Stainless Steel Piping: Expert Guide to Grades, Standards, and Applications

When you think about the essential materials that hold modern construction together, stainless steel piping is right at the top of the list. It’s valued for its sheer durability and incredible resistance to corrosion, but in the demanding climate of the UAE, it’s more than just a good choice—it’s a necessity. Here, where infrastructure has to battle intense heat and humidity day in and day out, stainless steel is what ensures a project's safety and longevity.

Why is stainless steel piping essential for UAE construction?

Stainless steel piping is a must-have for UAE construction because its durability and corrosion resistance ensure the safety and longevity of projects in the region's harsh climate. In the fast-moving construction scene, from Dubai's skyscrapers to Abu Dhabi's industrial hubs, material selection directly affects project timelines, budgets, and long-term building performance. This is where stainless steel piping has become the go-to material for any engineer, contractor, or facility manager who refuses to compromise on quality.

Its popularity isn't by chance. The natural strength and anti-rust properties of stainless steel make it the perfect fit for a wide range of critical systems.

- MEP (Mechanical, Electrical, and Plumbing) Systems: It’s the backbone for reliable water flow and HVAC performance in countless high-rise towers and commercial complexes.

- Industrial Facilities: In manufacturing and energy plants, it’s trusted to transport chemicals, gases, and processed fluids safely and without contamination.

- The Hospitality Sector: For hotels and resorts, it provides clean, safe drinking water and robust fire protection systems, meeting the highest standards for guest safety.

The numbers back this up. Driven by the region’s massive infrastructure projects, the GCC stainless steel pipes and tubes market hit a value of USD 1.82 billion in 2023 and is on track to reach USD 2.36 billion by 2028. This isn't just growth; it's a clear signal of how central this material is to the nation’s development.

By choosing compliant stainless steel right from the start, developers and contractors are really protecting their investments. It helps them avoid costly rework down the road and guarantees their projects meet the strict UAE construction standards.

As the region continues to build, keeping an eye on the growing manufacturing industry in UAE is becoming crucial for anyone in the construction sector. This is why partnering with a knowledgeable building materials distributor is so important. A trusted supplier in Dubai, like Yasu Trading, doesn't just deliver certified materials. We also bring the technical expertise needed to navigate local regulations, making sure every single component is right for the job, from day one to final sign-off.

What are the most common stainless steel grades for piping?

The most common stainless steel grades for piping are Grade 304 and Grade 316, each offering a distinct mix of performance, corrosion resistance, and cost for different applications. Picking the right grade isn't just a technical detail; it's a critical decision that impacts the longevity, safety, and cost-effectiveness of your entire project. Think of it like choosing tyres for a vehicle—what works for a city runabout is completely unsuitable for a rugged desert crossing.

In the world of stainless steel piping, especially here in the demanding climate of the UAE, these key grades have proven themselves as reliable workhorses.

Grade 304 is the versatile, do-it-all option. It’s got excellent corrosion resistance for most everyday environments, making it a popular choice for general plumbing, food and beverage lines, and architectural features. It's strong, easy to work with, and polishes to a clean, bright finish that looks great.

But when the going gets tough, particularly along the coast, Grade 316 is the undisputed champion.

What makes Grade 316 better for coastal areas?

Grade 316 is better for coastal areas because it contains molybdenum, a key ingredient that provides superior protection against chloride corrosion from salty air. The humid, salty air that's a daily reality in Dubai, Abu Dhabi, and across the UAE coastline is loaded with aggressive chlorides that can cause pitting and failure in standard 304 steel.

The molybdenum in Grade 316 acts as a powerful defender, creating a robust shield against these chloride attacks. This makes it non-negotiable for any outdoor application near the sea, as well as for industrial plants handling saline solutions or harsh chemicals. As a seasoned supplier in Dubai, we don't see Grade 316 as an "upgrade" for coastal projects; we see it as an essential requirement for durability.

Choosing Grade 316 for coastal projects is a fundamental requirement for ensuring the longevity and safety of the piping system. It prevents premature failure and costly maintenance, aligning with stringent UAE construction standards.

To help you decide, here’s a quick-glance table comparing the most common grades you’ll come across.

