A Contractor's Guide to PP Bubble Sheets in Dubai

On any busy construction site in Dubai, you'll find materials that are absolutely essential but often go unnoticed. PP bubble sheets are one of them. Think of them as industrial-grade bubble wrap, but built tough enough to handle the chaos of a major building project. They're the go-to solution for protecting valuable surfaces, and as a leading supplier in Dubai, we at Yasu Trading Co. LLC see them on project sites all across the city.

What Are PP Bubble Sheets and Why Are They Used in Dubai?

A Polypropylene (PP) bubble sheet is a lightweight but surprisingly strong material made for temporary surface protection and, in some cases, creating voids in concrete. Forget the flimsy bubble wrap you use for parcels. This is a three-layer system: a thermoformed bubble core is sandwiched between two flat, tough PP sheets, creating a rigid and impact-resistant panel.

For a site manager, that structure is a game-changer. It means the sheet can take a beating from heavy foot traffic, dropped tools, and the general wear and tear of a worksite without easily tearing or getting punctured. It’s a dependable shield for expensive finishes like marble floors, newly installed sanitaryware, or large glass panels that could otherwise suffer costly damage.

What is the primary purpose of PP bubble sheets in construction?

The primary purpose of PP bubble sheets is twofold: providing serious, temporary protection for finished surfaces and creating lightweight voids within concrete structures. This flexibility makes them an incredibly efficient and budget-friendly choice for modern construction projects that must meet UAE construction standards.

This versatility is why they’ve become so common here. The demand for these sheets has grown right alongside Dubai's incredible construction boom. Consider this: between 2020 and August 2025, the UAE saw around USD 328.7 billion in construction contracts awarded, and Dubai accounted for a massive 75% of that. With the city's population expected to hit 7.8 million by 2040, the pace isn't slowing down. All that new development means these sheets will remain critical for everything from floor systems to roofing and facade work. For a deeper dive into these trends, check out the Knight Frank analysis on the UAE construction landscape.

In a market as fast-moving as Dubai's, protecting assets during construction isn't just a good idea—it's essential. PP bubble sheets offer a straightforward, effective way to prevent expensive rework and keep your project on track.

Working with a reliable building materials distributor is key to making sure these products meet strict local requirements. When you source high-quality sheets from a trusted name like Yasu Trading, you’re setting your project up for a smooth, flawless handover.

These sheets are simply indispensable for:

- Shielding floors, walls, and countertops during the busy fit-out stages.

- Forming structural voids in concrete slabs, which helps reduce the overall weight.

- Cushioning delicate fixtures and fittings while they’re being moved and installed.

Where Are PP Bubble Sheets Most Effective on UAE Construction Sites?

Anyone in the industry knows PP bubble sheets in Dubai are great for protecting floors. But if that's all you're using them for, you're missing out. Their real genius is how they solve problems at nearly every stage of a project, from the first concrete pour to the final touches before handover. On a busy UAE job site, they aren’t just a floor cover; they're a multi-purpose workhorse.

This versatility is a huge advantage here. In the UAE, traditional on-site construction still rules the day, making up about 90.5% of the market in 2024. This hands-on approach means we go through a staggering amount of temporary protection and other site materials. With residential projects expected to grow by 5.5% this year alone, the demand for reliable, versatile materials is non-stop. For a deeper dive into these numbers, the Mordor Intelligence report on the UAE market is a great resource.

How do bubble sheets protect floors and surfaces?

PP bubble sheets protect floors and surfaces by acting as a durable, cushioned barrier against impacts, scratches, and spills during construction. Their high-GSM, waterproof structure absorbs shocks from dropped tools and heavy foot traffic, preserving expensive finishes like marble, tile, and wood until project handover.

Let's start with the most obvious use: protecting finished surfaces. Picture this: you've just installed thousands of square metres of immaculate Italian marble in a new luxury hotel lobby. Now, the electricians, plumbers, and painters are coming in with their heavy gear, scaffolding, and tool belts.

