A Contractor's Guide to Paints for Wood in the UAE

For any contractor working in the UAE, picking the right paint for a wood surface is far more than just a matter of looks. It's a crucial call that determines how well the timber will hold up against our region's brutal sun, relentless heat, and humidity. Think of high-performance paints for wood as a protective shield, warding off UV damage, moisture, and the stress of daily temperature swings. Getting this choice right from the start is the only way to deliver a finish that lasts and meets the high standards expected here.

How do you choose the right wood paint in the UAE?

Choosing the right paint for wood in the UAE's tough construction climate isn't about simply picking a colour off a chart. It’s about specifying a complete protective system designed to fight back against our unique environmental challenges. One wrong move here can lead to finishes that fade, crack, and peel way too soon, leading to expensive rework and a hit to your reputation.

The intense Dubai sun is enemy number one. Its UV radiation attacks the binders in the paint, which is what makes the finish turn brittle and lose its colour. Then there are the wild daily temperature shifts that cause wood to constantly expand and contract. The paint you choose has to be flexible enough to move with the wood, or it will crack—guaranteed. Once that happens, moisture gets in and rot begins.

How do you meet regional construction demands?

Beyond just performance, your materials must tick all the boxes for UAE construction standards. Local municipalities have strict rules, especially around Volatile Organic Compounds (VOCs) for indoor paints, to maintain air quality and protect health. As a long-time building materials distributor, we know that compliance isn’t optional.

This demanding environment is actually fueling major growth. The UAE wood coatings market is one of the most active segments in the entire industry. It was valued at USD 0.92 billion in 2025 and is on track to hit USD 2.06 billion by 2034. That’s a compound annual growth rate of 9.38%, blowing past the general paints market. You can dive deeper into these numbers on Research and Markets. This trend clearly shows a growing demand for top-tier, durable wood finishes.

A successful project hinges on getting materials that aren't just adequate, but are perfectly suited for our local climate. Partnering with a knowledgeable supplier in Dubai means you’re getting coatings with a proven track record against UV, humidity, and heat—protecting your hard work for years.

At the end of the day, your choice of paint affects everything from your project schedule to long-term maintenance bills. Whether you're working on exterior cladding for a villa or fine interior cabinetry for a hotel, understanding the real differences between coating types is a must for any contractor who values quality. This guide will give you the practical, on-the-ground knowledge you need to make smart buying decisions.

What are the main types of paints for wood?

The main types of paints for wood are oil-based (alkyd), water-based (acrylic), and polyurethane finishes. When choosing a paint for wood in the UAE, you are selecting a protective system designed to stand up to specific climate challenges, and getting this choice right from the start is the difference between a finish that lasts and one that fails.

Your main options boil down to three families: oil-based (often called alkyd), water-based (latex or acrylic), and the more advanced polyurethane finishes. A simple way to think about them is that an oil-based paint forms a tough, rigid shell. A water-based paint acts more like a flexible, breathable skin. Polyurethanes? They’re the top-tier armour, providing an incredibly resilient, often clear, coating you see on high-end work.

To help you navigate these choices, here’s a quick-reference table that breaks down how each paint type performs in the context of typical UAE projects.

Comparison of Wood Paint Types for UAE Projects

| Paint Type | Best For | Key Advantage (UAE) | Key Disadvantage (UAE) | Typical Use Case |

|---|---|---|---|---|

| Oil-Based (Alkyd) | High-traffic interior wood: doors, trims, cabinetry. | Creates a very hard, scrubbable, and smooth finish. | Can yellow over time and become brittle in extreme sun/heat. | Interior doors in a hotel, office skirting boards, kitchen cabinets. |

| Water-Based (Acrylic) | Exterior wood, general interior use, quick-turnaround projects. | Excellent UV resistance and flexibility; won't crack as wood expands. | Less resistant to scuffs and knocks than oil-based paints. | Villa pergolas, exterior wooden cladding, residential window frames. |

| Polyurethane (PU) | High-end furniture, flooring, luxury joinery. | Unmatched durability, chemical resistance, and premium finish. | Higher cost and often requires more skilled application. | Bespoke joinery in a retail fit-out, hotel lobby furniture, hardwood floors. |

This table gives you a solid starting point for matching the right chemistry to the job at hand. Now, let’s dig into the specifics of where each one truly shines.

