A Contractor's Guide to Fosroc Concrete Repair in Dubai

When you're dealing with concrete repair in the UAE, you know that the climate is your biggest enemy. It’s not just about patching a crack; it's about guaranteeing the long-term integrity of the structure. This is where Fosroc’s concrete repair solutions, especially their Renderoc series, really prove their worth. These aren't just standard mortars; they are specifically engineered to stand up to the extreme heat and salinity we face daily.

Why Should You Choose Fosroc for Concrete Repair in the UAE?

Choosing the right repair material in the Emirates is a critical decision because getting it wrong can lead to serious threats to structural safety and longevity, not just cosmetic failures. Our environment is relentless—summer temperatures pushing past 45°C, oppressive humidity, and salt-laden air from the coast all work together to speed up spalling, cracking, and rebar corrosion.

This is exactly the battleground Fosroc systems were designed for. Unlike off-the-shelf mortars that can fail under these conditions, products in the Renderoc range are built to perform here. They deliver exceptional bond strength, have low permeability to keep chlorides out, and maintain dimensional stability to prevent the shrinkage cracks that are all too common when curing in our intense heat.

How is Fosroc Engineered for Regional Demands?

Fosroc products are specifically engineered for regional demands through a deep understanding of local challenges, backed by proven performance and a significant regional presence. This ensures their products are developed and tested to align perfectly with UAE construction standards.

- Climate Compatibility: These materials are formulated to be mixed, applied, and cured properly, even when the ambient temperature is soaring.

- Chloride Resistance: Their dense, impermeable finish is a lifesaver for protecting steel reinforcement, especially in coastal structures like Dubai's high-rises or Abu Dhabi's bridges.

- Structural Integrity: Whether you're doing a minor cosmetic patch-up or a major structural reinstatement, there’s a Renderoc product designed specifically for the load-bearing capacity you need.

This commitment to addressing our region's specific needs is precisely why project managers specify Fosroc. When you use a product that already meets or exceeds Dubai Municipality requirements, you avoid costly delays and compliance headaches down the line.

To help you navigate the choices, here's a quick reference table matching common concrete problems we see in the UAE with the most suitable Fosroc product.

Which Fosroc Product is Best for Common UAE Concrete Issues?

This product selector table helps identify the ideal Fosroc solution for typical concrete problems encountered in the region, from surface imperfections to structural damage.

| Common Problem | Recommended Fosroc Product | Primary Use Case |

|---|---|---|

| General-purpose, non-structural patch repairs | Renderoc FC | Filling blowholes, repairing surface imperfections, and providing a fair-faced finish. |

| Structural repairs in vertical or overhead areas | Renderoc HB40 | High-build repairs for spalled concrete on columns, beams, and soffits. |

| Large-volume structural repairs | Renderoc LA | Free-flowing micro-concrete for reinstating large sections, particularly in formwork. |

| Fast-setting repairs for trafficking | Renderoc S | Rapid-setting mortar for urgent repairs to floors, roads, and pavements. |

| Protecting steel reinforcement from corrosion | Nitoprime Zincrich | An anti-corrosion primer applied to exposed rebar before the repair mortar. |

This table is a great starting point, but always consult the technical data sheet to ensure the product is a perfect fit for your project's specific demands.

Why is a Reliable Supplier Important?

A reliable supplier is crucial because having the best materials means nothing if you can't get them to your site when you need them, potentially causing costly project delays. This is where a knowledgeable and efficient partner becomes indispensable. Yasu Trading Co. LLC has built its reputation as the premier supplier in Dubai for Fosroc products. With more than two decades in the business, they are far more than just a building materials distributor—they are a vital link in your project's supply chain.

For contractors in the UAE, procurement is about more than just price. It’s about getting the correct, municipality-approved materials to the site on time, every time. A reliable supplier like Yasu Trading eliminates logistical headaches and provides the technical support needed to ensure the products are used correctly.

The construction chemicals market in the UAE is booming, expected to climb past USD 1.81 billion by the end of this decade, with major infrastructure projects driving much of that growth. Fosroc is at the forefront of this expansion, and having a dependable supplier ensures you have uninterrupted access to these essential materials.