A single dropped wrench or a can of spilled paint could mean thousands of dirhams in repairs and, worse, project delays. This is exactly where a high-GSM PP bubble sheet proves its worth. When you tape it down properly, its cushioned structure takes the hits and contains spills, acting as a tough, temporary shield until the job is done.

Here’s where we see it used most often:

- Flooring: Shielding marble, granite, ceramic tiles, and engineered wood from scratches, stains, and impact.

- Sanitaryware: Wrapping new bathtubs, sinks, and toilets to keep them free of chips and cracks before the client sees them.

- Joinery and Countertops: Draping custom cabinetry, kitchen islands, and reception desks to protect them from dust and dings.

- Glass and Facades: Applying sheets to large glass panels and curtain walls to prevent scratches from flying debris during installation.

What is void forming in concrete?

Void forming is a structural engineering technique where bubble sheets are embedded within a concrete slab before it is poured, creating a grid of air pockets. This process displaces heavy concrete, significantly reducing the slab's overall weight (dead load) without compromising its structural integrity, leading to more efficient and cost-effective building designs.

Beyond just covering things up, PP bubble sheets play a surprisingly clever role in the structure of a building itself as void formers. In today's high-rise construction, one of the biggest challenges for structural engineers is managing the building's dead load—basically, its own weight. Heavier buildings need bigger foundations and beefier columns, which quickly drives up costs.

The genius here is that you're displacing a huge volume of heavy concrete without weakening the slab. The result is a much lighter floor system, which reduces the overall load on the building’s frame and allows for smarter, more cost-effective designs.

This technique is especially critical for projects that need to meet the strict UAE construction standards for structural efficiency. Any good building materials distributor will know exactly what you mean and can supply sheets engineered specifically for this job.

How are bubble sheets used for impact cushioning?

PP bubble sheets are used for impact cushioning by wrapping them around delicate or high-value items like custom mirrors, light fixtures, and electronics. The air-cushioned structure absorbs shocks and vibrations during transport and installation on a chaotic construction site, while the tough polypropylene outer layers resist punctures and tears.

This is where the "bubble" in the sheet really does its job, creating a protective air gap that absorbs shocks. Think about fitting out a five-star hotel. You've got custom-made mirrors, fragile light fixtures, and expensive electronics that need to get from a delivery truck, through a chaotic site, and installed in one piece.

Wrapping these items in PP bubble sheets gives them a tough, tear-resistant skin. Unlike flimsy bubble wrap, the rigid polypropylene structure won’t easily puncture if it snags on a sharp corner. It’s built to withstand the rough-and-tumble environment of a real job site. A reliable supplier in Dubai can help you pick the right thickness for whatever you need to protect.

How to Select the Right PP Bubble Sheet Specification

Picking the right PP bubble sheets in Dubai isn't just about grabbing the first roll you see. It's a calculated decision that can directly protect your project's bottom line. Get it wrong, and you either overspend on a sheet that's overkill for the job or, far worse, under-protect valuable surfaces and end up with costly rework. This guide will walk you through the key specs to help you make a smart choice that meets the demanding UAE construction standards.

The whole process boils down to three key variables: thickness (measured in GSM), bubble size, and the material grade. Think of it like choosing the right tool for a job. You wouldn't use a sledgehammer to tap in a finishing nail, right? In the same way, you don’t need the thickest, toughest sheet for every single application. A reliable building materials distributor can definitely steer you in the right direction, but understanding the basics yourself empowers you to order exactly what your site needs.