Comparing Common Stainless Steel Pipe Grades

| Grade | Key Properties | Best For (UAE Applications) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| 304 | General purpose, good formability, excellent finish | Indoor plumbing, kitchen fittings, architectural trim, food processing | Good | $$ |

| 316 | Enhanced chloride resistance (thanks to molybdenum) | Coastal MEP, marine hardware, desalination plants, outdoor structures | Excellent | $$$ |

| 316L | Low carbon version of 316, better for welding | Hot water systems, pharmaceutical and chemical processing piping | Excellent | $$$$ |

| Duplex (e.g., 2205) | Extremely high strength and stress corrosion cracking resistance | Oil & gas pipelines, large-scale infrastructure, chemical plants | Superior | $$$$$ |

This table makes it clear that while 304 is a great starting point, the specific application—especially its proximity to the coast and the nature of the fluid it will carry—is what should guide your final choice.

What about Duplex stainless steel?

Duplex stainless steel is a high-performance hybrid material with incredible strength and phenomenal resistance to stress corrosion cracking, making it ideal for the most punishing industrial environments. This isn't your standard material. Duplex grades combine the properties of both austenitic (like 304/316) and ferritic steels.

The result is a material with strength often double that of standard grades. The sectors driving this demand in the UAE are clear.

As this shows, the trifecta of high-rise construction, industrial expansion, and strict regulatory compliance constantly pushes the need for advanced materials like Duplex steel.

The demand for high-performance stainless steel piping is directly tied to the UAE's massive construction and energy projects. Grades like Duplex 2205 are now frequently specified for critical infrastructure, where their high chromium content and durability are perfect for coastal power plants or chemical facilities. To get a better sense of these market forces, you can explore more data on the Middle East stainless steel market.

Which is the best pipe for hot water?

The best pipe for hot water systems is Grade 316L stainless steel due to its excellent high-temperature stability and superior corrosion resistance. That little "L" is important—it signifies low carbon content.

This low carbon formulation is a game-changer because it drastically improves weldability and minimises the risk of corrosion setting in at the welded joints, which are often the most vulnerable points in a system exposed to high temperatures.

Here’s why 316L is the smart pick for hot water:

- High-Temperature Stability: It holds its shape and strength without becoming brittle, even with constant temperature fluctuations.

- Corrosion Resistance: It easily handles the chlorides and minerals found in municipal water supplies, preventing degradation from the inside out.

- Purity: It’s completely inert, meaning it won’t leach any contaminants into the water, keeping it safe and clean for consumption.

While Grade 304 can work for some residential hot water lines, specifying 316L is a wise long-term investment. It provides an extra layer of security and guarantees a much longer, trouble-free service life. Working with an experienced building materials distributor like us ensures you get the correct, certified grade for your potable water systems.

How do you choose the right pipe size and schedule?

Choosing the right stainless steel pipe size requires understanding Nominal Pipe Size (NPS), Outside Diameter (OD), and Schedule to ensure the system is both efficient and safe. This is one of the most critical decisions in system design. Engineers work with precise measurements that determine how much pressure a pipe can handle, making sure every component meets project specifications and UAE construction standards.

To get this right, you absolutely have to understand three core terms: Nominal Pipe Size (NPS), Outside Diameter (OD), and Schedule. Let's break down what they actually mean on a construction site in Dubai.

What is Nominal Pipe Size or NPS?

Nominal Pipe Size (NPS) is a North American standard that refers to the pipe's approximate inside diameter, but it is not a direct measurement. It is used for pipe sizes in all sorts of temperature and pressure environments.

For instance, a pipe labelled NPS 2 doesn't have an inside diameter of exactly 2 inches. Think of it as a standard name or identifier. For any pipe NPS 12 and under, the actual Outside Diameter (OD) will always be larger than the NPS number suggests.