It's also worth noting Fosroc's broader reputation among leading industrial coating suppliers, as their expertise extends well beyond repair mortars into a full suite of protective systems. Working with a distributor like Yasu Trading gives you access to this entire portfolio, providing comprehensive solutions for any construction challenge.

How Do You Select the Right Fosroc Repair Mortar?

Choosing the right Fosroc concrete repair mortar involves assessing the repair's structural requirements and environmental conditions to ensure longevity and integrity, especially in the demanding UAE climate. The decision really boils down to two main families of products: the trusty cement-based mortars and the heavy-duty epoxy ones.

For the vast majority of jobs you'll encounter, a cementitious mortar from Fosroc’s Renderoc series is your best bet. Think of these as the reliable workhorses of concrete repair. They're polymer-modified, which means they're designed to act and feel just like the original concrete. This is absolutely critical for handling the thermal stresses from our intense daily temperature swings, preventing cracks and delamination.

On the other hand, you have the epoxy-based mortars, like the Nitomortar range. These are specialist products. Their resin base delivers incredible compressive strength and a near-impenetrable barrier against chemicals, making them essential for harsh industrial settings.

What is the Best Mortar for Structural Repairs?

The best mortar for structural repairs is a high-strength, shrinkage-compensated cementitious product, as it needs to handle significant loads and integrate seamlessly with the existing concrete.

Imagine you're repairing a spalling column on a beachfront hotel in Jumeirah. The culprit is almost certainly chloride from the salty air, which has corroded the rebar and blown out the concrete cover. This is a perfect scenario for Fosroc Renderoc HB40. It’s designed for high-build vertical work, so you can apply it in thick layers without it slumping. More importantly, its formulation is built to resist chlorides and carbonation, tackling the root cause of the failure head-on.

When Should You Use an Epoxy Repair Mortar?

You should use an epoxy repair mortar when the repair environment is too aggressive for cement, demanding extreme chemical resistance and mechanical strength. If these are the top priorities, nothing else will do.

Picture a busy warehouse floor in Sharjah, battered by forklift traffic and frequent chemical spills. A standard cement patch would be eaten away or crushed in no time. This is where a product like Fosroc Nitomortar S shines. It cures into an incredibly tough, non-porous patch that shrugs off abrasion, heavy impacts, and a long list of industrial chemicals, keeping the floor safe and serviceable.

Key takeaway: Match the mortar to the challenge. For most structural and general repairs that need to meet UAE construction standards, cementitious mortars are your go-to solution. For specialised industrial zones where resilience is paramount, epoxy is the only way to go.

How Can a Supplier Help You Meet Local Standards?

A reliable building materials distributor helps you meet local standards, like those from Dubai Municipality, by ensuring the products you receive are fully approved and fit for purpose. This is a huge advantage, as making sure your product meets local regulations is non-negotiable.

A knowledgeable supplier in Dubai like Yasu Trading Co. LLC does more than just move boxes. They ensure the products you get are fully approved and fit for purpose, giving you peace of mind.

The market backs this up. Cementitious repair mortars are expected to hold a massive 54.7% market share in the Middle East and Africa by 2025. Why? Because they're affordable, easy to work with, and perfect for the kind of hand-trowel applications we see every day on bridges, buildings, and marine structures across the Emirates.

By keeping a full range of Fosroc products in stock—from heavy-duty structural grades to finer mortars for cosmetic fixes—Yasu Trading helps ensure you can get a reliable result, even in the most corrosive coastal environments. For a deeper dive, you can find more insights on the concrete repair mortars market from industry research. Sourcing your materials smartly is a cornerstone of any successful project.

How Do You Apply Fosroc Products Correctly?

A durable, long-lasting concrete repair is about more than just using a quality product; it's about craftsmanship and paying close attention to every single step from preparation to curing. In the demanding climate of the UAE, cutting corners is simply not an option, as each phase guarantees the repair will stand the test of time.

This isn't just about following the datasheet. It's about understanding why each step matters. Let's walk through the process, based on years of fieldwork.

How Should You Prepare the Concrete Surface?

Proper surface preparation is the foundation of a good repair, as failures are almost always traced back to a shortcut taken at the beginning. The goal is to create a clean, solid base for the new mortar to bond to.