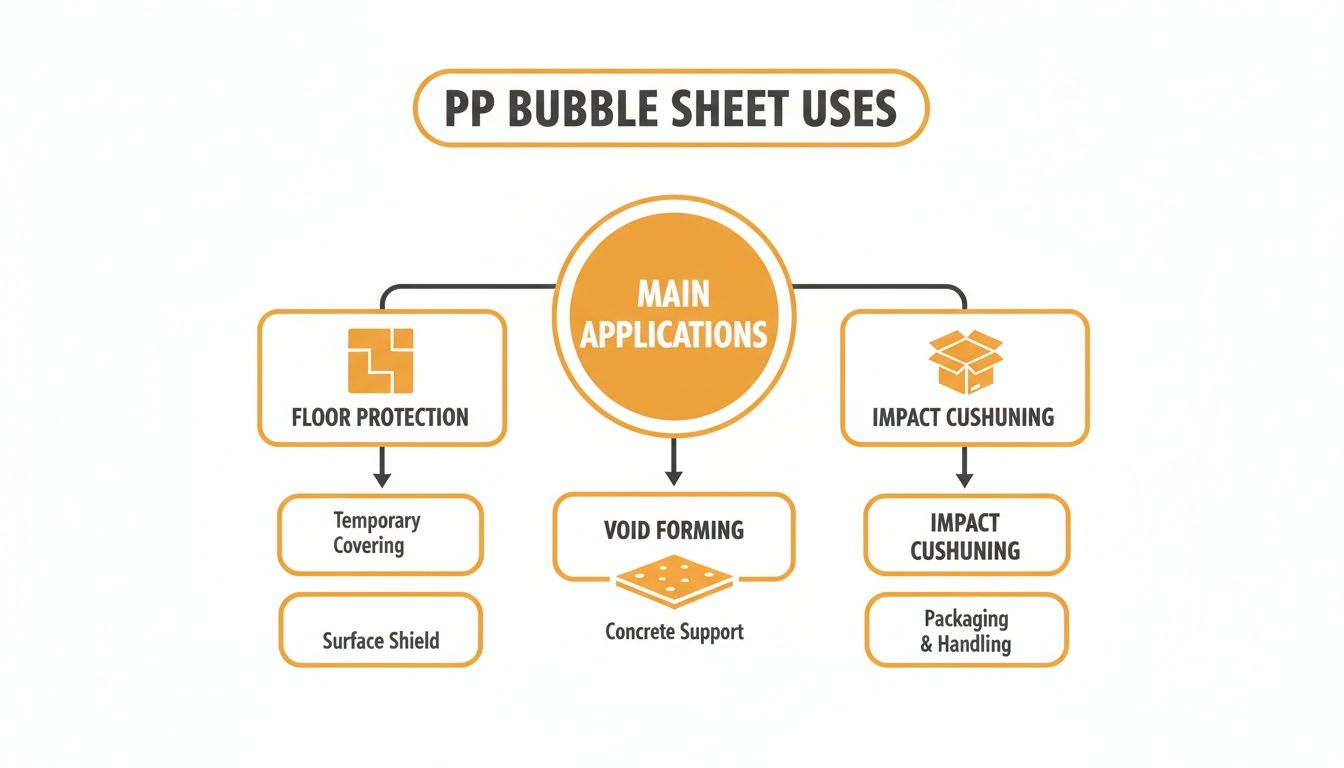

This quick flowchart breaks down the main jobs these sheets do, giving you a clear picture of where different specs fit into a project.

As you can see, their versatility is a huge plus. They can handle everything from rugged floor protection to creating structural voids, but each task calls for a very different set of material properties.

What is GSM and why does it matter most?

GSM, or Grams per Square Metre, is the most important specification for a bubble sheet because it measures the material's density and directly relates to its toughness. A higher GSM indicates a stronger, more durable sheet that offers better resistance to punctures and impacts, making it suitable for heavy-duty protection.

For example, a sheet with a 250 GSM rating is fairly lightweight. It’s perfect for jobs where you don't expect a lot of physical stress, like wrapping sanitaryware or covering freshly painted walls to keep the dust off. On the other end of the spectrum, a heavy-duty sheet rated at 700 GSM or more is built to take a serious beating. This is what you need for high-traffic corridors, areas where you're setting up scaffolding, or on floors where heavy equipment will be rolling through.