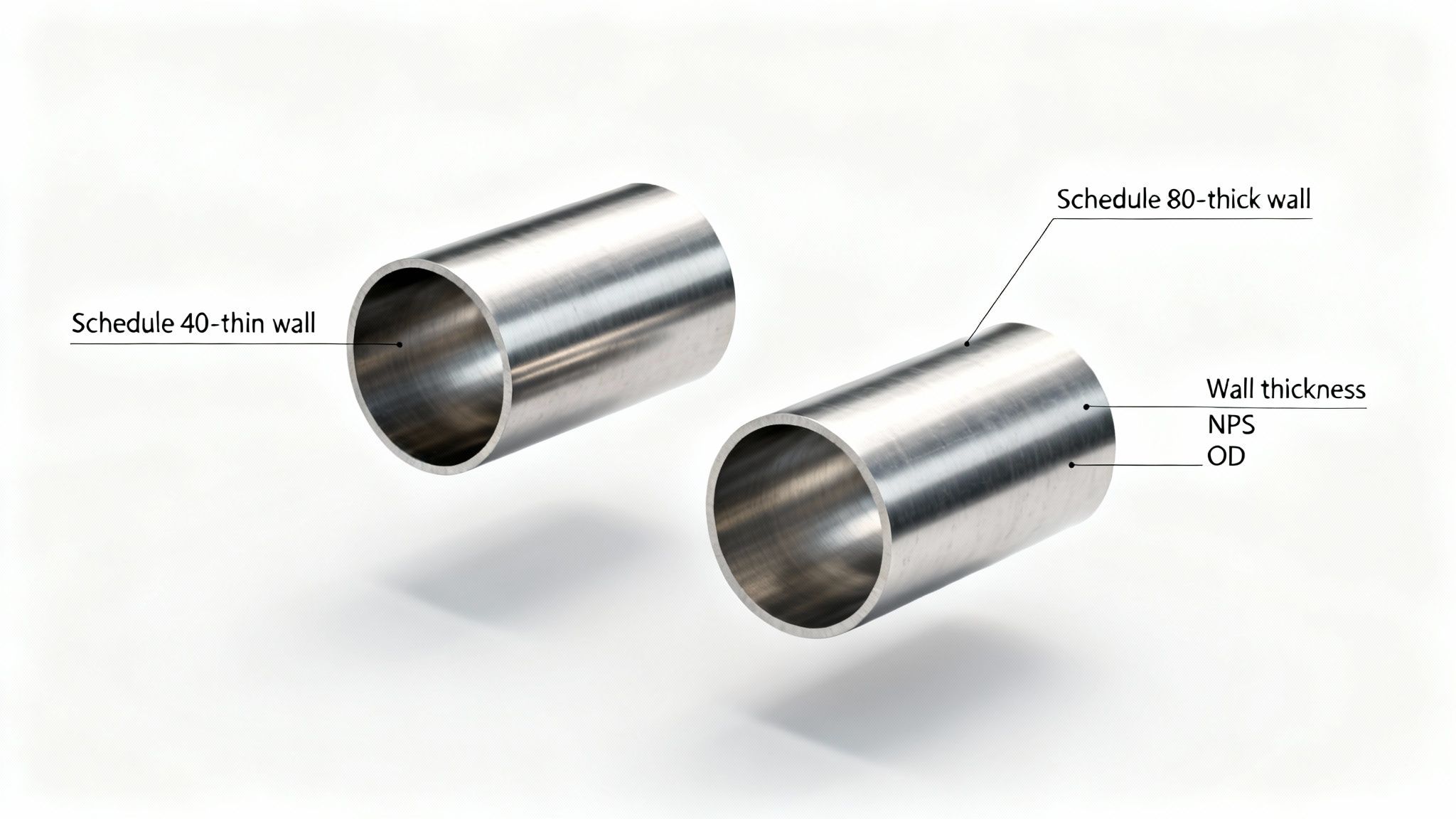

What is a pipe schedule?

A pipe's "Schedule" (SCH) is a number that indicates the thickness of its walls, which directly relates to its ability to handle pressure.

Imagine it like the wall of a fortress. A low schedule number means a thinner wall, perfect for low-pressure jobs like residential plumbing. A high schedule number, on the other hand, means a thick, reinforced wall built to handle serious pressure.

This measurement is absolutely critical for the safety and integrity of the entire system. As the schedule number goes up for a given NPS, the wall thickness increases. But here's the catch: the outside diameter stays the same. That means the inside of the pipe gets smaller.

A common mistake is thinking a higher schedule number means a bigger pipe. It actually means a stronger pipe, one that can take more internal pressure because of its thicker walls. A knowledgeable supplier in Dubai can double-check that the schedule you've specified is truly up to the task for your project's pressure demands.

How do pressure ratings affect pipe selection?

Pressure ratings directly affect pipe selection because higher pressures and temperatures demand pipes with thicker walls, meaning a higher schedule number is required for safety. This rating is calculated from a combination of the material's grade, its wall thickness (schedule), and the system's operating temperature.

Engineers use detailed calculations based on standards like ASME B31 to figure out the absolute minimum wall thickness required.