Start by saw-cutting the perimeter of the repair area. You want a clean, square edge at least 10 mm deep. This prevents "feather-edging," which is a weak point waiting to fail. Once you have your boundary, it's time to remove all the bad concrete inside that area using light-duty breakers or, even better, high-pressure water jetting.

You need to get down to a sound, stable substrate. An old but effective trick is the "hammer test." Tap the surface with a hammer—a sharp, ringing sound tells you the concrete is solid. If you hear a dull thud, you've got more work to do.

A Word of Caution: Resist the urge to use heavy-duty breakers. They cause micro-fractures in the surrounding concrete, which compromises the bond of your new repair. Precision and control are your best friends here.

How Do You Clean and Protect Steel Reinforcement?

Once loose concrete is removed, any exposed rebar showing signs of corrosion must be dealt with properly by cleaning it back to bright steel and applying a protective primer. Leaving rust behind is like leaving a cancer in the structure; it will continue to expand and eventually blow out your new patch from the inside.

Your target is to clean all the rebar back to bright steel. Get rid of every trace of rust, scale, or contamination. Grit blasting or needle scaling works best to achieve a surface that meets local UAE construction standards.

As soon as the steel is clean, it needs protection. Don't wait. Fosroc Nitoprime Zincrich is the go-to for a reason. This isn't just a paint; it’s a zinc-rich epoxy that creates an active anti-corrosion barrier. In coastal areas like Dubai where chloride attack is relentless, this primer essentially sacrifices itself to protect the steel. Make sure you get a thorough, complete coat on all exposed rebar surfaces.