When in doubt, always plan for the worst-case scenario. If a hallway is going to have workers in heavy boots walking through it all day, spending a bit more on a higher GSM sheet isn't an extra cost—it's cheap insurance against damaging an expensive floor.

Should I choose virgin or recycled material?

The choice between virgin and recycled PP bubble sheets depends on your project's needs and budget. Virgin polypropylene offers maximum strength and consistency for critical tasks like void forming, while high-quality recycled sheets provide excellent protection for general surface covering at a lower cost and with a smaller environmental footprint.

Both have their place, and the choice usually comes down to balancing performance needs with your budget and sustainability targets. Any good supplier in Dubai should stock both and be able to walk you through the trade-offs.

- Virgin PP: This is the premium stuff, made from brand new, unprocessed polypropylene resin. These sheets give you the absolute best in strength, clarity, and consistency. You’d choose virgin material for critical applications where performance is non-negotiable.

- Recycled PP: Made from post-industrial or post-consumer plastic waste, these sheets are easier on the wallet and the environment. While they might be slightly less tough than their virgin counterparts, they provide more than enough protection for general-purpose jobs like covering floors.

For a huge number of projects here in Dubai, a high-quality recycled PP sheet strikes that perfect balance of performance and value.

What is the best bubble sheet for heavy-duty protection?

The best bubble sheet for heavy-duty protection is a high-GSM version, typically in the 500-700 GSM range, made from either virgin or top-grade recycled material. This combination delivers superior impact absorption and puncture resistance, creating a reliable shield against dropped tools, heavy trollies, and constant foot traffic that won't easily tear or crush.

To make things even simpler, we've put together this quick reference table. It maps common applications in Dubai to the ideal bubble sheet specification. Use it as a starting point when discussing your project with a materials supplier.

PP Bubble Sheet Specification Guide for Common Dubai Applications

| Specification (GSM) | Recommended Application | Key Benefit | Example Scenario |

|---|---|---|---|

| 250-350 GSM | Light-duty protection, dust barrier | Cost-effective, flexible | Wrapping delicate fixtures like lighting or covering kitchen cabinets during painting. |

| 350-500 GSM | Medium-duty floor protection | Balanced durability and cost | Protecting tile floors in residential rooms with moderate foot traffic during fit-out. |

| 500-700 GSM | Heavy-duty floor protection | High impact & puncture resistance | Covering marble floors in a busy hotel lobby or main corridors during renovation. |

| 700+ GSM | Structural void forming, extreme protection | Maximum strength and rigidity | Creating voids in concrete slabs or protecting floors under heavy scaffolding. |

This guide should give you a solid foundation for choosing the right sheet. Matching the GSM and material to the specific demands of your site will ensure your surfaces stay pristine from start to finish.

How Do PP Bubble Sheets Compare to Traditional Materials?

When you're planning a project, it's natural to weigh the cost of new materials against the old standbys like plywood, cardboard, or basic plastic sheeting. So, when it comes to protecting surfaces, is it really worth investing in PP bubble sheets in Dubai? Especially with the demands of the UAE climate, the answer is a clear and simple yes.

Frankly, traditional materials just can’t compete with modern polypropylene sheets. While they might look cheaper at first glance, their shortcomings almost always lead to higher costs later on, thanks to damage, rework, and wasted time. Let's dig into exactly where PP bubble sheets leave the old guard behind.

Why is waterproofing important for floor protection in Dubai?

Waterproofing is critical for floor protection in Dubai because construction sites constantly face moisture from high humidity, spills, and cleaning crews. PP bubble sheets are 100% waterproof, unlike cardboard which turns to pulp and plywood which warps, preventing moisture damage and costly repairs to finished surfaces.

A construction site in the UAE is in a constant fight with moisture. This is where the difference between materials becomes glaringly obvious.