Getting this wrong isn't an option. The consequences can range from frustrating leaks to catastrophic system failures. That’s why following the engineering specifications to the letter is completely non-negotiable.

Which pipe schedule is most common?

Schedule 40 (SCH 40) is one of the most common pipe schedules specified for general-purpose work in commercial and industrial projects across the UAE. It hits a sweet spot, offering a great balance of strength, flow capacity, and cost.

Of course, not every job is "general purpose." For more demanding systems, other schedules are the go-to choice:

- Schedule 10 (SCH 10): Used for lower-pressure applications where keeping weight and cost down is a priority.

- Schedule 80 (SCH 80): Specified when you need that extra strength and durability for higher-pressure systems.

- Schedule 160 (SCH 160): This is the heavy-hitter, reserved for extremely high-pressure, critical industrial applications.

Ultimately, the right schedule is always determined by the system's specific demands, not just what’s popular. When sourcing your materials, it’s vital to partner with a building materials distributor who stocks a comprehensive range of schedules.

For a more detailed breakdown, have a look at our guide to the stainless steel pipe size chart to see exactly how all these dimensions fit together. Consulting with your engineering team and a reliable supplier ensures you get the exact components your project needs, without any compromises.

How do you meet UAE standards for stainless steel piping?

To meet UAE standards, you must ensure every piece of stainless steel piping adheres to specific international and local codes like ASTM and EN and is accompanied by a valid Mill Test Certificate (MTC). In the UAE's tightly regulated construction world, every component must meet these strict standards for quality, chemical makeup, and durability.

Compliance isn't just a box to tick; it’s a hard-and-fast rule for getting your project signed off. Authorities in Dubai, Abu Dhabi, and across the Emirates demand full traceability for critical building materials. This ensures that from the main water line down to the smallest fitting, every component meets UAE construction standards, protecting the integrity of the building and the safety of everyone inside.

This makes sourcing compliant materials one of the most fundamental steps for any legal, successful project. It's why working with a proven building materials distributor is so crucial. A good supplier doesn't just sell you pipes; they provide the certified paperwork that proves your materials are exactly what they claim to be.

What are the key standards for pipes in the UAE?

The key standards for pipes in the UAE are international codes like ASTM (American Society for Testing and Materials) and EN (European Standards), which are globally accepted blueprints for manufacturing. You will also encounter SASO standards from Saudi Arabia, which carry weight across the Gulf region.

On almost any project here, you'll run into these three main families of standards:

- ASTM (American Society for Testing and Materials): This is the big one, recognised and used all over the world. A classic example is ASTM A312, the go-to specification for stainless steel pipe used in high-temperature and general corrosive environments.

- EN (European Standards): These are the technical standards used across Europe. They are highly respected, and you'll often see them specified in project tenders throughout the UAE.

- SASO (Saudi Standards, Metrology and Quality Organisation): While officially from Saudi Arabia, SASO standards carry a lot of weight across the Gulf and are often referenced in regional projects, reflecting a shared commitment to quality construction.

How do you verify pipe compliance?

You verify pipe compliance by requesting and carefully reviewing the Mill Test Certificate (MTC) for every batch of material you purchase. The MTC is the pipe's official certification from the manufacturer, detailing its exact chemical and physical properties.

An MTC is non-negotiable. It provides complete traceability, linking the physical pipe you're holding back to the specific batch of steel it was forged from. Without a valid MTC, you have no way to prove to an inspector that your materials meet the project's required specifications.

This document is your ultimate safety net. Any reputable supplier in Dubai will provide a clear, legitimate MTC for all their certified stainless steel piping. It’s what gives you the confidence that your installation will pass inspection without getting tangled in costly delays or disputes.

The UAE's incredible pace of development puts a massive strain on high-performance materials. The country is a huge consumer of stainless steel seamless pipes, especially for its critical oil & gas and desalination industries. With over 5 million cubic metres of desalinated water produced every day, the pipelines that form the backbone of these systems face incredibly harsh conditions and must meet the highest possible standards. You can discover more insights about the Middle East stainless steel market to get a better sense of these regional demands.

Why is stainless steel the best choice for hot water systems?

Stainless steel is the best choice for hot water systems because of its superior durability, exceptional corrosion resistance, and ability to preserve water purity, especially under high temperatures. Constant heat and chemically treated water will destroy lesser materials, leading to leaks and contamination. Stainless steel piping really proves its worth, standing out as the top choice for safety and long-term performance.