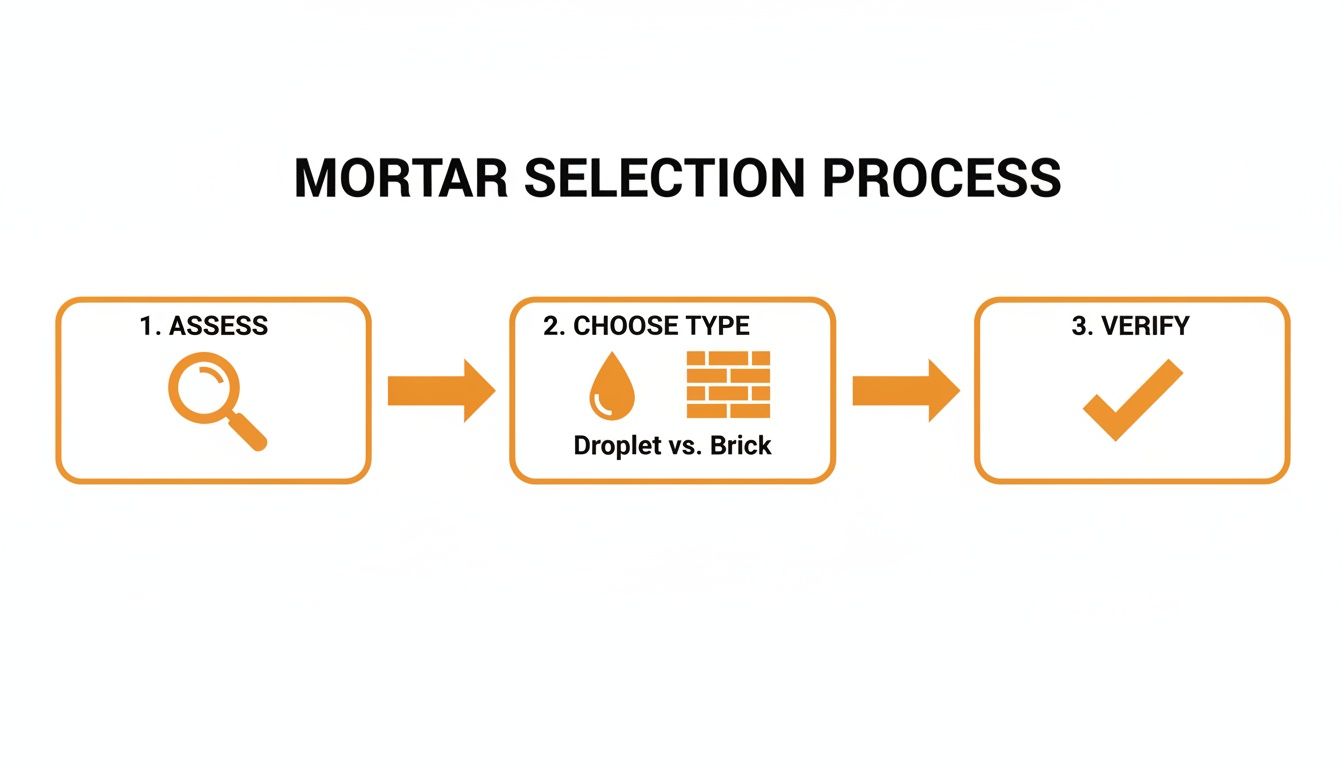

This flowchart breaks down how to think about your repair before you even start mixing.

Following this logic ensures you’ve not only prepped the area correctly but have also selected a mortar that can handle the job's specific demands.

Why is Substrate Priming Necessary?

Substrate priming is a critical step because it seals the porous concrete, preventing it from absorbing water too quickly from the fresh mortar, and acts as a powerful adhesive. This creates a tenacious bond between the old and new material.

Before priming, you need to thoroughly soak the concrete with clean water. You’re aiming for a Saturated Surface Dry (SSD) condition—the concrete pores are full of water, but there's no standing water on the surface.

For most Renderoc jobs, a simple cementitious slurry primer is perfect (you can often make this by mixing some of the Renderoc powder with a bonding agent like Nitobond SBR). Work this slurry firmly into the damp surface with a stiff brush. The key is to apply the repair mortar while this primer is still wet and tacky to get that monolithic bond.

What are the Best Practices for Mixing Renderoc?

The best practices for mixing Renderoc involve precise water measurement, using a slow-speed drill, adding powder to water, and using chilled water in hot weather. The water-to-powder ratio is non-negotiable; too much water weakens the mix, while too little makes it unworkable.

Here are a few field-tested tips:

- Measure your water. Always use a calibrated jug. Never eyeball it.

- Use the right tool. A slow-speed drill (400-500 rpm) with a proper mixing paddle is essential. It folds the material without whipping in air, which can create weak spots.

- Powder to water. Add the Renderoc powder to the pre-measured water, not the other way around. You’ll get a much smoother, lump-free mix.

- Beat the heat. On hot days, use chilled water. This gives you a bit more working time and helps manage the heat from the chemical reaction, reducing the risk of thermal cracking.

Mix for a solid 3-5 minutes until it's perfectly uniform. I like to let it sit for a minute to let the polymers wake up, then give it one last quick spin before application.

How Should You Apply and Finish the Mortar?

Mortar application depends on the location; for vertical repairs, use a trowel with firm pressure, while for bulk-fill repairs, use a flowable product like Renderoc LA poured into formwork. How you apply the mortar depends on where you're working. For vertical and overhead repairs with a product like Renderoc HB40, you need to apply it by trowel with some real pressure. Build it up in layers, forcing the material into the primed substrate to ensure there are no air pockets.

When it comes to finishing, a steel trowel will give you a nice, dense surface. Just be careful not to overwork it—that can draw water and fine particles to the surface, creating a weak layer.

For facility managers and owner associations, a properly executed Fosroc repair isn't just a patch; it's an investment that can extend the life of a concrete structure by 20-30 years. We’ve seen this proven on major maintenance projects across Palm Jumeirah. Working with a premier supplier in Dubai like Yasu Trading is a big part of that success, ensuring contractors get genuine products and sound advice. This is especially vital for MEP specialists who are constantly battling the severe chloride ingress in coastal environments. You can learn more about how top players are shaping the concrete restoration market and the importance of these systems.

Why is Curing so Important in Dubai's Climate?

Curing is crucial in Dubai's climate because the intense heat, low humidity, and wind can rapidly dry out fresh repair mortar, stopping the cement hydration process. This results in a weak surface, poor durability, and significant shrinkage cracks.

If that happens, the cement stops hydrating. The result? A weak surface, poor durability, and a map of shrinkage cracks.