PP bubble sheets are 100% waterproof. Because they're made from non-porous polypropylene, they form a solid barrier that keeps liquids sitting right on the surface. You can just wipe it away, and it's like it never happened.

Now, think about cardboard. The second it gets wet, it turns to a useless, soggy mess. Plywood fares a bit better, but over time it will still warp, swell, and peel apart when wet, sometimes trapping moisture right against the surface you're trying to protect.

Are bubble sheets better than plywood for impact resistance?

Yes, PP bubble sheets are often better than plywood for impact resistance due to their unique air-cushioned structure which effectively absorbs and dissipates shocks. While plywood can resist a heavy impact, it is more likely to transfer the force or sustain a deep gouge, whereas a high-GSM bubble sheet often causes dropped items to bounce off with minimal damage.

Water isn't the only enemy on a job site. It's a minefield of potential damage, from dropped tools and dragged materials to all sorts of chemical spills.

- Impact Resistance: That unique three-layer, air-cushioned design of a PP bubble sheet isn't just for show—it gives them incredible impact absorption. A hammer that would tear right through cardboard or leave a deep gouge in plywood often just bounces off a high-GSM bubble sheet.

- Chemical Resilience: Polypropylene is naturally tough against a whole host of common construction chemicals, from solvents and oils to mild acids. A splash of paint thinner or a cleaning agent spill won't eat through the protective layer.

This built-in toughness means your protection stays solid from day one to project completion, easily meeting the high bar set by UAE construction standards.

Think about it: a single sheet of plywood ruined by a spill costs you in both materials and the labour time to replace it. A reusable PP bubble sheet that shrugs off that same spill saves you money on both, making it the smarter financial choice over the life of a project.

Are PP bubble sheets reusable?

Yes, a major advantage of PP bubble sheets is their reusability, which makes them a highly cost-effective and efficient choice for contractors. Their durable, waterproof, and easy-to-clean polypropylene construction allows them to be wiped down, rolled up, and reused on multiple projects, unlike single-use materials like cardboard.

The real value of PP bubble sheets shines through long after the first job. Their sheer durability means big savings, thanks to reusability and smoother site logistics.

One of the biggest wins is that you can use them again and again. Unlike cardboard, which is usually a one-and-done deal, a quality PP bubble sheet can be wiped clean, rolled up, and taken to the next site. This drastically cuts down your cost-per-use, a massive benefit for any large contractor or building materials distributor trying to manage their inventory smartly.

On top of that, these sheets are incredibly lightweight. One worker can easily carry and lay down a large roll, while wrestling with heavy, awkward sheets of plywood is often a two-person job. This simple difference speeds everything up, from installation to cleanup, saving on labour and even transportation costs.

How to Get the Most Out of Your PP Bubble Sheets on a Dubai Job Site

Choosing the right PP bubble sheets in Dubai is a great first step, but it’s only half the job. To get the full protective power you paid for, your teams on the ground need to know how to handle and install them properly. A sloppy application can lead to gaps, slips, and the exact kind of damage you were trying to avoid in the first place.

Let's be clear: following best practices isn't just about ticking a box. It's about making sure every square metre of finished flooring, every delicate fixture, and every surface stays pristine. This is especially true on a busy Dubai job site where different trades are constantly coming and going. A properly laid protective layer is a non-negotiable part of keeping the site safe and efficient.

How do I properly secure PP bubble sheets to a floor?

To properly secure PP bubble sheets, first clean the floor thoroughly, then roll out the sheets, overlapping each seam by at least 10-15 cm. Use a high-quality, low-tack construction tape to secure the entire perimeter and seal all overlapping seams to create a single, solid protective barrier that won't shift.

Covering a large floor is pretty simple, but the details matter.

- Prep the Surface: First things first, get the floor spotless. Make sure it's completely free of dust, debris, or any moisture. Any grit you leave underneath will act like sandpaper as people walk over it.

- Lay the First Roll: Start by rolling out the first sheet parallel to the longest wall. It's good practice to leave a small, even gap at the edge.