What is the best paint for high-traffic interior woodwork?

The best paint for high-traffic interior woodwork is a traditional oil-based paint, which is ideal for areas that take a daily beating like doors, skirting boards, and cabinetry. It cures into an exceptionally hard, durable film that stands up beautifully to scuffs, knocks, and constant cleaning.

One of its biggest professional advantages is how well it levels out. It flows smoothly, erasing brush marks to create an almost glass-like finish. This makes it a go-to for achieving that premium look on detailed architectural woodwork. While it does take longer to dry and has a stronger smell due to higher VOCs, its sheer toughness in high-contact zones is hard to beat. Your building materials distributor can point you towards modern formulas that balance this durability with current UAE construction standards for indoor air quality.

Are water-based paints suitable for exterior wood in Dubai?

Yes, modern water-based acrylic paints are not just suitable but often superior for most exterior wood applications in Dubai. Their two biggest strengths are flexibility and UV resistance, which are non-negotiable for surviving the region's climate.

Here, the wood is constantly expanding and contracting with the drastic day-to-night temperature swings. A rigid oil-based paint can become brittle under this stress, leading to cracking and failure. A good acrylic, however, moves with the wood. This flexibility is what prevents the peeling and flaking that plagues lesser coatings. On top of that, they hold their colour far better under relentless sun, resisting the fading that UV radiation causes. Their low odour, fast drying time, and simple water clean-up are also huge practical wins on a busy construction site.

The real enemy for exterior wood here isn’t just the heat; it’s the combination of intense UV radiation and thermal shock. A high-quality acrylic paint recommended by your supplier in Dubai will have advanced binders and pigments engineered to fight this assault, protecting the timber and your project's reputation.

When should you specify polyurethane finishes?

You should specify polyurethane finishes when a project demands the absolute best in durability and appearance. Think of high-end hotel furniture, luxury retail displays, premium wooden flooring, or kitchen cabinetry where the finish has to look perfect and perform flawlessly for years.