As soon as you’ve finished trowelling, get a high-quality curing compound like Fosroc Concure on the surface. It forms a thin film that locks the moisture in, allowing the mortar to achieve its full design strength. In really extreme conditions, I’d even recommend covering the repair with wet hessian and polythene sheeting for the first 24-48 hours. It might seem like overkill, but it’s cheap insurance for a long-lasting repair.

How Can You Avoid Common Pitfalls in Concrete Repair?

Using a top-tier product like Fosroc gets you halfway to a successful repair, but in the demanding UAE climate, the real test is in the application. Even the best materials on the market will fail if you trip over common on-site mistakes. Getting it right the first time is non-negotiable—it saves you from expensive rework, wasted materials, and frustrating project delays.

Let's walk through the most frequent issues we see on Fosroc concrete repair jobs and how to sidestep them. Knowing what can go wrong is the first step to making sure everything goes right.

What is the Number One Cause of Repair Failure?

The number one cause of repair failure is poor surface preparation because if the substrate is weak or contaminated, the new mortar cannot form a strong, monolithic bond. This inevitably leads to delamination and spalling down the road.

You simply can't put good material on a bad foundation. This means getting aggressive and removing every last bit of unsound, spalled, or contaminated concrete. Any exposed rebar has to be cleaned back to bright steel, and the concrete surface itself must be brought to the perfect Saturated Surface Dry (SSD) condition before you even think about applying the mortar.

A repair is only as good as the surface it’s bonded to. Rushing the prep work is the most expensive shortcut you can take, as it all but guarantees the Fosroc concrete repair will fail prematurely.

What Happens if You Get the Water Ratio Wrong?

Getting the water ratio wrong is a critical error that directly impacts the final strength and durability of the repair mortar, as too much water increases porosity and shrinkage. It can be tempting to add a little extra water to make the mix feel more workable, especially in the heat, but this is a massive mistake.

The temptation is real on a hot UAE day, but fighting it is crucial to the integrity of the product's engineering. Stick to the technical data sheet (TDS) like glue.

- Measure, don't guess: Always use a proper measuring jug. Precision is everything.

- Chill the water: When the mercury climbs above 35°C, using chilled mixing water is a pro move. It buys you more working time and helps manage the heat from the chemical reaction.

- Powder to water: Always add the powder to the water, not the other way around. This helps create a smooth, consistent mix and stops clumps from forming at the bottom.

Why Do Cracks Appear After Finishing a Repair?

Cracks that appear after finishing a repair are typically plastic shrinkage cracks caused by improper curing, where the mortar's surface loses moisture too quickly. This is a constant risk with the high temperatures, low humidity, and wind we deal with on Dubai construction sites.

Proper curing isn't optional; it's a vital part of the process. The moment the finishing work is done, you have to protect that surface from drying out. This gives the cement the time it needs to hydrate properly and build up to its designed strength.

To head off cracking:

- Use a Curing Compound: As soon as you've finished trowelling, spray the surface with a high-quality curing agent like Fosroc Concure. It creates a film that locks in moisture.

- Add Physical Barriers: In really tough conditions, don't rely on the compound alone. Cover the repair with wet hessian cloth and then a layer of polythene sheeting for the first 24-48 hours.

This two-pronged approach is essential for meeting UAE construction standards and achieving that perfect, crack-free finish.

Who Should You Talk to Before Starting a Repair?

Before you start, you should always talk to your supplier if you are in doubt about any step of the process, as every site has its own unique quirks and challenges. Never hesitate to get an expert opinion. The TDS is your bible, but a good building materials distributor is more than just a place to buy products; they're your technical support.

As a trusted supplier in Dubai, Yasu Trading offers direct access to specialists who know the entire Fosroc range inside and out. A quick call to clarify mixing ratios, application techniques, or which product is best for your specific situation can prevent a world of hurt later on.

How Do You Ensure Quality and Safety on Your Repair Project?

When it comes to a Fosroc concrete repair, the job isn’t just about getting a strong, durable finish. It's about getting it done right and getting it done safely. In the demanding construction environment here in the UAE, the quality of your work and the well-being of your crew are two sides of the same coin.