- Overlap for a Tight Seam: When you lay down the next roll, overlap it with the first one by at least 10-15 cm. Don't be tempted to skimp on this—that generous overlap is what stops dirt and debris from sneaking in between the sheets.

- Tape Down Everything: Now, tape down the entire perimeter of the area you've covered. Crucially, you also need to run tape along every single overlapping seam. This turns multiple sheets into one solid, protective barrier.

What are the do's and don'ts for using bubble sheets on-site?

The key do's are to clean surfaces before application, use a sharp knife for clean cuts, and tape all seams securely. The main don'ts are dragging heavy equipment across them, using aggressive tapes that leave residue, and leaving any gaps that allow debris underneath.

To make life easier for your site supervisors, here's a quick guide to prevent the common mistakes that can ruin your surface protection efforts. Sticking to these simple rules helps you maintain the high UAE construction standards for site cleanliness and looking after the client's property.

Do:

- Do clean surfaces meticulously before you lay anything down.

- Do use a sharp utility knife to get clean, straight cuts—no jagged edges.

- Do keep an eye out for any tears or punctures as you work and patch them immediately with tape.

- Do label your stored rolls with their sizes and condition so they're easy to grab for the next job.

Don't:

- Don't drag heavy toolboxes or sharp equipment across the sheets without putting down an extra layer, like a piece of plywood.

- Don't use cheap, super-sticky tapes (like duct tape) that will leave a stubborn residue behind.

- Don't leave any gaps between the sheets or along the walls.

- Don't forget to sweep or vacuum the sheets now and then to get rid of any abrasive grit that gets tracked in.

Getting the best value from your materials goes beyond the initial purchase from a supplier in Dubai. Taking the time to care for, clean, and store sheets for reuse can seriously cut down the long-term cost. After a project wraps up, just wipe them clean, roll them up tight, and store them somewhere dry.

By making these simple handling and installation steps a standard part of your process, you ensure your PP bubble sheets do the job they were designed for. It’s a proactive approach that doesn't just protect expensive finishes—it also leads to a safer, more professional work environment. For more tips on getting your site ready, check out our guide on essential safety equipment for construction crews.

Why is Choosing the Right Dubai Supplier Key to Project Success?

In Dubai's fast-paced construction world, your materials are only as good as the people who get them to you. Choosing the right supplier in Dubai for your PP bubble sheets isn't just a simple purchase—it's a critical decision that directly affects your project's schedule, budget, and final quality. The best suppliers act less like a store and more like a partner, helping you cut through the noise of sourcing and logistics.

Making the wrong choice can cause some serious headaches. Picture this: your project is on a razor-thin deadline, but your materials are stuck in transit. Or worse, the wrong specs show up on-site. These kinds of logistical nightmares are all too common, leaving work crews standing around and pushing your schedule—and costs—into the red. A solid building materials distributor is your best defense against these very real problems.

What makes a building materials distributor a true partner?

A true partner does more than just fill an order; they understand the pressures of a Dubai job site and offer reliable support. This includes maintaining a large local inventory, providing expert product knowledge that aligns with UAE construction standards, and operating a dependable logistics network capable of same-day or next-day delivery to prevent project delays.

This partnership is even more important as costs rise. The UAE construction industry is expected to grow by 4–5% in 2025, but overall project costs are also projected to climb by 4–6%. With over 56% of industry leaders pointing to talent shortages, efficiency is everything. This is where the advantage of a reliable supplier offering same-day or next-day delivery becomes a huge asset. You can review the full economic outlook on AECOM's publication site to see the bigger picture.

In a city that moves as fast as Dubai, waiting for materials is not an option. Your supplier's ability to deliver the right product at the right time is the foundation of a successful project schedule.

This is where an established company like Yasu Trading Co. LLC makes a real difference. We've spent over two decades building our reputation on one thing: reliability. Our location in Naif, Deira, isn't just an address—it's a logistics hub engineered for quick dispatch across the entire UAE.