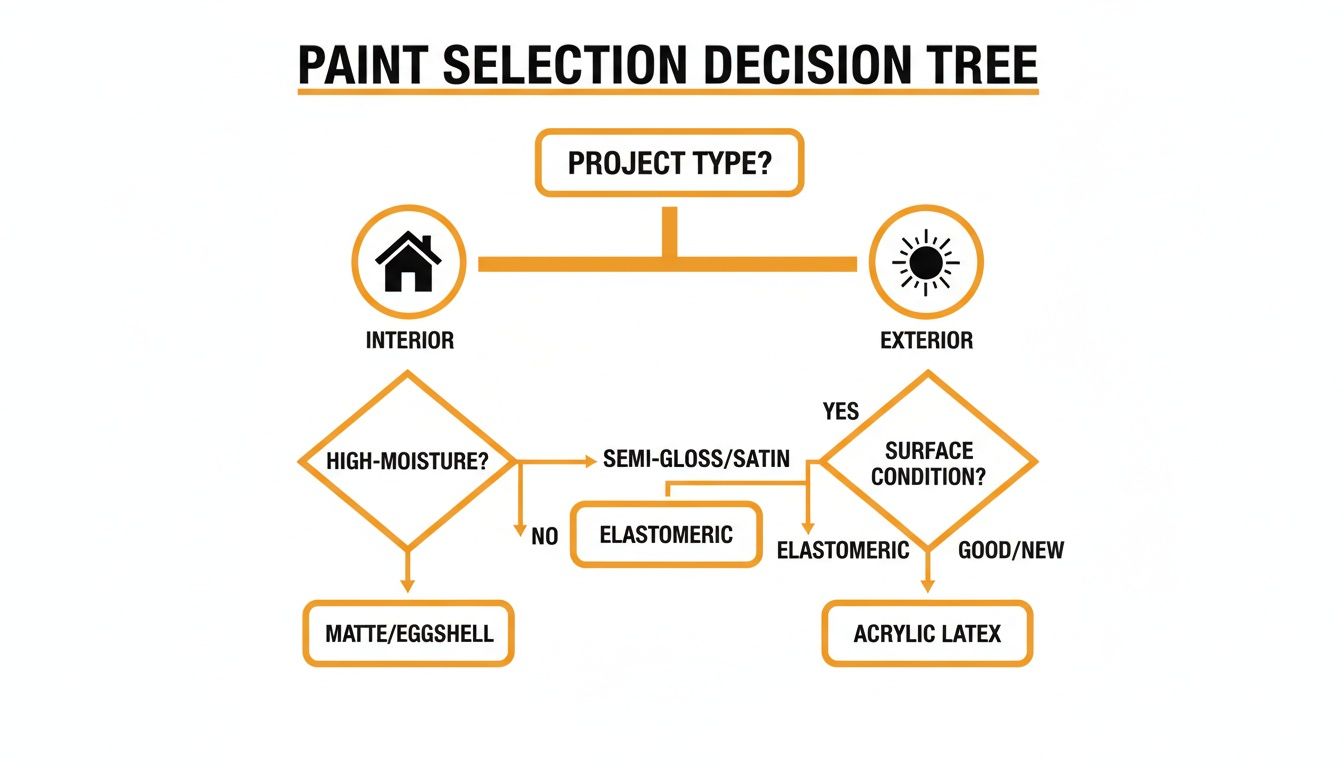

This simple flowchart can help guide your initial thinking, showing how the environment—interior vs. exterior—is the first major fork in the road.

As the flowchart suggests, once you know the location, you can drill down into the surface conditions and desired outcome to land on the right technology.

The demand for these high-performance systems is growing rapidly. While the global wood coatings market is forecast to grow at a steady 5.03% CAGR, the UAE market is projected to expand at nearly double that rate, hitting 9.38% CAGR between 2025 and 2034. Polyurethane coatings are a major driver of this growth, prized for their superior toughness and finish.

For specific applications like cabinetry, diving deeper into the best paint for kitchen cabinets reveals why polyurethanes are so valued. Available in both water-based and solvent-based versions, they create a non-porous, chemical-resistant surface that’s incredibly easy to maintain—a smart investment for long-term performance.

Why is primer essential for wood painting in a hot climate?

Primer is essential for wood painting in a hot climate because it seals the porous wood, ensuring the topcoat adheres properly and creates a durable, even finish. In a demanding climate like the UAE's, skipping primer isn't just cutting a corner—it's practically guaranteeing the paint job will fail.

Imagine trying to paint a dry sponge. Raw wood is just as porous, and it will soak up your expensive topcoat, leaving you with a blotchy, uneven finish that demands extra coats and wastes a lot of material. A primer is the dedicated foundation that seals the wood, creating a smooth, non-porous canvas. For any project held to high UAE construction standards, this step is non-negotiable.

What does a primer actually do for wood?

A good primer seals the wood's surface to create a stable base, preventing problems like blistering and peeling which are common in extreme temperatures. It acts as the glue that locks the topcoat to the wood, creating a finish built to last, while also blocking stains from natural oils and tannins in the wood from bleeding through the paint.

But it also plays another critical role: stain blocking. Many woods popular in the region, like meranti, are full of natural oils and tannins. Without a primer to act as a barrier, these tannins will slowly "bleed" through the paint, causing ugly yellow or brown stains to ruin the finish. The primer effectively locks them in place.

For any project manager or contractor, understanding primer isn't just about paint; it's about asset protection. It's the most cost-effective insurance policy you can buy to guarantee the longevity and aesthetic integrity of your woodwork against the harsh Dubai sun.

Which primer is best for exterior vs interior jobs?

For exterior jobs, an oil-based primer is generally best for its superior stain-blocking and durability against the elements. For interior jobs, a water-based (acrylic) primer is often the go-to choice due to its flexibility, fast drying time, and low odour.

- Oil-Based Primers: These are the heavy lifters for exterior work and serious stain blocking. Their formulation is second to none for sealing stubborn tannins and stopping rust from nail heads from bleeding through. If you're prepping an outdoor pergola or exterior cladding, an oil-based primer gives you that tough, resilient foundation needed to stand up to the elements.

- Water-Based (Acrylic) Primers: When you move indoors, water-based primers are usually the go-to. They’re more flexible, dry much faster, and have significantly lower odours and VOC content. This makes them perfect for interior trim, doors, and furniture, where a quick, low-fume application is essential for homes, hotels, or offices.