Think about the alternatives. Plastic pipes can soften, warp, or even leach chemicals into the water over time. Galvanised steel, once a common choice, is highly susceptible to rust and corrosion, a problem that accelerates at the high temperatures found in hot water lines. Stainless steel simply doesn’t have these weaknesses; its inherent strength means it won't fail under pressure or heat.

What is the best pipe for hot water?

The hands-down best pipe for hot water systems is Grade 316L stainless steel, valued for its heat tolerance and exceptional resistance to chloride corrosion. The "L" stands for low carbon, which is crucial because it prevents weld decay at the joints, ensuring a leak-proof, robust system that keeps the water pure.

The magic behind stainless steel's resilience is its chemical makeup. Chromium in the alloy reacts with oxygen to form a very thin, invisible, and self-repairing layer on the pipe's surface. You can think of it as a microscopic shield that instantly regenerates if it gets scratched or damaged, actively preventing rust and pitting. It’s this passive layer that gives stainless steel its legendary lifespan.

Why is stainless steel ideal for the UAE climate?

Stainless steel is ideal for the UAE climate because Grade 316, fortified with molybdenum, is specifically engineered to resist the high chloride content found in desalinated water. Chlorides are notoriously aggressive and will quickly corrode most metals. This makes it a non-negotiable choice for any project that needs to comply with UAE construction standards.

This superior resistance translates directly to reliability and a lower total cost of ownership. Yes, the initial material cost for stainless steel might be higher than some alternatives, but its incredible durability means you aren’t dealing with frequent repairs or premature replacements down the line.

For facility managers and developers, choosing stainless steel for hot water systems isn't just a purchase; it's a strategic investment in the building's future. The minimal maintenance and long service life deliver significant lifecycle savings, helping you avoid the operational headaches and financial drain of failing pipework.

Does stainless steel affect water quality?

No, stainless steel does not negatively affect water quality; in fact, it actively preserves it by being non-reactive and non-porous. It won’t leach harmful chemicals or impart any metallic taste into the water supply. What's more, its smooth internal surface discourages the growth of bacteria and biofilm, ensuring the water that comes out of the tap is clean, safe, and pure.

This is a critical factor for potable water systems in homes, hotels, and especially healthcare facilities. Any reputable building materials distributor will tell you that using certified stainless steel is fundamental to meeting the strict health and safety regulations set by municipalities in Dubai and Abu Dhabi.

While stainless steel is a star performer in many areas, it's particularly suited for hot water. Understanding technologies like Megaflow high pressure hot water systems helps put into context how crucial material selection is for the performance of the entire system.

Ultimately, the blend of heat resistance, unmatched corrosion defence, and water purity preservation makes stainless steel piping the smartest, most reliable choice. It is the gold standard for modern hot water systems, delivering peace of mind and lasting value. When you work with a trusted supplier in Dubai, you’re ensuring your project is built to last from the inside out.

What is a smart procurement checklist for piping materials?

A smart procurement checklist involves verifying the material grade and certification with an MTC, confirming the correct pipe schedule and dimensions, and coordinating logistics with your supplier. When sourcing stainless steel piping, it’s tempting to focus solely on the price tag. But experienced procurement managers know that getting it right involves so much more. This disciplined approach ensures the materials are precisely what engineers specified and fully certified.

Think of this checklist as your guide through the critical checkpoints. Following these steps helps you sidestep common project delays and forge a strong relationship with a trustworthy building materials distributor. A great supplier is more than a vendor; they become a partner, offering the technical backup and logistical savvy needed to keep your project moving forward.

Nail Down the Material Grade and Certification

This is your first, and arguably most important, checkpoint. Your project plans will call out a specific grade, like 304L or 316L. Your job is to make absolutely sure the pipes delivered match that specification to the letter.

How can you be certain? Insist on a Mill Test Certificate (MTC) for every single batch you receive. This document is like a birth certificate for the steel, providing a full breakdown of its chemical makeup and mechanical properties. Without an MTC, you have no real proof that you’re meeting crucial UAE construction standards.

A valid MTC isn't just a piece of paper; it's your guarantee of quality and complete traceability. Any reputable supplier in Dubai will provide this documentation without question. It’s a non-negotiable for passing municipal inspections.

What’s the difference between schedule and dimensions?

Schedule refers to the pipe's wall thickness, which determines its pressure rating, while dimensions cover the Nominal Pipe Size (NPS) and precise outside diameter. It's easy to get these mixed up, but both need to align perfectly with the engineering drawings.