For any site supervisor or project manager, this means a constant focus on both fronts. Quality assurance keeps the repair on spec and compliant with tough UAE construction standards, while a solid safety plan protects your team. Nail both, and you deliver a project that stands the test of time, completed without a single incident.

How Can You Put Quality Assurance into Practice?

You can put quality assurance (QA) into practice by using a systematic on-site playbook, or checklist, that translates project specifications and the Fosroc technical data sheet (TDS) into simple, verifiable checks. This isn't just paperwork; it’s your best tool for catching small issues before they snowball into costly rework.

Your QA process needs to cover the entire job, from the moment the pallets of Renderoc arrive until the final curing checks are signed off. Is the substrate prepared correctly? Is the mixing ratio exact? Is the application technique what the manufacturer specified? For more on this, looking at a detailed building inspection checklist can offer a great framework for developing your own internal procedures.

To make this truly practical, a simple table is often the most effective tool for site engineers to use day-to-day.

What Should Be on an On-Site Quality Assurance Checklist?

An on-site quality assurance checklist should include verification methods and acceptance criteria for material verification, surface preparation, mixing, application, and curing. Here’s a practical checklist that site supervisors can use to ensure every stage of the Fosroc repair process meets the required quality standards.

| Check Point | Verification Method | Acceptance Criteria |

|---|---|---|

| Material Verification | Check product bags/tins against project specs and TDS. Confirm expiry dates. | Correct Fosroc product is on-site and within its shelf life. No damaged packaging. |

| Surface Preparation | Visual and physical inspection of the substrate. | Concrete is free of dust, oil, and laitance. Exposed rebar is clean. Surface is pre-soaked to a Saturated Surface Dry (SSD) condition. |

| Mixing | Observe the mixing process. Time the mixing and check water addition against the TDS. | A full bag is mixed at once using a calibrated measuring jug. The mix is smooth, lump-free, and consistent. |

| Application | Watch the application technique. Measure the thickness of applied layers. | Mortar is firmly compacted into the repair area. Applied thickness is within the min/max range specified in the TDS. |

| Curing | Inspect the curing method being used (e.g., Nitobond AR, polythene sheeting). | Curing compound is applied evenly, or the repair is kept continuously damp for the specified duration (typically 3 days). |

This checklist acts as a live record, proving that every critical step was followed correctly. It’s an invaluable document for client handovers and demonstrating compliance.

How Can You Keep Your Team Safe During Fosroc Applications?