A quick chat with a knowledgeable building materials distributor can help you match the perfect primer chemistry to your specific wood and project needs.

How should primer be applied for best results?

To apply primer for the best results, start with a clean, dry, and lightly sanded wood surface, then apply a thin, even coat of primer, ensuring full coverage. Allow the primer to cure completely according to the manufacturer's instructions before applying the topcoat.

Having the right product is only half the battle; how you apply it is just as important. You can't just slap it on and hope for the best. Achieving a durable finish, especially under the relentless UAE sun, requires a disciplined approach.

Follow these steps for a flawless on-site application:

- Apply a Thin, Even Coat: Whether you're using a brush, roller, or sprayer, aim for consistent coverage. Avoid laying it on too thick, as that can lead to drips and an uneven texture under your topcoat.

- Check for Full Coverage: Make sure every single inch of the wood is primed. Pay extra attention to the end grains—they're like straws and will drink up the primer, so they often need a little extra.

- Respect the Curing Time: This is the most critical step, and it's the one most often rushed. Always check the manufacturer's technical data sheet for the specific drying and curing times. Painting over primer that isn't fully cured will undermine the entire paint system.

- Lightly Sand Before Painting: After the primer has fully cured, a final, very light sanding with fine-grit sandpaper will knock down any raised grain. This simple action is the secret to getting that ultra-smooth, professional-looking surface for your final paint coat.

Any trusted supplier in Dubai should be able to provide the technical data sheets for their products, giving your team the exact specifications needed for a perfect application, every single time.

How do you choose a durable finish for exterior wood?

To choose a durable finish for exterior wood, you must select a high-performance, exterior-grade paint specifically engineered with UV resistance and flexibility. This shield is designed to survive the UAE's scorching UV radiation, wild temperature swings, and humidity, which will destroy an interior-grade paint quickly.

The biggest mistake we see on projects is applying interior logic to an exterior problem. An interior paint, no matter how tough it seems, will be completely destroyed by the Dubai sun in a surprisingly short time. You absolutely must use specific, exterior-grade paints for wood built with advanced protective chemistry.

What makes a paint UV resistant?

A paint is made UV resistant by including special additives like hindered amine light stabilizers (HALS) and UV absorbers. These compounds act like a powerful sunscreen mixed into the paint, absorbing or deflecting the sun’s destructive ultraviolet rays that cause colour fade and break down the paint's structure.

Without this protection, intense UV radiation essentially shatters the polymer chains holding the paint together. The finish becomes brittle, chalky, and weak. It’s why a cheap, non-UV-rated paint can look decades old after just one summer. When you’re sourcing materials, your supplier in Dubai must provide a technical data sheet confirming the presence and quality of these crucial UV-protective additives.

Why is flexibility essential for exterior coatings?

Flexibility is essential for exterior coatings because wood naturally expands and contracts with daily temperature changes in regions like the UAE. A flexible paint moves with the wood, preventing the finish from cracking, peeling, and allowing moisture to seep in and cause rot.

Modern acrylic and polyurethane formulas are designed with superior elasticity. Their molecular structure allows them to stretch and move right along with the wood, maintaining a continuous, unbroken barrier against the elements.

In contrast, more rigid coatings like traditional oil-based paints can become brittle under constant thermal stress. This inflexibility leads to microscopic cracks, which are invitations for moisture to seep in and cause the wood to rot from within.

How do you protect wood from moisture and mould?

To protect wood from moisture and mould, use a high-quality exterior paint that creates a waterproof barrier and contains biocides like fungicides and mildewcides. This dual-action approach blocks liquid water from reaching the wood while actively preventing mould and algae growth on the surface.

Top-tier exterior paints for wood tackle moisture in two critical ways:

- Creating a Barrier: The paint film itself acts as a waterproof membrane, blocking liquid water from ever reaching the wood’s surface. High-quality acrylics are brilliant at this, forming a breathable film that keeps rain out but allows any trapped water vapour to escape. You can learn more about how these systems work in our guide on waterproof paint solutions.

- Including Biocides: Premium paints come formulated with fungicides and mildewcides. These active ingredients are mixed directly into the paint to stop mould and algae from taking hold. This keeps the finish clean and prevents the biological decay that can completely destroy the wood.

