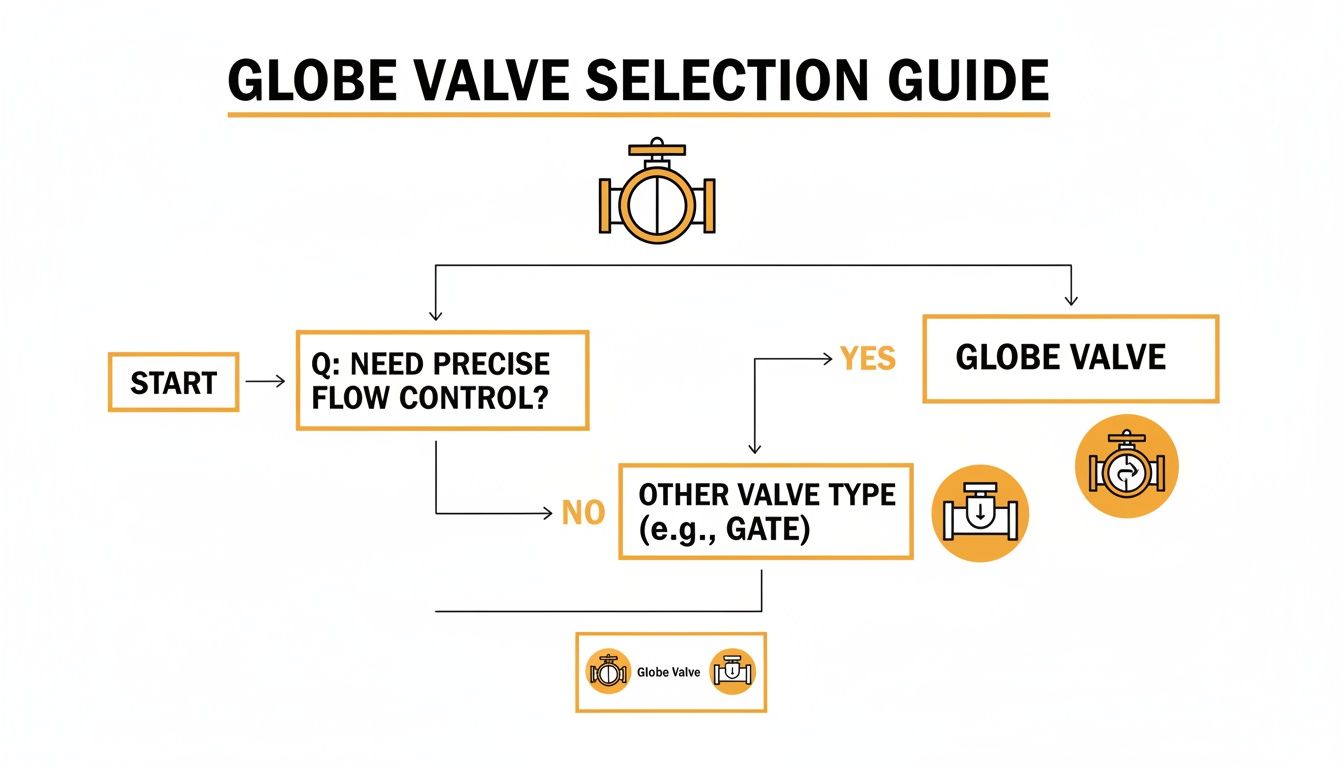

When it comes to globe valves, the selection process is almost always about the need for precision. This flowchart gives you a quick visual guide for deciding when a globe valve is the best fit.

The main takeaway here is simple: if you need to modulate or throttle the flow, not just turn it on or off, a globe valve is the superior engineering choice.

How Do You Choose Between a Gate, Ball, or Globe Valve?

To choose between them, consider the primary function: use a gate valve for simple on/off isolation with low pressure drop, a ball valve for fast quarter-turn shut-off, and a globe valve for precise throttling and flow regulation. This selection matrix simplifies the decision based on the most common criteria.

| Selection Criterion | Gate Valve | Ball Valve | Globe Valve |

|---|---|---|---|

| Primary Function | On/Off Isolation | On/Off Isolation | Throttling/Flow Regulation |

| Flow Control | Poor | Poor (can cause wear) | Excellent |

| Pressure Drop | Very Low | Very Low | High |

| Sealing (Shut-off) | Good | Excellent (Bubble-tight) | Good |

| Operating Speed | Slow (Multi-turn) | Fast (Quarter-turn) | Slow (Multi-turn) |

| Size & Weight | Large & Heavy | Compact & Light | Large & Heavy |

| Cost | Moderate | Low to Moderate | Moderate to High |

| Typical Use Cases | Main water lines, slurry | Process flow, HVAC zones | Cooling lines, pressure control |

This matrix isn't exhaustive, but it provides a solid starting point for narrowing down your options based on what your system needs most.

Case Study A Mixed-Use Tower in Dubai

Let's put this into a real-world context. Imagine you're speccing the valves for a new mixed-use tower.

A project of this scale requires a strategic mix of valve types, each chosen to meet specific system demands and comply fully with UAE construction standards. The wrong choice in one area can create a bottleneck or a maintenance nightmare for the entire facility.

In the main water supply lines coming into the building, you need full, unimpeded flow. Here, gate valves are the obvious choice. For isolating individual HVAC zones or apartments for maintenance, you need quick shut-off capability, making ball valves the perfect fit.