Even a minor mismatch here can jeopardise the entire system's integrity. Don't just trust the packing slip. Physically measure a sample from the delivery or, at the very least, confirm the markings stencilled on the pipes match your purchase order and the project's technical specs.

- Verify NPS and Schedule: Look for the stencilled markings on the side of the pipe. It should clearly state the details, for example: NPS 2, SCH 40.

- Inspect End Finishes: Are the pipe ends plain, bevelled for welding, or threaded? Getting the wrong finish can bring work to a grinding halt and add unexpected costs.

- Check for Physical Damage: Give the shipment a once-over. Look for any dents, deep gouges, or signs of rough handling during transport. These aren't just cosmetic issues; they can create dangerous weak points.

Coordinate Logistics and Delivery

Finally, smooth logistics are the glue that holds a project schedule together. Work closely with your supplier to lock down delivery windows, confirm site access points, and plan for offloading. A professional building materials distributor who knows the UAE construction scene understands these pressures inside and out.

Good, clear communication means your materials show up exactly when and where you need them, ready for your installation team to get to work. Building this kind of rapport also makes future orders easier and gives you a reliable expert to call with technical questions. To dig deeper, check out our guide on choosing the right stainless steel pipe suppliers in the UAE.

Got Questions? We've Got Answers on Stainless Steel Piping

When you're specifying materials for a major project, you need straightforward answers, not guesswork. Here are some of the most common questions our team gets from engineers and procurement managers across the UAE when it comes to stainless steel piping.

What's the real difference between seamless and welded pipe?

The difference lies in manufacturing and strength; seamless pipe is extruded from a solid billet for uniform strength in high-pressure uses, while welded pipe is rolled and welded, making it cost-effective for general applications. Think of seamless pipe as being carved from a single block of steel with no joints. This makes it the go-to choice for mission-critical systems where even a hint of a weak point is unacceptable.

Welded pipe, on the other hand, starts as a flat steel plate that is rolled and welded along a seam. This process is more cost-effective and produces a pipe that's perfectly reliable for a huge range of everyday uses, from general plumbing and HVAC lines to architectural handrails.

Is stainless steel pipe approved for drinking water in Dubai?

Yes, stainless steel pipe is fully approved and is one of the best materials for drinking water in Dubai. Grades like 304 and 316L are completely safe and highly resistant to corrosion, meaning they won't leach any unwanted chemicals or metallic tastes into the water.

Beyond that, the incredibly smooth interior of stainless steel pipe makes it tough for bacteria and biofilm to get a foothold and grow. This inherent hygienic quality is a major reason why it easily meets the strict health and safety standards set by Dubai Municipality for public water systems.

Which grade is best for hot water systems?

The best grade for hot water systems, especially in the UAE, is Grade 316L, due to its low carbon content and added molybdenum. The "L" stands for low carbon, which drastically reduces the risk of weld decay—a form of corrosion that can happen at the joints after welding. This, combined with molybdenum, gives it superior resistance to both high temperatures and the chlorides often found in our water. It’s simply the most durable choice for a hot water network.

How can I get an accurate quote from a pipe supplier in Dubai?

To get an accurate quote from a supplier in Dubai, provide clear and complete technical specifications, including the steel grade, Nominal Pipe Size (NPS), wall thickness (Schedule), total length, and required standards. A professional building materials distributor can't guess what you need; they rely on your project data to give you a precise price and lead time.

Before you pick up the phone or send an email, get this information together:

- The Steel Grade: Be specific (e.g., 316L, 304).

- Nominal Pipe Size (NPS): The standard diameter you require.

- Wall Thickness (Schedule): Let them know the schedule number (e.g., Sch 40, Sch 80).

- Total Length: The total meterage you need for each size and type.

- Required Standards: Mention any specific certifications you need, like ASTM A312 or compliance with certain UAE construction standards.

When you provide a complete spec sheet upfront, a specialised supplier in Dubai can give you a comprehensive quote without any back-and-forth. This simple step saves everyone time and helps keep your project procurement running smoothly and on schedule.

Ready to source high-quality, fully certified stainless steel piping for your next project? The experts at Yasu Trading Co. LLC are here to help. With a vast inventory and deep technical knowledge, we ensure you get the right materials that meet all UAE construction standards, delivered directly to your site. Contact us today for a competitive quote and reliable service.