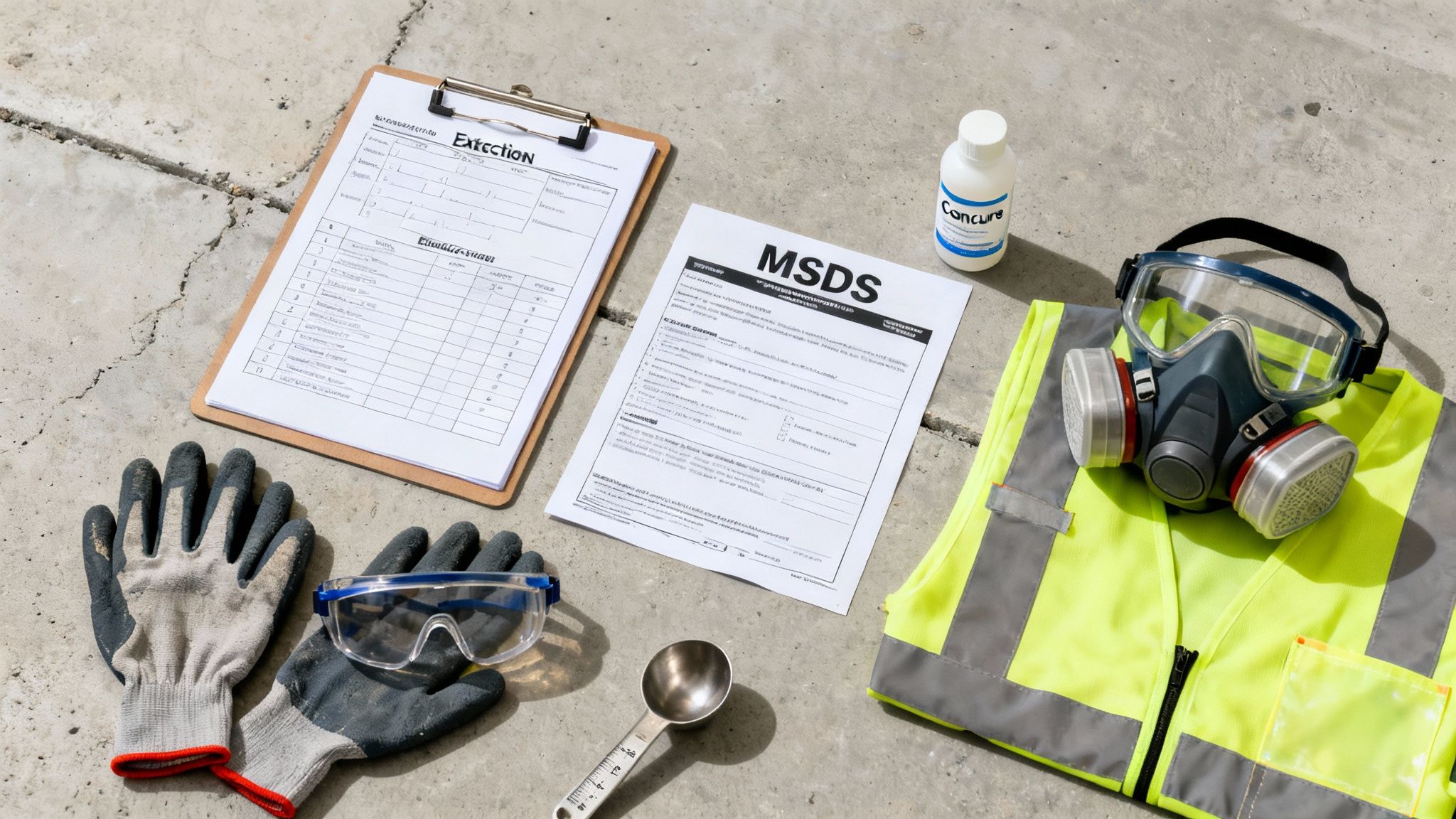

To keep your team safe, a clear, well-communicated safety plan is essential, covering personal protective equipment (PPE), environmental controls, and having Material Safety Data Sheets (MSDS) readily available. There’s no room for compromise on site safety. It’s all about a proactive mindset to manage the risks that come with handling high-performance construction chemicals.

First things first: PPE is non-negotiable. Every person involved in the repair needs to be properly kitted out before they even think about opening a bag.

- Eye Protection: Safety glasses are a must to shield against splashes from the wet mix or airborne dust during breakout work.

- Respiratory Protection: When cutting, grinding, or mixing, an FFP2 or FFP3 dust mask is critical to prevent the inhalation of fine cement and silica particles.

- Hand Protection: Always wear alkali-resistant gloves. Wet cementitious products are highly alkaline and can cause serious skin irritation or chemical burns.

- Protective Clothing: Long-sleeved overalls provide a necessary barrier, protecting skin from accidental contact with the repair materials.

Beyond what your team wears, the environment itself needs to be managed. Ensure there’s good ventilation, particularly if you're working in basements or confined spaces, to help disperse dust and any fumes.

Finally, every reputable building materials distributor provides a Material Safety Data Sheet (MSDS) for each product. As a leading supplier in Dubai, we ensure you have these from day one. The MSDS contains critical information on safe handling, storage, and what to do in an emergency. Make sure it's kept on-site where everyone can access it.

Where Can You Source Fosroc Products in Dubai?

Getting a Fosroc concrete repair job done right comes down to two things: your team's skill and the quality of the materials in their hands. When you're up against a tight deadline, the last thing you need are delays because your supplier can't deliver. That’s why choosing where you buy your materials is just as important as the application itself.

For any contractor in the UAE, this means finding a building materials distributor who does more than just sell boxes. You need a partner who understands the urgency, has the stock ready to go, and has the logistics to get it to your site on time, every time.

Who is the Go-To Fosroc Supplier in Dubai?