Then you have the fire suppression sprinkler system. Here, precise pressure regulation is a life-safety issue, so globe valves are essential. Understanding these different requirements is everything. For complex mechanical systems, a detailed approach to estimating for HVAC projects can be incredibly helpful in planning.

By working with a trusted supplier in Dubai, the project manager can source valves that are not only right for the application but are also certified to handle the climate and meet all local building codes. This is the kind of thoughtful selection that leads to a reliable, efficient, and safe building for years to come.

How Do You Properly Install and Maintain Industrial Valves?

Proper installation involves ensuring clean, aligned pipe flanges and tightening bolts evenly in a star pattern with a torque wrench. Proper maintenance includes quarterly visual checks, annual operational cycling, and periodic lubrication to prevent leaks, seizure, and premature failure.

Even a top-tier valve from a quality building materials distributor can fail if it's handled poorly during installation. A little care and attention to detail here will pay for itself many times over in system reliability and safety down the line.

What is the Most Common Valve Installation Mistake?

The most common valve installation mistake is improper flange alignment and uneven bolt tightening. When bolts are torqued unevenly, it puts immense stress on the valve body, which can easily lead to a leaky flange gasket or, in severe cases, a cracked valve body.

Getting the installation right is a craft. It’s all about creating a perfect seal and setting that valve up for a long, reliable service life.

Here’s a quick field checklist for a solid installation:

- Start Clean: Before you do anything, make sure the valve and pipe flanges are spotless. Any bit of grit or old gasket material can ruin the seal.

- Align it Right: The pipe flanges have to be perfectly parallel and lined up with the valve. Never, ever use the valve bolts to pull misaligned pipes together. That’s a recipe for disaster.

- Fresh Gasket, Every Time: Always use a new, correctly sized gasket. Reusing an old one is asking for a leak; it's already compressed and won't seal properly again.

- Follow the Pattern: Tighten the flange bolts in a star or crisscross sequence. This distributes the pressure evenly. And please, use a torque wrench to hit the manufacturer's specs – it’s a requirement under most UAE construction standards for a reason.

How Often Should You Inspect Industrial Valves?

As a general rule, industrial valves should receive a visual inspection quarterly and a hands-on operational check at least annually. However, valves in critical or high-cycle service require a much more frequent inspection schedule to ensure system safety and reliability.

Being proactive with maintenance saves a lot more time and money than dealing with a sudden failure. A simple, structured schedule helps you catch small issues before they blow up. A good supplier in Dubai won't just sell you a valve; they'll give you the technical know-how to maintain it properly.

A well-maintained valve is a reliable valve. Simple, routine checks for corrosion, leaks, and operational integrity are the single best way to lower long-term operational costs and ensure workplace safety.

To keep things simple, build your maintenance plan around these core tasks:

- Visual Checks: Walk the lines and look for obvious signs of trouble—external corrosion, any weeping from the stem packing, or physical damage.

- Cycle the Valve: Make a point to fully open and close the valve. This confirms it operates smoothly and prevents it from seizing up, which is a common problem for valves that sit in one position for months.

- Keep it Lubricated: The stem, threads, and any gear operators need periodic lubrication. Just follow the manufacturer's guidance on what to use and how often.

This commitment to upkeep is fundamental. To really dive deep, you can learn more about building a solid strategy in our complete guide on preventive maintenance in MEP systems. Follow these real-world practices, and you'll get the maximum performance and lifespan out of every valve you install.

Industrial Valve FAQs: Your Questions Answered

When it comes to selecting and procuring valves, a few questions always seem to come up on site or during the design phase. Getting straight answers to these common queries can save a lot of headaches down the line.

What's the Real Difference Between a Gate Valve and a Globe Valve?

The simplest way to think about it is function. A gate valve is your go-to for straightforward on/off control. It’s designed to be either fully open or fully closed, creating a clear, unobstructed path for the fluid with very little pressure drop. Think of it as a light switch for your pipeline – it's either on or off.

A globe valve, on the other hand, is built for throttling. Its internal design is all about giving you precise control over the flow rate. This precision comes with a trade-off, though: a significantly higher pressure drop compared to a gate valve, which you have to account for in your system design.

Can I Use a Ball Valve for Throttling?

In a word, no. I've seen this mistake made in the field, and it almost always ends badly. Ball valves are designed for quick, reliable shut-off, not for regulating flow.

When you leave a ball valve partially open, you create a high-velocity jet of fluid that blasts against the soft seats and the ball itself. This constant erosion will chew up the seals in no time, leading to leaks and a valve that fails much sooner than it should.

Throttling with a ball valve is a common field error that significantly shortens the valve's service life. Always use a globe valve when you need to regulate flow, not just stop it.

Which Valve Material Works Best for Seawater in the UAE?

This is a critical question for any coastal project in the UAE, where the high salinity and temperature create a brutally corrosive environment. You need materials that can stand up to the challenge.

Your best bets are typically:

- Bronze

- Duplex Stainless Steel

- Monel alloys

These materials have a proven track record for excellent corrosion resistance in marine applications. However, don't just pick one from a list. It's absolutely vital to talk to your supplier in Dubai. They can confirm that the material you've chosen fully complies with UAE construction standards for marine environments and provide the necessary certifications. A good building materials distributor will be your best guide here.

For all your project needs, from industrial valves to a full range of construction supplies that meet the highest local standards, trust Yasu Trading Co. LLC. Find the right components to ensure your project's success and longevity. Learn more at https://yasutrading.com.