How does a supplier’s location impact project timelines?

A supplier's location directly impacts project timelines through delivery speed and efficiency, especially in a bustling city like Dubai. A centrally located distributor can navigate traffic more effectively, enabling rapid dispatch for same-day or next-day delivery, which minimizes crew downtime and helps keep projects on schedule.

For contractors, this means you don't have to keep a huge inventory on-site. You can order what you need, right when you need it, which also reduces the risk of materials getting damaged or lost on a busy job site.

Here’s the value Yasu Trading brings to the table:

- Rapid Dispatch: Our Deira headquarters allows for immediate loading and dispatch, getting your PP bubble sheets on the road in no time.

- Same-Day or Next-Day Delivery: We promise to get materials to your site anywhere in Dubai, Abu Dhabi, Sharjah, or the Northern Emirates, period.

- Reduced Downtime: Quick delivery means your teams keep working, which maintains project momentum and avoids expensive idle time.

At the end of the day, choosing the right supplier is about securing your peace of mind. It’s about knowing you have a partner who understands the local landscape and is invested in your success. For a closer look at what separates the best from the rest, check out our guide on selecting the top building materials suppliers for your specific needs.

Got Questions About PP Bubble Sheets? We've Got Answers

When you're dealing with construction materials, a few questions are bound to pop up. To make things clearer, here are the answers to some of the most common things we hear from contractors and project managers about using pp bubble sheets in Dubai.

Are PP bubble sheets actually eco-friendly?

Yes, they can be a very eco-friendly option because most PP bubble sheets are 100% recyclable. Polypropylene is a thermoplastic, meaning it can be melted down and reused to create new products, which supports sustainability goals and green building certifications common in Dubai projects.

The key is to check with your supplier in Dubai. Ask them directly about the recycled content in their sheets and how they can be recycled locally. This ensures the material you choose lines up with your project's green goals.

What is the typical price for PP bubble sheets in the UAE?

The price of PP bubble sheets in the UAE varies based on the specification (GSM), roll size, and order volume. A thicker, heavy-duty sheet will cost more per square metre than a lightweight one, and buying in bulk from a wholesale building materials distributor typically provides significant cost savings.

As a major distributor, Yasu Trading Co. LLC offers competitive wholesale pricing designed for the construction trade. The best way to nail down the cost is to get a formal quote based on your project's volume and the exact GSM you need.

Buying in bulk from a dedicated distributor is a game-changer. Contractors often see significant savings compared to making smaller, last-minute purchases. It also guarantees you get the same quality of material from start to finish.

Can I use these sheets outside?

Generally, PP bubble sheets are designed for temporary indoor use, as prolonged exposure to direct sunlight and intense UAE UV rays can make the material brittle. While they are suitable for short-term outdoor tasks, you should consult your supplier about UV-stabilised versions for any application requiring long-term outdoor durability.

They'll do the job for short-term outdoor tasks, no problem. But if you need something that will last a long time out in the elements, you’ll want to look for special UV-stabilised versions or consider other materials built for outdoor use. Always have a chat with a technical expert at your supplier to make sure you're getting the right product for the job.

How do PP bubble sheets get delivered to a construction site in Dubai?

A reputable supplier in Dubai delivers PP bubble sheets directly to construction sites across the UAE, typically as large, palletised rolls for easy handling by forklifts. Top suppliers offer flexible and rapid logistics, including same-day or next-day delivery, to ensure materials arrive precisely when needed, preventing work stoppages and aligning with strict project schedules.

That's the sign of a top-notch supplier who gets the demands of a modern job site and the importance of meeting UAE construction standards.

Ready to source high-quality PP bubble sheets with the reliability your project deserves? Yasu Trading Co. LLC provides a comprehensive range of building materials with fast, direct-to-site delivery across the UAE. Visit us online to get a quote today.