When you're writing specifications, especially for villas or resorts near the water, making sure the paint contains these biocides is vital. It’s a key detail that aligns with stringent UAE construction standards and protects the long-term value of the asset. For more in-depth techniques, this guide on painting outdoor wood is a great resource for achieving lasting results.

Why are VOC rules important for wood coatings in the UAE?

VOC (Volatile Organic Compounds) rules are important for wood coatings in the UAE because they are strict, enforced requirements designed to meet green building codes and protect air quality. Non-compliance can lead to failed inspections, project delays, and financial penalties.

These aren't just polite suggestions—they're strict requirements enforced by municipalities to meet green building codes like Estidama and the Dubai Green Building Regulations. So, what are VOCs? Essentially, they're the solvents that evaporate into the air as paint dries. That strong, chemical smell you get from old-school, solvent-based paints? That’s them. These emissions are bad for indoor air quality and the environment.

What are the VOC limits for paints in Dubai?

The specific VOC limits for paints in Dubai are set by Dubai Municipality and other local authorities, putting firm caps on the allowed content, especially for indoor applications. For most interior jobs—think schools, hotels, offices, and residential buildings—this means low-VOC or zero-VOC water-borne paints are now the standard requirement.

If you try to use a non-compliant, high-VOC paint, you’ll fail your inspection. That means stripping it all off and starting again, which will absolutely wreck your timeline and budget. This regulatory push has completely changed the market, forcing a massive shift away from traditional solvent-based paints. As a result, water-borne coatings now dominate the UAE market, a trend you can explore in these UAE paint market findings on marknteladvisors.com.

How does this affect product selection?

VOC regulations directly impact product selection by making compliance a primary factor alongside performance and aesthetics. It is no longer good enough for a paint to just look great and last a long time; it absolutely must have the right certifications to get signed off on-site. Specifying the wrong product isn't a small technical mistake—it's a compliance disaster waiting to happen.

This is precisely where having a solid building materials distributor on your side pays off. A good supplier isn't just an order-taker; they’re your compliance partner, making sure every can of paint you buy meets the latest UAE construction standards.

Working with a trusted supplier in Dubai like Yasu Trading Co. takes the guesswork out of compliance. We make sure the products we recommend, from top brands like National Paints, are fully municipality-approved and have all the right paperwork, protecting your project from any regulatory headaches.

What is the supplier's role in keeping you compliant?

A supplier's role in keeping you compliant is to provide technical documentation, confirm municipality approvals, and suggest compliant alternatives for your specified products. They act as a compliance partner, ensuring every can of paint meets the latest UAE construction standards.

A reliable distributor will:

- Supply Technical Data Sheets (TDS): These documents are your proof. They clearly state the VOC content, letting you verify compliance before you even place an order.

- Confirm Municipality Approval: They should be able to tell you instantly which products are on the approved lists for Dubai, Abu Dhabi, and other emirates.

- Suggest Compliant Alternatives: If a paint you’ve specified doesn’t meet local rules, a good supplier will find you an equivalent that does, without sacrificing performance.

By teaming up with a distributor who knows the local regulations inside and out, you can rest easy knowing the materials showing up on your site will pass inspection, keeping your project running smoothly.

How do you specify and procure the right wood paints in Dubai?

To specify and procure the right wood paints in Dubai, you must create a detailed specification sheet and follow a structured procurement workflow. A vague request like "wood paint" is a surefire way to get the wrong materials, leading to project delays and budget overruns.

Think about ordering a custom door. You wouldn't just ask for "a wooden door," right? You’d specify the exact dimensions, the type of timber, the hardware, and the finish. Applying that same detailed logic to paint is the only way to guarantee you get exactly what your project needs.

What goes into a paint specification sheet?

A paint specification sheet should include the substrate type (e.g., Meranti, MDF), application area (interior/exterior), specific performance needs (e.g., UV resistance), desired finish (e.g., matt, gloss), and compliance requirements (e.g., VOC limits). This document acts as the blueprint for your project's coatings, ensuring you get exactly what you need.

Your sheet needs to clearly spell out these details:

- Substrate Type: What kind of wood are you painting? Be specific—Meranti, Teak, MDF, etc.