The go-to Fosroc supplier in Dubai is Yasu Trading Co. LLC, which has over 20 years of experience and a solid reputation as the trusted source for contractors needing quality and reliability. They’ve been in the game for over 20 years, building a solid reputation as the trusted source for contractors who can't afford to compromise on quality or deadlines, especially when meeting strict UAE construction standards.

Working with Yasu Trading isn't just about buying a product; it’s about securing your project's supply chain. Here’s what that looks like in practice:

- Massive In-Stock Inventory: They keep a huge range of Fosroc products on hand, from the full Renderoc mortar series to Nitoprime primers. This means no waiting for shipments to arrive – they have what you need, when you need it.

- Fast, Direct-to-Site Delivery: Their logistics team is built for speed. They can get materials to your site in Dubai, Abu Dhabi, or Sharjah the same day or the next day, which is a lifesaver for keeping your project on track.

- Fair Wholesale Pricing: As an authorised Fosroc dealer, they offer competitive pricing that helps you manage your budget without cutting corners on the quality of your materials.

When you can get everything from one place, you cut out the headaches of dealing with multiple suppliers. Yasu Trading’s logistics desk streamlines the whole process, saving you time from the moment you ask for a quote to the minute the materials land on your site.

Their central location in Naif, Deira, is perfect for quick dispatch across the Emirates, making them a true one-stop-shop for MEP, civil, and finishing works. For more tips on sourcing materials, take a look at our guide to finding the best building materials in Dubai.

If you need a quote or some technical advice for your next Fosroc concrete repair job, get in touch with the team at Yasu Trading. They’re ready to help make sure your project is built with the high-performance materials it needs for a finish that will last.

Got Questions? We've Got Answers on Fosroc Concrete Repair

When you're out on a site in the UAE, questions always pop up. Here are some of the most common ones we hear from construction pros about working with Fosroc repair systems, along with some straight-to-the-point answers.

What is the Real Shelf Life of Fosroc Renderoc in this Climate?

The real shelf life of Fosroc Renderoc in the UAE climate is typically 6 to 12 months, but only if the bags are stored properly in a dry, shaded, and ideally temperature-controlled location.

The heat and humidity here in the UAE can be brutal on building materials. It's absolutely essential to store these products in a dry, shaded place—ideally, a temperature-controlled store. Before you even think about mixing, always check the manufacturing date on the bag. An expired product is a failed repair waiting to happen.

When in doubt, a quick call to your supplier in Dubai can confirm the best storage practices and help you avoid any costly mistakes.

Is it Possible to Apply Fosroc Products in Dubai's Summer Heat?

Yes, it is possible to apply Fosroc products in Dubai's summer heat, but you must adapt your methods by working during cooler times and using techniques like chilled mixing water. You can't just work like it's a cool day in January. For any Fosroc concrete repair you're tackling when the thermometer climbs above 35°C, your best bet is to schedule the work for cooler times. Think early morning or even late evening.

Here are a few other tricks of the trade:

- Use chilled mixing water. This slows down the chemical reaction, giving you a bit more time to work with the mortar before it starts to set.

- Pre-dampen the concrete substrate thoroughly. This stops the hot, dry concrete from sucking the moisture right out of your fresh repair mortar, which can cause it to fail.

- Get on top of curing immediately. Don't wait around.

The most critical thing to remember for hot-weather work is that curing isn't an afterthought—it's part of the application process. The moment you've finished tooling the mortar, you need to apply a curing compound like Fosroc Concure. This locks in the moisture and protects your hard work from the harsh sun, preventing shrinkage cracks.

Are Fosroc Products Approved by Dubai Municipality?

Yes, many Fosroc products are widely specified and approved for projects under Dubai Municipality and other UAE construction standards, but approvals can be project-specific and regulations may change.

Your supplier should be your first point of contact here. As a leading building materials distributor, they'll have the most current information and can provide the documentation you need. This is the simplest way to ensure your repair work will pass inspection without a hitch.

For genuine Fosroc products and the technical support you need for your next project, get in touch with Yasu Trading Co. LLC. Find out how our reliable site-direct delivery can keep your project moving forward at https://yasutrading.com.