- Application Area: Is this for an interior or exterior job? The demands are completely different.

- Performance Needs: Note any special requirements. Does a pergola need extreme UV resistance? Do interior doors need to be scuff-proof?

- Desired Finish: Specify the sheen you're after, whether it's matt, semi-gloss, or high-gloss.

- Compliance Requirements: List any must-have certifications, especially those needed to meet UAE construction standards like VOC content limits for Dubai Municipality approvals.

When you hand a detailed brief like this to a trusted building materials distributor, you cut right through the noise. They can immediately recommend the perfect system—the right primer and topcoat—and back it up with technical data sheets to prove it meets your needs.

What is the procurement workflow for sourcing paints?

A standard procurement workflow for sourcing paints involves submitting a detailed Request for Quotation (RFQ), reviewing the supplier's quote and technical data, and then placing the order for scheduled delivery. This systematic approach ensures you get the right product, good value, and reliable logistics.

A professional supplier in Dubai will walk you through a simple, effective journey:

- Request for Quotation (RFQ): You send them your detailed specification sheet. A good supplier won't just send back a price; they’ll often provide a quick technical consultation to double-check the details and perhaps suggest a better solution.

- Quote and Technical Data Review: You’ll get a formal quote laying out the products, wholesale pricing for your bulk order, and realistic lead times. Now's your chance to scrutinise the technical data sheets (TDS) and confirm the proposed materials tick every box on your spec sheet.

- Order Placement and Delivery Scheduling: After you approve the quote, you place the purchase order. This is where partnering with an established distributor really pays off. They should confirm a clear delivery window and have the logistics to get the paint directly to your site, whether it’s in Dubai, Sharjah, or Abu Dhabi.

This straightforward process eliminates the guesswork and frees you up to focus on the project itself. For more tips on finding the right partners, have a look at our guide on selecting the best paint suppliers in the UAE.

Got Questions About Wood Paints? We’ve Got Answers.

When you're on a job site, the theory goes out the window and practical questions come up fast. Here are some of the most common things we get asked by contractors and project managers across the UAE, with straight-to-the-point answers.

How long does wood paint really last in the Dubai sun?

A top-tier, UV-resistant acrylic or polyurethane paint can last 5 to 7 years on exterior wood in the Dubai sun, provided it was applied properly over the correct primer. In contrast, a lower-grade paint may fail within 2 to 3 years due to intense solar exposure.

Regular cleaning to get sand and dust off the surface is also non-negotiable if you want to get the maximum life out of any coating.

Can I just paint over an old varnished wooden door?

Yes, you can paint over an old varnished door, but you cannot "just paint over it" without proper preparation. You must thoroughly sand the old varnish to remove all gloss and create a rough surface for the new paint to adhere to.

After sanding, wipe the surface completely clean of dust. Don't skip the primer—an oil-based primer is your best bet here. It creates a bulletproof bond and stops any stains from the old finish from bleeding through your fresh topcoat.

What’s the best paint for wood furniture in high humidity?

The best paint for wood furniture in high humidity is a water-based polyurethane or a marine-grade paint. These coatings form a tough, sealed barrier that stops moisture from penetrating the wood, which prevents swelling, warping, and the growth of mould and mildew.

When sourcing materials, make sure the product is rated for interior use and meets local low-VOC regulations to stay compliant with UAE construction standards. Any decent building materials distributor should have the technical data sheets to prove it.

Which paint finish is the easiest to keep clean?

A semi-gloss or gloss finish is undoubtedly the easiest paint finish to keep clean. The smooth, non-porous surface prevents dirt and grime from settling in, making it easy to wipe down, which is perfect for high-traffic areas like doors, window frames, and kitchen cabinets.

A matt finish looks fantastic and very modern, but its porous texture can make it a magnet for stains and scuffs. Cleaning it requires a much gentler touch. A good supplier in Dubai can help you strike the right balance between the look you want and the real-world maintenance the project can handle.

For all your project needs, from high-performance paints for wood to a complete range of construction supplies, trust Yasu Trading Co. LLC to deliver quality materials and expert advice. Simplify your procurement by exploring our extensive inventory at https://yasutrading.com today.